CNC AC-CNC2017-2S User manual

www.arduinoclub.de

Operating instructions

CNC Motion Controller: AC-CNC2017-2S (REV03)

Dear customer, thank you for choosing our product.

All our products are checked and subject to the controls of our

Quality assurance. We therefore guarantee that our products are free of

Defects in materials and workmanship.

Please read the safety instructions under 5.0 before you begin the work carefully.

Table of Contents :

1.0 Instructions for self-builders

1.1 You need help?

1.2 Note

2.0 Soldering instructions

2.1 Scope of delivery and required tool

2.1.1 Scope of delivery

2.1.2 Required Tool

2.2 Assembly of components

3.0 Functional test

3.1 Connecting of CNC Motion Controller

3.2 Setting the EstlCam Software

3.3 Programm the CNC Motion Controller

3.4 Preparation

3.5 Inputs and outputs

3.6 Inverter and HF milling spindle

3.7 Testing the driver ports

4.0 Start-up the finished control card

4.1 Limit switches and Inductive sensors

4.2 Stepper Motor Driver Module

4.3 Stepper Motors

4.4 Milling Motor, for connection to 230vac

4.5 Frequency inverter and HF spindle

4.6 Sensor input (SE) and length sensor/touch plate

4.7 Error input (FE)

4.8 Outputs A1, A2-Water pump and laser

4.9 Connection to the computer and power supply

5.0 Safety Instructions

6.0 Warranty and Guarantee

7.0 Disposal

1.0 Instructions for self-builders

CNC Motion Controller: AC-CNC2017-2S (REV03)

1.1 You need Help?

You have chosen a kit.

If you have any concerns, we can also offer you the assembly of the components at

this point in time. Just send us an email with your request to: [email protected].

Everything else is then clarified.

1.2 Note

This kit was built and tested many times as a prototype before go to production. Only when

optimum quality is achieved in terms of function and operational safety, it is released for the

series.

In order to achieve a certain functional safety during the construction of the controller, the

entire structure was share down into two stages:

1. Stage I: 2.1 Assembly the components

2. Stage II: 3.0 Functional test

When soldering the components, make sure that they are soldered to the board (if not

indicated otherwise) without distance to the PCB.

All protruding connection wires are cut off directly above the solder.

Since this kit is sometimes very small or narrow spaced pads (solder danger), it is only

possible to solder here with a soldering iron with a small soldering tip. Solder carefully.

2.0 Soldering instructions

1. When soldering electronic circuits, never use Soldering water or soldering grease.

these contain acid, which destroys components and traces.

2. Use as soldering material only PB38SN60CU2 (lead 28%, tin 60%, copper 2%) with a

rosin core which also serves as a flux.

3. Use a small soldering iron with a maximum of 30 watts of power.

4. The soldering must be done quickly, too long soldering destroys the components by

excessive heat..

The maximum temperature is 250 °c for 5 seconds per pad.

5. The cleanliness of the soldering tip is essential for a good soldering result.

6. After each soldering, clean the soldering tip with a damp sponge or a silicone wiper.

7. After soldering, protruding connection wires are cut directly above the solder with a

side or flat cutter.

8. After the fitting, always check each circuit again to make sure that all components are

correctly inserted and poled. Also check whether connections or conductors with tin

were accidentally bridged. This can lead not only to malfunctions, but also to the

destruction of the components.

9. Please note that improper solder joints, wrong connections, incorrect operation and

assembly errors are outside our sphere of influence.

10. Be sure to observe the safety instructions under point 5.0!

2.1 Scope of delivery and required tool

2.1.1 Scope of delivery:

● 5 pieces optocoupler with 4 connections

● 1 piece optocoupler 16 connections

● 1 piece DC-DC Converter, set to +5V

● 1 piece Precision Potentiometers

● 2 pieces 15-pin female socket

● 4 pieces one pole pin bar (Possibly pre-assembled)

● 1 piece of LED ø3mm

● 12 pieces screw terminals, dual pole

● 2 pieces Screw Terminals, three pole

● 1 piece Capacitor

● 1 piece 5V Arduino Nano V 3

● 1 piece professional produced PCB with pre-installed SMD components

2.1.2 Required Tools:

● Soldering iron (30 watts)

● Soldering Tin ø0.5mm (e.g. Pb38Sn60Cu2) or equivalent.

● Side- or flat Cutter

● Well would also be a breadboard

2.2 Assembly of components

All parts are marked on the top of the board.

Now proceed as follows:

1. Insert the two 15-pin socket on the Arduino nano

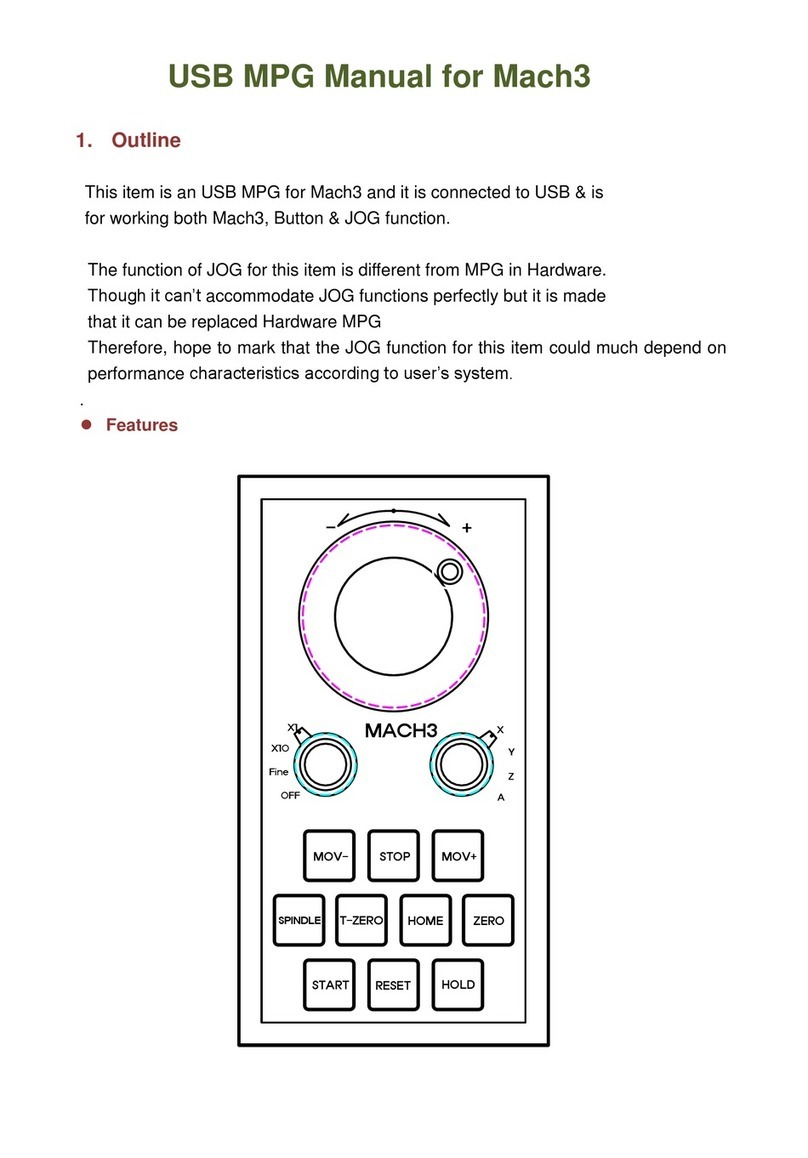

Figure 2.2.1

2. Place all Optocoupler and the 16-legged optocoupler as in

Figure 2.2.2 shown on the board and solder it.

Figure 2.2.2

3. Now place all screw terminals as shown in Figure 2.2.3 on the board and solder them.

Figure 2.2.3

4. Now place the LED on the PCB, attention check the polarity,

5. the longer leg of the LED is the anode (+) and solder it.

Figure 2.2.4

6. Now place the capacitor on the PCB, look the correct polarity, and solder it.

Figure 2.2.5

7. Now plug the Arduino Nano with the socket onto the board and solder it.

After soldering, please remove the Nano from the PCB!

Figure 2.2.6

8. Place the precision potentiometer on the PCB as shown in Figure 2.2.7 and solder it.

Figure 2.2.7

9. Now solder the four one pin strips at the corner on the DC-DC converter. If you have a

breadboard, you can do this to help you place the pins straight. If the solder are

already soldered, you can proceed to step 9.

Figure 2.2.8

10. Now place the DC-DC converter as shown in Figure 2.2.9 on the PCB,

11. Check the right polarity (inputs and output) and solder them.

Figure 2.2.9

12. Shorten the protruding legs of the LED, capacitor,precision potentiometer

and DC-DC converter.

13. Perform a conscientious visual check and watch for any short circuits!

3.0 Functional test

Estlcam: Version: 10,xxx

CNC Motion Controller: AC-CNC2017-2S (REV03)

3.1 Connecting of CNC Motion Controller

Connecting the control card:

Now insert the Arduino Nano into the CNC Motion Controller.

Supply CNC Motion Controller with 24VDC (screw terminal "24V in").

In attention check the correct polarity.

Connect the CNC Motion Controller to the computer using a USB cable.

3.2 Setting the EstlCam Software

Settings in Estlcam:

Open Estlcam and got to „Setup->CNC Controller“

Tap Basic settings:

● Preset: nothing

● USB/COM port: YOUR COM Port

● Pin layout: Estlcam

Figure 3.2.1

Tap Spindle (if you use a HF Spindle):

● Lower RPM limit: 6000 rpm

● Upper RPM limit: 2400 rpm

Figure 3.2.2

Please refer the datasheet (from spindle manufacturer) of your milling spindle

for the exact connections and speed limits.

Tap Inputs:

End-switch 1, 2, 3;Probe input (SE); Error input(FE)

● Enabled: on

● Inverted: on

● Pull up 5V: off

See Figure 3.5.1 below.

3.3 Programm the CNC Motion Controller

Programming the CNC motion controller card with the help of the Estlcam software

Tap basic settings:

Press the Button: „Programm Arduino“

3.4 Preparation

Tools:

You need a voltage meter and a through tester or a corresponding instrument.

You also need a short piece of wire with 3mm naked ends

as a wire bridge, and a small screwdriver.

3.5 Inputs and outputs

Test the inputs (SE, FE, E1, E2, E3):

Open Estlcam and got to „Setup->CNC Controller->Inputs“

Figure 3.5.1

At the screw terminals, use the wire to bridge the limit switch 1, 2, 3; Sensor input and

error input (E1, E2, E3, SE, FE).

Figure 3.5.2

If all the inputs are working, this was shown as "triggered".

If problems occur, program the controller new, check all solder, check the installation

direction of the Optocoupler.

Measure if the screw terminals are connected to the + 5V.

Test the Outputs (A1, A2):

Open Estlcam and got to „Setup->View->CNC controller“

Check the Checkboxes, „Output 1“ and „Output 2“.

Figure 3.5.3

Figure 3.5.4

If the outputs work properly, measure + 5v at the outputs.

If you have problems, reprogram the controller, check the installation direction of the

LTV846 chip. At the output of the DC-DC converter, measure the + 5V.

Figure 3.5.5

Additionally check all relevant solder connections.

Testing the output (SpRel) for switching relays/milling spindles:

Open Estlcam and got to „View->CNC Controller (F2)“

Figure 3.5.6

In the control, press the "play" icon, the spindle is now turned on and the symbol now

appears in red.

Figure 3.5.7

Now you should measure at the screw terminal, + 5 volts.

For problems, proceed as described in "Test the outputs (A1, A2)".

3.6 Inverter and HF milling spindle

Testing FOR/DCM:

In the Estlcam Software:

Open Estlcam and got to „View->CNC Controller (F2)“

In the window, press the "play" icon, the spindle is now turned on and the symbol now

appears in red. (See figure 3.5.6)

Check the passage from FOR to DCM, the red measuring line of your measuring

device to FOR and the black to DCM.

Figure 3.5.8

Now you should measure a current pass.

For problems, proceed as described in "Test the outputs (A1, A2)".

Setting and testing from output 0-10v:

In the Estlcam Software:

Open „View->CNC Controller (F2)“. (See figure 3.5.9)

Set the speed to the upper speed limit of your milling spindle e.g. 24000 rpm.

Figure 3.5.9

Place a voltage meter at the output "0-10v".

Figure 3.5.10

In the control, press the "play", the spindle is now turned on and the symbol now

appears in red. (See figure 3.5.6)

Figure 3.5.11

Use a screwdriver to turn the adjusting screw of the precision potentiometer (next to

the Arduino Nano) counterclockwise to increase the voltage or to reduce the voltage

clockwise.

Set the voltage to + 10.0 v.

If you have any problems, make sure that the 24V connection is in fact 24V and that

everything has been poled correctly.

Testing the voltage of output 0-10v:

Example of the following preset parameters:

Lower RPM limit (LR

) = 6000 RPM

Upper RPM limit (UR

) = 24000 RPM

Turn off the milling spindle.

Berechnung des Drehzahl-Mittelwertes :

Result = ( UR

- LR

) / 2

RPM = LR

+ Result.

Result = ( 24000 – 6000 ) / 2 =

9000

RPM = 6000 + 9000 =

15000

Set a speed of 15000 RPM.

Turn on the milling spindle.

Your meter should now display + 5v.

3.7 Testing the driver ports (optional)

Test your XYZ and step xyz with the help of an oscilloscope:

For this purpose we put scanner tip 1 on dir x and GND and scanner tip 2 at step x and

GND. If your oscilloscope only has one scanner, you can carry out the measurements

sequentially.

Figure 3.7.1

In the Estlcam Software:

Open „View->CNC Controller (F2)“.

Process the X axis.

Figure 3.7.2

Depending on the direction in which you use X method, the measured values shown in

Figure 3.7.3 are as follows.

Step is a PWM signal and dir depending on the direction low (0v) or high (5v).

Figure 3.7.3

As with the above connection pattern, you can test each axis.

Of course you can also measure with a multimeter, but with an oscilloscope you can

observe the interaction of the direction changes and methods of the axes better.

4.0 Start-up the finished control card

The commissioning of the control card includes an interaction of electronic components and settings

in the control software of your machine, here EstlCam.

4.1 Limit switches and Inductive sensors

Figure 4.1.1

The control card allows the connection of one limit switch or inductive sensor at the X, Y and Z

axes. The switches, together with the control software, ensure that your machine only travels

within defined limits. This effectively prevents damage to your machine in case of faulty

G-code instructions.

The limit switches are connected to the control card according to the following scheme:

Figure 4.1.2

The figure shows the connection of the limit switches with inverted setting in the Estlcam

software. If the limit switches are closed, this is shown in the software under "triggered".

In the Estlcam Software:

Open „Setup->CNC Controller ->(Tap) Inputs“.

Figure 4.1.3

Instead of the mechanical limit switches, you can also connect induction sensors that

are operated with 5 volts.

Figure 4.1.4

Connect the sensors and then measure the voltage that is connected to the E1-3

terminals, then you can adjust them up to 5v at the potentiometer of the DC-DC

converter.

4.2 Stepper Motor Driver Module

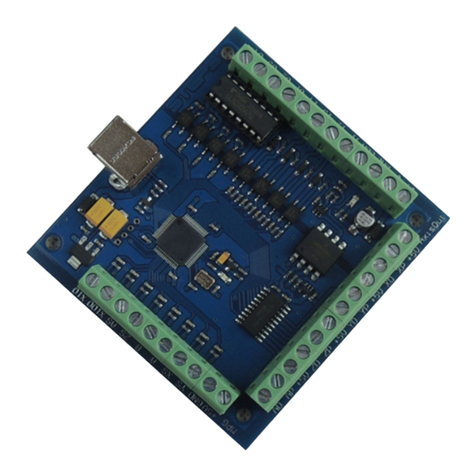

Figure 4.2.3

The control card allows you to connect up to three stepper motor drivers.

These connect your control card to the stepper motors, and supply them with electric power.

The drivers regulate the direction and speed of the stepper motors.

The stepper motor drivers are connected as follows:

Version 1: Drivers are supplied with power supply for the motors.

Figure 4.2.4

Table of contents

Other CNC Controllers manuals

Popular Controllers manuals by other brands

Unitronics

Unitronics Vision OPLC V350-35-TA24 installation guide

IMO Precision Controls

IMO Precision Controls i3 Tutorial

salmson

salmson COFFRETS EC-DRAIN Installation and starting instructions

ABB

ABB STD 420E manual

Philips

Philips TDA8002C datasheet

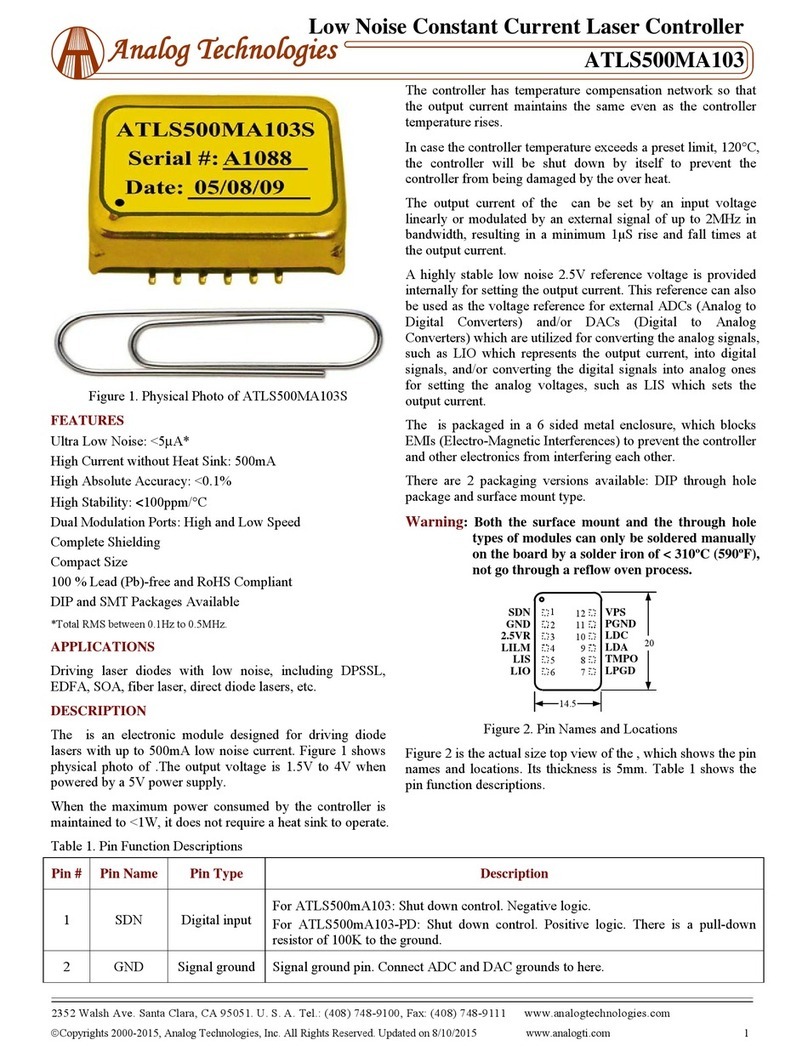

Analog Technologies

Analog Technologies ATLS500MA103 quick start guide