Cloos Arc Flash 4 evo User manual

Operating

instructions

and

spare parts list

Welding helmet

CLOOS Arc Flash 4 evo

Rev. 1.2

Original instructions

2

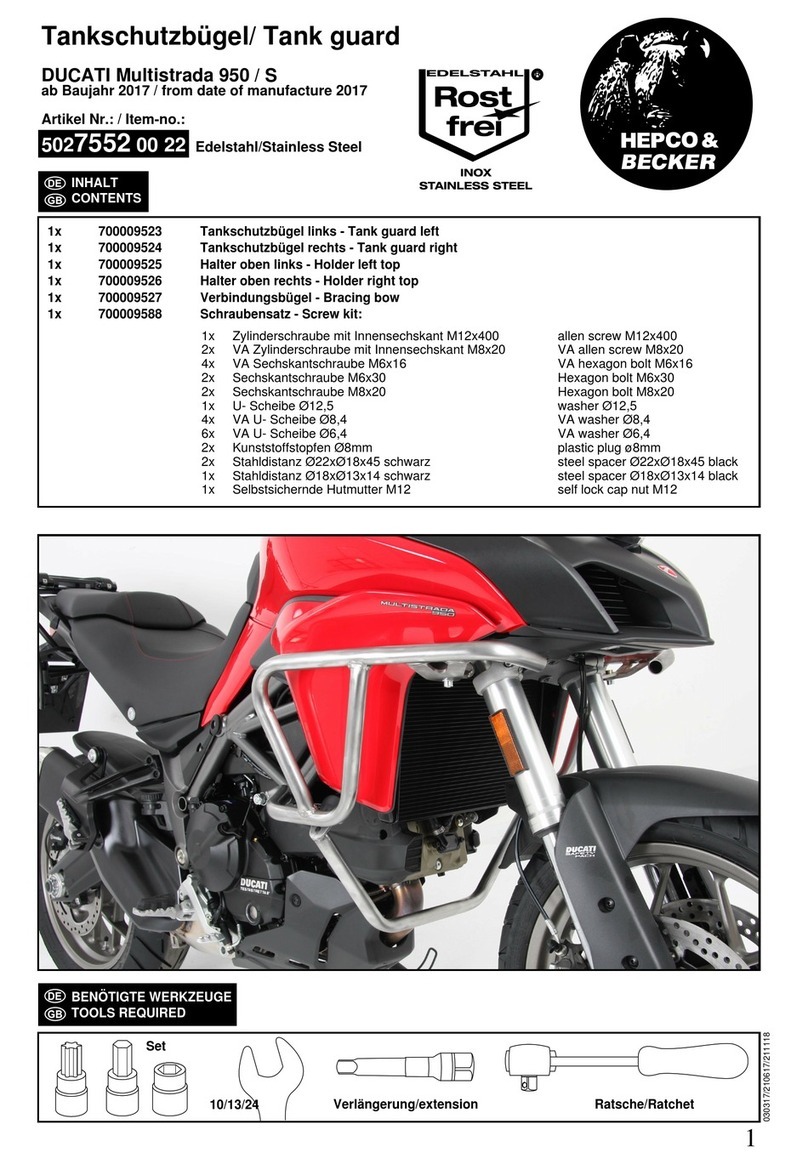

The CLOOS welding filters are tested for eye protection by the following

notified body: ECS GmbH, Obere Bahnstrasse 74, 73431 Aalen, Germany,

notified body 1883, that provides approval and continual quality system

under the control of the European Commission, the German Ministry for

Work and the Central Office of the Provinces.

European Conformity mark.

This confirms that the product fulfills the requirements of the

Directive 89/686/EWG

Notified Body ECS GmbH

Registration Number 1883

Obere Bahnstrasse 74

73431 Aalen

GERMANY

Filter Marking Explanation

CE 4/9-13 WT 1/1/1/2/379

4 - light state scale number

9- lightest dark state scale number

13 darkest state scale number

WT - Manufacturer identification

1 - Optical class

1 - Diffusion of light class

1 - variation in luminous transmittance class

2 – Angle of Dependence classification

379 - Number of the standard

3

Content

1. General information................................................................................. 4

1.1 Operating instructions.......................................................................................... 4

1.2 Explanation of symbols......................................................................................... 4

1.3 Limitation of liability.............................................................................................. 5

1.4 Copyright ..................................................................................................................... 5

2. Safety ........................................................................................................... 6

2.1 Proper use.................................................................................................................... 6

2.2 Reasonably foreseeable misuse......................................................................... 6

2.3 Personnel requirements........................................................................................ 6

2.4 Hazards......................................................................................................................... 7

3. Technical data ............................................................................................ 8

3.1 Environmental condition...................................................................................... 8

3.1.1 Ambient temperature............................................................................................ 8

3.1.2 Humidity...................................................................................................................... 8

4. Function and use....................................................................................... 9

4.1 Operation..................................................................................................................... 9

4.1.1 Adjustment of headgear....................................................................................... 9

4.1.2 Setting the shade ...................................................................................................10

4.1.3 Recommended shadelevels ...............................................................................11

4.1.4 Setting the filter......................................................................................................11

4.1.5 Setting the delay ...................................................................................................12

4.1.6 Testing settings.......................................................................................................12

5. Servicing and maintenance .................................................................. 13

5.1 Replacing the outer spatter lens.....................................................................13

6. Spare parts................................................................................................ 14

4

1. General information

1.1 Operating instructions

These operating instructions contain important information for the safe,

efficient handling of the device. Compliance with all of the safety instruc-

tions and operating instructions contained herein is a pre-condition for

safe working with the device.

Illustrations in these instructions are intended to provide a basic under-

standing, and may differ from the actual design of the device. Claims

cannot be derived therefrom.

Information manual for the welder protective helmet complying with Para-

graph 1.4 of Appendix ll of the EC regulations. The welding helmet is a high

quality product that contribute to the comfort and safety of the welder.

The welding helmet may be used only in connection with arc welding.

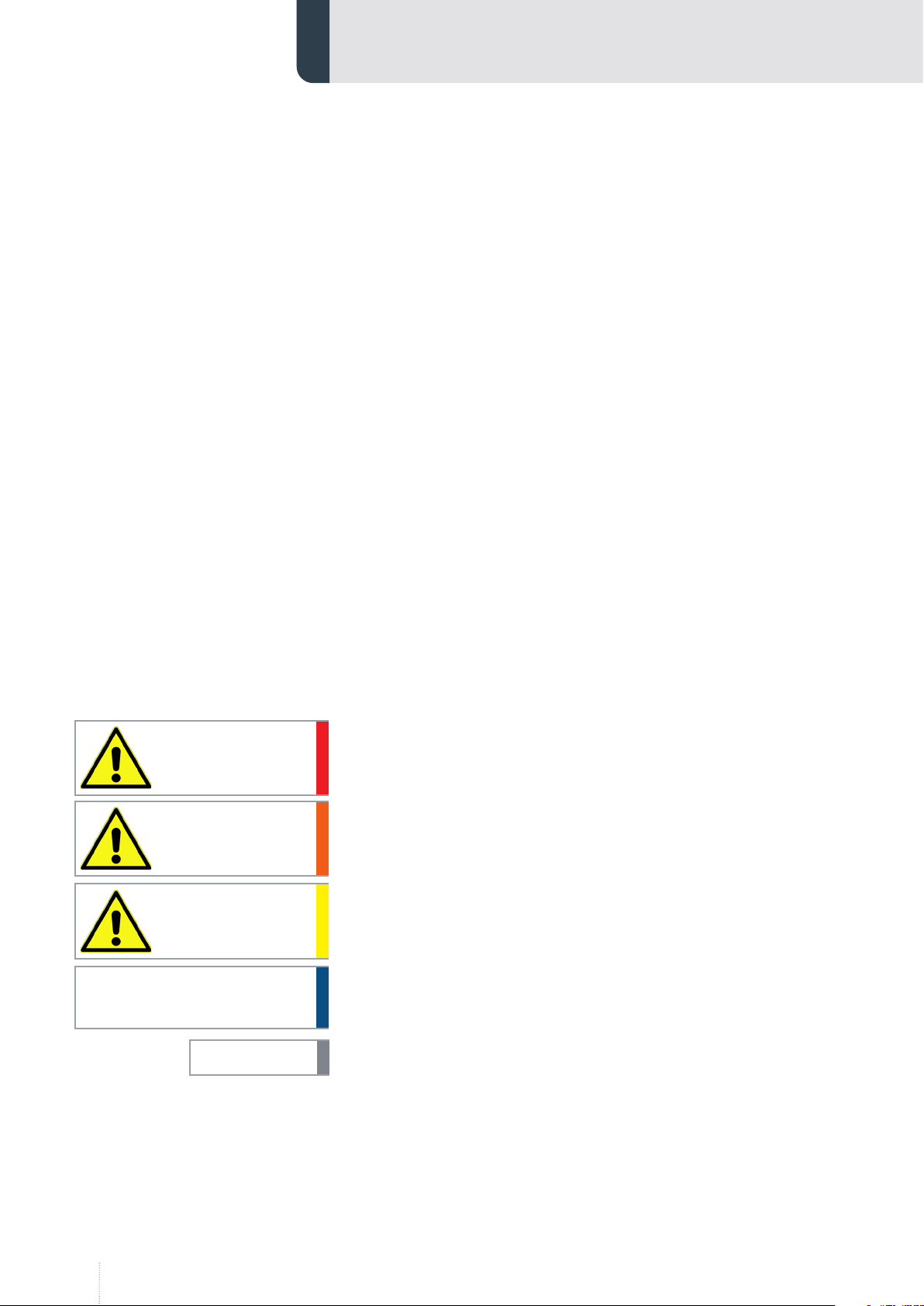

1.2 Explanation of symbols

Warning and safety instructions in the manual are identified by means of

pictograms and highlighted in a colour-coded block.

Warning and safety instructions which draw your attention to basic haz-

ards are additionally marked with signal words which express the level of

damage. These are categorised as follows:

The signal word indicates a hazard with a high level of risk, which, if not

avoided, leads to fatal or severe injury.

The signal word indicates a hazard with a moderate level of risk, which, if

not avoided, can lead to fatal or severe injury.

The signal word indicates a hazard with a low level of risk, which, if not

avoided, leads to minor or moderate injury.

The signal word indicates a hazard without risk of a physical impairment,

which, if not avoided, can lead to property damage.

Tips and recommendations as well as information for efficient and

smooth operation.

DANGER!

WARNING!

CAUTION!

ATTENTION!

NOTICE

5

1.3 Limitation of liability

All information and notes in this manual were compiled taking into con-

sideration the applicable standards and regulations and the state of the

art, as well as our many years of knowledge and experience .

The manufacturer assumes no liability for damages caused by:

• Non-observanceofthemanual

• Improperuse

• Useofuntrainedandnon-instructedpersonnel

• Unauthorisedalterations

• Technicalchanges

• Useofunauthorisedspareparts

1.4 Copyright

This document is protected by copyright.

The unauthorised transfer of these instructions to third parties, reproduc-

tion of any kind and in any form, even in excerpts, as well as the recovery

and/or notification of the content is prohibited without the written per-

mission of the publisher.

Infringements of this trademark will be subject to compensation for dam-

ages. All rights to further claims reserved.

6

2. Safety

2.1 Proper use

The device is only to be used for the following purpose:

The device affords reliable protection for the eyes whilst electric arc

welding. It offers permanent protection against UV/IR rays, heat & sparks

in any state from the clear to dark.

The welding helmet can be used for the following applications:

• Electrode

• MIG

• Mag

• Tig

The welding filters operate well under extreme low lighting and very

strong sunlight.

Risk from improper use!

Any use of the device other than the intended purpose can lead to hazard-

ous situations.

• Thedeviceshouldnormallyonlybeusedinaccordancewiththeinfor-

mationinthisdocument,inparticularwithrespecttocompliancewith

theapplicationlimitvaluesgiveninthetechnicalspecifications.

• Refrainfromanyuseofthedevicewhichdiffersorextendsbeyond

theselimits.

• Donotconvert,retrofitorotherwisealterthestructureorindividual

fittedcomponentswiththeaimofalteringthescopeofapplicationor

usabilityofthedevice.

Claims of any kind for damages caused by improper use are excluded.

2.2 Reasonably foreseeable misuse

The device is intended exclusively as protection for the eyes against UV/IR

rays, heat & sparks in any state from the clear to dark whilst arc welding.

They are not suitable for use with laser systems and oxy-acetylene (gas

welding) applications. The welding filter must not be used for any other

purpose other than welding. They should never be used as sunglasses

when driving as this could lead to incorrect identification of the colour of

traffic light.

2.3 Personnel requirements

Work may only be performed by a trained specialist. All personnel involved

must be instructed with regard to the safety requirements, safety regula-

tions and operational instructions which must be applied in their work.

WARNING!

7

2.4 Hazards

The warning and safety notices listed here and in the operations chapters

of these instructions must be observed in order to prevent potential harm

to health and hazardous situations.

Radiation

Ultraviolet and infrared radiation are released during welding. This can

cause a painful inflammation of the cornea and irreparable damage to the

lens of the eye leading to cataracts.

• Protectskinandparticularlytheeyes.Keepeyedropsandskincream

withahighsunprotectionfactoravailable.

• Donotlookdirectlyatweldingrayswithunprotectedeyeswhenthearc

strikes.

• AlwaysusesafetyglassesaccordingtoDINEN166andDINEN379in

yourwelder’sprotectiveshieldorhelmet.

• ProtectotherpersonsinthevicinityoftheweldingareafromUVrays

andspatterbysuitable,non-flammablepartitionwalls.

• Alwayswearsafetyglasseswithsideprotectionwhenyouareinan

areawhereweldingtakesplaceorwhereslagisremoved.

Allergic reaction

Materials that may get in contact with the wearers skin could cause Aller-

gic reactions to susceptible individuals.

• Ifthecontactcan´tbeavoided,atalktoadoctoraboutusingcreamsis

recommendedtokeeptheskinsafe.

DANGER!

WARNING!

8

3. Technical data

3.1 Environmental condition

3.1.1 Ambient temperature

Welding helmets and filters only resist a certain amount of heat. Please do

not place them near naked flames or hot work areas etc.

Operating temperature of electronic filter -5°C…55°C.

3.1.2 Humidity

The auto-darkening filters fitted in the helmets are not waterproof and will

not work properly if they have been in contact with water.

9

4. Function and use

Welding helmets afford reliable protection for the eyes whilst electric

arc welding. They offer permanent protection against UV/IR rays, heat &

sparks in any state from the clear to dark. The protection shades of the

welding helmets have been chosen to avoid eye damage caused by the

welding arc.

Welding helmets allow the welder to see the point of arc strike more pre-

cisely. This leads to a real time saving. The helmet does not have to be flip-

ped up and down during welding, both hands are kept free and because of

the helmets lightweight fatigue is reduced.

The helmet is available in 2 options. The helmet can be supplied with or

without UVIR shade 5 side windows – the side windows giving the user a

degree of side vision whilst still giving protection from the welding rays.

4.1 Operation

Before using the helmet for the first time the protective films must be

removed from the front spatter lens. The films cannot be removed from

the front spatter lens with the lens in place. Please follow the instructions

below to remove the spatter lens, see chapter „5.1 Replacing the outer

spatter lens“ on page 13

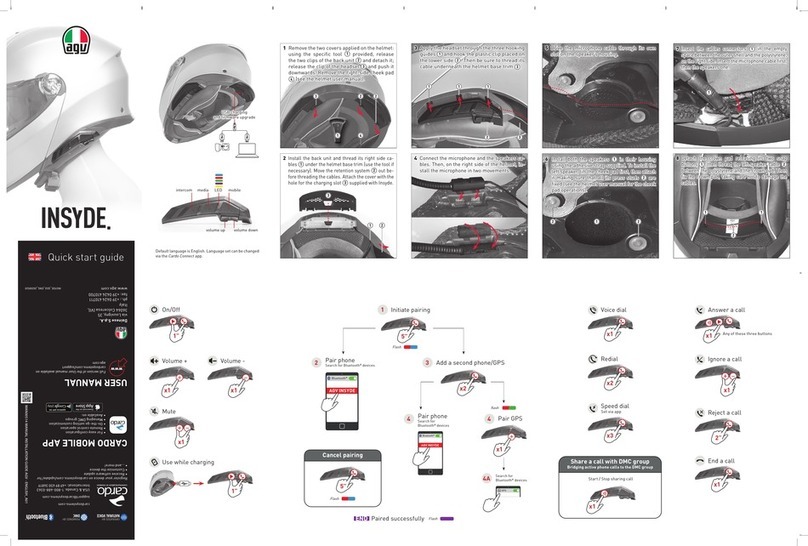

4.1.1 Adjustment of headgear

Welding helmets are equipped with a comfortable headgear that can be

adjusted in three different ways.

Push and Move

„Head height“

Push and turn

„Head size“

Rake

Adjustment

10

4.1.2 Setting the shade

On the welding helmet, the welding shade is selected by pushing the

"Weld/Grind" button.

2 ranges of welding shades are available:

• From DIN 5 to DIN 8, and

• From DIN 9 to DIN 13,

Select the welding shade by pushing the arrows on the Range button, up

and down to clear or darken the welding shade.

The welding helmet also offers a Grinding Mode with the "Weld/Grind"

button. The shade is then blocked in a shade DIN 4.

11

4.1.3 Recommended shadelevels

The most suitable shadelevel settings can be found on this chart or choose

using your experience. This setting can also be made manually during the

welding process.

4.1.4 Setting the filter

To allow the filter to switch, the sensors on the front of the filter must not

be covered. The filter then switches to the dark state when the arc strikes

and to the clear state when it stops. The filter switches to the light state

when the welding arc stops.

Once you have selected the Sensitivity MODE, push the UP arrow to the

maximum setting. Depending upon the surrounding light the filter will

switch to the dark state or will flicker (if the surrounding light is very low,

the filter may not switch to the dark state). Push the DOWN arrow until the

filter switches to the clear state.

The filter is now set to its optimum sensitivity (According to the surround-

ing light conditions).

Current internally in amperes

Welding process or related techniques

0,5 2,5 10 20 40 80 125 175 225 275 350 450

1 5 15 30 60 100 150 200 250 300 400 500

Flux core electrodes

Fluxed stick electrodes 9 10 11 12 13 14

MIG

Steels, alloyed steels, copper and its

alloys etc.

10 11 12 13 14

MIG

Aluminium, copper, nickel and other

alloys

10 11 12 13 14 15

TIG 9 10 11 12 13

MAG

Constructions steel, hardened and

tempered steels, Cr-Ni-steel, Cr-steel and

other alloyed steels

10 11 12 13 14 15

Electric arc compressed air joining 10 11 12 13 14 15

Plasma cutting 11 12 13

Micro-plasma welding 2,5

45 6 7 8 9 10 11 12 13 14 15

12

4.1.5 Setting the delay

The clearing delay can be adjusted manually by selecting the Delay MODE

and then by pushing the arrows on the "Ranges" button, up and down, to

select a delay between a fast clear (0.1 s) up to a slow clear (1.9 s).

4.1.6 Testing settings

Before use of the welding helmet the auto darkening filter (ADF) and hel-

met needs to be checked according to the following procedure:

• Check outer protection lens is clean and can be seen through.

• Ensure the the sensors are covered in any way and are clean.

• Once these checks have been carried out you can now test the ADF.

Select the darkest setting (shade 13) and set the sensitivity to the highest

setting. Now point the sensor towards a light source such as an overhead

light, lamp etc. The ADF should now switch to the dark state (please note if

the ADF is stored in a dark area away from light it may need to be left out

in strong light for 20 minutes to absorb power, if after 20 minutes if the

ADF does still not react then there is an issue with the sensor). Once the

filter is in the dark state you can check the shade variation is functioning

correctly, simply adjust the shade. By doing this, the shade should get ligh-

ter. If the shade does not appear to alter then you have an issue with the

shade variation.

To test the delay function set the delay to the maximum setting. Now

move the filter sensor away from the light source it should take 1 second to

return to the light state, now alter the delay setting to the minimum and

repeat the process, the time taken to return to the clear state should be 0.1

second. If the ADF does not react in this way then there is an issue with the

delay function.

Testing the sensitivity. Set the sensitivity to minimum setting and point

the ADF at the light source you used to test the other functions. If filter

switches to dark state, move away until the filter returns to clear state.

Slowly reduce the sensitivity until the filter switches to dark state (if it does

not, then move closer to the light until it reacts). If the ADF does not react,

then there is an issue with the light sensors.

If any of the functions fail during test or in use then please do not use the

ADF and contact your local distributor.

13

5. Servicing and maintenance

If used properly the welding filter requires no further maintenance during

its lifetime. The filter should be cleaned when changing the protection

lenses.

This can be done by any of the following ways:

• Wipe with a clean, dry piece of cloth.

• Clean with a piece of smooth cloth moistened with pure alcohol.

• Clean with a commercial disinfectant

If a filter should be replaced on a welding helmet, use exclusively certified

products. (DIN-CE marks). We recommend the use of CLOOS welding filters

in all CLOOS Arc Flash helmets.

The filter itself contains no special or toxic products and can be disposed of

in the same way as other electronic devices.

Always make sure that the helmet is equipped with an outside and inner

lens (in front of the filter on the outside and on the inside behind the filter).

These protection lenses must be replaced if damaged in any way (see over-

leaf). They are consumables and should checked and replaced regularly.

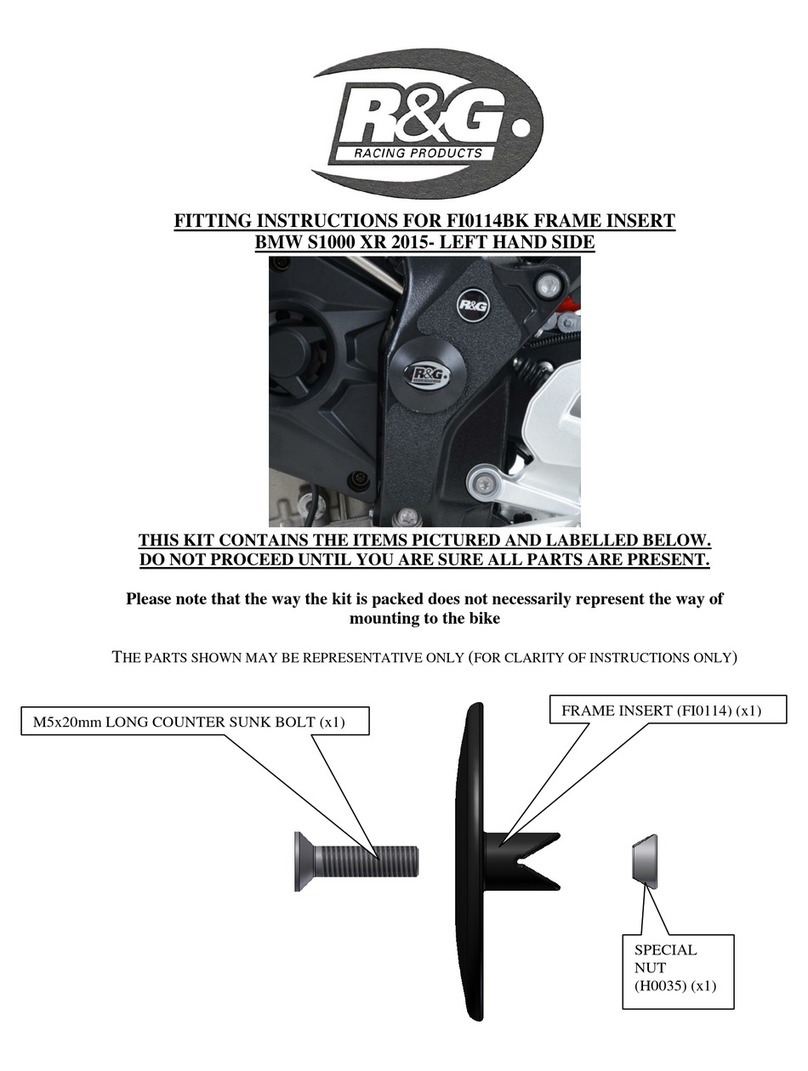

5.1 Replacing the outer spatter lens

Ensure that the helmet is always equipped with an Outside Lens (before

the filter, on the outside of the helmet) and an Inner Lens (behind the filter,

inside the helmet). These protection lenses must be replaced if broken,

damaged or covered with welding spatter to such an extent that vision is

impaired. Inner and Outer Lenses are consumables and must be replaced

regularly with certified CLOOS spare parts (CE marked).

To insert the new outer protection 4lens the filter must be removed by

unscrewing the two retaining screws 8from the inside of the helmet 1.

The old protection lens can then be removed and the new lens inserted

followed by the light seal cradle 6, ADF 7, inner protection lens 5and

then the ADF retaining frame 8and finally replace the two retaining

screws (see drawing).

14

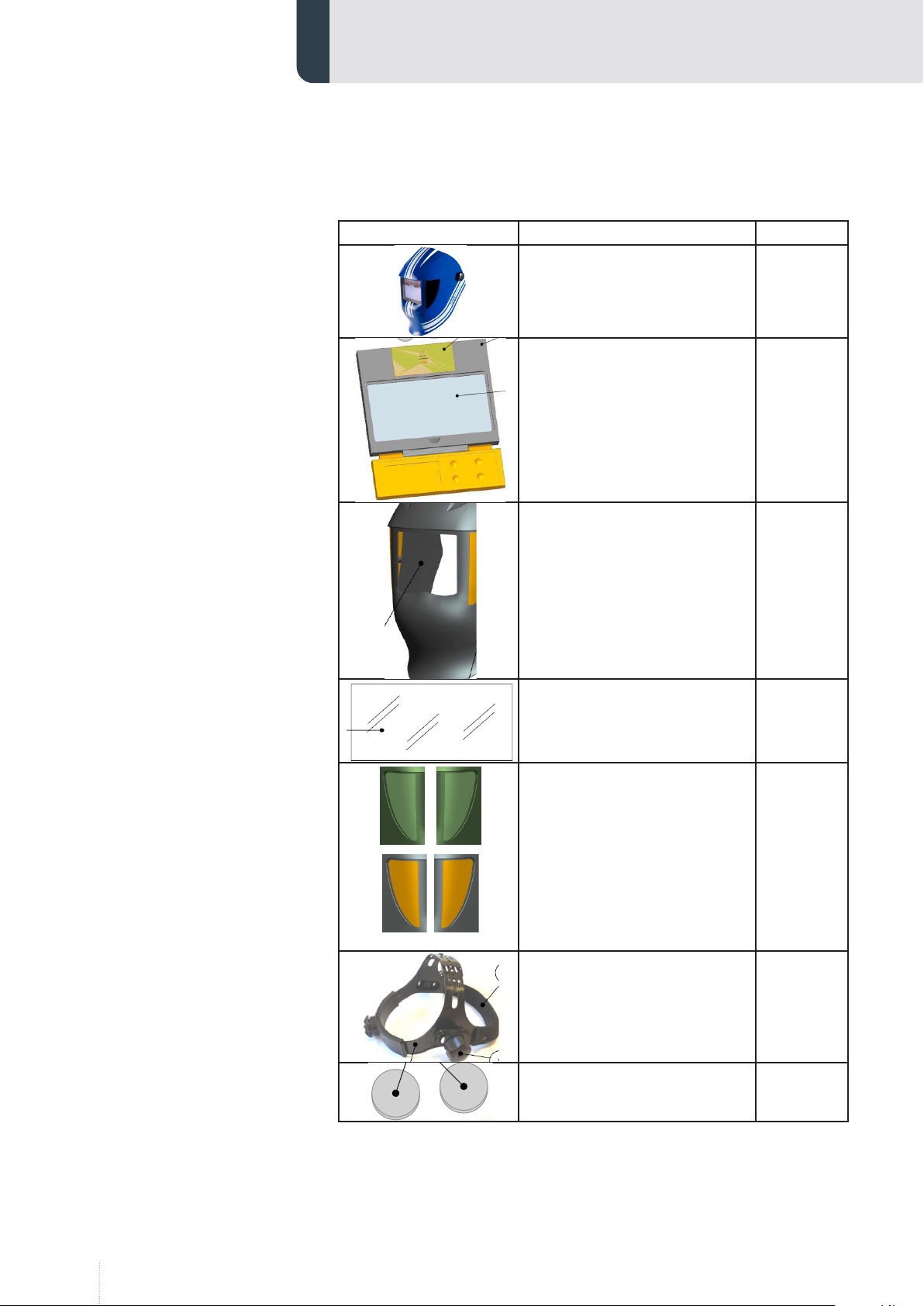

6. Spare parts

Item Designation Part No.

Welding helmet

Cloos ArcFlash 4 evo 875006200

CLOOS Arc Flash 4 evo automatic

filter cpl 875006201

CLOOS Arc Flash 4 evo protect

glass out (10pc) 875006202

CLOOS Arc Flash 4 evo protect

glass in (10pc) 875006203

orange = black

CLOOS Arc Flash 4 evo

sideglass DIN S5 l+r

CLOOS Arc Flash 4 evo

sideglass black l+r

875006204

875006205

CLOOS Arc Flash 4 evo headgear

cpl. 875006206

CLOOS Arc Flash 4 evo battery

(2pc) 875006207

15

www.cloos.de

Carl Cloos Schweisstechnik GmbH

Industriestrasse 22-38

D-35708 Haiger

Telephone +49 (0)2773 85-0

Telefax +49 (0)2773 85-275

E-Mail [email protected]

www.cloos.de

Other manuals for Arc Flash 4 evo

1

Table of contents

Popular Motorcycle Accessories manuals by other brands

Gammatronix

Gammatronix Black top Dual System installation manual

PUIG

PUIG 3758 Mounting instructions

hepco & becker

hepco & becker 6607546 01 01 Mounting instructions

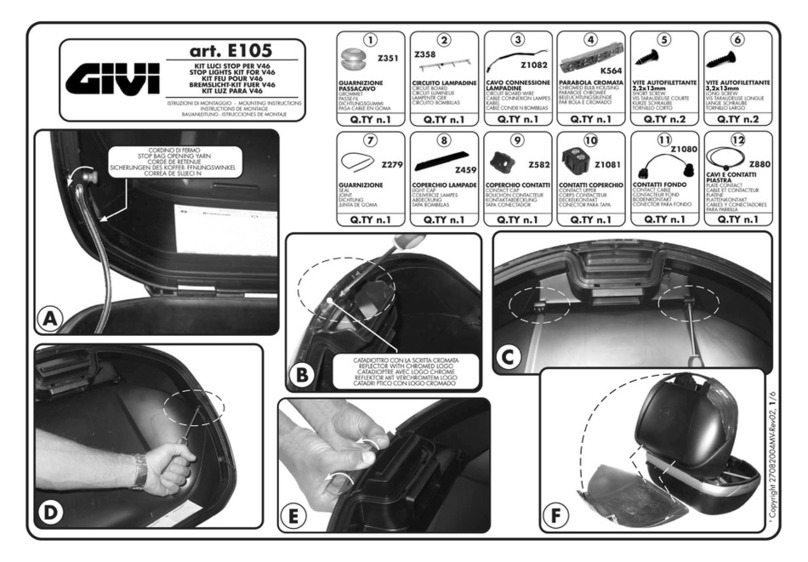

GIVI

GIVI E105 Mounting instructions

Wunderkind Custom

Wunderkind Custom 106852-F15 Installation and safety manual

R&G

R&G PKS0057SI Fitting instructions