IMO Precision Controls i3 Operation instructions

Modbus Master

Modbus Master

Table of Contents

Table of Contents..........................................................................................................2

Introduction...................................................................................................................3

i3 Modbus Map...............................................................................................................4

Protocol Configuration.................................................................................................4

Device Addressing........................................................................................................8

Ladder Logic Programming .........................................................................................8

Screen Editor Programming.......................................................................................10

Screen 1.......................................................................................................................10

Screen 2.......................................................................................................................10

Screen 3.......................................................................................................................11

Wiring Diagram ..........................................................................................................12

MJ2 Pins......................................................................................................................12

Running the Program................................................................................................12

©IMO Precision Controls Ltd. 2

Introduction

The purpose of this tutorial is to demonstrate the Modbus Master communication

functions of the i3. Modbus has been an industry standard for many years with more

and more devices being Modbus enabled. Thus almost any device from Pressure

transducers, to remote I/O and inverter drives can be controlled by an i3.

In this tutorial we will demonstrate the i3as a Modbus master, controlling a network

of Modbus devices. The i3 can read and write to and from single and multiple registers

and is easily configured.

We will demonstrate the i3 as a Modbus master controlling 2 Modbus slave enabled

devices: an IMO Temperature controller and an IMO Jaguar Inverter Drive.

We will read and write the set point and current temperature to a DTP40A and read

and write the Frequency, and start and stop the Jaguar inverter.

Master. Station # :0 Slave 1. Station # : 1 Slave 2. Station # : 2

Network Parameters: Baud Rate 9600

Data bits 8

Stop bits 2

Parity None

RS485, two wire.

Please note the Drive and temperature controller will both have to have their own

parameters set up to accept the Modbus communication and network parameters.

Refer to the individual product manuals for this information.

www.imopc.com 3

Modbus Master

i3Modbus Map

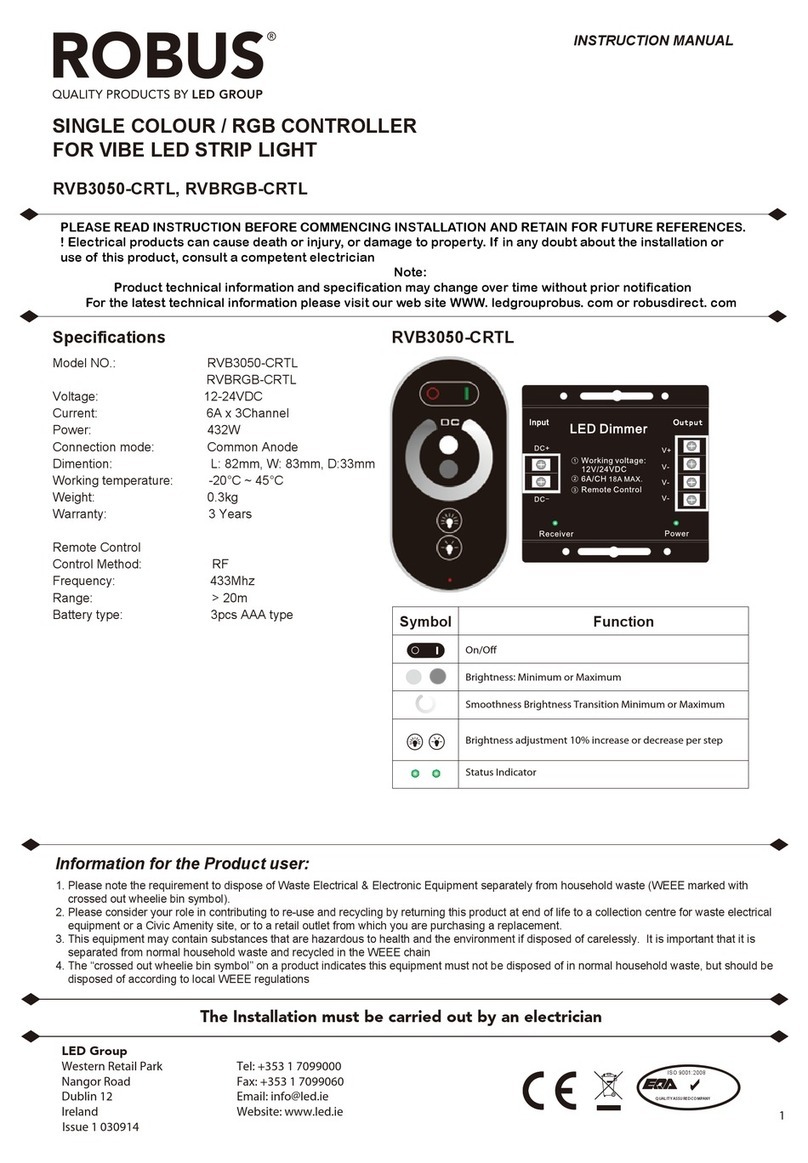

Modbus Master Mapping

Internal

Reference Maximum

Range

Traditional

Modbus

Reference

Expanded

Modbus

Reference Modbus Command(s) Modbus

Offset

%Q1 2048 00001 000001 00000

%M1 2048 03001 003001 03000

%T1 2048 06001 006001 06000

%QG1 256 09001 009001

Read Coil Status (1) Force

Single Coil (5) Force

Multiple Coils (15) 09000

%I1 2048 10001 100001 00000

%IG1 256 13001 103001 03000

%S1 256 14001 104001 04000

%K1 256 15001 105001

Read Input Status (2)

05000

%AI1 512 30001 300001 00000

%AIG1 32 33001 303001 03000

%SR1 32 34001 304001 Read Input Register (4) 04000

%AQ1 512 40001 400001 00000

03000

%R 9999 (Previously 43001

for 2048 registers) 410001 06000

%AQG1 32 46001 406001

Read Holding Registers (3)

Preset Single Register (6)

Preset Multiple Registers

(16) 10000

Protocol Configuration

The Modbus master is configured in the Program drop down menu.

We can then configure the programmable ports

of the i3. Select either Port 1 or Port 2, however

it is easier in this case to configure port 2 and

leave port 1 to solely programming. Each port

can have different protocols and therefore the

i3can be utilised as a data exchanger.

To configure the i3as a Modbus Master select

the protocol.

©IMO Precision Controls Ltd. 4

The Modbus master protocol utilises the Modbus function codes 03 to read single and

multiple registers, 10 to write to multiple registers and 06 to write to single registers.

Most Modbus slave devices only use the function codes 03 to read and 06 to write.

Therefore the i3 can communicate with any Modbus enabled device.

Now the protocol has been selected the 3 buttons can now be selected. Start by setting

up the network.

The network has to match the slowest device, so checking the equipments’

capabilities before setting up the network is essential. All devices on the network must

be configured to the same parameters.

In this small example the Network parameters to suit all devices will be:

Baud Rate = 9600, RS485 (Half Duplex), Modbus RTU, 8 data bits, 2 stop bits.

Protocol

help can be

accessed

here by

pressing

the button.

Once

complete

p

lease click

the OK

button.

To see the

status of

the network

assign a

%R register

here.

www.imopc.com 5

Modbus Master

Now that the Network has been set up we need to add the slave devices. Select the

Devices button to open up the editor.

This screen

will initially be

b

lank until you

set it up. To

add devices

click on the

Add button.

Enter a name for the device

and assign it a Modbus

address (1-255)

Some slave devices require

special options.

Just like in the network the

individual devices can have a

register set up to monitor and

control the status information

of the device.

Set up the two IMO devices to be:

Temperature Controller: ID 1, status register %R10.

VXM Inverter Drive: ID 2, no status register.

Once the devices have been set up click OK and set up the addresses of the two

devices we are going to read and write to. Select Scan List.

©IMO Precision Controls Ltd. 6

Select the Modbus device

register address and the

length of the data

The data in the device

address will be stored in

the i3locally where

specified in a particular

register

The type command and

update type are define

here. Whether the data is

read or write and polled

always or triggered on a

b

it.

In the Temperature controller we want to Read the Current Value (CV) and write to

the Set Point (SP). These addresses are:

We are going to read and write to similar in the VXM Drive. We want to read the

current frequency, write the set point, but also start and stop the drive. The associated

addresses are:

www.imopc.com 7

Modbus Master

Device Addressing

Function Device Modbus Address i3 Local Register

Set Value DTP40A 40002 %R3

Present Value DTP40A 40129 %R1

Set Frequency VXM 41797 %R4

Current Frequency VXM 42057 %R5

Start Drive VXM 01798 %M01

Ladder Logic Programming

Now that the protocol has been configured. We need to control the process. The user

will be able to set the desired temperature in the PID controller and then the i3 will

drive the VXM that controls a fan. The user can enter the frequency at which the

inverter will drive and also check the communication status of the network.

With the protocol set up in the Protocol Config, for the communications all we are

required to do is to open the port. Click the “open port” icon from the

Communication functions menu and insert it in a rung with an “always on” contact

Enter the details as shown opposite to

configure the port to the desired

communication parameters.

©IMO Precision Controls Ltd. 8

Next we have to enter the logic to control the fan for the reading of the temperature

controller. If the Present Value is greater than the Set Point then we need the fan to

switch on.

Select the Greater than icon from the Compare functions menu and insert it in a rung

with a N/O contact assigned to “always on”. Set up the function so that the inputs are

PV and SP. Have the output of the function driving a bit, %M1 named “Auto_Fan”.

Lastly we need to insert the logic for the manual override. The user will be able to

switch on the fan even when the temperature doesn’t demand it. To do this we are

going to “OR” the Auto_fan bit with a Man_Fan bit that then operates the Drive_Fan

bit, that is communicated to the VXM drive.

Insert a N/O contact and assign to %M1. using the Vertical line tool draw two

lines and the beginning and end of the previous contact. Insert a N/O contact in the

gap just created and assign to %M2. Connect this OR gate to a N/O coil and allocate

to %M3.

That is all the ladder logic required, thanks to the protocol config option.

www.imopc.com 9

Modbus Master

Screen Editor Programming

We need to set up three screens:

1. For entering the set point temperature and monitoring the present temperature

2. Frequency entry to the drive and manual override operation of the drive.

3. Communication status monitoring.

Screen 1

Insert a static text item an edit the legend to display “Cooling Fan Control”. Next add

two numeric data function. Assign the one to SP, with the following parameter

settings: digits set to two, limits 0-99, engineering units ‘degrees Celsius’ and

editable. Assign the second numeric function to PV with the same basic parameters,

except that it will not be editable. Finally insert a screen jump button, editing the

legend to display “Manual Override”, jumping to screen 2.

Screen 2

On screen two the user will be able to monitor the output frequency of the drive, set

the frequency to the drive and manually start the drive if need be.

Insert two numeric functions. The first will be editable and assigned to “Set_Freq”,

with parameters of: 4 digits, limits of 0 – 9999, legend = “Set”. The second will be

assigned to “Read_frq”, with the parameters of: non-editable, 4 digits, limits of 0-

9999 and a legend displaying “Actual”.

Finally there will be two screen jumps, one to return to the previous screen and the

second to jump to the communication status screen.

©IMO Precision Controls Ltd. 10

Screen 3

The third and last screen will display the communication status of the two devices as

set up in the protocol config.

Place two numeric data functions on the screen and one screen jump function two go

back to the first screen.

Assign one numeric function to the temperature controller status and the second to the

drive status, both will be none editable. Enter a static text field to inform the user of

what screen they are on.

www.imopc.com 11

Modbus Master

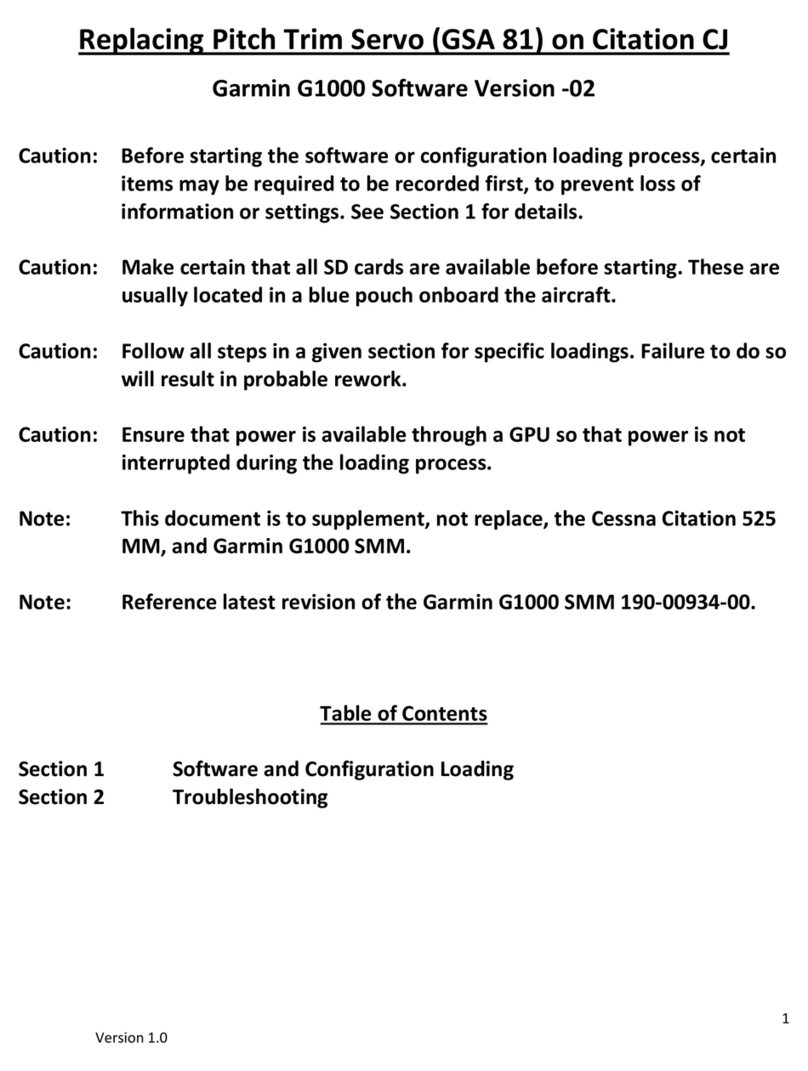

Wiring Diagram

We are using Port 2 on the i3 as a RS485, 2 wire to connect to the PMU330TT. The

wiring for this is as follows.

Port 2 connections. Pin MJ2 Pins

8 TXD OUT

7 RXD IN

6 0 V Gnd

5 N/C N/C

4 TX- OUT

3 TX+ OUT

2 RX- IN

1 RX+ IN

i3 to DTP40A & VXM / iDrive

Termination

resistor

MJ2

A

A

B

B

Factory Use

RS-485 Terminatio

n

for MJ2

RS-485 Terminatio

n

for MJ1

Remember to

connect the RS-

485 termination

j

umper as shown

Running the Program

Please connect the network as shown. Also note that the temperature controller and

drive need to have their communication parameters set appropriately.

Please use the program: Modbus_master.csp by clicking on the paperclip below.

©IMO Precision Controls Ltd. 12

www.imopc.com 13

Other manuals for i3

2

Table of contents

Other IMO Precision Controls Controllers manuals