Clopay Avante Pro Series Maintenance and service guide

INSTALLATION & MAINTENANCE

Aluminum Full Vision Residential Garage Door Instructions

Model: Serial No.:

(Provided on label on interior door surface)

Size:

Homeowners Should Retain This Booklet for Future Reference

This Manual Contains Important Safety Information

CONSUMER HOTLINE 1-800-2CLOPAY 1-800-225-6729

Hours of Operation (ET): Mon. Fri., 8:30 AM - 7 PM; Sat. 8:30 AM - 5 PM.

Installed By: Ê*i>ÃiÊV«iÌiÊEÊ>ÊÜ>ÀÀ>ÌÞÊÀi}ÃÌÀ>ÌÊV>À`°

Register your product online at http://warranty.clopaydoor.com

Clopay® Pro-Series® Limited Warranty

Avante® Door Limited Warranty Information

We will repair or replace (at our option) any garage door section or hardware that is defective in material or workmanship pursuant to the

terms of this limited warranty. This warranty extends to and benefits only the original purchaser of the garage door. This warranty does not

apply to commercial, industrial or any other non-residential installation.

We will provide, at no cost to you, sections/section components, hardware, springs/spring components or windows to repair or replace

defective sections, hardware, springs/spring components or windows. All labor costs associated with the removal and reinstallation of any

repaired section/section components, hardware or spring/spring components, and the installation of replacement sections/section

components, hardware, spring/spring components, or windows will be your responsibility. We reserve the right to inspect and/or verify any

claimed defect.

The applicable limited warranty periods are as follows:

Model # Paint System Hardware/ Springs

AV, AVI 5 yrs. 3 yrs.

Terms and limitations of the limited warranty are further detailed below:

Paint System Limited Warranty

Clopay warrants the sections of the Models listed above against paint finish cracking, checking or peeling (losing adhesion) as follows: (a) in

residential single family installations for the years designated above from the date of delivery to the original purchaser; (b) in all other

residential installations (including installations on facilities owned in common by condominium associations or similar organizations), for one

(1) year from date of delivery to the original purchaser, pursuant to the terms of this limited warranty.

Hardware/Spring & Spring Component/Sections/Section Components Limited Warranty

We will repair or replace (at our option) any garage door hardware, spring, and/or spring component that is defective in material or

workmanship for the term defined in the chart above, pursuant to the terms of this limited warranty. In addition, we will repair or replace (at our

option) any garage door section/section component that is defective in material or workmanship.

WE WILL NOT PAY FOR ANY DAMAGES, INCLUDING INCIDENTAL OR CONSEQUENTIAL DAMAGES, CAUSED BY OR RESULTING

FROM DEFECTIVE GARAGE DOOR SECTIONS OR HARDWARE. Some states do not allow the exclusion of incidental or consequential

damages, so the above limitation may not apply to you.

Our warranty shall not extend to or cover deterioration due to damage to the garage door caused by fire, an act of God, other accident or

casualty, vandalism, radiation, harmful fumes or foreign substances in the atmosphere, or occurring as a result of any physical damage or the

failure of paint that is not applied per the manufacturer's specifications after the garage door left our factory, or failure to follow all installation

and maintenance instructions. Nor shall our warranty extend to or cover any damages due to normal wear and tear, or claims with respect to

any products that in any way or degree have been altered, processed, misused or improperly handled or installed.

If your garage door does not conform to this warranty, notify us in writing at the following address promptly after discovery of the defect.

Clopay Building Products, Attn: Consumer Services Dept., 101 Miller Road, Russia, Ohio 45363. Additional copies of our installation and

maintenance instructions may be obtained by calling 1-800-225-6729.

WE MAKE NO OTHER WARRANTIES, REPRESENTATIONS, OR COVENANTS, EXPRESS OR IMPLIED, WITH RESPECT TO THIS

PRODUCT, INCLUDING BUT NOT LIMITED TO WARRANTIES, REPRESENTATIONS OR COVENANTS AS TO WORKMANSHIP,

DESIGN, CAPACITY, QUALITY, CONDITION, MERCHANTABILITY, OR FITNESS FOR ANY PURPOSE OF THE PRODUCT, EXCEPT FOR

ANY “IMPLIED WARRANTY” AS THAT TERM IS DEFINED IN THE MAGNUSON-MOSS WARRANTY-FEDERAL TRADE COMMISSION

IMPROVEMENT ACT, SUCH IMPLIED WARRANTIES TO BE LIMITED IN DURATION TO A PERIOD OF ONE YEAR FROM THE DATE OF

PURCHASE.

This warranty gives you specific legal rights, and you may also have other rights that vary from state to state.

© Clopay Building Products Company, Inc.

A Griffon Company, Inc. 2005

3

Table of Contents

Introduction and Opening Preparation

STEP 1 – Things to Know Before You Begin 3

STEP 2 – Read Safety Information 4

STEP 3 – Check Headroom, Backroom, Sideroom 5

STEP 4 – Removing the Existing Door Springs 6

STEP 5 – Removing Door Sections and Track 7

STEP 6 – Preparing the Opening 7

Preparing the New Door

Typical Garage Door Installation Illustration 8

Hardware Components 9

Torsion Spring Hardware Components 10

Installing the New Door

STEP 7 – Preparing Bottom Section 11

STEP 8 – Outside Lift Handle Attachment 15

STEP 9 – Installing Door Sections 16

STEP 10 – Reinforcing the Top Section for Opener Attachment 18

STEP 11 – Assembling and Installing Track 19

STEP 12 – Lock Installation (if included) 21

STEP 13 – Pull Rope 21

STEP 14 – Spring Installation 22

STEP 15 – Attaching an Automatic Opener 27

Maintenance/Adjustments/Options

Painting and Windows 28

Maintenance 29

Checking and Adjusting the Door 29

Replacement Parts 29

STEP 1 – Things to Know Before You Begin

Read the instructions completely before starting the installation

of the door. Becoming familiar with the components before

assembling the door will reduce the installation time.

Be sure all hardware components for your new door are

included before removing existing door (see pages 6,7). If your

door is missing any parts, call the toll-free Consumer Services

number listed on the front of this manual.

Allow enough time to do the work; removing an existing door

will take approximately 1-3 hours.

An assistant may be required for lifting the unsprung door. It

can weigh from 100 to 800 pounds.

A typical installation takes between 9 and 12 hours to

complete.

Keep in mind when planning the installation that the garage

will be open and unsecured when disassembling the old and

assembling the new door.

If the garage door is the only opening in the structure make

sure everything you need is inside. You will have no way of

leaving the garage until the track is assembled and installed.

This will take approximately 5 hours.

To avoid damage to the door, you must reinforce the top

section of the door in order to provide a strengthened

mounting point for attachment of an automatic opener (see

page 18).

Low Headroom doors require special instructions. Options for

doors with low headroom can be found on page 5. Purchase of

additional hardware may be required. Check headroom

requirements in the chart on page 5 before beginning.

To avoid installation problems which could result in personal

injury or property damage, never reuse old track or hardware.

Doors installed in high windload regions (Florida and other

high wind prone areas) may require additional reinforcement

beyond what is detailed in these instructions. Please refer to

supplemental instructions for these areas.

Express warranties apply only to doors installed using original,

factory-supplied sections, parts, and hardware installed in strict

accordance with these instructions.

Tools Needed

“C” Clamps or Locking Pliers

Hammer

Screwdriver

Tape Measure

Level

Socket wrench kit

Pliers

Drill, 9/64”, 3/16", 1/4", & 3/8" drill bits, and 7/16" socket bit

Step ladder

Saw horses (with carpet or other soft material on top surface; 2

for doors up to and including 10’0”, 3 for doors over 10’0”) or

other supports for placing section on while assembling

Hacksaw

Wood Saw

T-Square

3/32” Allen (Hex) Wrench

Two 1/2" diameter, 18" long cold rolled solid steel winding bars

(NOTE: Winding bars are available at most hardware stores)

Locking Pliers

Additional Material Required

Light household oil

1-1/4" x 1-1/4" Minimum punched angle

- 13 ga. (3/32") minimum thickness for Operator

Reinforcement (see page 18)

- 16 ga. (1/16") minimum thickness for rear track hangers

on doors weighing up to 300 lbs. that use torsion

springs. If your door exceeds these weight limitations, or

if you do not know the weight of your door, 13 ga. angle

should be used. (See page 20)

Eight 3/8" x 1" bolts and nuts for rear track hangers

Six 5/16" x 11/2" lag screws for rear track hangers

Twelve 10d 3" nails

Stop Molding

Wood Block

Wood Anchor Pad for Torsion Spring (See page 20 for size and

material specifications)

Rope

4

STEP 2 – READ THIS SAFETY INFORMATION

IMPORTANT!

To Protect Yourself From Injury You Must Carefully Read The Following Safety

Information and Warnings Before You Install Or Use Your New Garage Door

You can install your new garage door yourself IF…

a) you have help (it may weigh up to 800 lbs.);

b) you have the right tools and reasonable mechanical

aptitude or experience; and

c) you follow these instructions very carefully.

Garage doors use springs to balance them. There are

two types of springs installed — extension or torsion.

Each of these is available in either a standard or EZ-

Set™assembly option. Please look at the drawings on

page 8 to see which springs your old door has.

If your old door uses torsion springs, do not

attempt to remove the door or the springs yourself.

Have a qualified door repair service remove them.

Attempting to remove a torsion spring assembly without

proper training or tools may result in an uncontrolled

release of spring forces which can cause serious or

fatal injury.

Only the track specified and supplied with the door

should be used.

The brackets at the bottom corners of your garage door

are under great tension. Do not attempt to loosen any

bracket fasteners except when and as directed in

detail in the following instructions. Otherwise, the

bracket could spring out with dangerous force.

Do not permit children to play beneath or with any

garage door or electric operating controls.

In removing a garage door that has extension springs,

follow the instructions carefully, including the use of “C”

clamps or locking pliers on both sides of the door in

order to keep the door from moving once the springs

are removed.

When installing a door with torsion springs, always use

solid steel 1/2" x 18" winding bars. Winding bars are

available from many professional door installers. The

use of screwdrivers or any substitutes for winding bars

will risk severe injury. See page 23 for further safety

instructions regarding winding bars.

Keep hands and fingers clear of section joints, track,

and other door parts when the door is opening and

closing to avoid injury. The lift handles are located for

safe operation as well as easy use.

Bolts must be installed at the rear end of horizontal

tracks. These act to stop the rollers and keep the door

from rolling off the back of the track.

Track installations must use sway braces on the rear

track hangers to prevent sideways movement. If the

tracks are not firmly stabilized they might spread,

allowing the door to fall and cause severe injury and

damage.

The center torsion spring assembly uses a wooden pad

that must be of good quality and firmly attached to the

wall. Four 3⁄8" x 3" lag screws should be used to attach

wood structure. The wood needs to be made of a Grade

2 or better Southern Yellow Pine (also known as

Southern Pine or Yellow Pine.) Other acceptable types

of wood for this application are beech, birch, hickory,

and oak. The wood must be free of splits and cracks.

Do NOT use wood labeled as Spruce-Pine-Fir (or

SPF). Four 3⁄8" masonry anchors can be used on

concrete or block walls. If the wood splits once the

torsion spring is in place, it should be replaced by a

professional installer. Do not try to remove or repair a

torsion spring assembly or red fasteners once the spring

is wound.

Springs, cables, and bottom fixtures are under strong

spring tension. Do not attempt to loosen any

fasteners on these components. You could suddenly

release spring forces and risk severe injury.

If the garage door and/or any of the supporting track are

damaged, operating the door could be hazardous.

Call an authorized representative of the manufacturer or

professional door repair service promptly.

If repairs are ever required to your door, safety and

trouble-free operation can be best assured by using

original replacement parts.

Once you have completed the installation of your new

garage door, please be sure that your garage complies

with all applicable ventilation requirements before you

enclose any vehicles in the garage. Good ventilation

avoids fire and health hazards caused by fumes

accumulating within a well-sealed garage.

Clopay Building Products Company disclaims all liability

for any installation that is not in compliance with

applicable state or county building codes.

Doors equipped with automatic door operators can

cause serious injury or death if not properly adjusted and

operated. To ensure safety of these doors:

a) test the sensitivity of the operator’s safety reverse

mechanism monthly;

b) if your door has a pull down rope, you must remove

the pull down rope;

c) make sure the door remains unlocked;

d) do not allow children to play with the controls.

In the interest of safety this symbol means WARNING or

CAUTION. Personal injury and/or property damage may

occur unless instructions are followed carefully.

5

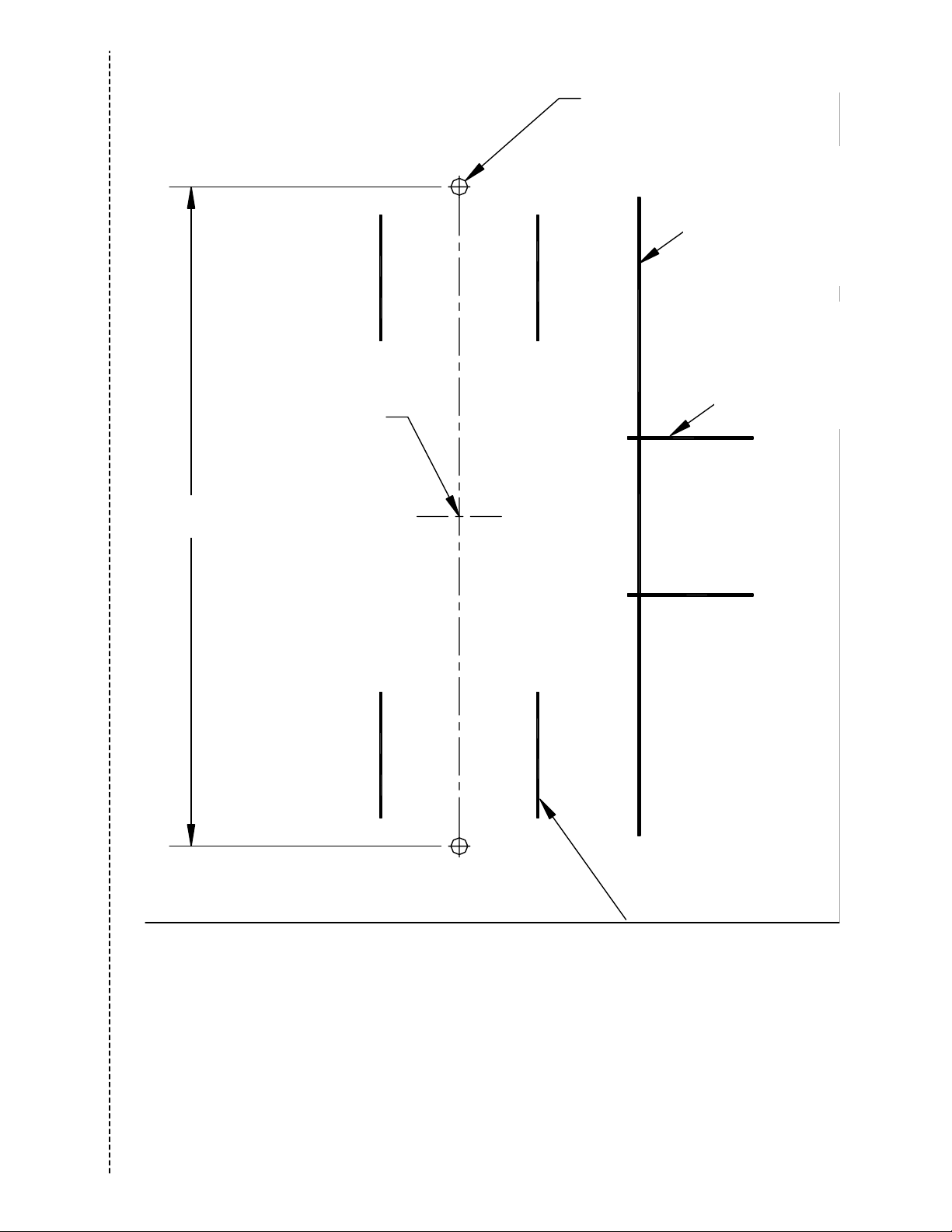

STEP 3 – Check Headroom/ Backroom/

Sideroom

Headroom is the space needed above the top of the door for the

door, the overhead tracks, and the springs. Measure to check

that there are no obstructions in your garage within that space.

The normal headroom space requirement is shown in Table 3-A.

The backroom distance is measured from the back of the door

into the garage, and should be at least 18" more than the height

of the garage door. A minimum sideroom of 3-3/4" should be

available on each side of the door on the interior wall surface

to allow for attachment of the vertical track assembly. The

rough opening should be the same size as the door. (Fig. 3-A)

Track Radius: The radius of your track can be determined by

measuring the dimension “R” in Fig. 3-B. If dimension “R”

measures 11" to 12", then you have a 12" radius track. If “R”

equals 14" to 15", then you have a 15" radius track. (Fig. 3-B)

Headroom requirements

The standard headroom space requirement is shown in Table

3-A at right.

Low Headroom? If you have restricted headroom, several

remedies are available. See Table 3-B for various options.

NOTE: Installation of the various Low Headroom Options differs

from the installation of a standard headroom door. Supplemental

instructions are included with the hardware of each Low

Headroom Option.

Rough Opening = Door Size

FIG. 3-A

FIG. 3-B

Table 3-A: Standard Headroom

Requirement Chart

Spring Type

Track

Radius

Headroom

Required

Torsion Spring 12” 12”

Torsion Spring 15” 14”

Table 3-B: Low Headroom Options*

Spring Type Low Headroom Option Reduces Required

Headroom to: How can I get this option?

Torsion Low Headroom Track

(Front Mount Spring) 9-1/2”

Available from and should be

installed by professional installer

only.

Torsion Low Headroom Track

(Rear Mount Spring) 4-1/2”

Available from and should be

installed by professional installer

only.

*About 3" of additional headroom height at the center plus additional backroom is needed to install an automatic garage door opener.

Check door opener instructions.

R

Backroom = Door

Height Plus 18”

3-3/4” Minimum Sideroom

Door

Height

Headroom

Required

6

STEP 4 – Removing the Existing Door

Springs

Garage doors use springs to balance the door weight. There are

two types of springs used — extension and torsion. Each of

these is available in either a standard or EZ-Set™assembly

option. If your present door uses standard torsion springs,

do not attempt to remove the door or the springs yourself.

They should be removed by a qualified door service

professional. Attempting to remove a torsion spring assembly

without proper training and tools may result in an uncontrolled

release of spring forces which can cause serious or fatal injury.

The following instructions detail how to remove Extension

springs and EZ-Set™Springs.

Serious injury could result if spring tension has not been

released before other work begins.

Removing Extension Springs

Use two or more helpers to assist you in lowering the door.

Step 4-1a: Raise the door to the full open position. Place “C”

clamps or locking pliers tightly on both sides of the track under

the door so the door is held securely in place. With the door fully

open, most spring tension has been removed. (Fig. 4-A)

Do not attempt to remove or adjust extension springs with door

in the down position. Use “C” clamps to keep the door from

moving or falling once the springs are removed.

Step 4-2: Detach the cable at both ends. Disassemble and

remove the springs and cable completely from the door.

NOTE: Wood blocks should be placed underneath the door

when closing to prevent fingers from being trapped.

Step 4-3: Remove the “C” clamps from the track and carefully

close the door. Some large doors might weigh as much as 500

pounds when the spring tension is removed. The weight of the

door will not be apparent when you first begin to close the door.

The door will feel progressively heavier as it is lowered until its

full weight (as much as 500 pounds) is realized about one foot

from the floor. A single car door may weigh as much as 200

pounds. (FIG. 4-B)

To avoid injury, keep hands and fingers clear of section

joints, track, and other door parts while the door is

opening and closing.

Removing EZ-Set™Extension or Torsion

Springs

Step 4-1b: With the door in the DOWN position, position a drill

with a 7/16” socket bit over the worm drive. Using the reverse

(counter-clockwise) direction on the drill, remove all the tension

from the spring (repeat for each side). After spring tension has

been removed, detach the lift cables at both ends. Disassemble

and remove the springs and cable completely from the door.

(Fig. 4-C)

FIG. 4-A

FIG. 4-B

FIG. 4-C

“C” Clamp

Wood

Block

Black

Housing Lifting

Cable

Safety

Cable

Red Mark

on Safety

Cable

Black

Bushing

Worm

Drive

Sheave

Fork

Sheave

7

STEP 5 – Removing Door Sections and Track

Step 5-1: The door can now be disassembled. Starting with the

top section, remove the hardware and unstack the sections one

at a time. (Fig. 5-A)

Step 5-2: After all sections have been removed from the

opening, detach all remaining track and hardware from the

jambs. The hangers that attach the rear ends of the overhead

track to the ceiling (called rear track hangers) in many cases can

be reused on the new door if made of 13 gauge (3/32") or

heavier steel and is not loose or unstable. (Fig. 5-B)

To avoid installation problems which could result in

personal injury or property damage, use only the track

specified and supplied with the door. Do not attempt to

reuse old track.

STEP 6 – Preparing the Opening

Step 6-1: On the inside of the garage your opening should be

framed with wood jambs, 2" x 6" if possible. The side jambs

should extend to approximately the same height as the

headroom required. If you have just removed an old door, the

jambs should be inspected for the condition of the wood. If the

wood is rotten, it should be replaced now. The jambs should be

plumb and the header should be level. If there are any bolts

fastening the jambs to the wall, the heads should be flush so

they don’t interfere with the installation of your new door.

(Fig. 6-A)

NOTE: Rough Opening (without stop molding)=door size

Step 6-2: Door stop molding should be temporarily nailed to the

edges of the jambs flush with the inside. (Fig. 6-B) Stop molding

featuring a built-in weather seal is offered as an option.

FIG. 6-A

*IMPORTANT: The Wood Anchor Pad is used to mount the

torsion spring and has specific requirements for wood quality,

species, and attachment that must be met. See “Spring

Installation” section on page 23 or 26 for requirements.

FIG. 5-A

FIG. 5-B

FIG. 6-B

Wood Anchor Pad* (2 x 6)

Center of Door Opening

Rear

Track

Hanger

Stop

Molding

2 x 6

“Side Jamb” 8”

Minimum

Center

Post

(With

Two

Doors

Side by

Side)

3-3/4” Minimum

Side Room

2 x 6

“Header Jamb”

Opening

Height

8

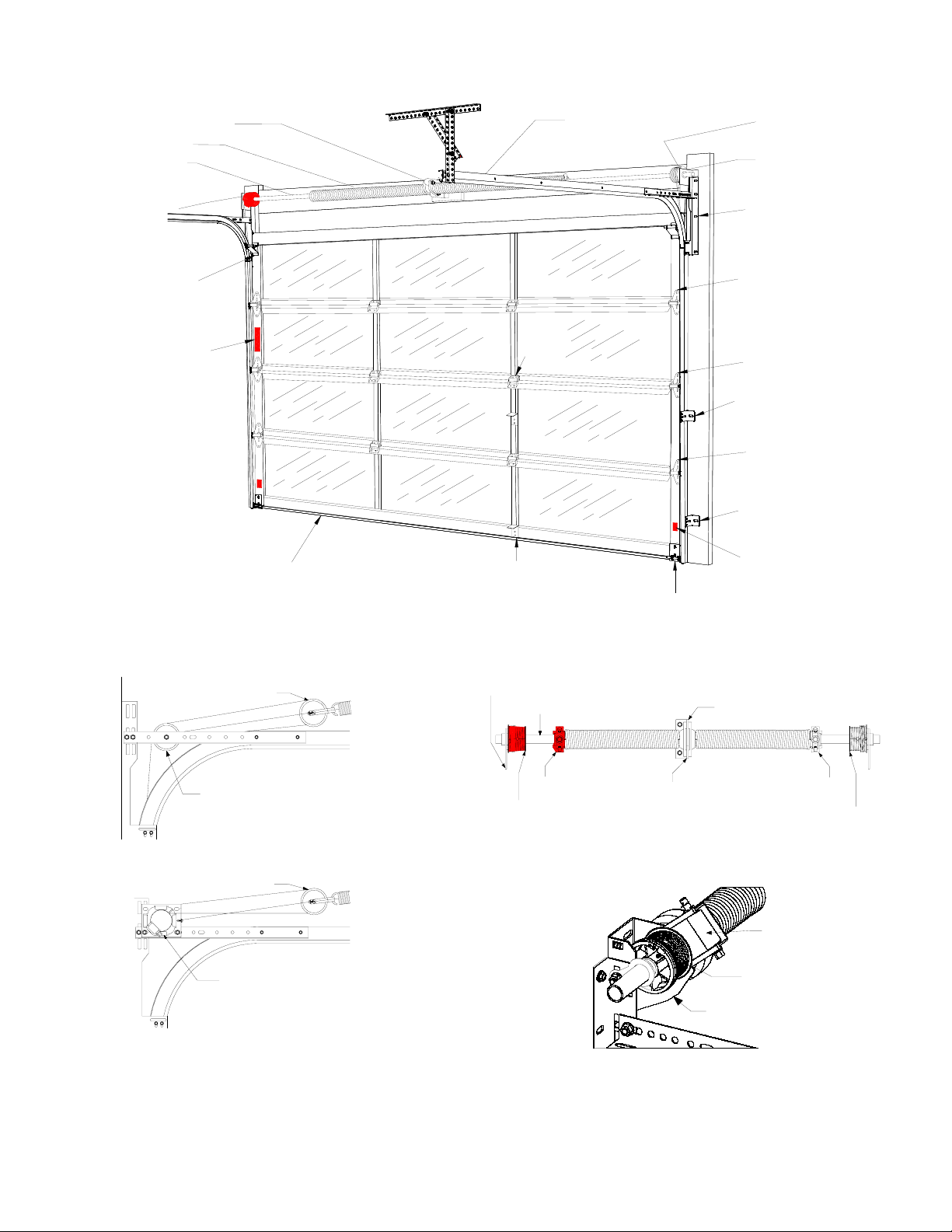

Typical Garage Door Installation Illustration

Right Cable

Drum (Black)

Left Cable

Drum (Red)

Torsion Shaft

Torsion Spring

End Bearing

Plate

Center Bearing Plate Horizontal Track

Bottom Bracket

Warning Label

Vertical Warning

Label

Inside Lift

Handle

#1 Hinge

#2 Hinge

#3 Hinge

Bottom

Bracket

Top

Roller

Bracket

Flag Bracket

Long Track

Bracket

Short Track

Bracket

Bottom Weatherstrip

Center

Hinge

Standard Extension Spring System*

EZ-SetTM Extension Spring System*

Standard Torsion Spring System

EZ-SetTM Torsion Spring System*

*Only torsion springs are available on the Avante door. While the other spring setups are not representative of Avante doors, they are

shown here to help determine the type of spring setup on existing door.

NOTE: The above illustration represents a composite of many of the features found on a variety of garage doors. While not

representative of any one door, it provides a handy reference for the location of specific components

Sheave

Sheave

Stationary Sheave

EZ-Set

TM

Winding Unit

End Bearing Plate

Torsion Tube Center Bearing Plate

Left (Red)

Cable Drum

Red Winding Cone

Stationary

Cone

Black Winding

Cone

Right (Black)

Cable Drum

EZ-Set

TM

Winding Unit

Left Cable Drum

EZ-SetTM Bracket

9

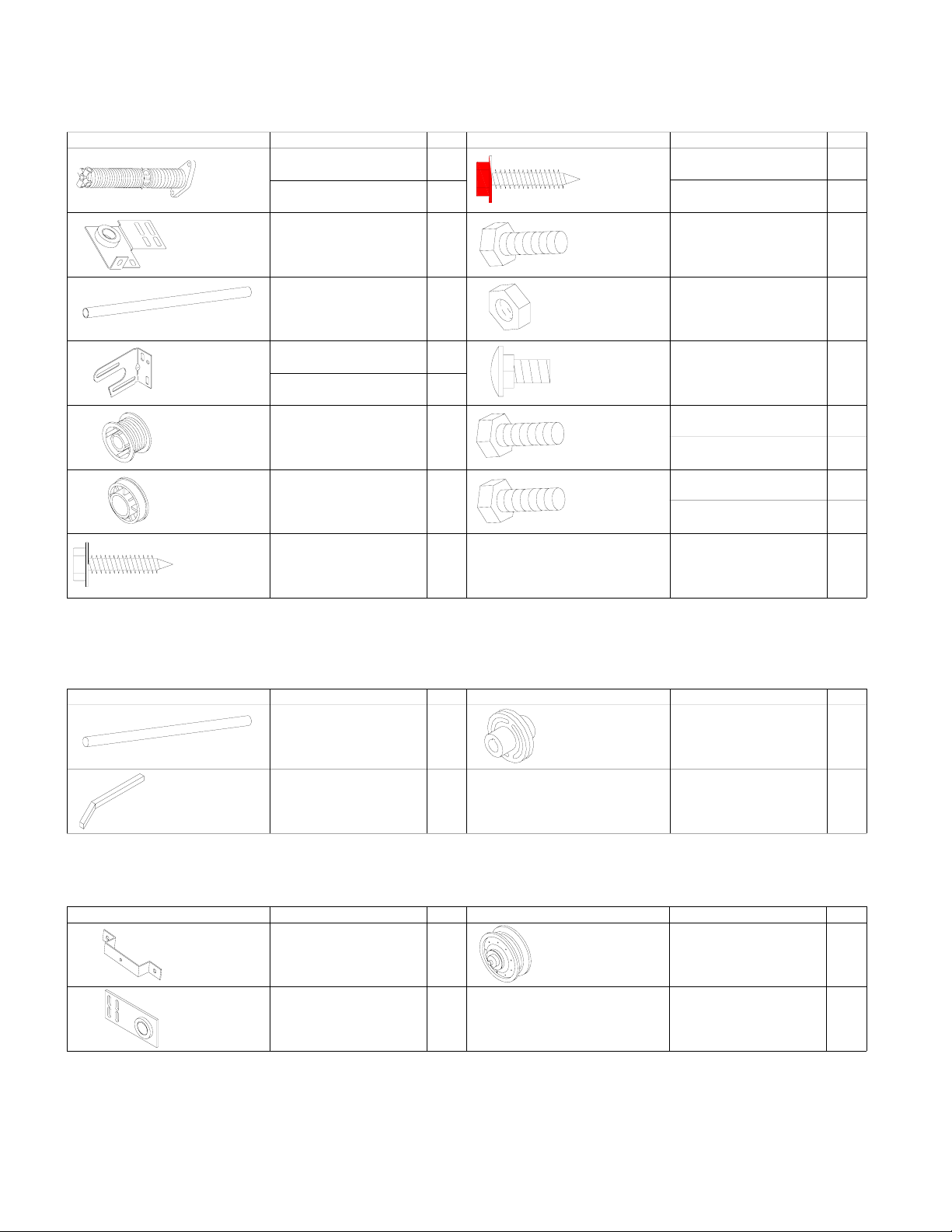

Hardware Components

Track Bracket

(Longer)

Track Bracket

(Shorter)

#2 Hinge

#3 Hinge

3

8''-18 x 3

4'' Lg.

Carriage Bolt

Top Bracket

Bottom Bracket

(1) Pair

Flag

Bracket

(1) Pair

Cable Assembly

Vertical

Track

Curved

Horizontal Track

3

8'' Washer

Horizontal Angle

3

8'' Hex Nut

1

4'' Flange Nut

#10 x 1'' Pan

Hd. Sheet

Metal Screw

Struts*

Lift Handle

5

16'' x 15

8''

Lag Bolt

1

4'' x 5

8'' Track Bolt

Lift Handle/

Step Plate

#1 Hinge

Short Stem

Rollers

Description: Qty. Qty.Door Size:

Description:

Single Car Doors

8' - 10'W x 6'6'' - 8'0''H

Double Car Doors

16'W x 6'6" - 8'0''H

22

46

6

24

0

4

2

2

16

22

10

12

1

4" x 3

4'' Hex Hd.

Self-Tapping

Screw 77

58

8

4 Section Doors

5 Section Doors 10

Pull Rope All Doors 1

Single Car Doors

8' - 10'W x 6'6'' - 8'0''H

Double Car Doors

16'W x 6'6" - 8'0''H

Single Car Doors

8' - 10'W x 6'6'' - 8'0''H

Double Car Doors

16'W x 6'6" - 8'0''H

5 Section Doors

4 Section Doors

Single Car Doors

8' - 10'W x 6'6'' - 7'0''H

Double Car Doors

16'W x 6'6" - 7'0''H

Single Car Doors

8' - 10'W x 6'6'' - 8'0''H

Double Car Doors

16'W x 6'6" - 8'0''H

All Doors

All Doors 2

All doors will receive (2) of these items:

(While not representative of any one model, the quantities below can be used as a guide. In some

instances, extra screws/bolts are provided in the event of strip out or loss of parts. Quantities for

doors over 8'0" high may be different, see extended height supplement.)

*More struts may be required in high windload areas.

Single Car Doors

8' - 10'W x 6'6'' - 8'0''H

Double Car Doors

16'W x 6'6" - 8'0''H

All Doors

All Doors

Handle Spacer

1

4" x 3

4''

Hex Hd. Bolt

Center Hinge

Single Car Doors

8' - 10'W x 6'6'' - 8'0''H

Double Car Doors

16'W x 6'6" - 8'0''H

3

9

Set Screw All Doors

4

4

4

2

All Doors 1

Long Stem

Rollers

1

4" x 3

4'' Hex Hd.

Self-Tapping Screw

(Red Head)

All Doors 10

Cable pin

Cotter pin

#2 Slide

Lock

10

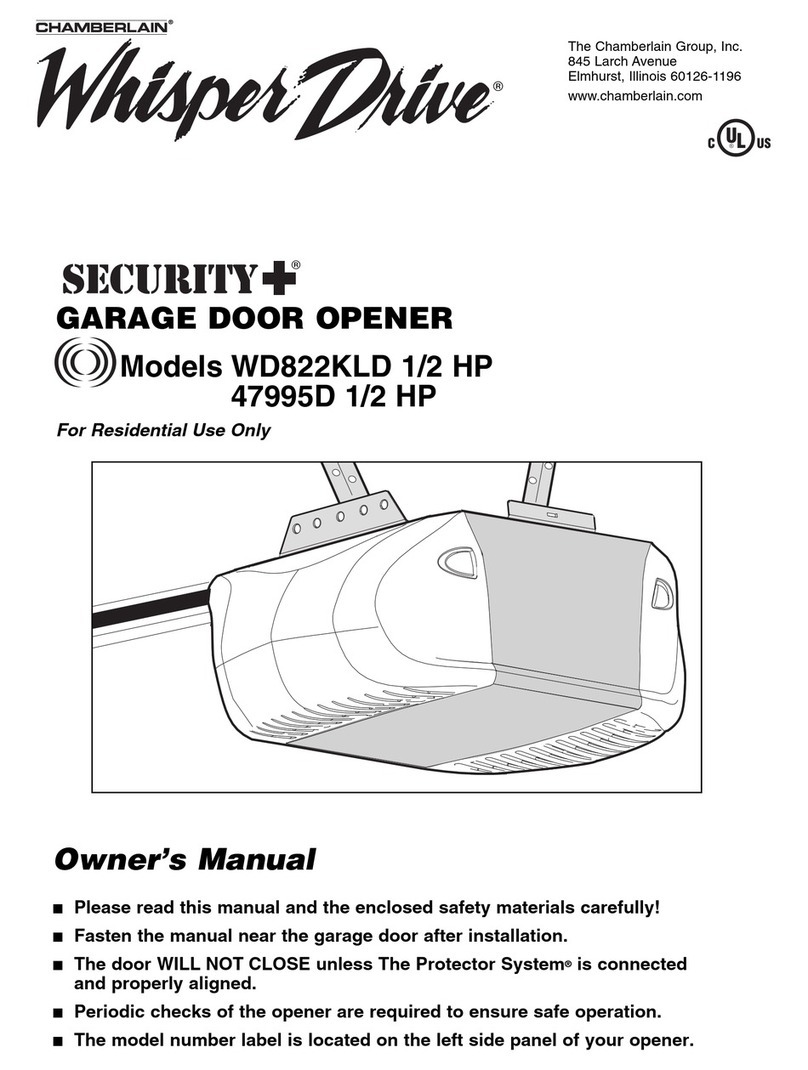

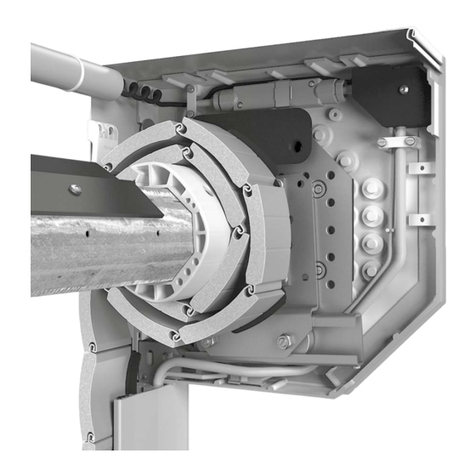

Torsion Spring Hardware Components

Description: Qty. Qty.Door Size:

Description:

Double Car Doors

16'W x 8'0''H

Single Car Doors

8' - 10'W x 8'0''H

Double Car Doors

16'W x 8'0''H

Single Car Doors

8' - 10'W x 8'0''H

Double Car Doors

16'W x 8'0''H

Single Car Doors

8' - 10'W x 8'0''H

5/16" x 1-5/8"

Lag Screw

(Red Head)

5/16" x 1-5/8"

Lag Screw All Doors

Steel Center

Bearing

Cable Drums

Center Bearing

Plate

All Doors

All Doors

Torsion Tube*

End Bearing

Plate All Doors

Torsion

Spring 2 or 4

2 per

center

bearing

plates

2

Solid Shaft Key

Coupler

Doors With Split

Solid Shaft

Doors With Split

Solid Shaft

3

0 or 1

1

1 or 2

2

1

3/8" x 1-5/8"

Hex Head Bolt

3/8" x 1"

Hex Head Bolt

1

1 or 2

1

2

3/8" Flange Nut

3/8"-16 x 3/4"

Carriage

Bolt

3/8" x 3/4"

Hex Head Bolt

Doors With

One Spring

Doors With

Two Springs

Doors With

One Spring

Doors With

Two Springs

2

0

0

2

All Doors

All Doors

All Doors

10

4

4

(While not representative of any one model, the quantities below can be used as a guide. In some

instances, extra screws/bolts are provided in the event of strip out or loss of parts. Quantities for

doors over 8'0" high may be different, see extended height supplement.)

Description: Qty. Description: Door Size: Qty.

Description: Qty. Description: Door Size: Qty.

All Doors

1 or 2

All Doors

Solid Steel Shaft

Pulley Saddle

End Bearing

Plate

4" or 5" Pulley

All Doors

All Doors

All Doors

2

2

2

* Some heavier doors receive a solid shaft and not a torsion tube

Solid Steel Shaft Hardware Components

Rear Mount Low Headroom Hardware Components

11

STEP 7 - Preparing Bottom Door Section

Step 7-1: Spread the hardware on the garage floor in groups so

that you can easily find the parts.

Step 7-2: Find the section with the aluminum weatherstrip

retainer fastened to one edge. The aluminum weatherstrip

retainer is on the bottom edge of the bottom section. Place the

section on saw horses face down. (Fig. 7-A) Be sure to cover

saw horses with carpet or cloth so as not to scratch section.

NOTE: Use 2 sawhorses for doors up to and including 10’0” wide

and 3 sawhorses for doors over 10’0” wide

Step 7-3: Attach the lift cable to the bottom bracket by inserting

the bottom bracket pin through the inside of the bottom bracket,

the looped end of the lift cable, and the outside ear of the bottom

bracket. Secure with cotter pin. (Fig. 7-B for standard door, Fig.

7-C for low headroom door)

Step 7-4: Attach the bottom brackets with (5) 1/4” x 3/4” red-

colored self-drilling screws to the bottom corners of the section.

(Fig. 7-D)

Red fasteners must be used for attachment of the bottom

roller brackets.

Step 7-5: Hinges are identified by number 1, 2, 3 (and higher for

doors over 8’0” high). This number is stamped on the hinge.

Attach a number 1 hinge at each end stile location along the top

edge of the section using 1/4” x 3/4” self drilling screws. The

number is stamped on the side of the hinge that is to be attached

to the section. (Fig. 7-E)

FIG. 7-D

FIG. 7-A

FIG. 7-B

FIG. 7-C

FIG. 7-E

A

luminum

Weatherstrip

Retainer

1/4” x 3/4” Red Colored Self Drilling Screws

Lift Cable

Bottom

Bracket

Pin

Lift

Cable

Cotter Pin

Lift Cable

Key

Cotter Pin

LHR Bracket

Lift Cable

Roller Location

End

Stile

LHR

Bracket

1/4” x 3/4” Self

Drilling Screws

#1 Hinge

12

STEP 7 - Preparing Bottom Door Section

(Continued)

Step 7-6: Attach center hinges to top rail fin using (2) 1/4” x 3/4”

hex head bolts and (2) 1/4” flange nuts at each center stile

location. (Fig. 7-F)

NOTE: If Table 7-A below shows a need for a reinforcing

aluminum angle on the bottom section, it should be attached to

the top rail fin at all center hinge locations using the same 1/4” x

3/4” bolts that attach the hinge to the top rail fin. Using the pre-

punched slots in the top rail fin as a guide, mark and drill 1/4”

holes through the aluminum angle. Install aluminum angle at the

same time as center hinges. (Fig. 7-F) The aluminum angle

should also be bolted to the top rail fin at the ends of the section

using 1/4” x 3/4” bolts and 1/4” flange nuts. It will be necessary

to drill 1/4” holes through the top rail fin and the aluminum angle

to install bolts. (Fig. 7-G)

Table 7-A –Reinforcement Schedule

Door Width

Glazing Type

Up to

11’-2”

11’-4” to

12’-2”

12’-4” to

14’-2”

14’-4” to

16’-2”

16’-4” to

20’-2”

Acrylic

OR

1/8” Tempered

None None G G H

1/2” Insulated

OR

1/4” Tempered

None G G H

G (1) 1-1/4" x 1-1/4" Aluminum Angle per Section

H (1) 2" x 2" Aluminum Angle per Section

NOTE: Doors installed in high windload regions (Florida and

other high wind prone areas) may require additional

reinforcement beyond what is detailed in these instructions.

Please refer to approved windload drawings for these areas.

Step 7-7: Install the inside step plate to the bottom rail of the

section using (2) 1/4” x3/4” self drilling screws. The step plate

should be located at the center stile closest to the horizontal

center of the door width. (Fig. 7-H)

NOTE: Cut out templates on pages 13 and 14; instructions are

continued on page 15.

FIG. 7-F: Center Hinge and Aluminum Angle Installation

FIG. 7-G

FIG. 7-H

1/4” Flange Nut Center Hinge

A

luminum Angle (If Required)

1/4” x 3/4” Hex

Head Bolt

1/4” Flange Nut

A

luminum Angle

1/4” x 3/4” Hex

Head Bolt

1/4” x 3/4” Self

Drilling Screws Center Stile

Bottom Rail Inside Step Plate

Top of

Section

13

Outside Lift Handle Template

5-1/2”

9/64” Dia. Hole (2 places)

Vertical Center o

f

2nd Section (Use

when locating

vertical outside

handle)

Line up with outside edges

of Center Stile of 2nd

section when locating

vertical outside handle.

Line up with top edge of

bottom rail of bottom

section when locating

horizontal outside handle.

Line up with outside

edges of Center Stile of

bottom section when

locating horizontal

outside handle.

Cut along Line

14

Template and Handle Hole Locations

Template and hole locations fo

r

bottom (horizontal) handle

Template and hole locations for

2nd section (vertical) handle

Bottom of Doo

r

Bottom Section2nd Section

15

STEP 8 – Outside Lift Handle Attachment

Bottom Section

Step 8-1: Using the template provided on page 13, mark and drill

(2) 9/64” dia. holes through the front wall of bottom rail of the

bottom section at the center stile closest to the horizontal center

of the door. DO NOT drill all the way through the door section.

Step 8-2: Using a Phillips head screwdriver, install (2) handle

studs at drilled hole locations using (2) #10 x 1” pan head sheet

metal screws. (Fig. 8-A)

Step 8-3: Place outside lift handle over handle studs. (Fig. 8-B)

Step 8-4: Attach outside lift handle to studs using 3/16” set

screws. Tighten set screws with 3/32” Allen wrench. (Fig. 8-C)

2nd Section (to be installed at the completion of step 9-5).

Step 8-5: Using the template provided on page 13, mark and drill

(2) 9/64” dia. holes through the front wall of center stile closest to

the horizontal center of the door. DO NOT drill all the way

through the door section.

Step 8-6: Using a Phillips head screwdriver, install (2) handle

studs at drilled hole locations using (2) #10 x 1” pan head sheet

metal screws. (Fig. 8-A)

Step 8-7: Place outside lift handle over handle studs. (Fig. 8-B)

Step 8-8: Attach outside lift handle to studs using 3/16” set

screws. Tighten set screws with 3/32” Allen wrench. (Fig. 8-C)

FIG. 8-A

FIG. 8-B

FIG. 8-C

#10 x 1” Pan

head Sheet

Metal Screw

Handle Stud

9/64” Dia.

Hole

Surface of door

rail or stile

Outside Lift Handle

Handle Stud

Outside Lift Handle

Set Screw

Tighten Allen

Wrench

16

STEP 9 – Installing Door Sections

Step 9-1: Place the section in the opening so that it is against

the stop molding and centered from side to side. Place a level on

the section and use a piece of wood under one end or the other

(if necessary) to make the section level. (FIG. 9-A)

Step 9-2: Remove the level and drive a 3” nail in the jambs at

each end and bend it over the edge of the section to hold the

section in place. (FIG. 9-B)

NOTE: These nails are all that will hold the stacked door section

in place until the tracks are secured to the back jambs. Be sure

the nails hold the sections firmly in position.

Step 9-3: With the Table 9-A below, determine the order in

which you will attach the remaining sections.

Table 9-A - Section Order for Various Door Heights

* Section with general safety label.

Step 9-4: Place the next section face down on the saw horses.

Identify the bottom edge as shown in the illustration. (FIG. 9-C)

Attach a number 2 hinge to each end at the top edge using

1/4” x3/4” self-drilling screws. Remember that the number

is stamped on the side of the hinge that is to be attached to

the section. (FIG. 9-C)

Step 9-5: Attach center hinge(s) to top rail fin at each center stile

location using 1/4" x 3/4" bolts and 1/4" flange nuts. If the

section requires an aluminum angle, attach to top rail fin (FIG.

7-F & FIG. 7-G, page 12).

Step 9-6: Install lift handle as shown on previous page.

FIG. 9-A

FIG. 9-B

FIG. 9-C

Section #Door

Height 1 (BTM) 2 3* 4 5 6

6’0” 24” 24” 24” - - -

6’3” 21” 18” 18” 18” - -

6’6” 21” 18” 18” 21” - -

6’6” 21” 21” 18” 21” - -

6’9” 21” 21” 21” 21” - -

7’0” 24” 21” 21” 21” - -

7’3” 24” 21” 21” 24” - -

7’6” 24” 24” 21” 24” - -

7’9” 24” 24” 24” 24” - -

8’0” 21” 21” 18” 18” 21” -

8’3” 21” 21” 21” 18” 21” -

8’6” 21” 21” 21” 21” 21” -

8’9” 24” 21” 21” 21” 21” -

9’0” 24” 21” 21” 21” 24” -

9’3” 24” 24” 21” 21” 24” -

9’6” 24” 24” 24” 21” 24” -

9’9” 24” 24” 24” 24” 24” -

10’0” 21” 21” 21” 18” 21” 21”

10’6” 21” 21” 21” 21” 21” 21”

10’9” 24” 21” 21” 21” 21” 21”

11’0” 24” 21” 21” 21” 21” 24”

11’3” 24” 24” 21” 21” 21” 24”

11’6” 24” 24” 24” 21” 21” 24”

11’9” 24” 24” 24” 24” 21” 24”

12’0” 24” 24” 24” 24” 24” 24”

¼” x ¾” Self

Tapping Screws

#2 Hinge

End Stile

Bottom Edge

Stop Molding

17

STEP 9 - Installing Door Sections

(Continued)

Step 9-7: Place the second section on top of the first section.

Drive a 3” nail in the jambs at each end and bend it over the

edges of the section to hold the section in place. Attach the

hinges from the top of the first section to the bottom of the

second. (FIG. 9-D)

Step 9-8: Place the third section face down on the saw horses.

Identify the bottom edge as shown in the illustration. (FIG. 9-E)

Attach a number 3 hinge to each end at the top edge using

1/4” x3/4” self-drilling screws. Remember that the number

is stamped on the side of the hinge that is to be attached to

the section. (FIG. 9-E)

Step 9-9: Attach center hinge(s) to top rail fin at each center stile

location using 1/4" x 3/4" bolts and 1/4" flange nuts. If the

section requires an aluminum angle, attach to top rail fin (FIG.

7-F & FIG. 7-G, page 12).

Step 9-10: Place the third section on top of the other sections

and nail in place as before. Attach the hinges from the top of

the previous section to the bottom of this section. (FIG. 9-D)

If you have multiple sections left, repeat Steps 9-7 and 9-9 using

#4 or higher number hinges on the end of the top edge and

center hinges to all other stiles along the top edge.

Step 9-11: The reinforcing aluminum angle should now be

attached to top rail with a 1/4" x3/4”: self-drilling screws at each

center stile.

Step 9-12: Place the last section on the saw horses. Attach the

top roller brackets as shown. The top roller brackets are to be

attached with two (low headroom doors) or four (standard lift

doors) 1/4” x3/4” self drilling screws. The bottom of the bracket

goes 6-1/4” down from top of section. (FIG. 9-F for standard

doors, FIG. 9-G for low headroom doors)

NOTE: The top bracket should be fastened to the top rail and

end stile as shown.

Step 9-13: Place a roller in the top and bottom brackets and in

the tubes in each of the hinges at the ends of each section. The

long stem roller is used in bottom bracket. Some hinges have

two tubes. Place the roller in the tube that is farthest from the

face of the door. (FIG 9-H)

FIG. 9-H

FIG. 9-D

FIG. 9-E

FIG. 9-F (Standard Lift)

FIG. 9-G (LHR Lift)

Bottom Bracket

#1 Hinge

#2, 3, 4, or 5

Hinge

Top Bracket

¼” x ¾” Self

Tapping Screws

#3 Hinge

End Stile

Bottom Edge

¼” x ¾” Self Tapping Screws

Standard

Top Bracket

End Stile

Safety

Label

Aluminum

Angle

(If Required)

End Stile

LHR Top

Bracket

¼” x ¾” Self Tapping Screws

Aluminum

Angle

(If Required)

6-1/4”

18

STEP 10 - Reinforcing the Top Section

for Opener

To avoid damage to your door, you must reinforce the top

section of the door in order to provide a mounting point for the

opener to be attached. You will need one (1), two (2), or three

(3) pieces of 1-1/4” x 1-1/4” minimum punched angle at least

13 gauge or 3/32” thick from your local hardware or building

supply store. Figures 10-B to 10-E show how punched angle

is to be affixed to door.

Horizontal Angle Attachment

Attach the horizontal punched angle (the longer piece) to the

top section as shown in Figure 10-A. Angle iron may need to

be trimmed depending on door section height and distance

between center stiles. Some doors with struts may not need

a horizontal angle; see Figures 10-B to 10-E to identify the

attachment method for your specific door.

Do NOT install the bracket supplied with the opener.

Failure to reinforce the door, as illustrated, will void your

warranty.

Odd Stiles under 12’ Wide Doors

FIG. 10-B

Required materials:

(1) 18”, 21” or 24” and (1) 48” length of iron,

(6) ¼” x ¾” self-tapping screws.

Odd Stiles over 12’ Wide Doors

FIG. 10-C

Required materials:

(1) 18”, 21” or 24” length of iron and (1) 48” aluminum angle,

(6) ¼” x ¾” self-tapping screws.

FIG. 10-A – Horizontal Reinforcement Attachment

(Top of Door Section – Side View)

NOTE: Operator may be attached up to 2 feet off center.

(Doors with Torsion Springs Only)

Even Stiles under 12’ Wide Doors

FIG. 10-D

Required materials:

(2) 18”, 21” or 24” and (1) 27” or 50” length of iron,

(5) ¼” x ¾” self-tapping screws,

(2) ¼” x ¾” bolts and nuts.

Even Stiles over 12’ Wide Doors

FIG. 10-E

Required materials:

(2) 18”, 21” or 24” length of iron and (1) 27” or 50” aluminum angle,

(5) ¼” x ¾” self-tapping screws,

(2) ¼” x ¾” bolts and nuts.

Punched Angle

Punched Angle

¼” x ¾” Self

Tapping Screws

¼” x ¾” Self

Tapping Screws

A

luminum Angle

Punched Angle

¼” x ¾” Self

Tapping Screws

¼” x ¾” Self

Tapping Screws

1/4" x 3/4”

Self-tapping

Screw

Horizontal

Punched Angle

Punched Angle

Punched

Angle

Punched Angle

¼” x ¾” Self

Tapping Screws

Punched Angle

For Operator Draw

Bar Attachment

Punched Angle

For Operator

Draw Bar

A

ttachment

A

luminum Angle

Punched

Angle

¼” x ¾” Self

Tapping Screws

Punched Angle

19

STEP 11 – Assembling and Installing

the Vertical Track

Before assembling brackets to vertical track be sure to read

Step 11-1 and Step 11-2. Refer to illustration for placement of

brackets on track.

NOTE: Brackets may already be riveted in place. If additional

adjustment is required, the rivets can be drilled out and the

brackets can be reattached with track bolts and flange nuts

(available through the toll-free Consumer Services number, see

outside cover).

To avoid installation problems that could result in injury or

property damage, use only track provided with new door.

Step 11-1: Loosely fasten the track brackets to the vertical

track using one 1/4" x 5/8" track bolt and 1/4" flange nut as

shown with the head of the bolt inside the track. There are

two sizes of brackets for 7’ high doors, and three sizes for 8’

high doors. The shortest track brackets should be installed ten

inches from the bottom of the track with the flange facing the

flat side of the track, one on the left and one on the right. The

next larger sized pair of brackets should be installed centered

on the track. If you have an 8’ high door, the remaining pair

of brackets should be installed ten inches from the top of the

vertical track. The flat side of the track goes toward the wall.

(FIG. 11-A)

Step 11-2: Loosely attach the flag bracket to the top of the

track with two 1/4" x 5/8" track bolts and 1/4" flange nuts with

the head of the bolts in the track. Make sure to place bolts and

nuts in correct holes (FIG. 11-B, See FIG. 11-C for bracket

placement).

(Refer to FIG. 11-B to determine proper bolt placement.)

NOTE: If additional adjustment is required, horizontal slots in

flag brackets can be used for attachment to vertical track.

Step 11-3: Place the track over the rollers on the door. Move

the track close to the door so that the rollers are all the way

into the hinges. Do not force the track too tightly or the door

will bind. This should leave about 1/2" between the edge of the

door and the track. Pilot holes of 3/16" are required at each

lag screw location before installing the lag screw. Lift track

about 1/2" from the floor and fasten the flag bracket and track

brackets to the jamb with 5/16" x 1-5/8" lag screws. The flag

bracket requires three screws, one each in the top, middle, and

bottom holes. Do this for both sides of the door. When the track

brackets and flag brackets are securely fastened to the jamb,

tighten the track bolts and flange nuts connecting the flag

brackets to the tracks. (FIG. 11-D)

NOTE: The tops of the vertical tracks must be level with

each other. Check this by measuring from the top of the door

sections to the top of the track on both sides. If they are not

equal, cut some material off the bottom of one track to lower it

or raise the other track.

Do not raise the vertical track beyond the bottom rollers

on the bottom section of door.

NOTE: Do not attach any brackets directly to drywall. All track

brackets, flag brackets, and spring brackets should only be

attached directly to wood jams.

FIG. 11-A

FIG. 11-B

FIG. 11-C

FIG. 11-D

1/4" Flange

Nut

1/4" x 5/8”

Track Bolt

Wall

Side

Top View

Left Side

Note: Use One

Track Bolt In Slot

1/4" Flange Nut

Use These

Two Holes

1/4" x 5/8”

Track Bolt

Top

Bottom

Shorter

Track

Bracket

Right Hand

Vertical

Track

A

ssembly

Longer

Track

Bracket

Flag Bracket

Left Hand

Vertical Track

Assembly

20

NOTE: Pressure-treated lumber purchased after January 2004 is

treated with chemicals that have highly corrosive effects on

metal fasteners. The fasteners provided with your door are

intended for use with standard lumber (not pressure-treated)

only. If you are installing your door into an opening framed with

pressure-treated lumber purchased after January 2004, two

items must be changed: 1) 5/16" x 1-5/8" lag screws with a

minimum galvanization equivalent to G185 must be purchased

for this application, and 2) to prevent potential corrosion between

lumber and track/spring components, paint either the surface of

the pressure-treated lumber or those surfaces of the track and

spring components that come in contact with the pressure-

treated lumber.

STEP 12 - Assembling and Installing of

Standard Radius Horizontal Track

Step 12- 1: Fasten the horizontal angle to the horizontal

(curved) track with two 1/4" x 5/8" track bolts and 1/4" flange

nuts so that the heads of the track bolts are on the inside of

the track. On some doors this angle may be 82" long and will

require three additional fasteners per side. If the angle has

been preassembled, and proceed to Step 12-2. (FIG. 12-A)

Step 12-2: Temporarily support the rear end of the track with

a rope from the trusses overhead in the garage or on a tall

ladder. (FIG. 12-B)

Step 12-3: Place the track over the roller in the top bracket.

Attach the curved end of the horizontal track to the flag

bracket with two 1/4" x 5/8" track bolts and 1/4" flange nuts

so that the heads of the screws are on the inside of the track.

The horizontal and vertical track must join together to form

a continuous channel for the rollers. Attach the end of the

horizontal angle to the top of the flag bracket with a 3/8” x 3/4”

carriage bolt and 3/8” hex nut. Use the top set of slots for 15”

radius track, the middle set of slots for 12” radius track, and the

bottom set of slots for Low Headroom track. (FIG. 12-C)

Step 12-4: Rear track hangers need to be made at this time.

Use 1-1/4" x 1-1/4" punched angle, 13 gauge or 3/32" steel.

These are not provided with the standard hardware. They

are used to attach the rear of the horizontal track to the

ceiling joist.

Enough angle iron or punched angle should be purchased to

make two rear track hangers. These hangers must be strong

enough to hold the full weight of the door. Attach a bolt at least

1" long through the end of each track to stop the door at the

end of its travel. (FIG. 12-D)

Sway braces must be used to prevent tracks from

spreading and allowing door to fall, which could cause

serious injury. Bolts placed in the end of each track

(FIG. 12-D) must be at least 1" long to prevent the top

section from exiting the track.

NOTE: Rear track hangers should not be mounted any farther

than 6" from the end of horizontal track.

Step 12-5: Placement of rear track hangers is critical for the

door to operate properly. The rear track hangers should hold

the horizontal track level and square to the door. Squareness

should be measured by comparing two diagonal distances: 1)

the distance from the top left-hand corner of the door to the

rear of the right-hand horizontal track and 2) the distance from

the top right-hand corner of the door to the rear of the left-hand

horizontal track. (FIG. 12-E, opposite page)

FIG. 12-A

FIG. 12-B

FIG. 12-C

FIG. 12-D

Horizontal Track

Horizontal Angle

Flag Bracket

Horizontal

Track

Vertical

Track

Horizontal Angle Bracket

Rope

3/8” x 3/4"

Carriage

Bolt

Horizontal Angle

Horizontal Track

3/8” x 1”

Bolts & Nuts

(4 places)

Sway Brace

Bolt Blocks

Door Travel

12” Radius

Track

This manual suits for next models

2

Other Clopay Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

CAME

CAME V6000P installation manual

Cardin Elettronica

Cardin Elettronica 305/GLi824 instruction manual

SEA

SEA Saturn 600 Mounting and Connecting Instructions

Chamberlain

Chamberlain Whisper Drive Security+ 47995D owner's manual

Craftsman

Craftsman 139.18616SR owner's manual

B&D

B&D PanelPro installation instructions

Nice

Nice TITAN12L 912L Installation & reference manual

Riello Elettronica

Riello Elettronica Cardin Elettronica SLX Series instruction manual

Roma

Roma Rolento B1/55 Assembly instruction

Linear

Linear LCO75 installation instructions

Chamberlain

Chamberlain Whisper Drive Security+ 459950 owner's manual

Vimar

Vimar Elvox EFA1 quick start guide