CMA Dishmachines CMA-180VL User manual

Other CMA Dishmachines Dishwasher manuals

CMA Dishmachines

CMA Dishmachines L-1C User manual

CMA Dishmachines

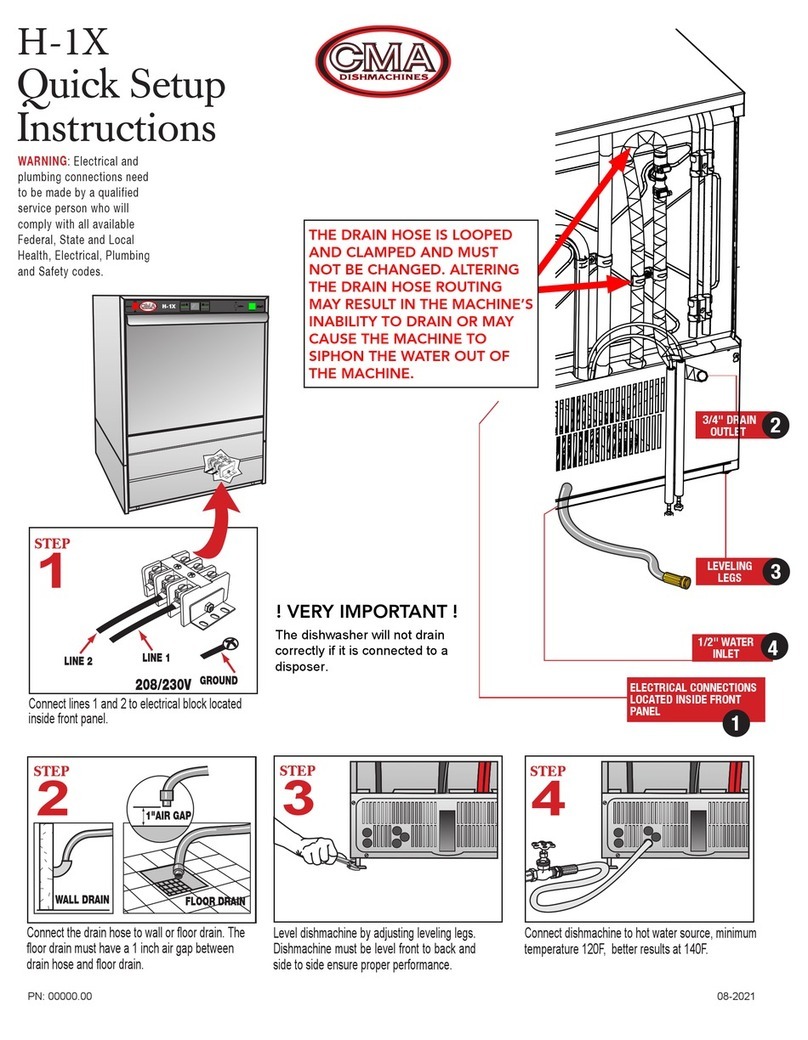

CMA Dishmachines H-1X Manual

CMA Dishmachines

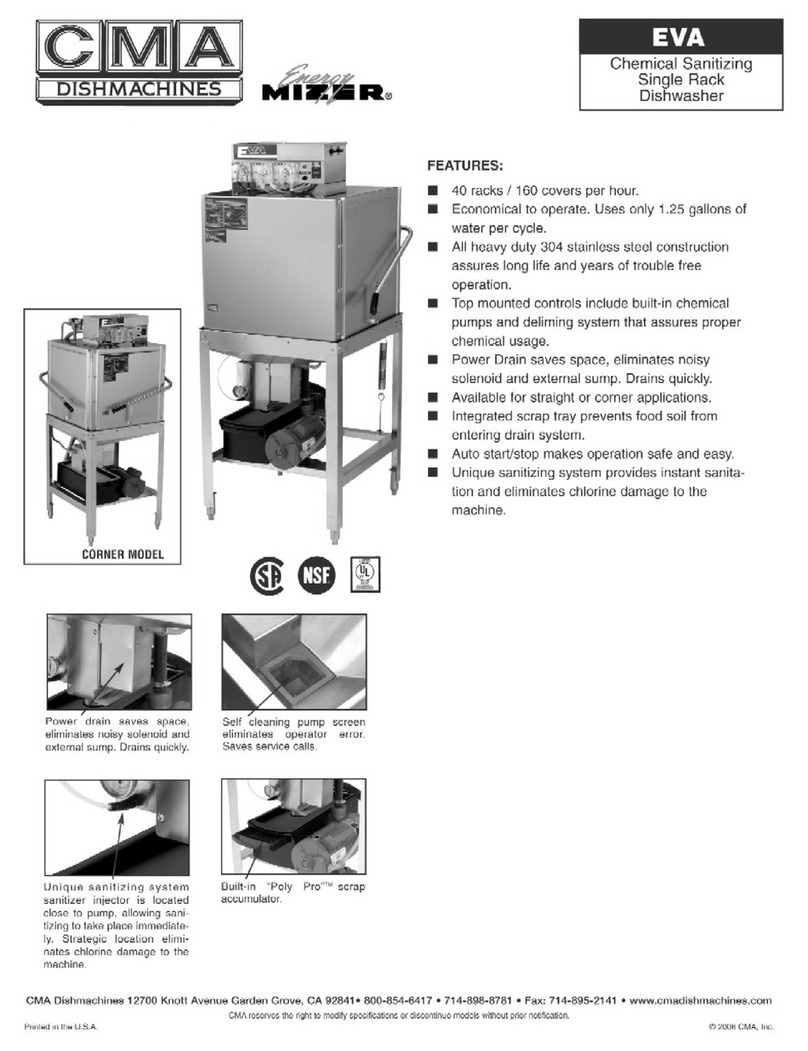

CMA Dishmachines EVA-AH-T User manual

CMA Dishmachines

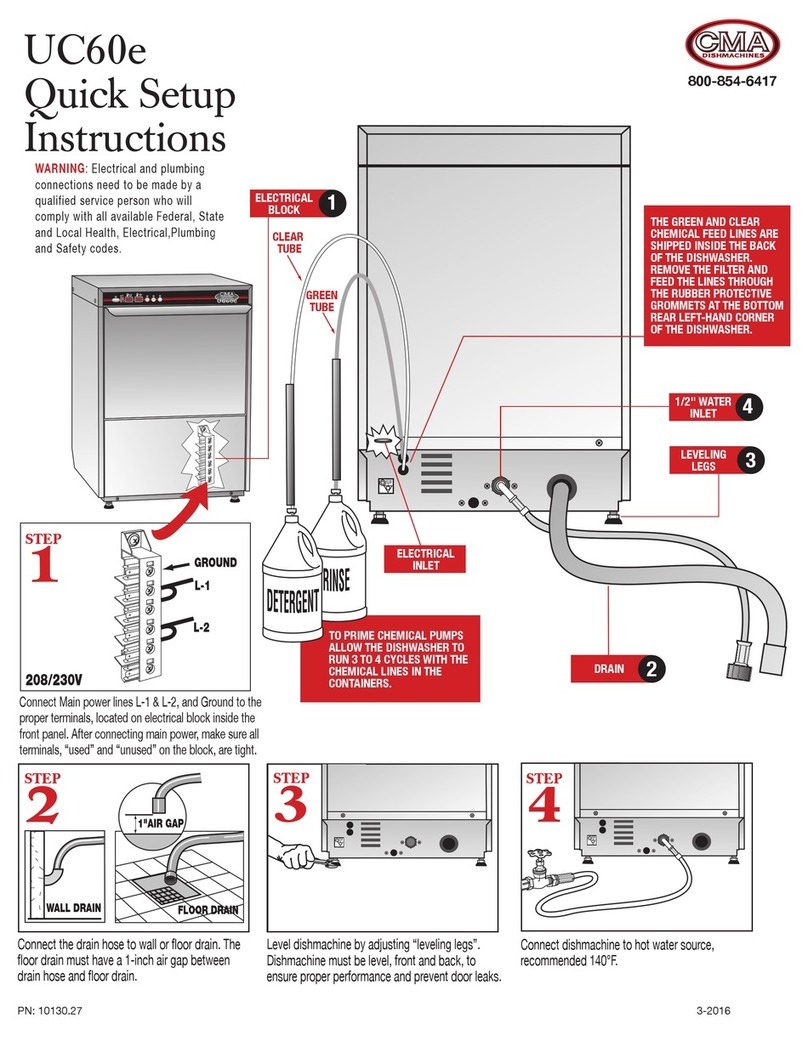

CMA Dishmachines UC60E Manual

CMA Dishmachines

CMA Dishmachines CMA-181VL User manual

CMA Dishmachines

CMA Dishmachines UC60E User manual

CMA Dishmachines

CMA Dishmachines CMA-180VL Manual

CMA Dishmachines

CMA Dishmachines S-AH User manual

CMA Dishmachines

CMA Dishmachines CWS Guide

CMA Dishmachines

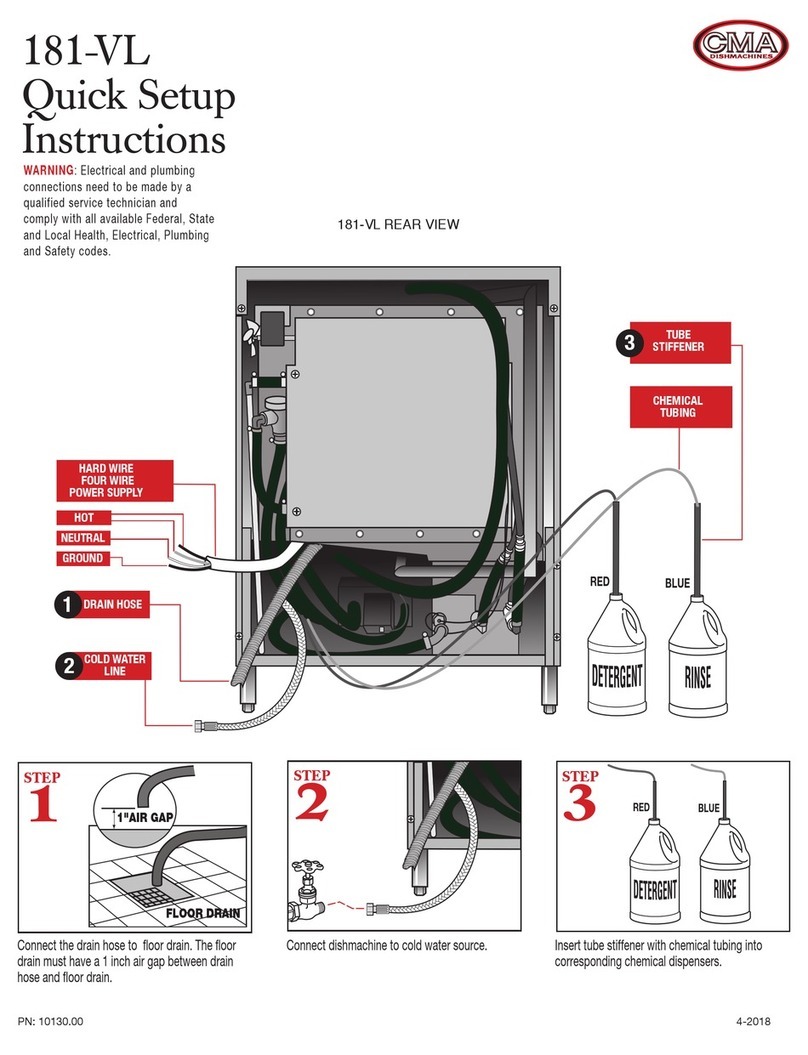

CMA Dishmachines 181-VL Manual

CMA Dishmachines

CMA Dishmachines CMA-66 L.T. User manual

CMA Dishmachines

CMA Dishmachines CMA180UCW/CD User manual

CMA Dishmachines

CMA Dishmachines CWS User manual

CMA Dishmachines

CMA Dishmachines L-1X User manual

CMA Dishmachines

CMA Dishmachines MODEL GL-C User manual

CMA Dishmachines

CMA Dishmachines CMA-180UC User manual

CMA Dishmachines

CMA Dishmachines CMA-180VL User manual

CMA Dishmachines

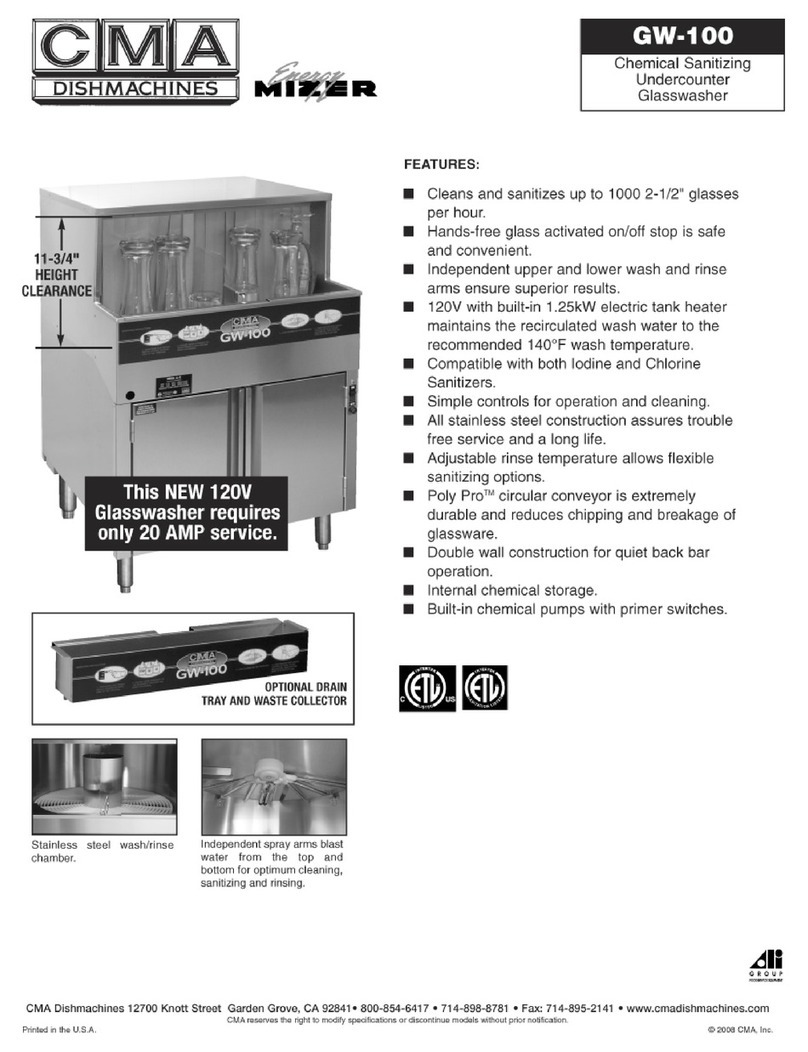

CMA Dishmachines GW-100 Instruction Manual

CMA Dishmachines

CMA Dishmachines GL-X User manual

CMA Dishmachines

CMA Dishmachines CMA-180TC User manual