232001250G(06)

Content

Chapter I - Safety.....................................................................................................................................5

1.1 Principles of a CO2 Laser ..................................................................................................5

1.2 Safety Ratings.......................................................................................................................5

1.3 The Safety Interlock System..............................................................................................5

1.4 Safety Labels.........................................................................................................................6

1.5 Safety Measures .............................................................................................................. - 1 -

1.6 Operating Environment ................................................................................................. - 2 -

1.7 EC-Declaration of conformity....................................................................................... - 3 -

Chapter II - Unpacking & Contents.................................................................................................... - 4 -

2.1 Unloading and Unpacking............................................................................................. - 4 -

2.2 Contents and Accessories Checklist......................................................................... - 8 -

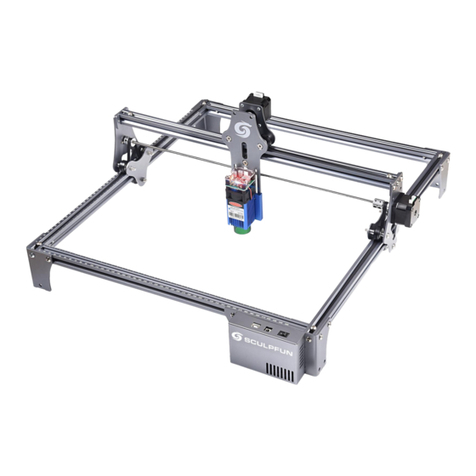

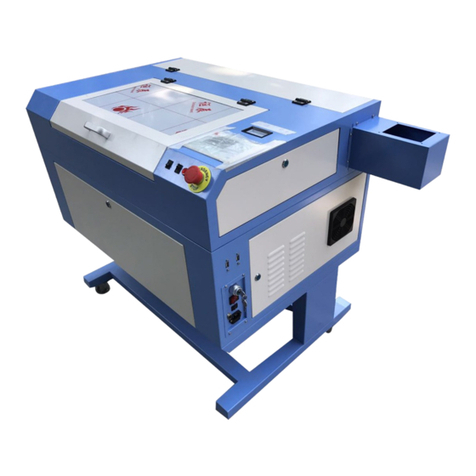

Chapter III - Mechanical Overview.................................................................................................... - 9 -

3.1 Front View ......................................................................................................................... - 9 -

3.2 Top View .......................................................................................................................... - 10 -

3.3 Right (Profile) View....................................................................................................... - 10 -

3.4 Left (Profile) View.......................................................................................................... - 12 -

3.5 Rear View......................................................................................................................... - 12 -

Chapter IV - Setup and Installation .................................................................................................. - 13 -

4.1 Machine Setup................................................................................................................ - 13 -

4.1.1 Before Powering Up the Machine.......................................................................... - 13 -

4.1.2 Powering Up the Machine........................................................................................ - 16 -

4.1.3 Connecting the Computer ....................................................................................... - 16 -

4.2 Graphics Software Setup............................................................................................ - 16 -

4.2.1 Recommended Computer Configuration............................................................. - 17 -

4.2.3 Installation of Common USB................................................................................... - 17 -

4.2.5 Installation of the LaserPro Print Driver.............................................................. - 18 -

4.2.6 Parallels Desktops..................................................................................................... - 19 -

4.2.6 Using Inventor with GCC LaserPro machine.............................................. - 24 -

Chapter V - Operating the LaserPro X380 ...................................................................................... - 29 -

5.1 Using the Hardware ...................................................................................................... - 29 -

5.1.1 Adjusting the LCD Display Screen’s Contrast Setting .................................... - 29 -

5.1.2 Graphic Control Panel Overview (Description).................................................. - 30 -

5.1.3 Graphic Control Panel Navigation Chart............................................................. - 32 -

5.1.4 Graphic Control Panel Function Pages ............................................................... - 33 -

5.2 The LaserPro X380 Print Driver......................................................................................52

5.2.1 Page Setup and Orientation.........................................................................................52

5.2.2 Color Management..........................................................................................................53

5.2.3 Using the LaserPro X380 Print Driver........................................................................54