CMT ORANGE TOOLS CMT300 User manual

Instruction Manual

Manual de instrucciones

Manuel d‘instruction

Manuale di istruzioni

Gebrauchsanweisungen

Instrukcja obsługi

Инструкция

EN p. 4

ES p. 20

FR p. 36

IT p. 52

DE S. 68

PL S. 84

RU S.100

CMT300

UNIVERSAL JOINTING SYSTEM

Sistema universal de empalme para encajes

Système universel pour assemblages à encastrement

Sistema di giunzioni universale per incastri

Universelle Bohrhilfe für Verbindungen

Uniwersalny system do wykonywania połączeń

Универсальная соединительная система

C.M.T. Utensili S.p.A.

Via della Meccanica

61122 Pesaro, Fraz. Chiusa di Ginestreto

Italia

tel_+39 0721 48571

fax_+39 0721 481021

e-mail_info@cmtorangetools.com

web site_www.cmtorangetools.com

CMT USA, inc.

7609 Bentley Road Suite D

Greensboro, NC 27409 USA

Phone 336-854-0201

Fax 336-854-0903

e-mail_info@cmtorangetools.com

AA

4

www.cmtorangetools.com

INDEX page

1) Contents of the package 4

2) Assembling the CMT300 5

3) Installing the router 7

4) Using the CMT300 and standard CMT300-T128 template 7

5) Optional CMT300-T064 template 9

6) Optional CMT300-T080 template 11 - 13 - 14

7) Optional CMT300-T127 template 12 - 13 - 14

8) Optional CMT300-T129 template 15 - 17 - 18 - 19

9) Optional CMT300-T190 template 16 - 17 - 18 - 19

10) Conclusions 19

INDEX AND CONTENTS OF THE PACKAGE

Thanking you for having purchased our products, we wish you many hours of enjoyable work with thems!

Whether you are a professional or not, our universal assembly system will enable you to make any type

of joint easily and rapidly.

This system can be adapted to any type of router, thanks to its special universal sub-base in transparent

PETG (supplied separately).

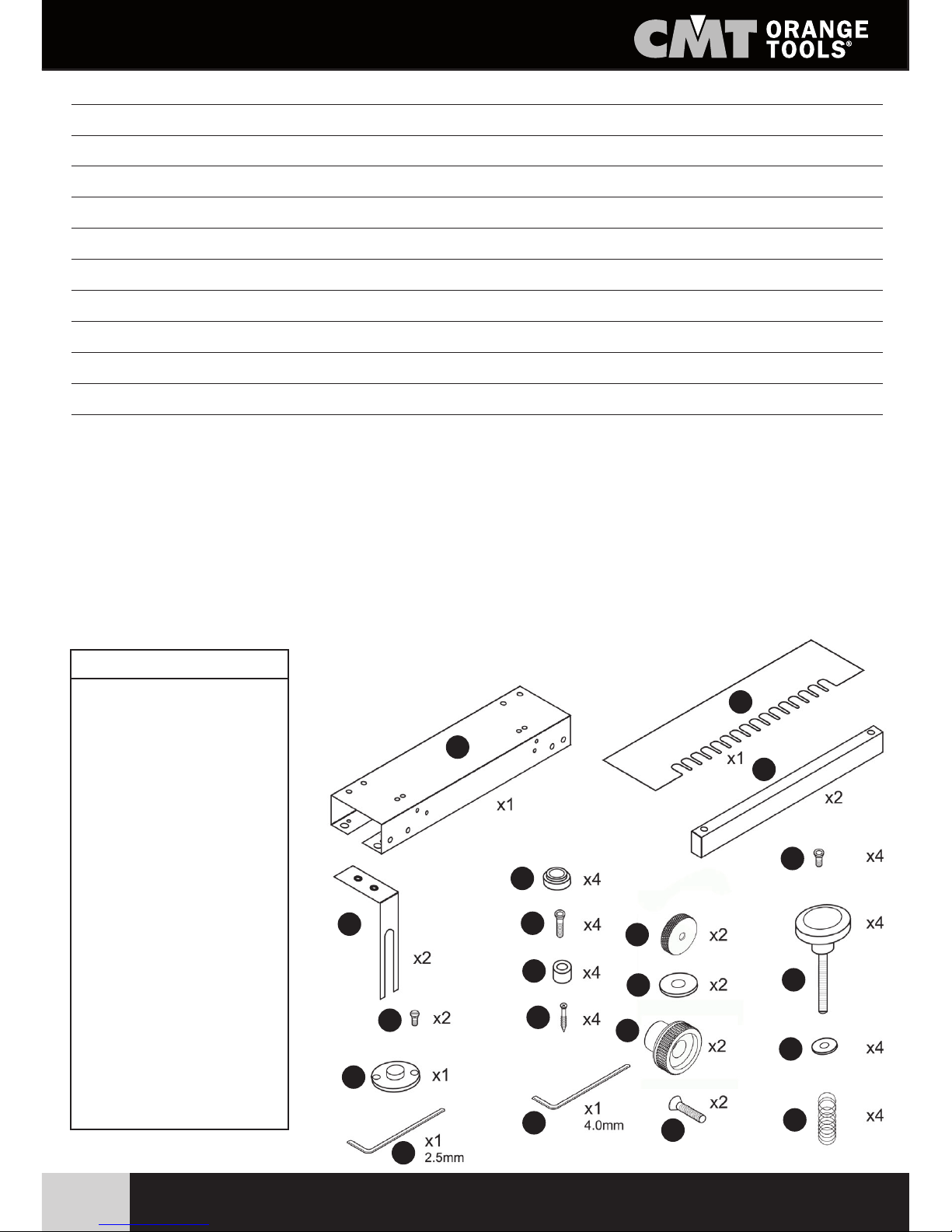

1. Contents of the package

When you open the package, you will find the following parts inside:

No. Order No. Q.ty

11 CMT300-01 1

12 CMT300-02 2

13 CMT300-03 4

14 CMT300-04 2

15 CMT300-T128 1

16 CMT300-06 4

17 CMT300-07 4

18 CMT300-08 4

19 CMT300-09 4

10 CMT300-10 4

11 CMT300-11 2

12 CMT300-12 2

13 CMT300-13 2

14 CMT300-14 4

15 CMT300-15 2

16 CMT300-16 4

18 CMT300-18 2

19 899.005.00 1

20 991.062.00 1

21 991.064.00 1

1

10

11

12

13

14

15

16

18

19

20

21

2

3

4

5

6

7

8

9

AA

5

www.cmtorangetools.com

Fig.3

Template

ASSEMBLING THE CMT300

2) Assembling the CMT300

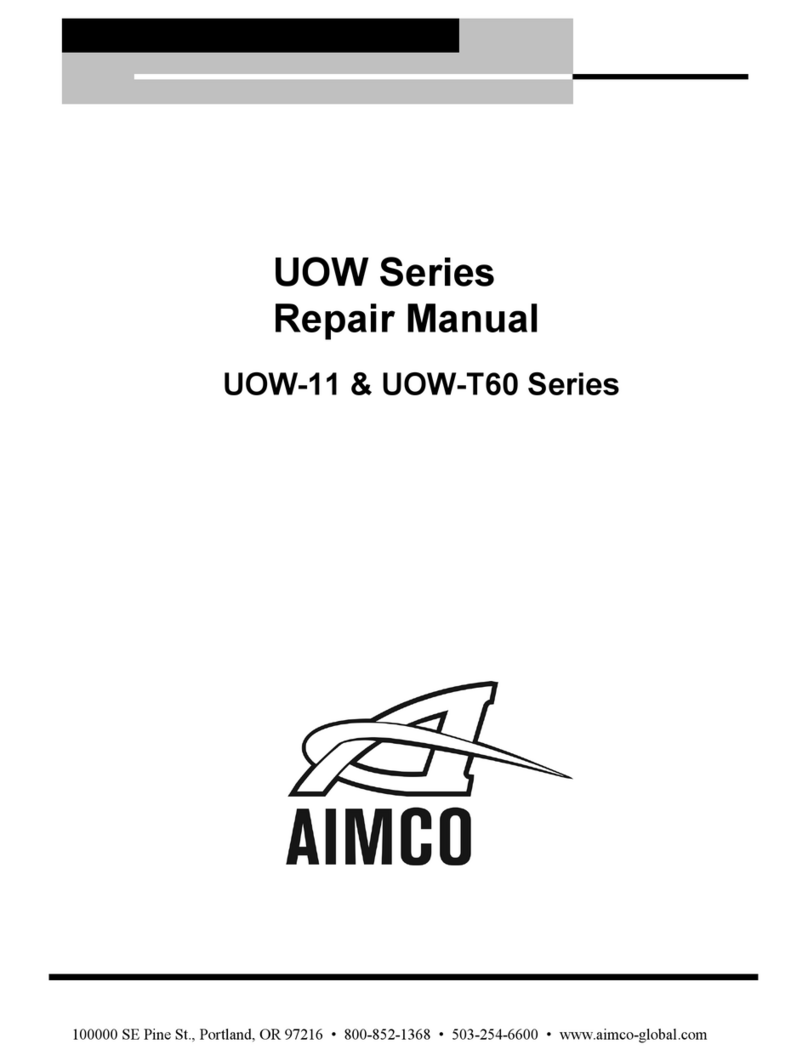

Fig. 1: The first job is to mount the CMT300 on the workbench. Four self-tapping screws are supplied for

this purpose.

Fig. 2: This diagram enables to understand how to mount the components required to adjust the position

of the template. First of all, fit screw 15 in the hole of the body, using the hex key (supplied) and carefully

tightening it, fitting lock nut 2 on the other side, then fit washer 11 and tighten nut 12 manually. Repeat this

procedure on the other side of the body.

The components (3) and screws (10) are used to position the wood. Tighten the stops (3) on the body (1)

using the screws (10). Set the stops in the positions U1 on the top of the system and F1 on the front of the

system.

Fig. 3: : This diagram enables to mount the template 5.

Fit the two adjustable supports (13) on it with the four screws (14).

Fig. 4: This diagram shows how to install the clamping bars that will enable the workpiece to be held in place.

These bars have a sandpaper coating, which ensures more grip and therefore a better hold on the workpiece

during machining.

Fit the two screws with over-sized locking knobs (7) in the washers (8), in the bar (4) and in the spring (9).

Workbench

Unit

Workbench

Fig.1

Fig.2 Overhead view

Front view

AA

6

www.cmtorangetools.com

All that has to be done now is to tighten the two screws with the over-sized locking knobs in the threaded

holes.

Repeat this procedure for the front bar.

Fig. 5: Lastly, place the template on the body of the CMT300.

To do so, just fit the supports (13) between parts 2 and 11.

Fig. 6: Once the template is positioned, it can be adjusted on the two axes - X and Y. Just tighten or loosen

the stop nut (2) for X-axis settings and raise or lower the guides (13) for Y-axis settings. Once the exact

setting has been found, tighten nut 12 to lock in place. Assembly is now complete.

ASSEMBLING THE CMT300

CMT300

CMT300

As

s

e X

Asse Y

Fig.4

Fig.5

Fig.6

Adjusting the template

AA

7

www.cmtorangetools.com

INSTALLING THE ROUTER

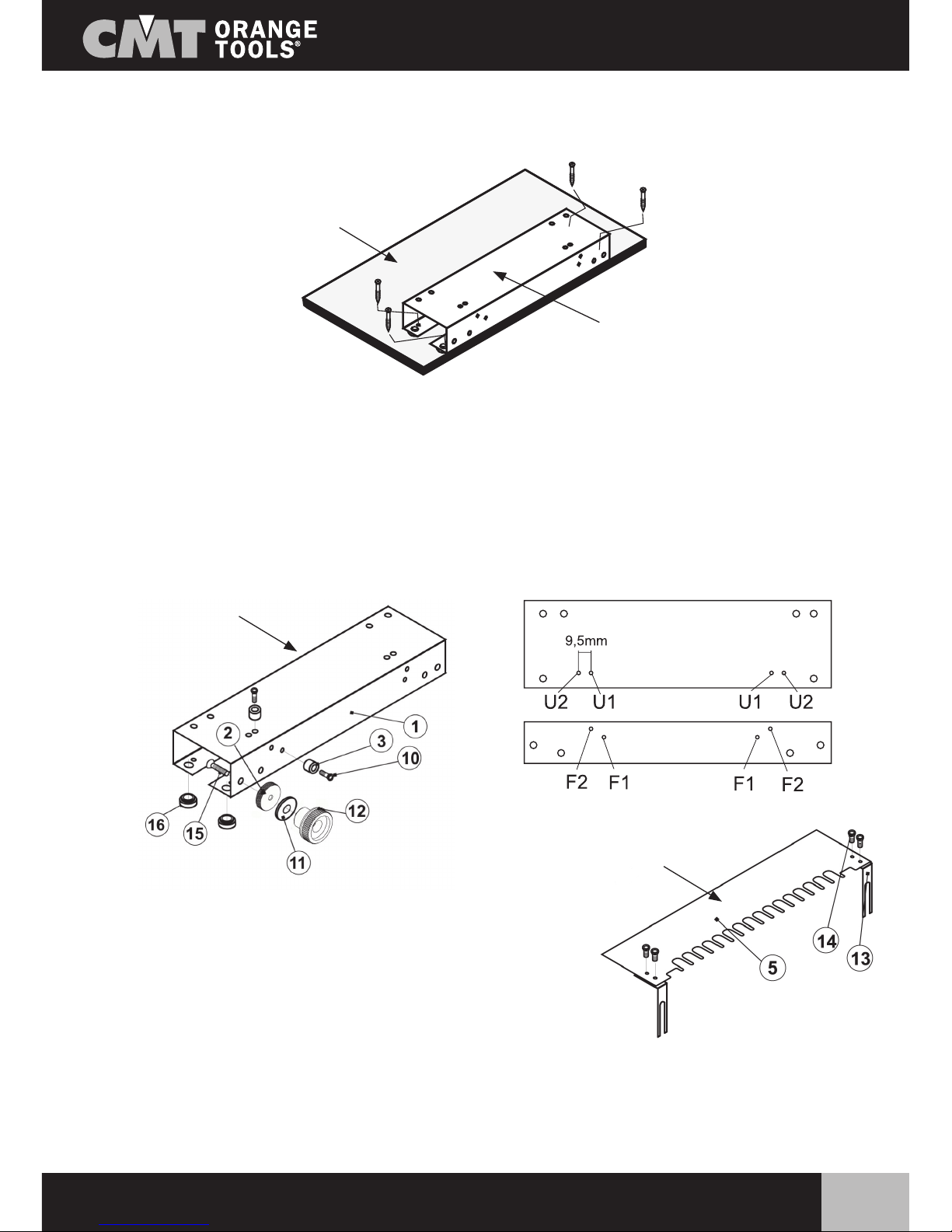

3) Installing the router

To use the CMT300 system, a router is required, on which a guide ring must be fitted, to enable the machine

to be controlled on the template.

be impossible to install the guide ring on the router being used (due to the dimensions), a universal sub-base

(supplied separately) is available.

This sub-base has an external diameter of 170mm and is supplied with a line-up/centering pin to enable it

to be correctly fitted to the router.

Optional universal sub-base supplied separately

CMT300-SB1 (for Ø8 and Ø12mm shanks)

CMT300-SB2 (for Ø6.35 and Ø12.7mm shanks)

Once the guide is installed on the router, a CMT dovetail bit can be fitted for machining the wood.

4) Using the CMT300 with a standard CMT300-T128 template

The CMT300 system is supplied with a standard template (CMT300-T128), with which 12.7mm half-blind

dovetail joints can be machined using a normal CMT dovetail bit (purchased separately).

Bits that can be used with the standard CMT300-T128 template:

718.127.11 (Ø6mm shank)

818.128.11 (Ø6.35mm shank)

918.127.11 (Ø8mm shank)

Ø

50mm

Guide ring

(50mm wheelbase)

Router

Line-up

centering pin

Universal sub-base

(for guide ring)

Half-blind dovetail joint

(CMT300-T128)

21.5mm

9.5mm

(3/8”)

12.7mm

(1/2”)

AA

8

www.cmtorangetools.com

USING THE CMT300 WITH A STANDARD

CMT300-T128 TEMPLATE

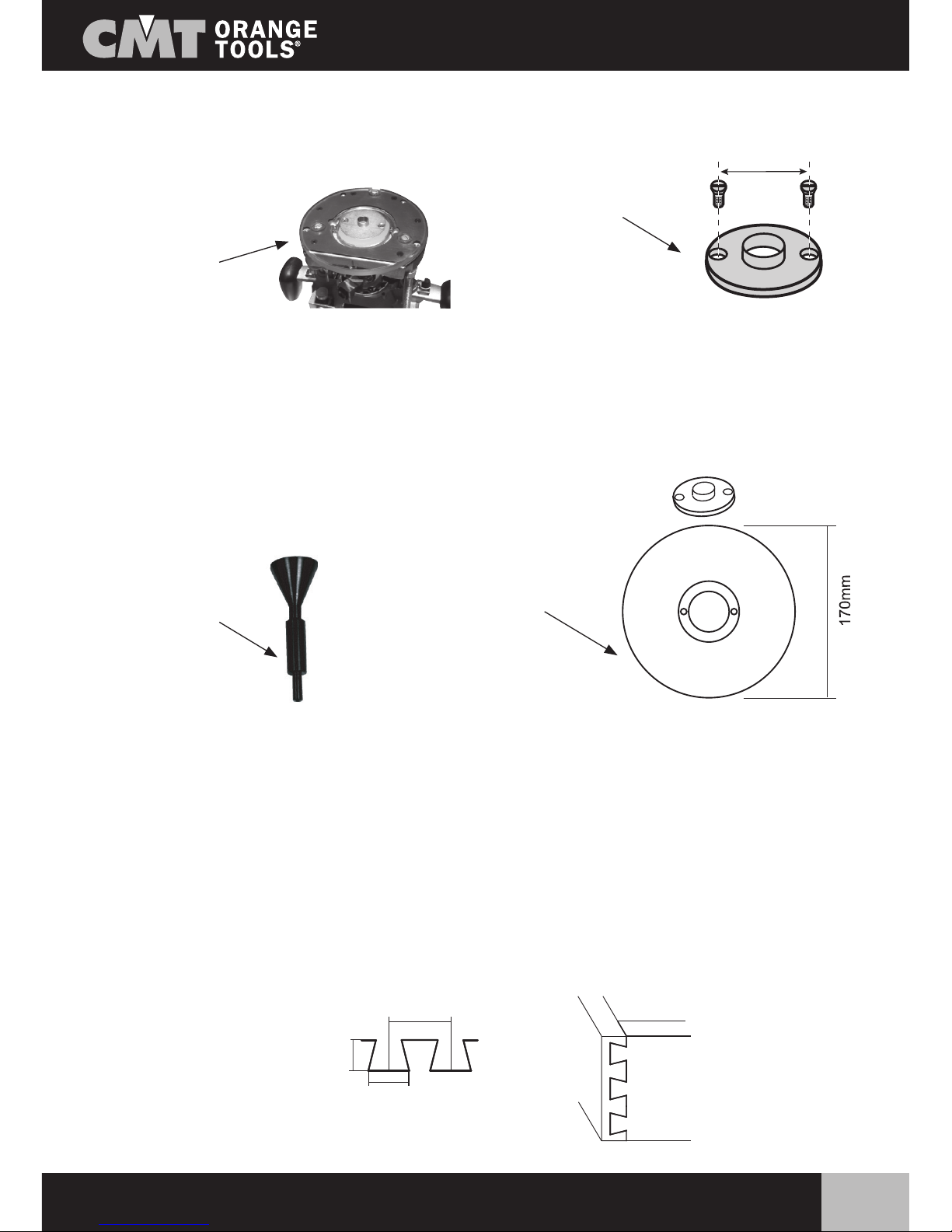

Example of making a drawer with a standard CMT300-T128 template:

Y4 Y3

Y1 Y2

X4

X1

X3

X2

X3

X4

Y3

X2

X1

Y4

Y1 Y2

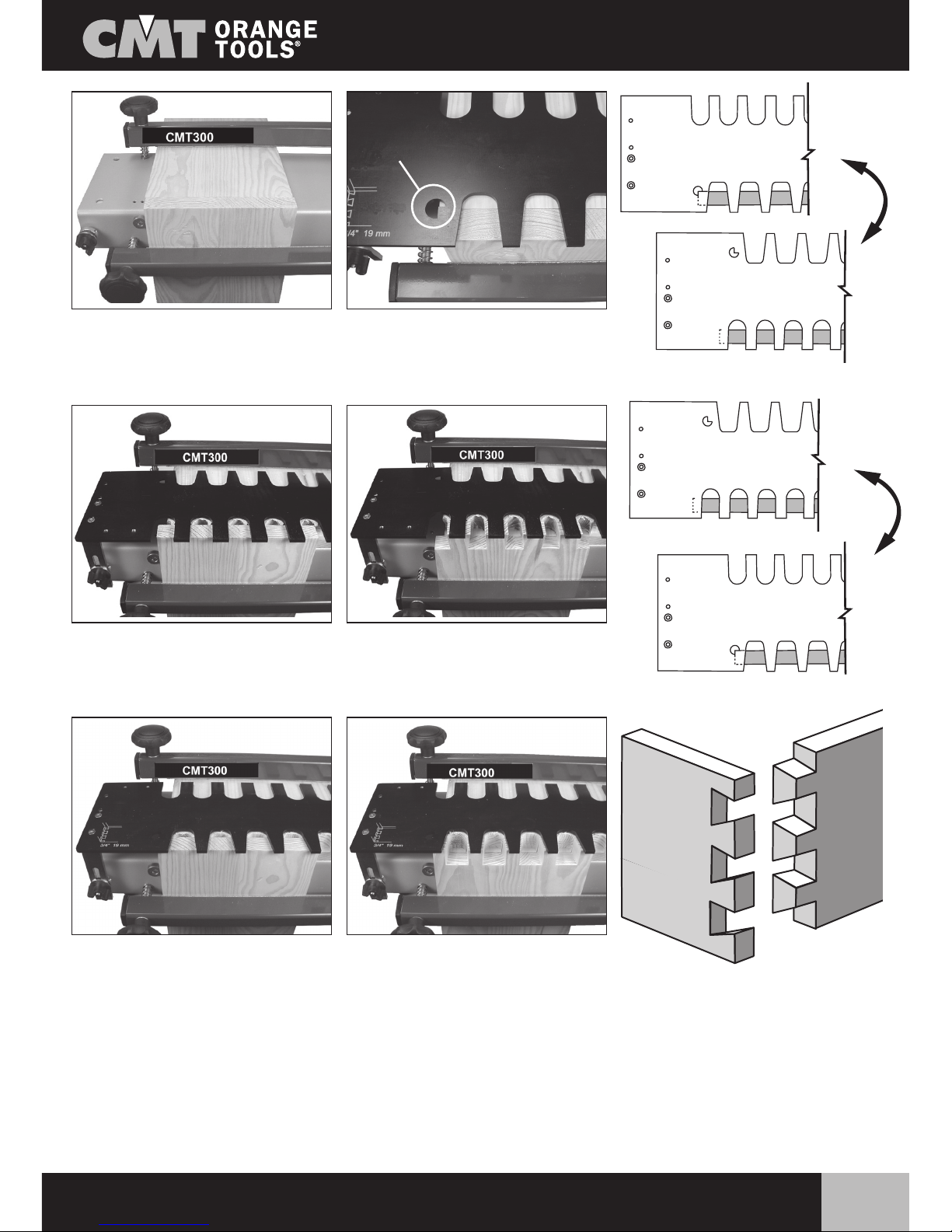

With each pass of the router on the board edge, a complete

assembly is machined (X1 con Y1, X2 with Y2...), so to make a

complete drawer, four work cycles must be carried out.

Positioning the wood parts and machining:

1) Place the wood part (X1, X2....) vertically against the small

positioning buffer and clamp it sufficiently with the bar to ensure

it does not slip.

2) Place the wood part (Y1, Y2....) horizontally against the small

positioning buffer and clamp it sufficiently with the bar to ensure

it does not slip.

3) Level the two pieces of wood.

4) Tighten the clamping bar of the vertical part completely.

5) Tighten the clamping bar of the horizontal part completely.

6) Position the template and tighten the nuts that hold it in place.

Dismantled

drawer

Right-hand

side

Left-hand

side

Rear

Front

7) Move up to and away from the workpiece from

the front - not from above - to avoid the risk of

missing the guide and ruining the joint.

8) Position the router and follow the profile of the

template to carry out the machining.

9)The first assembly is finished - repeat the previous

procedure as often as required.

AA

9

www.cmtorangetools.com

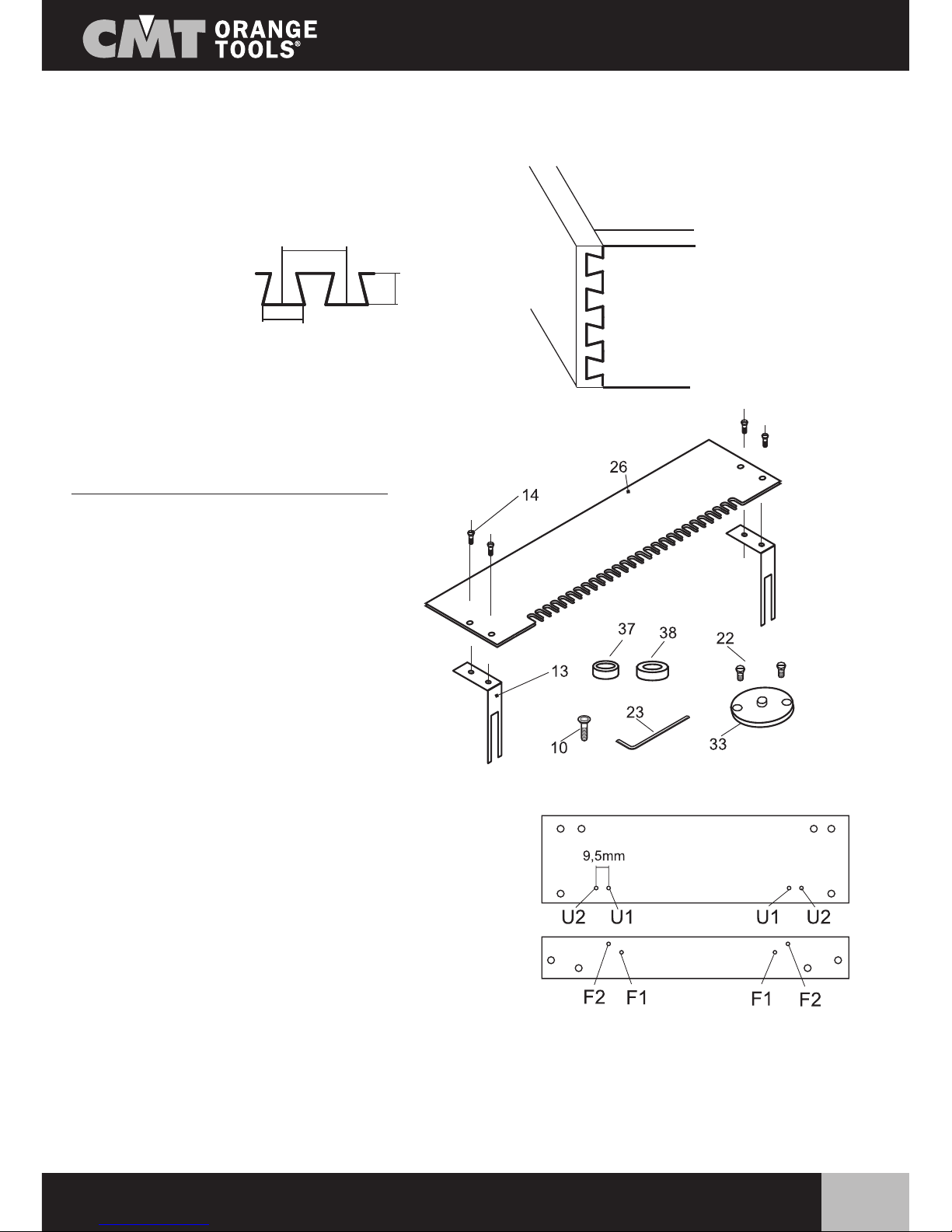

OPTIONAL CMT300-T064 TEMPLATE

5) Optional CMT300-T064 template

The CMT300-T064 template can be purchased as an optional and enables to make mini half-blind

dovetail joints.

Contents of the CMT300-T064 package:

26) CMT300-T064 template

14) Four M4x8mm screws

37) Two Ø15.8x6mm stop rings

38) Two Ø28.6x4mm stop rings

10) Four M4x16mm screws

33) Ø7.8x4mm guide ring

22) Two M5x8mm screws

23) 2.5mm hex key

Mounting the template: this template is mounted in the

same way as the standard model.

Remove the standard template from the CMT300 system

and replace it with the 26 template, fixing it on the

supports (13 - included in the CMT300 package), using

the screws (14).The stop rings (37 and 38) replace those

supplied as standard.

The 38 rings, which have a larger diameter than the 37

ones, are mounted on the front in F2, whereas the other

37 rings are mounted on the top part, in U1.

Fitting the guide ring: to use this template, it is necessary to dismantle the guide ring already on the

router, and replace it with the other ring (33). Then mount a dovetail bit (718.060.11 with Ø6mm shank or

818.064.11 with Ø6.35mm shank) to carry out the machining.

from

CMT300

from

CMT300

CMT300-T064

11.3mm

6mm

6.35mm

(1/4”)

Overhead view

Front view

Mini half-blind

dovetail joints

(CMT300-T064)

AA

10

www.cmtorangetools.com

OPTIONAL CMT300-T064 TEMPLATE

Example of making a drawer with a standard CMT300-T064 template:

Dismantled

drawer

Right-hand

side

Left-hand

side

Rear

Front

Y4 Y3

Y1 Y2

X4

X1

X3

X2

X3

X4

Y3

X2

X1

Y4

Y1 Y2

With each pass of the router, a complete assembly is machined on

the workpiece (X1 with Y1, X2 with Y2...), so to make a complete

drawer, four work cycles must be carried out.

Positioning the wood parts and machining:

1) Place the wood part (X1, X2....) vertically against the small

positioning buffer and clamp it sufficiently with the bar to ensure

it does not slip.

2) Place the wood part (Y1, Y2....) horizontally against the small

positioning buffer and clamp it sufficiently with the bar to ensure

it does not slip.

3) Level the two pieces of wood.

4) Tighten the clamping bar of the vertical part completely.

5) Tighten the clamping bar of the horizontal part completely.

6) Position the template and tighten the nuts to hold it in place.

7) Move up to and away from the workpiece from

the front - not from above - to avoid the risk of

missing the guide and ruining the joint.

8) Position the router and follow the profile of the

template to carry out the machining.

9) The first assembly is finished - repeat the

previous procedure as often as required.

AA

11

www.cmtorangetools.com

OPTIONAL CMT300-T080 TEMPLATE

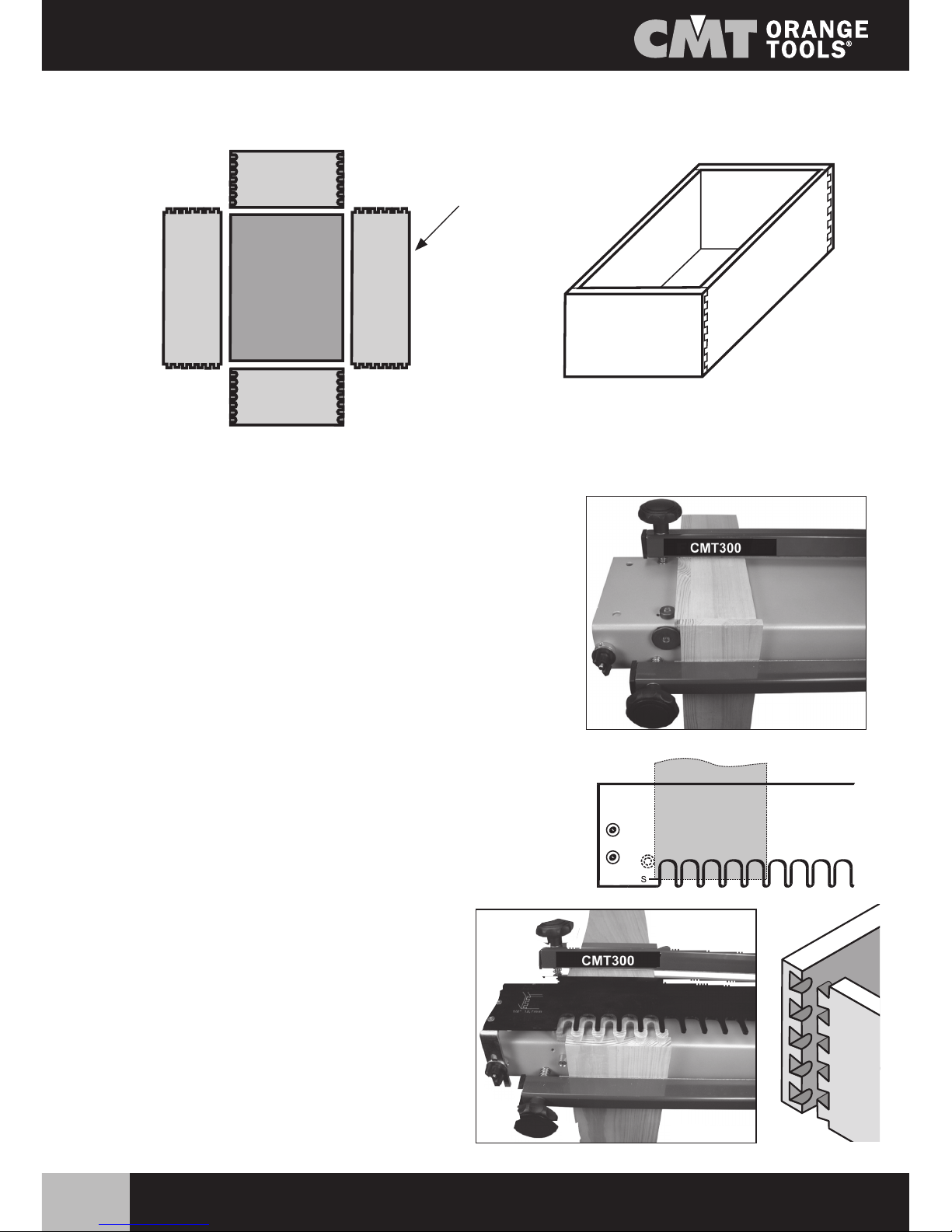

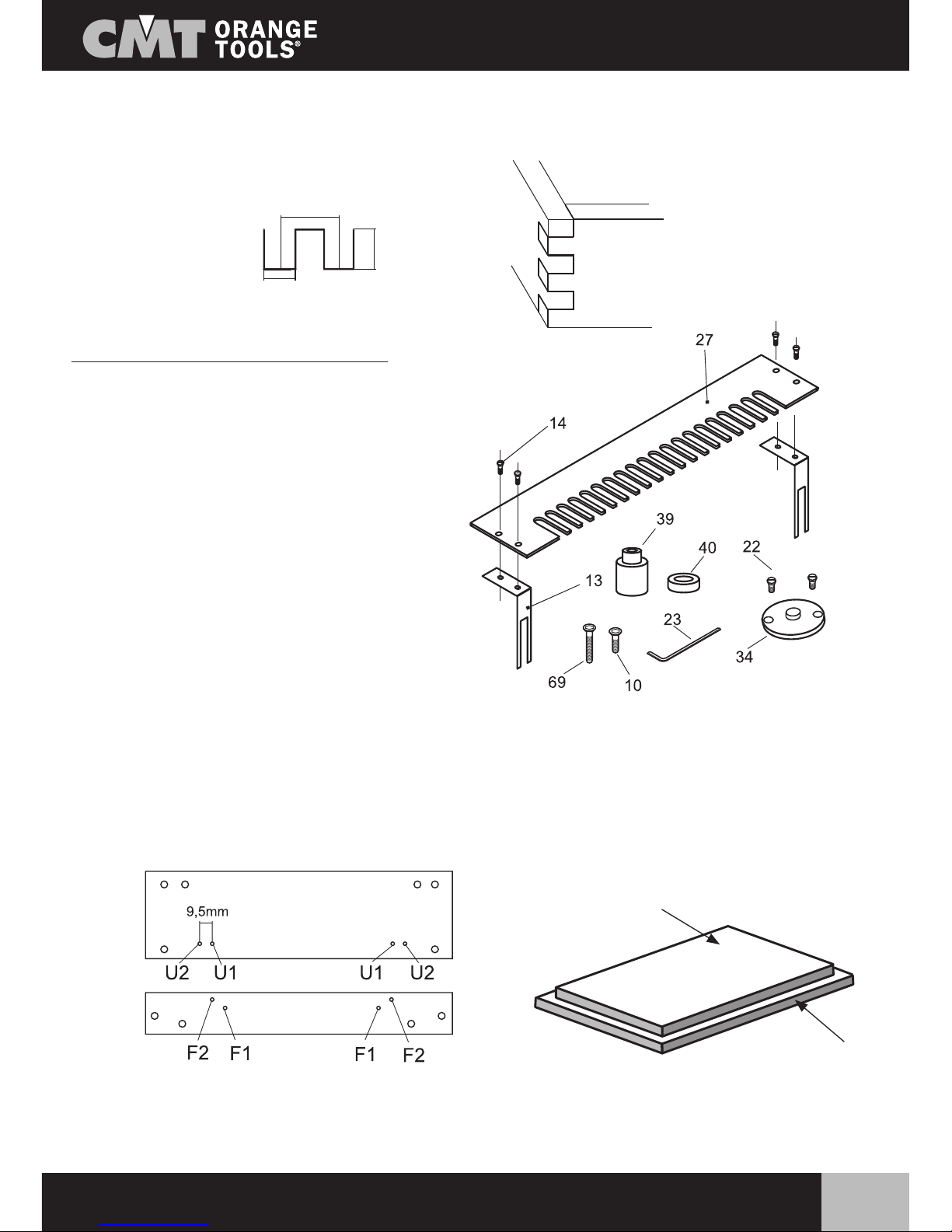

6) Optional CMT300-T080 template

The CMT300-T080 template can be purchased as an optional and enables to make mini box joints.

Contents of the CMT300-T080 package:

27) CMT300-T080 template

14) Four M5x8mm screws

39) Two Ø15x7/Ø21x18 stop rings

69) Two M4x35mm screws

40) Two Ø14x6mm stop rings

10) Two M4x16mm screws

34) Ø11.1x4 guide ring

22) Two M5x8mm screws

23) 2.5mm hex key

Mounting the template: this template is mounted in the same way as the standard model. Remove the

standard template from the CMT300 system and replace it with the other template (27), fixing it on the

supports (13 - included in the CMT300 package), using the screws (14).The stop rings (39 and 40) replace

those supplied as standard. The two rings 39 are mounted on the front in F2, whereas the others (40) are

fitted on the front in F1 and are only used for machining a particular structure, as can be seen in Fig.7. In this

case, the upper part of the wood is up against ring 40 and the lower part up against ring 39.

Fitting the guide ring: replace the guide ring already on the router with ring 33. Then mount a straight bit

(881.081.11 with Ø6.35mm shank or 912.080.11 with Ø8mm shank), which will carry out the machining.

Mini box joints

(CMT300-T080)

from

CMT300

from

CMT300

CMT300-T080

Overhead view

Front view

Upper part

Fig.7

Lower part

16mm

(5/8”)

8mm

(5/16”)

20/30mm

AA

12

www.cmtorangetools.com

OPTIONAL CMT300-T127 TEMPLATE

Overhead view Upper part

Fig.7

Lower part

7) Optional CMT300-T127 template

The CMT300-T127 template can be purchased as an optional and enables to make box joints.

Contents of the CMT300-T127 package:

29) CMT300-T127 template

14) Four M4x8mm screws

43) Two Ø7.8x7/Ø17.2x24 stop rings

69) Two M4x40mm screws

44) Two Ø19.65x6mm stop rings

10) Two M4x16mm screws

23) 2.5mm hex key

Mounting the template: this template is mounted in the same way as the standard model. Remove the

standard template from the CMT300 system and replace it with template 29, fixing it on the supports (13 -

included in the CMT300 package), using the screws (14).The stop rings (43 and 44) replace those supplied

as standard. The two (longer) rings (43) are mounted on the front in F2, whereas the others (44) are fitted

on the front in F1 and only used for machining a particular structure, as can be seen in Fig.7. In this case,

the upper part of the wood is up against ring 44 and the lower part up against ring 43.

Box joints

(CMT300-T127)

from

CMT300

from

CMT300

from

CMT300

CMT300-T127

Front view

25.4mm

(1”)

30/35mm

12.7m

m

(1/2”)

Fitting the guide ring: to use this template, it is necessary to mount the Ø15.8x4mm guide ring (35)

already on the CMT300. Then mount a CMT straight bit (812.127.11 with Ø6.35mm shank, 912.127.11

with Ø8mm shank or 812.627.11 with Ø12.7mm shank), which will carry out the machining.

AA

13

www.cmtorangetools.com

OPTIONAL CMT300-T080 AND CMT300-T127 TEMPLATE

Example of making a drawer with CMT300-T080 and CMT300-T127 template:

X3

X4

Y3

Y2

Y4

Y1

X2

X1

Dismantled

drawer

Right-hand

side

Left-hand

side

Rear

Front

With each machining run, an assembly is made (X1, X2..., Y1

Y2), so, to make a complete drawer, eight machining cycles

have to be carried out.

With these two templates, two types of joints can be made, as

can be seen in the following illustrations.

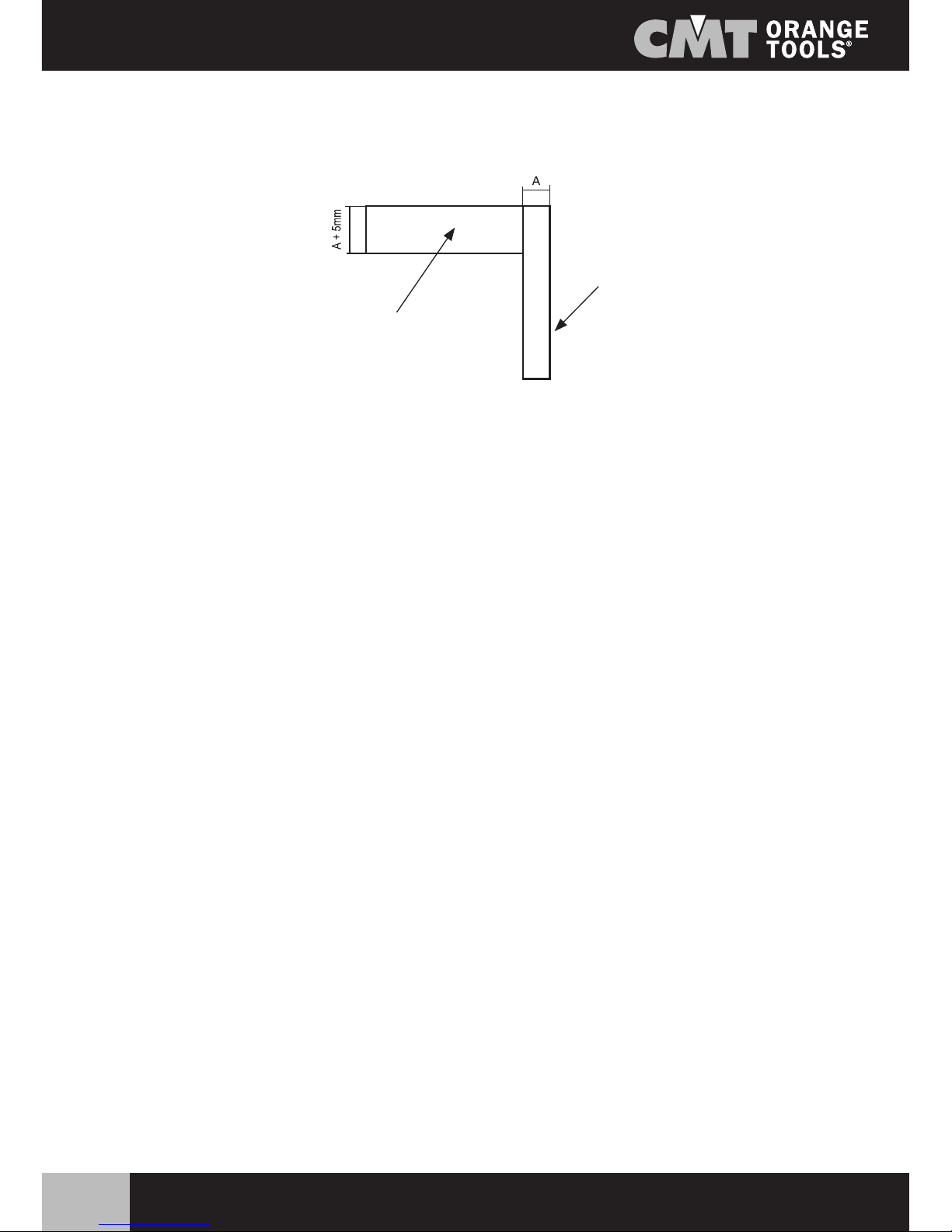

For the machining, a piece of scrap stock 5mm thicker than the piece to be machines must be placed

horizontally. This piece of wood used horizontally is only used to support the vertical part to be machined.

Scrap stock

Wood to be

machined

X1

X2

X4

X3

Y1 Y4

Y2 Y3

AA

14

www.cmtorangetools.com

OPTIONAL CMT300-T080 AND CMT300-T127 TEMPLATE

Positioning the wood parts and machining:

1) Place the wood part (X1..., Y2....) vertically against the small positioning buffer and clamp it sufficiently

with the bar to ensure it does do not slip.

2) Place the piece of scrap stock horizontally and push it against the vertical piece.

3) Match the ends of the two pieces of wood.

4) Tighten the clamping bar of the vertical part completely.

5) Tighten the clamping bar of the horizontal part completely.

6) Position the template and tighten the nuts to hold it in place.

7) Move up to and away from the workpiece from the front - not from above - to avoid the risk of missing

the guide and ruining the joint.

8) Position the router and follow the profile of the template to carry out the machining.

9) The first assembly is finished - repeat the previous procedure as often as required.

AA

15

www.cmtorangetools.com

OPTIONAL CMT300-T129 TEMPLATE

8) Optional CMT300-T129 template

The CMT300-T129 template can be purchased as an optional and enables to make 12.7x20mm open

dovetail joints.

Contents of the CMT300-T129 package:

31) CMT300-T129 template

14) Four M4x8mm screws

44) Two Ø21.85x6mm stop rings

14) Two M4x16mm screws

34) Ø11.1x4mm guide ring

22) Two M5x8mm screws

23) 2.5mm hex key

Mounting the template: this new template is mounted in

the same way as the standard model. Remove the standard

template from the CMT300 system and replace it with

template 31, fixing it on the supports (13 - included in the

CMT300 package), using the screws (14). The stop rings

(45) replace those supplied as standard and are mounted

on the front in F2.

Mounting the guide ring: it can be seen that this template has two sides, as the joint is made using two

bits: one for each side of the template. On the first (straight) side, the Ø12.7 dovetail bit (818.129.11 with

Ø6.35mm shank or 918.129.11 with Ø8mm shank) will be used, with the standard Ø15.8x4mm guide ring

(supplied with the CMT300), whereas on the other (dovetail) side, the Ø8mm straight bit (811.081.11 with

Ø6.35mm shank or 912.080.11 with Ø8mm shank) will be used with Ø11.1x4mm ring (34), supplied with

the template.

from

CMT300

from

CMT300

from

CMT300

CMT300-T129

Overhead view

Front view

Open dovetail joints

(CMT300-T129)

20mm

12.7mm

(1/2”)

AA

16

www.cmtorangetools.com

OPTIONAL CMT300-T190 TEMPLATE

9) Optional CMT300-T190 template

The CMT300-T190 template can be purchased as an optional and enables to make 19x22mm open dovetail

joints.

Contents of the CMT-T190 package:

32) CMT300-T190 template

14) Four M4x8mm screws

46) Two Ø16.3x6mm stop rings

10) Two M4x16mm screws

36) Ø22x4mm guide ring

22) Two M5x8mm screws

23) 2.5mm hex key

Open dovetail joints

(CMT300-T190)

from

CMT300

from

CMT300

from

CMT300

CMT300-T190

Assembling the template: this template is mounted in the

same way as the standard model. Remove the standard

template from the CMT300 system and replace it with

template 32, fixing it on the supports (13 - included in the

CMT300 package), using the screws (14). The stop rings

(46) replace those supplied as standard and are mounted

on the front in F2.

Mounting the guide ring: it can be seen that this template has two sides, as the joint is made using two

bits: one for each side of the template. On the first (straight) side, the Ø19mm dovetail bit (718.190.11

Ø6mm shank – 818.190.11 Ø6.35mm shank – 918.190.11 Ø8mm shank – 918.690.11 Ø12mm shank

– 818.690.11 Ø12.7mm shank) will be used, with the Ø22x4mm guide ring (36) supplied with the template,

whereas on the other (dovetail) side, the Ø12.7mm straight bit (812.127.11 Ø6.35mm shank – 912.127.11

Ø8mm shank – 811.627.11 Ø12.7mm shank) will be used with the standard Ø15.8x4mm ring, supplied

with the template.

Overhead view

Front view

20/30m

m

19mm

(3/4”)

AA

17

www.cmtorangetools.com

OPTIONAL CMT300-T129 AND CMT300-T190 TEMPLATE

Example of making a drawer with CMT300-T129 and CMT300-T190 template:

With each completed run, an assembly is made (X1, X2...., Y1 Y2...), so to make a complete drawer, eight

work cycles must be carried out.

Using the two sides:

The first part of the template (with the straight slots) enables to make the X-axis cuts (X1, X2...), using a CMT

dovetail bit and the corresponding guide ring.

The second (dovetail) part of the template enables to make the Y-axis cuts (Y1, Y2...), using a CMT straight

bit and the corresponding guide ring.

X3

X4

Y3

Y2

Y4

Y1

X2

X1

Second side of the template

(to be used with the straight bit)

First side of the template

(to be used with the dovetail bit)

Dismantled

drawer

Right-hand

side

Left-hand

side

Rear

Front

AA

18

www.cmtorangetools.com

Positioning the wood parts and machining:

1) Place the wood part X1 vertically against the small positioning buffer and clamp the bar sufficiently to

ensure it does not slip.

2) Place the scrap stock horizontally and push it against the vertical piece.

3) Match the ends of the two pieces of wood.

4) Tighten the clamping bar of the vertical part completely.

5) Tighten the clamping bar of the horizontal part completely.

6) Place the template on its second (dovetail) side and check in the small hole in the template that the two

pieces are well matched.

7) Turn the template on to the first side (with the straight slots). Make certain to use the correct guide ring

and the CMT dovetail bit.

8) Move up to and away from the workpiece from the front - not from above - to avoid the risk of missing

the guide.

9) Position the router and follow the profile of the template to carry out the machining.

10) The first assembly is finished - repeat the previous procedure to make all X-axis cuts.

11) Remove the template and leave the scrap stock in place.

12) Place the wood part (Y1) vertically against the small positioning buffer and clamp the bar sufficiently to

ensure it does not slip.

13) Match the ends of the two pieces of wood.

14) Tighten the clamping bar of the vertical part completely.

17) Turn the template on to the second (dovetail) side. Make certain to use the correct guide ring and the

CMT straight bit.

16) Move up to and away from the workpiece from the front - not from above - to avoid the risk of missing

the guide.

17) Position the router and follow the profile of the template to carry out the machining.

18) The first assembly is finished - repeat the previous procedure for the rest of the joints to be made.

The following page has some illustrations that help to better understand the stages described above.

For the machining the wood components, a piece of scrap stock necessary for the machining (which will later

be thrown away) that is 5mm thicker than the piece to be machined must be placed horizontally.

This scrap stock is a piece of wood required to hold the vertical part to be machined steady.

OPTIONAL CMT300-T129 AND CMT300-T190 TEMPLATE

Scrap stock

Wood to be

machined

AA

19

www.cmtorangetools.com

OPTIONAL CMT300-T129 AND CMT300-T190 TEMPLATE

10) Conclusions:

You have just assembled and used the CMT300 system. In addition to these instructions, there is the

commercial documentation of the items and relative code numbers of the CMT300 system. In particular,

there are the optional templates, the description of the bits use and the relative code numbers.

We hope you enjoy working with the CMT300 system.

Fig.1 Fig.2

Fig.3

Fig.4 Fig.6

Fig.5

Fig.7

Fig.6

Fig.8

Fig.6

Wood

position

Scrap stock

Work piece

Fig.9

20

www.cmtorangetools.com

1

10

11

12

13

14

15

16

18

19

20

21

2

3

4

5

6

7

8

9

ÍNDICE página

1) Contenido del embalaje 20

2) Montaje del CMT300 21

3) Instalación de la electrofresadora 23

4) Utilización del CMT300 y plantilla estándar CMT300-T128 23

5) Plantilla opcional CMT300-T064 25

6) Plantilla opcional CMT300-T080 27 - 29 - 30

7) Plantilla opcional CMT300-T127 28 - 29 - 30

8) Plantilla opcional CMT300-T129 31 - 33 - 34 - 35

9) Plantilla opcional CMT300-T190 32 - 33 - 34 - 35

10) Conclusiones 35

ÍNDICE Y CONTENIDO DEL EMBALAJE

Le agradecemos la compra de nuestros productos y le deseamos buen trabajo.

Que sea Ud. un profesional o no, con nuestro sistema de empalme universal podrá crear fácil y rápidamente

cualquier tipo de encaje.

Este sistema puede adaptarse a cualquier tipo de electrofresadora gracias a la base universal especial de

PETG transparente (suministrada a parte).

1. Contenido del embalaje

Al abrir el embalaje, encontrará las piezas siguientes:

No. Código Cant.

11 CMT300-01 1

12 CMT300-02 2

13 CMT300-03 4

14 CMT300-04 2

15 CMT300-T128 1

16 CMT300-06 4

17 CMT300-07 4

18 CMT300-08 4

19 CMT300-09 4

10 CMT300-10 4

11 CMT300-11 2

12 CMT300-12 2

13 CMT300-13 2

14 CMT300-14 4

15 CMT300-15 2

16 CMT300-16 4

18 CMT300-18 2

19 899.005.00 1

20 991.062.00 1

21 991.064.00 1

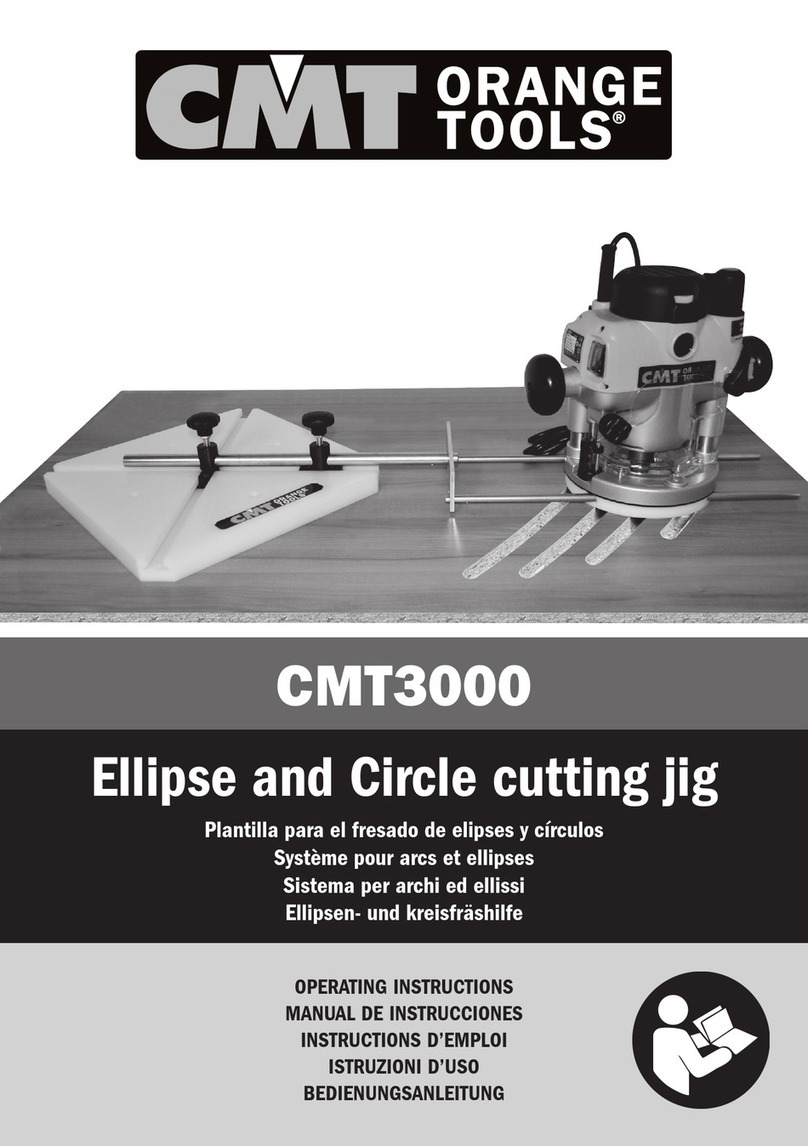

Table of contents

Languages:

Other CMT ORANGE TOOLS Power Tools manuals

CMT ORANGE TOOLS

CMT ORANGE TOOLS POCKET-PRO PPJ-002 User manual

CMT ORANGE TOOLS

CMT ORANGE TOOLS CMT3000 User manual

CMT ORANGE TOOLS

CMT ORANGE TOOLS CMT333 User manual

CMT ORANGE TOOLS

CMT ORANGE TOOLS CMT7E User manual

CMT ORANGE TOOLS

CMT ORANGE TOOLS TW-200 User manual

CMT ORANGE TOOLS

CMT ORANGE TOOLS Industrio Operating instructions