Support and Manua ls

3 / 26

Introduction

The OpenBuilds LEAD CNC is a machine with greatly enhanced functionalities and a vast range of

applications. Thanks to its build, it is very rigid and therefore very accurate. It can be used by

amateurs, hobbyists, and professionals alike for processing various types of soft and hard materials at

scale and with an even higher degree of precision than ever before. Extending the machine by

adding a quality laser head to it, such as Opt Lasers PLH3D-6W-Series laser head, enables

unmatched fast precision engraving and cutting of various types of materials.

The OpenBuilds LEAD CNC machine is available in two versions:

§OpenBuilds LEAD CNC Machine 1515 (60" x 60")

§OpenBuilds LEAD CNC Machine 1010 (40" x 40")

The Z-axis position of the cutting and engraving laser head can be changed at will to enable this

machine to efficiently cut and engrave taller specimens.

The OpenBuilds LEAD CNC machine prices range from $1300 to $1800 depending on the version of

choice. With the amazing material processing capabilities it offers, it is definitely worth the price.

The PLH3D-6W-XF Laser OpenBuilds LEAD CNC Upgrade Kit includes a high-power engraving laser

head equipped with thermal protection and a professional high-speed driver. Its design ensures that

function as an air nozzle, protecting the lens from dirt while cooling the laser head at the same time.

Attaching a magnetic nozzle makes it even more convenient to use.

The laser head, combined with the LEAD CNC machine and the BlackBox controller, allows you to cut

or engrave materials such as rubber, wood, paper, leather, plastic, cardstock, and many others.

Thanks to its PWM/TTL power modulation modes support,

or change the output power between consecutive runs. High-speed modulation (the PLH3D-6W-XF

laser head can handle frequencies up to 100 kHz) allows for a high movement rate during engraving,

even when engraving sophisticated patterns. This rate is more than enough to take advantage of the

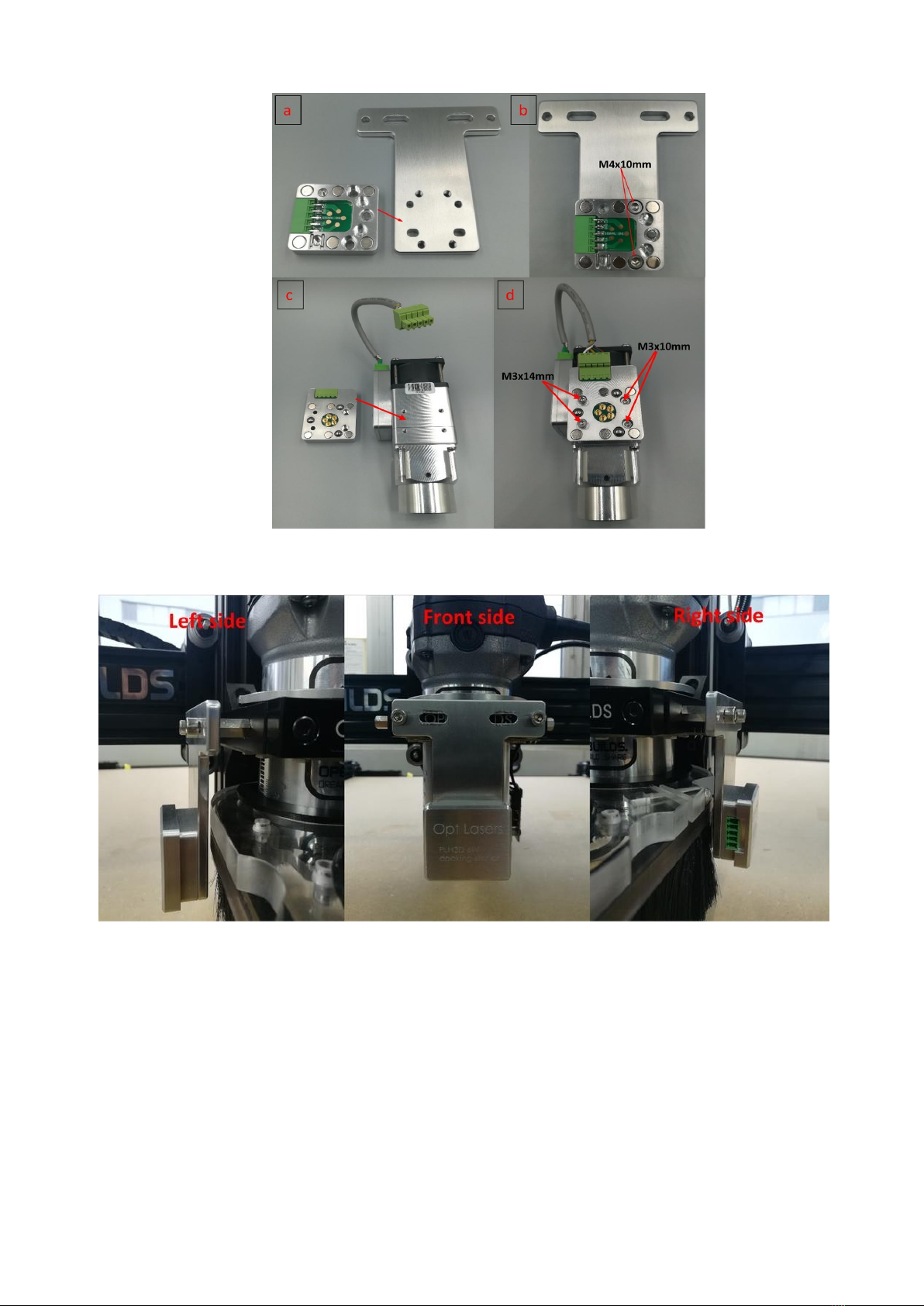

Using the PLH3D-CNC Adapter guarantees reliable and safe work via overcurrent protection, an

independent power supply, a key switch, and an arm button. Furthermore, using the Magnetic

Docking station to mount the laser head on the LEAD CNC machine reduces the time needed to

mount/dismount and to secure the laser head to just a few seconds (while it requires no

additional tools). Moreover, it enables a person to operate the laser without the need for

disassembling the spindle. This module operates a brand new NUBM44 450nm diode (capable of

emitti ng up to 6 Watts of power), which is the strongest blue laser diode that is available on the

market. The lifetime of this laser diode amounts to 10 000 hours according to the manufacturer.