Status Indicator LED

EVPD PROPORTIONAL VALVE DRIVER

Installation & Operations Manual

Section 2 Tuning

Step 1:

Adjusting Command Threshold

This will assure the valve remains closed until the

Command Signal is greater than the Command Threshold

Step 1a: Apply a Command Signal according to the table

below to the driver

Step 1b: Turn DB clockwise until Status Indicator LED (green)

turns Off. Then turn counter-clockwise just enough to turn

the LED On

Step 2: Adjusting Opening Current

This will assure the valve opens at just above the

minimum Command Signal.

Step 2a: Connect supply air to the valve

Step 2b: Apply a Command Signal according to the table

below to the drive (same as Step 1)

Step 2c: Turn Imin

clockwise until valve opens

Command Range 0 to 5 VDC 0 to 10 VDC 4 to 20 mA 0 to 20 mA

Min. Command Signal* 0.1 VDC 0.1 VDC 4.2 mA 0.2 mA

Command Range 0 to 5 VDC 0 to 10 VDC 4 to 20 mA 0 to 20 mA

Min. Command Signal* 0.1 VDC 0.1 VDC 4.2 mA 0.2 mA

Step 3: Adjusting Max Current

This will assure that the maximum Command corresponds to

maximum desired flow

Step 3a: Apply maximum Command Signal according to the

table below to the driver

Step 2d: Turn Imin slightly

counter-clockwise until

valve barely closes

Command Range 0 to 5 VDC 0 to 10 VDC 4 to 20 mA 0 to 20 mA

Signal to Apply 5 VDC 10 VDC 20 mA 20 mA

Step 3b: Turn Imax clockwise to

increase flow to desired maximum. To

reduce maximum flow, turn Imax

counter-clockwise to below the target

flow, then clockwise to the desired

maximum.

Caution: Do not exceed the

maximum current of the DVP/EVP valve

or permanent damage may occur to the valve.

ignal to Appl

Command Ran

e

Status Indicator LED

Turn DB (RP1) clockwise until Status LED is Off

Status Indicator LED (green) will be On at first

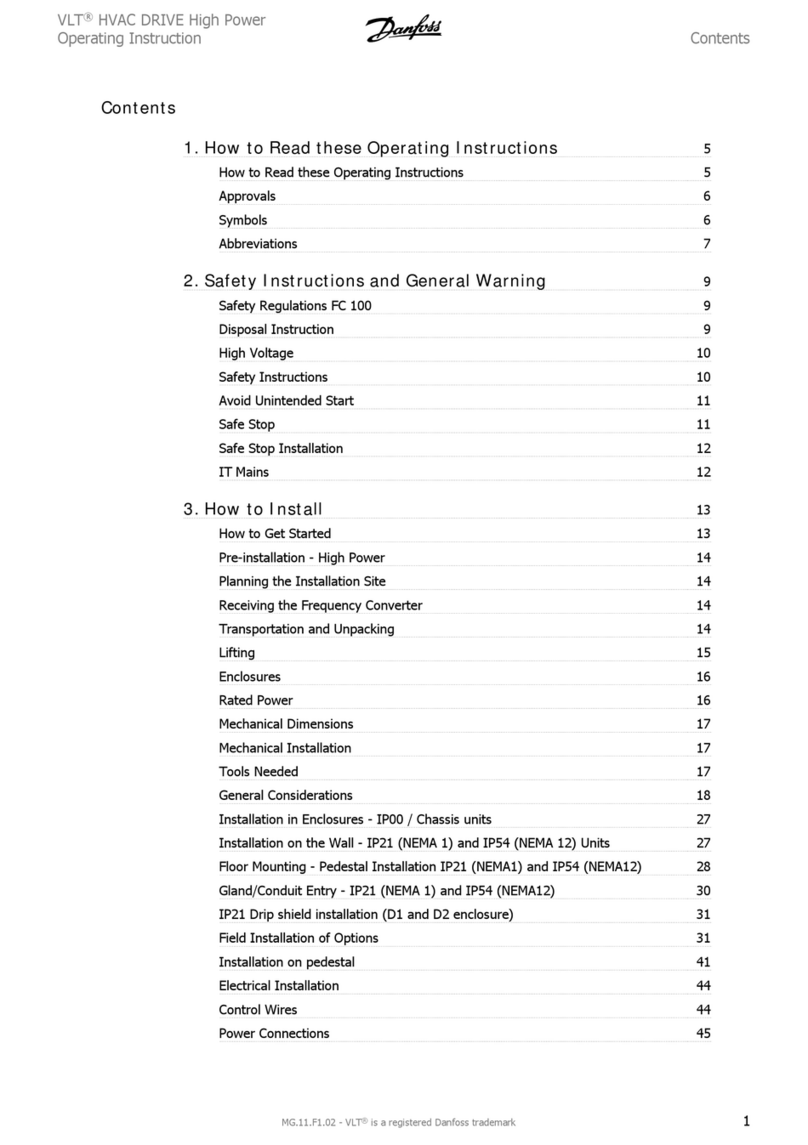

Current

Min.

Current

Min.

Current

Max.

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0 2 4 6 8 10 12

Command Signal (0 to 10 VDC for this example)

Normalized Driver Output Current

Tuning Parameters

lmax

The output current of the Driver

when the Command Signal is at

maximum value

Command Threshold

When the Command

Signal is less than this

value, the Driver

output current is zero

lmin

The output current of the Driver

when the Command Signal just

exceeds the Command Threshold

WARNING: Installation and operation of electronic and high pressure systems (fluids and

compressed gas) involves risk including property damage and personal injury or death.

Users should be properly trained or certified and take safety precautions.

* The 0.1 VDC value for the Command Threshold is a minimum value that may be increased according to the needs of the application, therefore the Command Signal

values given in steps 1 and 2 are given as minimum values, not as the only possible values.

Turn DB counter-clockwise just enough to turn the Status

Indicator LED (green) On

Status Indicator LED Δ

!

877-245-6247 | clippard.com

CLIPPARD INSTRUMENT LABORATORY, INC. • ISO 9001:2015