Cloudray MP Pro Series User manual

Laser Machine

Troubleshooting

Guide

Cloudray Laser

THE PDF TROUBLESHOOTING GUIDES REPRESENT SOME OF THE MORE

COMMON QUESTIONS OR ISSUES THAT YOU MAY ENCOUNTER WITH

CLOUDRAY LASER. THE PDFS ARE LAID OUT IN A STEP-BY-STEP FASHION

WITH SUPPLEMENTARY LINKS TO RELEVANT BOSS YOUTUBE VIDEOS. IF

YOU THINK YOU NEED FURTHER HELP CONTACT US:

1.Laser Engraving Machine Type

2.Installation and driver

3.Software: Ezcad2/3 & Lightburn

4.Red Light Settings

5.F-theta Lens

6.Foot switch

1.Laser Engraving Machine Type

MP-60 LiteMarker 60W Split Laser Engraver Marking Machine

MP-60 comes with 800mm manual lifting tower, which supports max

scan fields

≤

300*300mm.

This unit comes with EZCAD2/EZCAD2 Lite software, which is compatible

with Lighbturn software

(Pro) MP Series-Auto Focus 60W Laser Engraver Marking Machine

(Pro)MP-60 comes with 500mm electric lifting tower(with motor), which

supports scan fields

≤

200*200mm. This unit comes with

EZCAD2/EZCAD2 Lite software, which is compatible with Lighbturn

software

Autofocus, free your hands, can realize high speed, marking, and high

precision. Before marking job, system senses the height of the work and

adjusts the height of the galvo head automatically using the electric lift

column. But It will not adjust automatically while engraving. The auto-

focus galvanometer only focuses once before processing, and will not

focus in real time during processing.

AR-60 60W Split Laser Engraver 2.5D Fiber Marking Machine

AR-60comes with 500mm electric lifting tower(with motor), which

supports scan fields

≤

200*200mm.

This unit comes with EZCAD3 software,Can be used with Z-axis auto

focus to achieve 2.5D engraving.

2.Installation and driver problems

A short circuit was caused when the machine was installed

Unplug the power cable, ensure the machine is powered off, open the

upper and side cover of the chassis (Remove three hexagonal screws at the

front and back)

1. Check whether switching power supply for the galvo head is 90-264V(the

left-most one), and the 24V switching power supply is at 115V

2. Check whether the wires at the back end of the button is broken, touched

with the metal of the chassis or burnt.

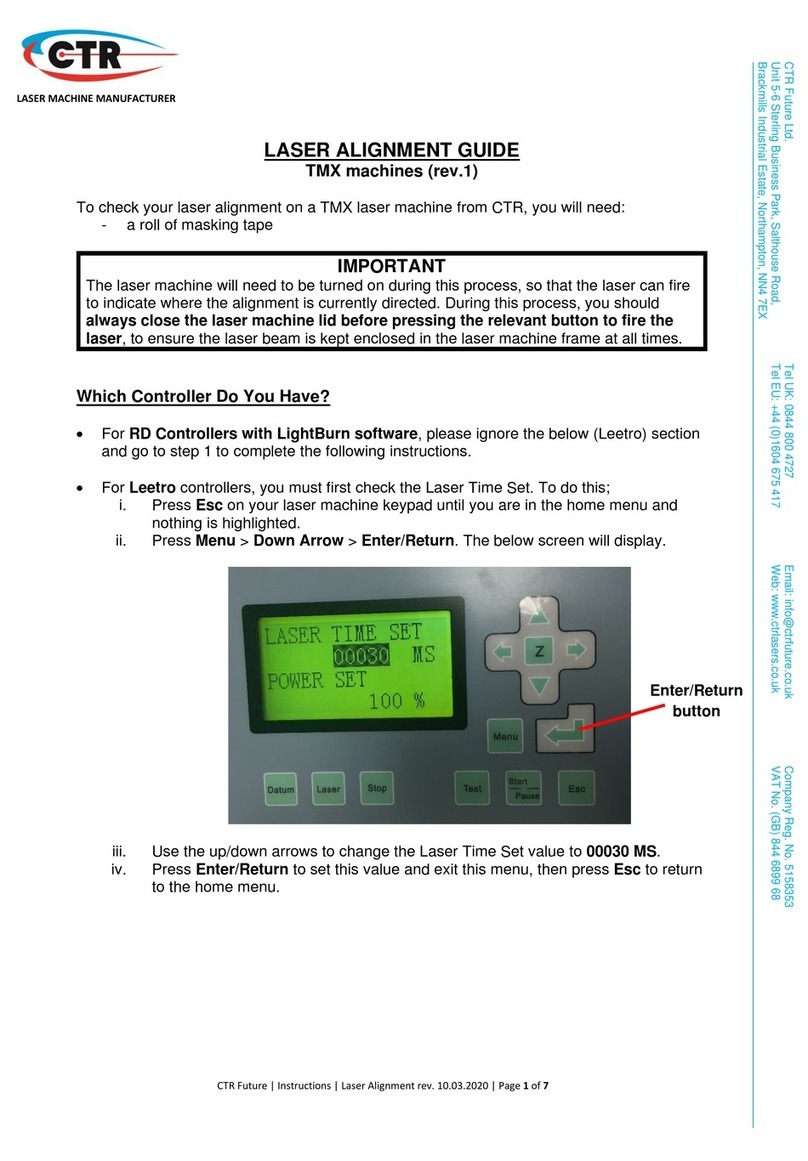

Yellow Exclamation Mark Issue in

Device Manager

"Failed to open lmc device" error

Please confirm whether you installed the

driver software which is in the U disk.(The

compressed file in the U disk is a backup

file, which can be decompressed and used

when the original folder is damaged.)

Check whether there is a yellow

Exclamation Mark Issue in Device Manager.

If yes, that means that you installed wrong

driver. Please uninstall the current V2 or V4

driver and reinstall another V2 or V4 driver.

Uninstall the installation video of the driver:

https://youtu.be/jHvBR4P0T9g

2.Installation and driver problems

“error code 52”

After doing uninstall the driver & install

the driver, it is recommended to restart

the computer to see if the driver is

normal. If the issue is not fixed, please

show us related pictures or videos for us

to check If still not work, Would you

please record a video for us to check or

help us judge where the problem is?

More details concerning the technology

problem when you use the product will

be useful too.

3.Software: Ezcad2/3 & Lightburn

Lightburn

Does Cloudray marking machine support lightburn?

At this time, only devices that are supported by EzCad2 or EzCad2 Lite

software will work with LightBurn and only those that connect to a computer

over USB. Raycus, JPT, IPG, and Max Photonics fiber sources, as well as CO2

laser sources are supported. (Max Photonics are JPT compatible

)

Does Lightburn offer a free trial?

30-day free trial

Laser display "Disconnected" alarm

1. Shift-click the ‘Devices’ button in the ‘Laser’ window, you force LightBurn

to re-establish communications with your device.

2.Try rebooting Lightburn, disconnecting and reconnecting Cloudray laser,

shift click on Device, tried reloading Device, rebooting your lap top, Com

port is selected.

3. Do you have multiple copies of LightBurn running, maybe? Or any other

software that might be holding on to your COM port? Try bringing up the

task manager (Ctrl+Shift+Esc) and seeing if anything is running that you

don’t expect, or a hung copy of LightBurn running in the background.

Can use the EzCad2 software but can't

get the Lightburn software

Software driver maybe wrong. Ezcad2

and Lightburn software have different

drivers. If using lightburn software, you

have to install Ezcad2 driver(Used by

galvos), please check attached picture as

referenced. Only one driver can be

installed on a computer.

3.Software: Ezcad2/3 & Lightburn

Ezcad2

What's wrong with the prompt "can not open correct file" after

opening the Ezcad?

It is because there is no correction

file and the “Use the correction

file” in the F3 parameter is

checked. If there is a correction

file, please select the correct path;

if there is no one, you can leave

“Use the correction file”

unchecked.

How to solve the problem that the line are not straight when marking

the grid?

There may be a coordinate problem with

the galvo correction.

How to set to repeat marking twice by pressing F2 once?

Because it is a 20W laser marking machine, it is a little bit not clear enough,

so I will mark twice. But I have to press F2 twice every time. Is there a setting

method that it will automatically mark twice by pressing it directly?

If the power is not enough, you can increase the frequency and reduce the

speed to increase the depth of marking.

If it is essential to mark twice at a time, you can check key F3 Parameters –

Other – Auto reset mark count, and exit to change the Total number to 2 in

the marking column.

3.Software: Ezcad2/3 & Lightburn

Ezcad2

After the driver is installed, the ezcad software still prompts that the

dongle can't be found?

Win10 64-bit, the driver installation has been displayed, but the software

prompts that the dongle cannot be found, what should I do?

First, the marking board does not require an external dongle. Then check

the followings:

1. There is a mismatch between the driver, board, and software. Try

changing the software version.

2. Check whether the marking board is genuine and whether its specific

model supports the corresponding computer system.

3. After confirming that the laser has been started, check whether the

connection between the laser and the board is loose or not in good contact.

Or just try another wire.

The image or text inversion problem of fiber laser marking machine

Just click on the parameter

settings (F3) and select "Galvo 2"

Tips

:

Regarding the common problems of Ezcad2, most problems can

be solved by reinstalling software and drivers.

3.Software: Ezcad2/3 & Lightburn

Ezcad3

“Ezcad3 software licenses invalid”

“The correct file format is error!”

Please download the correct file:

https://cdn.shopify.com/s/files/1/2222/7859/files/COR.rar?v 1671441314

Reference video:

https://youtu.be/NOL6BGlKJEs

The authorization code is as shown on the USB flash drive (for reference only)

4.Red Light Settings

Red light preview outline lost, or it doesn’t have the red light contour

Red light pointer settings

Justcheck this button "Show contour"

1. Click the parameter button (F3)

2. Select "other"

3. Select "Red Light pointer"

4. Select "Enable always show"

5. Please confirm the save operation

4.Red Light Settings

”See 3 red Points”

2 red light under the galvo head.

Turn the focus wheel to adjust the

two red dots to coincide to achieve

focus.

1 red light from laser source, which

is used for red preview.

The red light disappears

First determine where the red light disappears,

galvanometer or fiber laser;

1. Galvanometer: The two red lights at the

galvanometer do not emit light, and the ±15V

switching power supply is faulty

;

If only one of the

two red lights at the galvanometer does not emit

light, then the red light is faulty.

Red Dot Pointer in Laser Path Fiber Laser With Red

Dot Pointer

2. Fiber Laser: Restart the

software to check if the red light

is on.If not, the red light that

comes with the fiber laser may be

faulty or the red light in the laser

path is faulty.

Laser stopped working, the red light disappeared

Restart the software; if the laser does not work, check the ±24V switching

power supply; if the power supply is normal, then the laser or control card

may be faulty.

5.F-theta Lens

How do I change the focus lens to work with the 110 x 110 lens?

As a reference, please check the Youtube video

:

How to adjust the focal length: https://youtu.be/fp-0jzAmX6U

How to do with marking size not fit: https://youtu.be/8usA4ucynrw

Therefore, it is necessary to set the correct focal distance between the

marking head and the workpiece before any marking. An incorrect focal

length is the most common cause of poor or indistinguishable markings.

The focal distance (A) is measured between the lower edge of the galvo head

(B) and the upper surface of the workpiece (C). The correct focal distance

depends on the F-theta lens used (focal length)

The laser galvo sporadically started moving in unwanted directions.

Thank you for contacting Cloudray Office.

1. We feel sorry for the inconvenience with your order. Would you mind

offering us your order number so that we can check for you?

And please provide the label picture on your current laser.

2. The issue you met may be related to switching power supply for galvo

head.Would you please record the working video for us?

6.Foot Switch

How to connect the foot switch of the laser marking board?

Key “F3” parameters – “Port”, find “Start

Marking IO”, select the “Input” port number.

It is necessary to select the generic IO port on

the board. The input port number on the

software should correspond to the GIN number

on the board (note: it is not the pin number, but

the generic input port number corresponding to

the pin).

Just connect the switch signal of the foot switch

to the input port, and connect the other signal to

the GND on the board.

The level is set to HIGH, because it is connected

to the 5V power supply, and the laser marking

starts to work after the power is turned on. If the

low level is selected, the marking will continue

without pressing the foot switch.

Why does the laser marking machine not respond after changing the foot

switch?

1. The signal line is not connected to the

interface.

Check whether the 1-pin and 14-pin or other

pin ports of the con4 interface of the laser

marking board are connected.

2. Software settings.

It may be that the software has been reset,

and the input port needs to be set in the

software Param(F3) – Port – Start Mark IO.

There are 15 ports in it. If you are not sure

which port is used, you can test them one by

one until the foot switch responds.

3. The foot switch of the laser marking

machine is damaged.

Email: [email protected]

CONTACT US

If you have other questions and need our help to solve, please provide the

following documents

1. Order number

2. Laser engraving machine label picture

3. Machine fault operation video

Support Forum: forum.cloudray.com

This manual suits for next models

2

Table of contents

Other Cloudray Engraver manuals

Popular Engraver manuals by other brands

MARKAL

MARKAL PN.500 quick start guide

GRS

GRS Magnum instructions

GCC Technologies

GCC Technologies LaserPro SmartCut X380 Series user manual

Thunder Laser

Thunder Laser MINI-60 Installation and operation manual

Dexter Power

Dexter Power PC150MD Assembly, Use, Maintenance Manual

Epilog Laser

Epilog Laser Fusion Step-by-Step