CLF Lighting Poseidon Beam Ultra User manual

V1.0 SEP 2023

manual

Poseidon Beam Ultra

Beam Ultra

table of CONTENTS

WWW.CLF-LIGHTING.COM

Dimensions 1

Safety instruction 2

Protection from burns and fire 3

Protection from injury 3

Lamp life 3

Fixture overview 4

Introduction 5

Powerful outdoor Beam Ultra 5

Using for the first time 5

AC Power 5

Power voltage 5

Power cables 6

Relaying power to other devices 6

Data link 6

Tips for reliable data transmission 6

Physical installation 7

Fastening the fixture to a flat surface 7

Rigging via omega bracket 8

Outdoor IP-rated fixtures 9

Condensation/moisture inside housing 9

Fixtures temperature specification 9

9Temporary usage

Setup 10

Control panel and menu navigation 10

DMX address setting 10

W-DMX control 10

Onboard control menu 11

DMX protocol 14

Gobo overview 17

Photometrics 18

Circuit connection diagram 19

Specifications 20

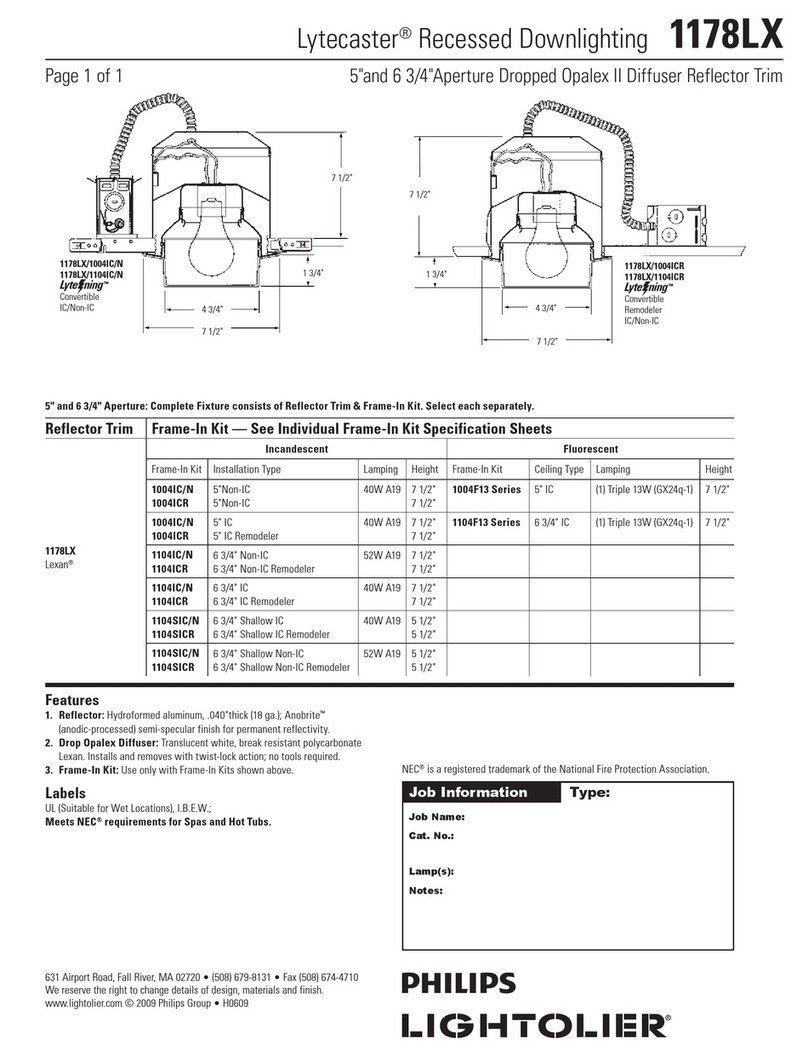

Dimensions

ALL DIMENSIONS ARE IN MILLIMETERS

WWW.CLF-LIGHTING.COM

1

Safety Instruction

WWW.CLF-LIGHTING.COM

2

WARNING!

Read the safety precautions in this section before

installing, powering, operating or servicing this

product.

The following symbols are used to identify important safety information on the product and in this manual:

DANGER!

Safety hazard.

Risk of severe

injury or death.

DANGER!

Hazardous

voltage. Risk of

lethal or severe

electric shock.

WARNING!

Fire hazard.

WARNING!

LED light

emission. Risk of

eye injury.

WARNING!

Burn hazard. Hot

surface. Do not

touch.

WARNING!

Wear protective

eyewear.

WARNING!

Refer to user

manual.

Do not look into the beam at short distance of the of the product.

Do not view the light output with optical instruments or any device that may concentrate the beam.

WWW.CLF-LIGHTING.COM

3

PROTECTION FROM BURNS AND FIRE

• The exterior of the fixture becomes hot during use. Avoid contact by persons and materials.

Allow the fixture to cool for at least 5 minutes before handling.

• Keep all combustible materials (e.g. fabric, wood, paper) at least 1 metres away from the fixture.

• Keep flammable materials well away from the fixture.

• Ensure that there is free and unobstructed airflow around the fixture.

• Do not illuminate surfaces within 8 metres of the fixture.

• Do not attempt to bypass thermostatic switches or fuses.

• If you relay power from one fixture to another using power throughout sockets, do not connect more than five

fixtures in total to eachother in an interconnected chain.

• Connect only other fixtures to fixture power throughout sockets.

• Do not stick filters, masks or other materials onto any optical component.

• Do not modify the fixture in any way not described in this manual.

PROTECTION FROM INJURY

• Fasten the fixture securely to a fixed surface or structure when in use. The fixture is not portable when installed.

• Ensure that any supporting structure and/or hardware used can hold at least 10 times the weight of all the devices

they support.

• Allow enough clearance around the head to ensure that it cannot collide with an object or another fixture when it

moves.

• Check that all external covers and rigging hardware are securely fastened.

• Block access below the work area and work from a stable platform whenever installing, servicing or moving the

fixture.

• Do not operate the fixture with missing or damaged covers, shields or any optical component.

lamp life

• Lamp life can vary, caused by many factors. For example external temperature, humidity, lamp strikes, dimming or

power/voltage.

WWW.CLF-LIGHTING.COM

4

Fixture overview

AC MAINS POWER INPUT

5P DMX INPUT

5P DMX OUTPUT

SAFETY ATTACHMENT POINT

WIRELESS ANTENNA

AC MAINS POWER OUTPUT

FUSE display battery

WWW.CLF-LIGHTING.COM

5

Introduction

powerful outdoor Beam Ultra

■

IP65 DUST AND WATER PROTECTION

■

200MM LENS FOR 1.6° BEAM

■

CMY AND COLOR WHEEL

■

GOBO WHEEL, FROST AND 2 PRISMS

■

LIGHT WEIGHT SLIM HOUSING

Using for the first time

Warning! For protection from electric shock, the fixture must be grounded (earthed). The power distribution

circuit must be equipped with a fuse or circuit breaker and ground-fault (earth-fault) protection.

Warning! Socket outlets or external power switches used to supply the fixture with power must be located near

the fixture and easily accessible so that the fixtures can easily be disconnected from power.

Important! Do not insert or remove live PowerCON TRUE 1 ® connectors to apply or cut power, as this may

cause arcing at the terminals that will damage the connectors.

Important! Do not use an external dimming system to supply power to the fixture, as this may cause damage to

the fixture that is not covered by the product warranty.

The fixture can be hard wired to a electrical installation if you want to install it permanently, or a power plug that is

suitable for the local power outlets can be installed on the power cable.

Power voltage

Warning! Check that the voltage range specified on the fixture serial number label matches the local AC mains power

voltage before applying power to the fixture.

The fixtures accepts AC mains power at 100-240V nominal, 50/60 Hz. Do not apply AC mains power to the fixture at any

other voltage than specified.

Warning! Read “Safety Information” before installing, powering, operating or servicing the fixture.

Before applying power to the fixture:

Check that the local AC mains power source is within the fixture’s power voltage and frequency ranges.

See “Power cables and power plug” on page 6. Install a PowerCON TRUE1 ® power input connector power cable.

Warning! This product contain a ni-mh battery

WWW.CLF-LIGHTING.COM

6

Power cables

Power input and throughput cables must be rated 16A minimum, have three conductors 1.5 mm² (16 AWG) minimum conductor size and

an outer cable diameter of 5 - 15 mm. Cables must be hard usage type (SJT or equivalent) and heat- resistant to 90°C minimum. In the

EU the cable must be HAR approved or equivalent.

If you install a power plug on the power cable, install a grounding-type (earthed) plug that is rated 16A minimum. Follow the plug

manufacturer’s instructions. Table 1 shows standard wire color-coding schemes and some possible pin identification schemes; if pins are

not clearly identified.

Data link

A DMX 512 data link is required in order to control a fixture via DMX. The fixture has 5-pin XLR connectors for DMX data input and output.

The pin-out on all connectors is pin 1 = shield, pin 2 = cold (-), and pin 3 = hot (+) Pins 4 and 5 in the 5-pin XLR connectors are not in use.

Tips for reliable data transmission

To connect the fixture to data:

1. Connect the DMX data output from the controller to the 5-pin XLR connector of the nearest fixture.

2. Connect the DMX output of the first fixture to the DMX input of the next fixture and continue connecting fixtures.

Relaying power to other devices

Warning! Do not connect more than four fixtures in total in one interconnected chain. Power can be relayed to another device via the

PowerCON TRUE 1 ® throughput socket.

If you daisy chain the fixtures in a chain so that they all draw AC mains power via the first fixture, certain points must be respected:

A heavy duty, three-conductor, 16 AWG or 1.5 mm² cable with SJT or equivalent cable jacket must be used to connect the first fixture to

AC mains power. PowerCON TRUE1 ® connectors must be used to draw AC mains power from the fixtures power throughput socket and

yellow PowerCON TRUE 1 ® connectors must be used to supply power at the fixture’s power input sockets.

Wire Color (EU models) Wire Color (US models) Conductor Symbol

Brown Black Live L

Blue White Neutral N

Yellow/Green Green Ground (earth) or

Table 1: Wire color-coding and power connections

WWW.CLF-LIGHTING.COM

7

Physical installation

Warning! The fixture must be either fastened to a flat surface such as a stage or wall, or clamped to a truss or

similar structure in any orientation using a rigging clamp.

Warning! Always attach an approved safety cable to one of the safety cable attachment points on the base.

Do not illuminate surfaces within 12 meters of the fixture. Ensure that flammable materials (wood, fabric, paper, etc.) are

minimum 1 meters from the fixture and allow a free airflow around the fixture.

Fastening the fixture to a flat surface

The fixture can be fastened to a fixed flat surface that is oriented at any angle. Check that the surface can

support at least 10 times the weight of all fixtures and equipment to be installed.

Warning! The supporting surface must be hard and flat or cooling may be blocked, which will cause overheating.

Fasten the fixture securely. Do not place it on unstable surfaces. Always attach a securely anchored safety cable to the

safety cable attachment point.

1. Block access under the work area. Working from a stable platform, hang the fixture on the truss with the

arrow on the base towards the area to be illuminated. Tighten the rigging clamp.

2. Secure the fixture against clamp failure with a secondary attachment such as an approved safety cable

that is rated for the weight of the fixture using one of the attachment points at the edges of the base (see

“Fixture overview”). Do not use any other part of the fixture as a safety cable attachment point.

The installation of the fixture has to be built and constructed in a way that it can hold 10 times the weight for 1 hour

without any harming deformation.

The installation must always be secured with a secondary safety attachment, e.g. an appropriate catch net. This

secondary safety attachment must be constructed in a way that no part of the installation can fall down if the main

attachment fails.

When rigging, derigging or servicing the fixture staying in the area below the installation place, on bridges, under high

working places and other endangered areas is forbidden.

The operator has to make sure that safety-relating and machine-technical installations are approved by an expert before

taking into operation for the first time and after changes before taking into operation another time.

The operator has to make sure that safety-relating and machine-technical installations are approved by an expert after

every four year in the course of an acceptance test.

The operator has to make sure that safety-relating and machine-technical installations are approved by a skilled person

once a year.

The fixture should be installed outside areas where persons may walk by or be seated.

IMPORTANT! OVERHEAD RIGGING REQUIRES EXTENSIVE EXPERIENCE, including (but not limited to) calculating

working load limits, installation material being used, and periodic safety inspection of all installation material and the

projector. If you lack these qualifications, do not attempt the installation yourself, but instead use a professional structural

rigger. Improper installation can result in bodily injury or damage to property.The fixture has to be installed out of the

reach of people.

WWW.CLF-LIGHTING.COM

8

If the fixture shall be lowered from the ceiling or high joists, professional trussing systems have to be used. The fixture

must never be fixed swinging freely in the room.

Caution: Fixture may cause severe injuries when crashing down! If you have doubts concerning the safety of a

possible installation, do not install the moving head!

Before rigging make sure that the installation area can hold a minimum point load of 10 times the fixture’s weight.

When installing the device, make sure there is no highly inflammable material (decoration articles, etc.) in a distance of

min. 0.5 m.

Use an appropriate clamp to rig the fixture on the truss.

Follow the instructions mentioned at the bottom of the base.

Make sure that the device is fixed properly! Ensure that the structure (truss) to which you are attaching the fixtures is

secure.

The fixture can be placed directly on the stage floor or rigged on a truss without altering its operation characteristics .

For securing the fixture to the truss, install a safety wire which can hold at least 10 times the weight of the fixture. Use

only the safety wire with a snap hook with screw lock gate. Fasten the safety cable in the attachment point and around

the truss as shown on the picture below.

Rigging via omega bracket:

Truss

Clamp

Safely chain

bracket with Quicklock

WWW.CLF-LIGHTING.COM

Outdoor IP-rated fixtures

CLF products are applied to official classified IP norm levels. For this product the IP rate is IP65 when using the covers for the chassis

parts. IP65 means according classified norm: shielded against dust and pressurized water from any side. Typical use for outdoor rated

stage events with normal weather acceptance. So no heavy rain, because then the water pressure over exceeds the IP norm.

Condensation/moisture inside housing

Because of high humidity levels during production condensation can occur inside the housing. This is mostly visible on the coldest parts of

the fixture, like the front glass or display. To prevent this problem we work with special conditioned areas for outdoor fixtures. Because of

the breathing air valves it is still possible to get humidity inside the fixture. This will evaporate slowly. Do not put wet fixtures in a flightcase,

this will help humidity enter the fixture.

Fixtures temperature specification

Make sure the fixture is used within its working temperature range. Outside this range we cannot guarantee correct operation.

Temporary usage:

Stage event equipment is designed for temporary outdoor use. Materials are not designed for long-term exposure to heavy weather

conditions. Rubber covers will be negatively affected by long-term UV exposure and should be checked by qualified service technicians

over time. Tightening screws too hard will negatively affect the IP-rating.

solid object

IP

Ingress

Protection

6 5

Protected against a solid object greater

than 50mm such as a hand.

Protected against a solid object greater

than 12.5mm such as a finger.

Protected against a solid object greater

than 2.5mm such as a screwdriver.

Protected against a solid object greater

than 1mm such as a wire.

Dust protected. Limited ingress of

dust permitted. Will not interfere

with operation of the equipment.

Dust tight. No ingress of dust.

Protected against vertical falling drops of

water. Limited ingress permitted.

Protected against water splashes from

all directions. Limited ingress permitted.

Protected against vertical falling drops

of water with enclosure tilted up to 15

degrees from the vertical. Limited

ingress permitted.

Protected against sprays of water up

to 60 degrees from the vertical.

Limited ingress permitted.

Protected against jets of water.

Limited ingress permitted.

Protected against powerful jets of water.

Limited ingress permitted.

Protected against the effects of

immersion in water between 15cm and

1m for 30 minutes.

Protected against the effects of

immersion in water under pressure for

long periods.

8

7

1

2

3

4

5

6

MOISTURE

1

2

3

4

5

6

9

WWW.CLF-LIGHTING.COM

10

Setup

Warning! Read “Safety Information” before installing, powering, operating the fixture.

W-DMX control

• This is an invisible menu. This menu will only be displayed when a wireless module is inserted.

• Do not use Wireless DMX and Wired DMX at the same time because it will give unwanted interference.

When this sign appears, it means: .“ ”Connected Transmitte and Wireless DMX Connect

When this sign appears, it means: .“ ”Connected Transmitte,No wireless DMX

When this sign appears, it means: .“ ”Not found transmitte and No wireless DMX

When this sign appears, it means: .“ off ”Wirreless off

WWW.CLF-LIGHTING.COM

11

Onboard control menu

Main menu Menu level 1 Menu level 2 Menu level 3 Menu level 4

DMX Address

─ Address:001-512 Address(***-***) (Default:001)

─ DMX Signal mode ─Wire -- WDMX OFF(Default)

─Wireless -- WDMX ON

─ Return(ESC)

Information

─ Power hours ─Total Hours: ***(H)

─Rst Hours: ***(H)

─ Lamp hours ─Total Hours: ***(H)

─Rst Hours: ***(H)

─ Lamp strikes ─Total Strikes: ***

─Rst Strikes: ***

─ Temperature ─E-ballast:000.0

─In

TEMP

:000.0

─ Logged

temperature

─ E-ballast

─Cur

TEMP:

***

─Max

TEMP:

***

─Min

TEMP:

***

─ In

temperature

─Cur

TEMP:

***

─Max

TEMP:

***

─Min

TEMP:

***

─Return(ESC)

─ Fan information

─ Lamp

fan

─1.Power1:**.*V

─2.Sp-Fan1:**.*%

─3.Sp-Fan1:****R

─4.Power2:**.*V

─5.Sp-Fan2:**.*%

─6.Sp-Fan3:**.*%

─7.Sp-Fan2:****R

─8.Sp-Fan3:****R

─ Out

fan

─1.Power:**.*V

─2.OutFan:**.*%

─3.OutFan:****R

─ In

fan ─1.Power1:**.*V

─2.Power2:**.*V

─ Base

fan

─1.Power:**.*V

─2.BaseFan1:**.*%

─3.BaseFan2:**.*%

─4.BaseFan1:****R

─5.BaseFan2:****R

─ Return(ESC)

─ RDM UID 02E2:********

─ DMX live

─1.Pan

000~255

─2.Pan

Fine

000~255

─3.Tilt

000~255

─4.Tilt

Fine

000~255

─5.P/T

Speed

000~255

─6.Function

000~255

─7.Cyan

000~255

─8.Magenta

000~255

─9.Yellow

000~255

─10.Color

000~255

─11.FixGobo

000~255

─12.Prism

000~255

─13.Prism

Rot

000~255

─14.Prism2

000~255

─15.Prism

Rot2

000~255

─16.Frost

000~255

─17.Focus

000~255

─18.Focus

Fine

000~255

─19.Shutter 000~255

─20.Dimmer 000~255

─21.Dimmer Fine 000~255

─ System version

─XY Board: V*.**

─CMY Board: V*.**

─FOCUS Board: V*.**

─FAN Board: V*.**

─DIS Board: V*.**

─ Return(ESC)

─ Auto lamp on ─OFF

─ON

─ Display lock ─OFF

─ON

Main Menu level 1 Menu level 2 Menu level 3 Menu level 4

Personal

─ Leak light protect ─OFF

─ON

─ Wireless options

─ Wireless ON/OFF ─ OFF

─ ON

─ wireless settings ─ ldle

─ Unlink transmitter

─ wireless status

─ Wireless off

─ Not found transmitte No wireless DMX

─ Connected Transmitte No wireless DMX

─Connected Transmitte Wireless DMX Connect

─ P/T invert

─ Pan invert ─ OFF

─ ON

─ Tilt

invert ─ OFF

─ ON

─ Return(ESC)

─ Display

─ Backlight ─ Always

on

─ Auto

off

(15s)

─ Rotate ─ Normal

─ Rotate

180

─ Backlight

blink ─ ON

─ OFF

─ Return(ESC)

─ P/T speed mode

─ Normal

─ Fast

─ Precise

─CMY TV mode ─ OFF

─ ON

Return(ESC)

Manual control

─ Channel control

─ 1.Pan

000~255

─ 2.Pan

Fine

000~255

─ 3.Tilt

000~255

─ 4.Tilt

Fine

000~255

─ 5.P/T

Speed

000~255

─ 6.Function

000~255

─ 7.Cyan

000~255

─ 8.Magenta

000~255

─ 9.Yellow

000~255

─ 10.Color

000~255

─ 11.FixGobo

000~255

─ 12.Prism

000~255

─ 13.Prism

Rot

000~255

─ 14.Prism2

000~255

─ 15.Prism

Rot2

000~255

─ 16.Frost

000~255

─ 17.Focus

000~255

─ 18.Focus

Fine

000~255

─ 19.Shutter

000~255

─ 20.Dimmer

000~255

─ 21.Dimmer

Fine

000~255

─ Return(ESC)

─ Program Editor

─ Editor

─ Scene Edit

─ Sequence ***

─ 1.Pan 000~255

─ 2.Pan Fine 000~255

─ 3.Tilt 000~255

─ 4.Tilt Fine 000~255

─ 5.P/T Speed 000~255

─ 6.Function 000~255

─ 7.Cyan 000~255

─ 8.Magenta 000~255

─ 9.Yellow 000~255

─ 10.Color 000~255

─ 11.FixGobo 000~255

─ 12.Prism 000~255

─ 13.Prism Rot 000~255

─ 14.Prism2 000~255

─ 15.Prism Rot2 000~255

─ 16.Frost 000~255

─ 17.Focus 000~255

─ 18.Focus Fine 000~255

─ 19.Shutter 000~255

─ 20.Dimmer 000~255

─ 21.Dimmer Fine 000~255

─ Save the scence

─ Return(ESC)

─ Wait Time

─ Static Scene:***

─ Time :*** SEC

─ Save the time

─ Return(ESC)

─ Static Scene:***

─ Time :*** SEC

WWW.CLF-LIGHTING.COM

12

─

CMY can fast cut-in the mode

Main menu Menu level 1 Menu level 2 Menu level 3 Menu level 4

─ Fade Time ─ Save the time

─ Return(ESC)

─ Copy Scene

─ Static Scene:***

─ Copy Scene

─ Return(ESC)

─ Paste Scene

─ Static Scene:***

─ Paste Scene

─ Return(ESC)

─ Clear Scene

─ Static Scene:***

─ Clear Scene

─ Return(ESC)

─ Return(ESC)

─ Program run

mode ─ Program

1

─ Program

Captured

DMX

─ Run Program ─ NO

─ YES

─ Stop Program ─ NO

─ YES

─ Run on power

on ─ NO

─ YES

─ Capture

DMX ─ Saved

DMX

data

─ Static Scene:***

─ Saved Scene from DMX

─ Return(ESC)

─ Return(ESC)

─ Return(ESC)

─ System reset

─ Reset

all

─ Pan/Tilt

reset

─ Head

motor

reset

─ Return(ESC)

─ Return(ESC)

Service

─ Error information

─ Error

list

─ Empty

list ─ NO

─ OFF

─ Return(ESC)

─ Reset Timers

─ Reset

Power

Hours ─ NO

─ YES

─ Reset

Lamp

Hours ─ NO

─ YES

─ Reset

Lamp

Strikes ─ NO

─ YES

─ Return(ESC)

─ Factory

─ Load

default ─ Go

back

─ Load

Default

─ Reset

Total

Timers

─ Total

Power

Hours

─ Total

Lamp

Hours

─ Total

Lamp

Strikes

─ Return(ESC)

─ Clear

logged

temperature

─ Calibration ─ 3256

─ Pan 000-255

─ Tilt 000-255

─ Cyan 000-255

─ Magenta 000-255

─ Yellow 000-255

─ Color 000-255

─ FixGobo 000-255

─ Prism1 000-255

─ Prism Rot 000-255

─ Prism2 000-255

─ Prism Rot2 000-255

─ Frost 000-255

─ Focus 000-255

─ Dimmer1 000-255

─ Dimmer2 000-255

─ Return(ESC) 000-255

─ Developer

─ Return(ESC)

─ Return(ESC)

Lamp ─ Off

─ On

Test

─ Test P/T ─ STEP ***

─ Test effect ─ STEP ***

─ Test all ─ STEP ***

─ Return(ESC)

Rotate display ─ Normal

─ Rotate 180

WWW.CLF-LIGHTING.COM

13

WWW.CLF-LIGHTING.COM

14

DMX protocol

CHANNEL FUNCTION VALUE SETTING NOTE

1 Pan 0-255 Pan

2 Pan Fine 0-255 Pan Fine

3 Tilt 0-255 Tilt

4 Tilt fine 0-255 Tilt fine

5 Pan/Tilt speed 0-255 Speed from max. to min

6 Power/Special

functions

0-9 Reserved (0=default)

10-14 Reserved

15-19 Reserved

* function is active only3 seconds after switching the fixture on

20-24 Reserved

25-29 Reserved

30-34 Reserved

35-39 Reserved

40-44 Reserved

45-49 Reserved

50-54

XY

Normal

mode

55-59

XY

Fast

mode

60-64 XY

Precise

mode

65-69 Reserved

70-74 CMY

TV

mode

Off

75-79 CMY

TV

mode

On

80-84 Reserved

85-89 Reserved

90-94

Reserved

95-99

Reserved

100-101 Reserved

102-103 Reserved

104-105 Reserved

106-107 Reserved

108-119 Reserved

120-124

Reserved

125-129

Reserved

130

-

139 Lamp

On

140

-

149 Pan/Tilt

reset

150

-

159 Head

motor

reset

160

-

169 Total

reset

170

-

179 Reserved

180

-

189 Reserved

190

-

199 Reserved

200

-

209 Reserved

210

-

229 Reserved

230

-

239 Lamp

Off

240

-

244 Reserved

245

-

249 Reserved

250

-

255 Reserved

7 Cyan 0

-

255 Cyan

from

min.

saturation

-->

full

cyan

(0=default)

8 Magenta 0

-

255 Magenta

from

min.

saturation

-->

full

magenta

(0=default)

9 Yellow 0 - 255 Yellow from min. saturation --> full yellow (0=default)

0-4 White

5-8 White+Red

9-12 Red

13-17 Red+Orange

18-21 Orange

22-25 Orange+Aquamarine

26-29 Aquamarine

WWW.CLF-LIGHTING.COM

15

CHANNEL FUNCTION VALUE SETTING NOTE

10 Colour

30-34 Aquamarine+Green

35-38 Green

39-42 Green+Light Green

43-46 Light Green

47-51 Light Green+Lavender

52-55 Lavender

56-59 Lavender+Pink

60-63 Pink

64-68 Pink+Yellow

69-72 Yellow

73-76 Yellow+Magenta

77-81 Magenta

82-85 Magenta+Cyan

86-89 Cyan

90-93 Cyan+CTO2

94-98 CTO2

99-102 CTO2+CTO1

103-106 CTO1

107-110 CTO1+CTB

111 -115 CTB

116-119 CTB+Blue

120-123 Blue

124-127 Blue+White

128-191 CCW,Fast→Slow

Rotation

192-255 CW,Slow→Fast

Rotation

11 Static gobo wheel

0-3

Open/Hole

(0=default)

Positioning

4-8 Beam

reducer

1

9-13 Beam

reducer

2

14-18 Gobo

1

19-23 Gobo

2

24-28 Gobo

3

29-33 Gobo

4

34-38 Gobo

5

39-43 Gobo

6

44-48 Gobo

7

49-53 Gobo

8

54-58 Gobo

9

59-63 Gobo

10

64-68 Gobo

11

69-73 Gobo

12

74-78 Gobo

13

79-83 Gobo

14

84-88 Gobo

15

Shaking gobos from slow to fast

89-95 Beam reducer 1

96-102 Beam reducer 2

103-109 Gobo 1

110-116 Gobo 2

117-123 Gobo 3

124-130 Gobo 4

131-137 Gobo 5

138-144 Gobo 6

145-151 Gobo 7

152-158 Gobo 8

WWW.CLF-LIGHTING.COM

16

CHANNEL FUNCTION VALUE SETTING NOTE

159-165 Gobo 9

166-172 Gobo 10

173-179 Gobo 11

180-186 Gobo 12

187-193 Gobo 13

194-200 Gobo 14

201-207 Gobo 15

Rotating

208-227 Forwards

gobo

wheel

rotation

from

fast

to

slow

228-229 No

rotation

230-249 Backwards

gobo

wheel

rotation

from

slow

to

fast

250-255 Auto

random

gobo

selection

from

fast

to

slow

12 Prism1

0-3 Open

position/hole

(0=default)

prism

in

4-199 Prism

1

200-255 Shaking

Prism

from

slow

to

fast

13 Prism1 indexing/rotation

0 No

function

1

-

63 Prism

1

indexing

64-127 Forwards

prism

rotation

from

fast

to

slow

128-191 Backwards

prism

rotation

from

slow

to

fast

192-207 from

slow

to

fast

90°Swing

208-223 from

slow

to

fast

180°Swing

224-239 from

slow

to

fast

270°Swing

240-255 from

slow

to

fast

360°Swing

14 Prism2

0-3 Open

position/hole

(0=default)

prism

in

4-199 Prism

2

200-255 Shaking

Prism

from

slow

to

fast

15 Prism2 indexing/rotation

0 No

function

1

-

63 Prism

2

indexing

64-127 Forwards

prism

rotation

from

fast

to

slow

128-191 Backwards

prism

rotation

from

slow

to

fast

192-207 from

slow

to

fast

90°Swing

208-223 from

slow

to

fast

180°Swing

224-239 from

slow

to

fast

270°Swing

240-255 from

slow

to

fast

360°Swing

16 Frost

0-3 Open

(0=default)

4-128 100%

Light

Frost

129-255 Reserved

17 Focus 0

-

255 Continuous

adjustment

from

far

to

near

(128=default)

18 Focus Fine 0

-

255 Fine

focusing

(0=default)

19 Shutter/ strobe

0 - 31 Shutter closed

32 - 63 Shutter open (32=default)

64 - 95 Strobe-effect from slow to fast

96 - 127 Shutter open

128 - 143 Opening pulse in sequences from slow to fast

144 - 159 Closing pulse in sequences from fast to slow

160 - 191 Shutter open

192 - 223 Random strobe-effect from slow to fast

224 - 255 Shutter open, Full lamp power

20 Dimmer intensity 0 - 255 Dimmer intensity from 0% to 100% (0=default)

21 Dimmer intensity - fine 0 - 255 Fine dimming (0=default)

WWW.CLF-LIGHTING.COM

17

gobo overview

2 4 Prism 8 Prism

Color disk Static gobo wheel

Dark red

628

White

Front

2

34

5

6

7

8

9

10

11

12

13

14

1

CT02

CT01

CTB

Dark red

Orange

Aquamarine Dark green

Green

Light purple

Pink

Y

M

Blue

Dark blue

White

C M Y

WWW.CLF-LIGHTING.COM

18

photometrics

510 15 20 30 40 500

Distance(m)

Diameter(m)

1.6 ° Lux(fc)

distance, spot diameter and illumination diagramSpot model

0

5

10

10

5

3640000(338290) 910000(84572) 404000(37546) 227000(21097) 101000(9387) 56000(5204) 36000(3346)

0.14 0.28 0.42 0.56 0.84 1.12 1.4

1.6°

Table of contents

Other CLF Lighting Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

CUDA

CUDA LLS-4700 Operation manual

Intermatic

Intermatic EL500E Installation and user instructions

Chauvet Professional

Chauvet Professional WELL Gobo Quick reference guide

Livoo

Livoo SA116 user manual

Lightolier

Lightolier Lytecaster 1178LX specification

Violet Defense

Violet Defense Vantage I User manual & warranty

Scolmore

Scolmore ESP duceri D130AWH manual

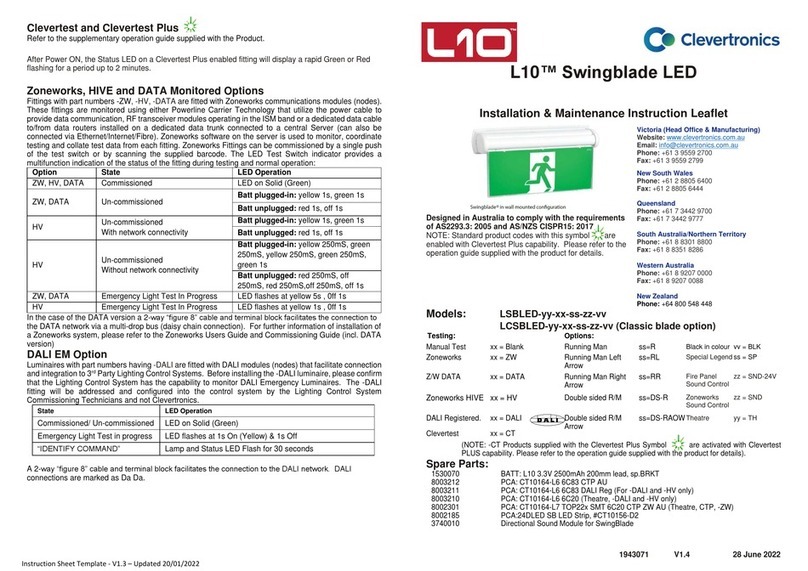

Clevertronics

Clevertronics L10 LSBLED Series Installation & maintenance instructions

Chauvet

Chauvet Colordash Accent Quad user manual

Chauvet

Chauvet D-Fi Plus user manual

BOSS ILLUMINATION

BOSS ILLUMINATION RAY II product manual

Coleman

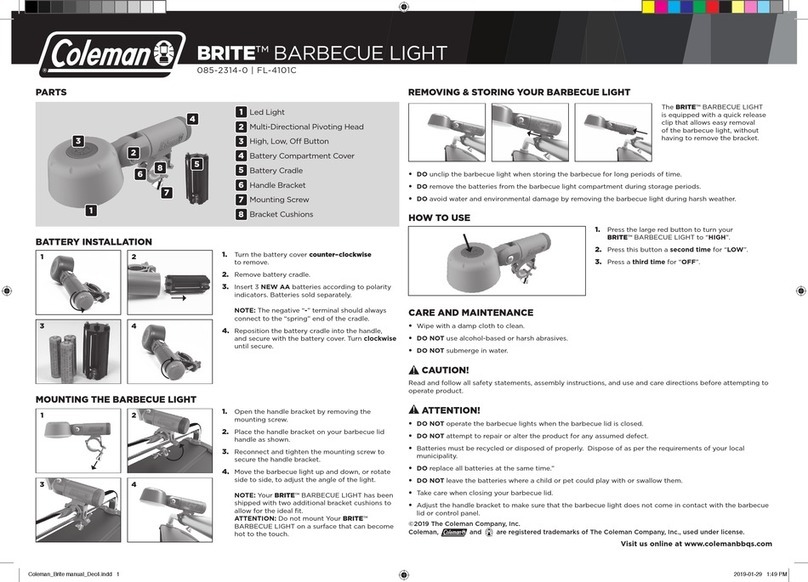

Coleman BRITE 085-2314-0 manual