CNC PYTHON XPR User manual

[USER GUIDE]

All rights reserved. This manual may not be reproduced or distributed, in whole or in part, without the prior written permission from CNC Factory. However,

reproduction and distribution, in whole or in part, by non-profit, research or educational institutions for their own use is permitted if proper credit is given, with full

citation, and copyright is acknowledged. Any other reproduction or distribution, in whatever form and by whatever media, is expressly prohibited without the prior

written consent of CNC Factory. For further information, please contact support@cncfactory.com.

CNC Factory makes no representations or warranties, express or implied, with respect to the content, accuracy, truthfulness or reliability of any information

contained in this manual, whether in full or in part, including any warranty of title, non-infringement of copyright or any other rights of others, merchantability, or

fitness or suitability for any purpose. Without limiting the generality of the foregoing, by using or attempting to use this manual, the user expressly acknowledges

that there are no warranties or representations made by CNC Factory regarding the content of this manual in terms of its accuracy or its completeness. In no event

shall CNC Factory be liable for any damages whatsoever resulting from, arising out of or in connection with the use of any information provided on this manual.

Furthermore, CNC Factory shall not be liable for any damages or losses suffered owing to any interruption in service or use of this manual.

[USER GUIDE]

Version 2021.5

Contents

GENERAL INFORMATION 5

For Your Safety 5

Router Specifications 5

General Warnings 6

Contacting Support 6

The Emergency Stop or E-stop 7

Maintenance 8

Connectivity 9

PARTS OF YOUR ROUTER 10

External Parts 10

Notable Terminology 12

UNDERSTANDING YOUR CONTROLLER 13

Main Controller vs. Control Cart 13

Parts of your Control Cart 14

BASIC OPERATIONS 17

Turning On the Router 17

Turning Off the Router 18

Getting Started with your Shortcuts 19

Main Screen 20

Operation Page 21

CNC Operation Controls 22

Auto Vs. Simulation Vs. Jog Mode 26

Utilities Page 27

CNC Utilities Controls 27

Advanced Page 32

Main Navigation Belt 33

Tool Measure Screen 34

Workpiece Coordinates Screen 36

Vacuum Zone Setup Screen 38

Run Screen 39

Function Keys Menu 41

Contents

STEP-BY-STEP GUIDES 43

Checking your Alarm History 43

Backing up your Files 43

Activating Function Keys 44

Executing your first (single) file 45

Using Working List/File 46

File Panel 46

Label Panel 47

Working List Step-by-Step 48

Changing your File Extension 49

Measuring Larger Tools 50

Adjusting Drill Block Offsets 51

CHECKLIST 52

5

GENERAL INFORMATION

Limited Warranty

Noise Emission

For your Safety

Router Specifications

As with all machinery, there are certain hazards involved with the operation and use of your router. Use it with

caution and at your own risk. Ignoring safety precautions may result in physical injury. When in doubt regarding its

installation and operation, do NOT use the equipment until you have consulted a CNC Factory technician.

Read the following carefully and fully before operating the router:

CNC Factory provides lifetime router support and warrants that it will be free of defects in workmanship

and materials for a period of 18 months beginning on the date of delivery. This warranty does not include

(wearable) parts consumed during normal operation or maintenance required in the ordinary course of

operation. For full warranty details, refer to the General Terms and Conditions for the Sale of Products and

Services signed during the purchase of this router.

This router is noise-emitting. However, the operator’s exact exposure to noise cannot be determined precisely

to set supplementary precautions, as it is affected by different factors, such as: duration of exposure, noise

from adjacent machines and other sources, characteristics of the work environment, etc. Noise emission

standards also vary country to country and we recommend consulting your local regulations. Wearing a

hearing protection device is highly recommended when operating this machine.

This guide is for the general operation of the Python XPR CNC Router. Since most routers are made-to-order, the

exact specifications of your router is found in your purchase order and its requirements in your pre-install guide.

1. Keep the work area clean and ensure adequate lighting is available.

2. Do NOT wear loose clothing, gloves, bracelets, necklaces, or ornaments that may be caught in the router.

3. Do wear face masks, safety goggles, ear muffs, and other body protection applicable for the operation or

environment.

4. Make sure the emergency stop ‘E-stop’ button is pressed when entering the router work area.

5. Ensure that the power is disconnected from the router before servicing.

6. Never leave the router running without supervision.

7. Do not use dull, deformed, or broken cutting tools.

8. Ensure that keys, adjusting wrenches, and all loose items have been removed from the router and stored in

a safe place.

9. Make sure all the nuts and bolts are secured in place.

6

General Warnings

Contacting Support

The program does NOT have an Undo button/option. If you configure and save the wrong

values by mistake, your only option to revert to the original is to type back the original

values and save again. If you do not remember the original values or are in doubt, please

contact your CNC Factory technician for help reverting to the original settings. Using

incorrect values may cause damage to your router or make it fail.

Critical interfaces that may cause irreparable damage to your router are usually

password-protected. This password is available upon request from your CNC Factory

technician. There will be advanced segments of the program that you will not need for

your day-to-day operations and are reserved for technicians’ use only, and they will be

identified as such. Please avoid tinkering with advanced features, which may or may not

be password-protected.

Improper operations that may cause the router to fail, damage it, or cause bodily

injury to the operator are prefaced with this warning sign.

Your lifetime technical support can be accessed by calling 714-581-5999* or online via:

We will try to resolve your issue as quickly as possible via phone call or remote access. Should those not

suffice, you may contact us at 714-581-5999 to talk about an on-site visit by a technician. Separate charges

may apply.

If you do not have a Zendesk

log-in, please contact support@

cncfactory.com.

*only available during regular office hours

LOG IN TO ZENDESK OPEN KNOWLEDGE CENTER

7

The Emergency Stop or E-stop

The E-stop is a safety feature that stops all operations of the router. You have three (3) emergency stop buttons

that are easily accessible while the router is operating:

To initiate an emergency stop, press the red button. Once pressed, the controller & router safety lights will turn red

to alert you that your router is stopped.

Pressing the E-stop sends an electrical pulse to the entire router that shuts all operations down

instantly— we recommend using it sparingly for emergencies and should not be utilized to

pause or as a regular stop button, as frequent use may damage your motors.

On the controller

To turn the router back on from an E-stop, turn the E-stop

button clockwise, in the same direction as the arrows

shown. The red safety lights will then turn to white.

For those on the gantry, a green ring appears when the

E-stop is disengaged. When pressed and engaged, the

green ring will disappear.

On both sides of the gantry

8

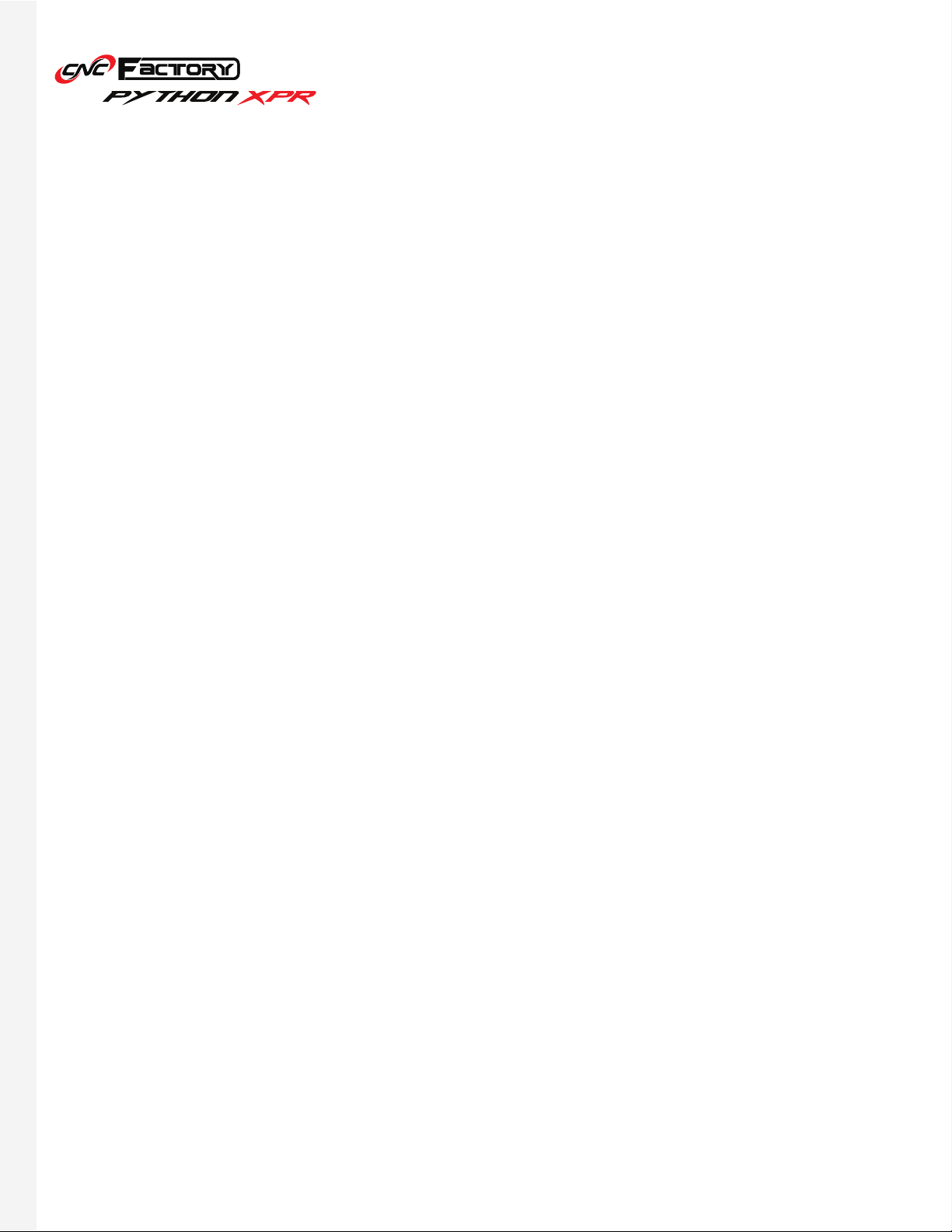

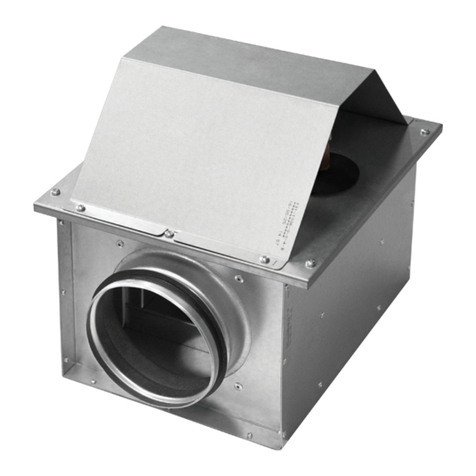

Lubrication

Daily Checks

Maintenance

Our routers come with a fully automated, pressurized lubrication

system for all the liner guides and ball screws. For best results,

use 000 Semi-Fluid Lithium Grease.

All helical racks & drill blocks require manual lubrication with

Klüber Isoflex Topas L32N Special low-temperature grease. As

a rule of thumb, apply 5cc of lubrication after every 40 hours of

operation.

1. Clean the router, wipe off any excess oil, and buff with a dry polishing cloth. This will reduce the chance for

dust build up.

2. Check all liner guides and ball screws. Make sure there is a thin layer of oil on it.

3. Check cutter teeth for chips and dullness.

When lubricating, jog the machine all the way up to

the area without the spoilboard, to avoid damaging it

in case of leaks or drips. Oil on the spoilboard can clog

it and affect material work holding.

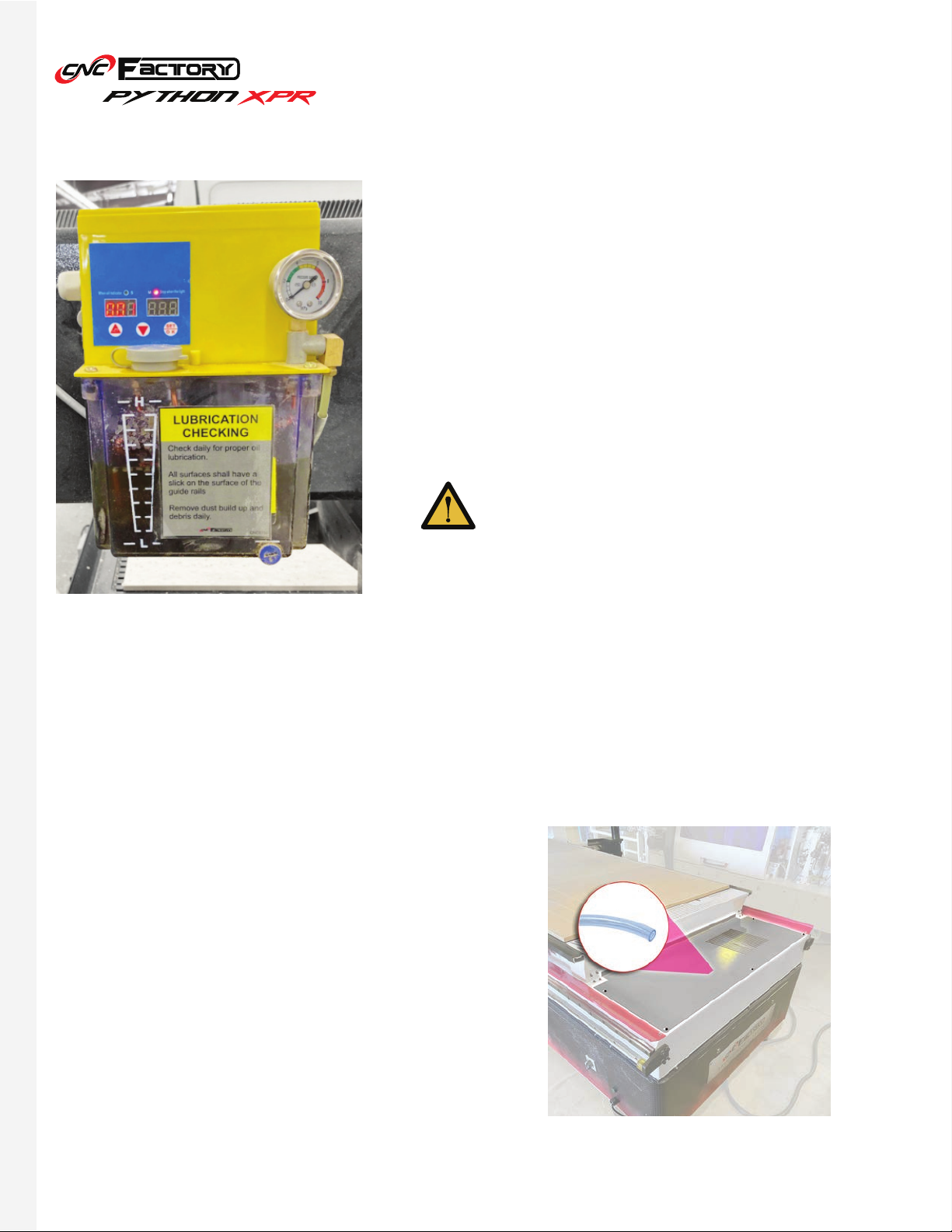

AC drain hose inside control cabinet

4. Collets and spindle collet holes must be cleaned

regularly. Ensure that the slots in the collets are free

of sawdust, as it can build up and prevent the collet

from compressing. If the collet or spindle holes

are clogged, the router bit may vibrate or get loose

while cutting. Serious spindle damage or bodily

injury may occur.

5. Check the AC unit drain, make sure it is not twisted

or leaking into the control cabinet under the router

bed.

9

Weekly Checks

Quarterly Checks

Annual Checks

1. Clean grease and dirt off the helical racks. Apply gear

grease on all helical racks.

2. Check the dust collection pipe and brush hood. Clean off

all debris and dust build up.

3. Generally inspect the router for any damage or loose/

worn parts.

4. Empty oil tray under the liner carts.

Conduct a drill block grease check.

Schedule an on-site service with a CNC Factory technician.

Connectivity

The Python has USB, WiFi and ethernet connections. It only requires the internet for virtual/remote access.

Configurations for your router’s connectivity will already be set-up by your technician during installation.

Oil trays

10

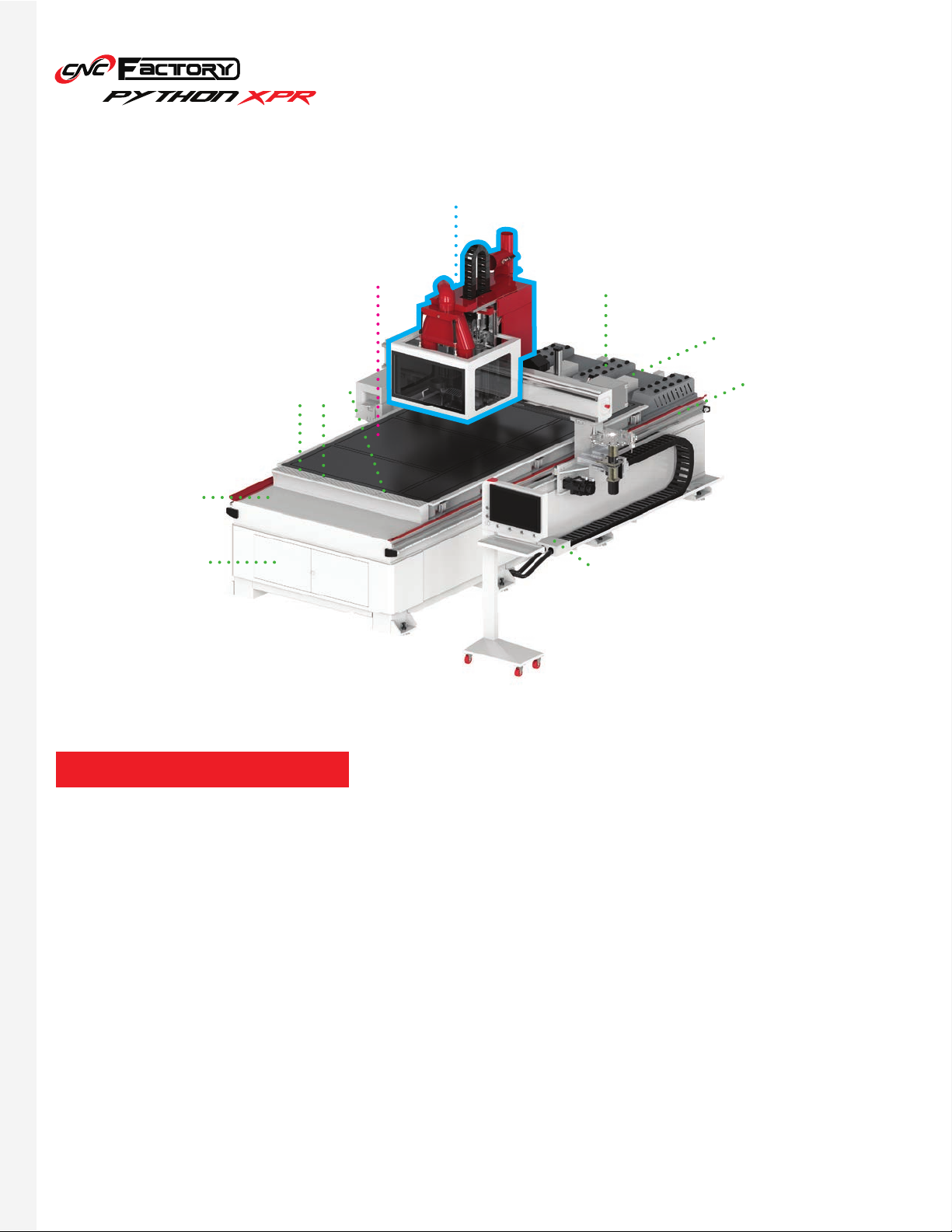

PARTS OF YOUR ROUTER

External Parts

10

Mobile Control

Cart

Machine

Safety Glass

Tool Carousel

Robotic Loading

Arm

Suction

Cup

Rear Pusher

Loading

Wheels

Safety Light

Metal foot

plates

Encased wiring

Servo MotorPlug & Play

Ports

Tool Carousel

Safety Light

21” touchscreen

Spindle

Machine

Safety Glass

Left Rail

Auto Tool

Measuring

Device

Air Pressure

Monitor

Right RailControl Cabinet

Drill block

slot

Gantry

Gantry

Label

Printer

Dust Extraction

Outlet

Dust Extraction

Outlet

11

Mobile Control

Cart

Cooling fans

Robotic Loading

Arm

Safety Light

Auto Tool

Measuring

Device

Main Contact

Switch

Digital vacuum

gauge

E-stop button

Servo Motor

Label Printer

Robotic

Dust Hood

Rear pusher

Rear pusher

Unloading Arm

Dust Extractor

Drill block

slot

Helical Rack

& Pinion Rail

System

2nd vacuum

pump switch

Tool Carousel

Plug & Play

Ports

Air Pressure

Monitor

Air Pressure

Monitor

Vacuum Ports Control Cabinet

Dust Extraction

Outlet

12

Notable Terminology

Refers to the block of components responsible for cutting that is anchored to the gantry (includes the

spindle, drill block, and dust hood). Whenever there is a mention of machine movement, it refers to this block

(and not to be confused with the router, since the router, after all, is stationary during operations).

Refers to the entire Python XPR, including its controller/control cart.

Router

Machine

Location Pins

Control Cabinet

Unloading conveyor

will be connected

here

Loading table will be

connected here

The “machine”

Dual layer, high

flow phenolic

vacuum table Loading

Wheels

Helical Rack

& Pinion Rail

System

Plug & Play

Ports

13

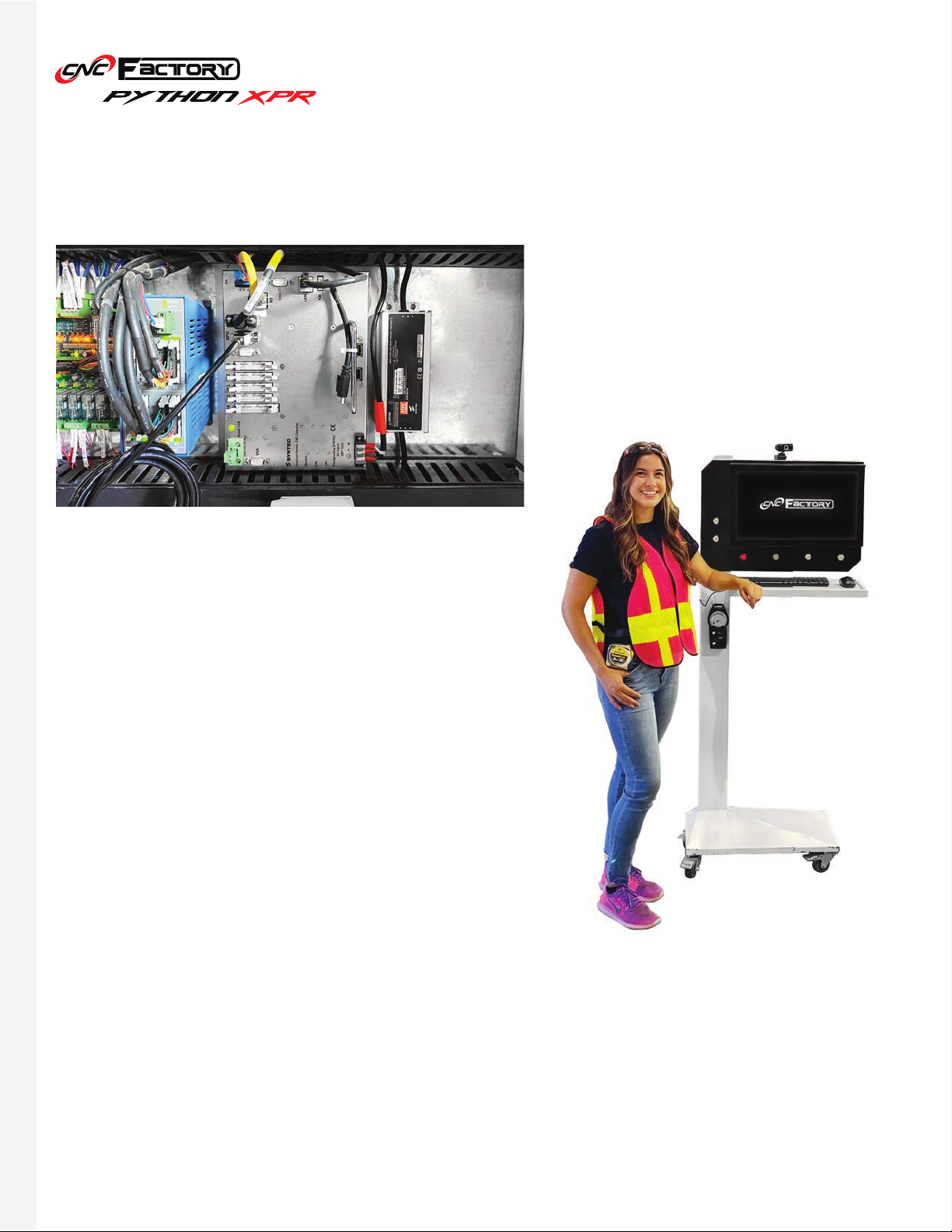

UNDERSTANDING YOUR CONTROLLER

Main Controller vs. Control Cart

(ABOVE) Your actual,

main

controller is located inside your

router cabinet. This is the brain of the machine. You may

operate the router directly by connecting a screen directly

to its VGA port, and importing files through its USB ports. We

recommend this option for advanced technicians.

(RIGHT) This “controller” is a PC with a Windows operating

system, and is sometimes referred to as the “control cart”. An

emulator allows this to behave similarly to your main controller.

We recommend using this in operating the router since it has

a bigger, touchscreen display, as well as the familiar Windows

system that is more user-friendly.

It is important to note the difference since some operations on the Python are typically used only for the main

controller and not for the PC controller/control cart. In this manual, we may also use the term “controller”

interchangeably for both. However, for clarity, when talking about the “main controller”, we are only referring to

the one inside your router.

14

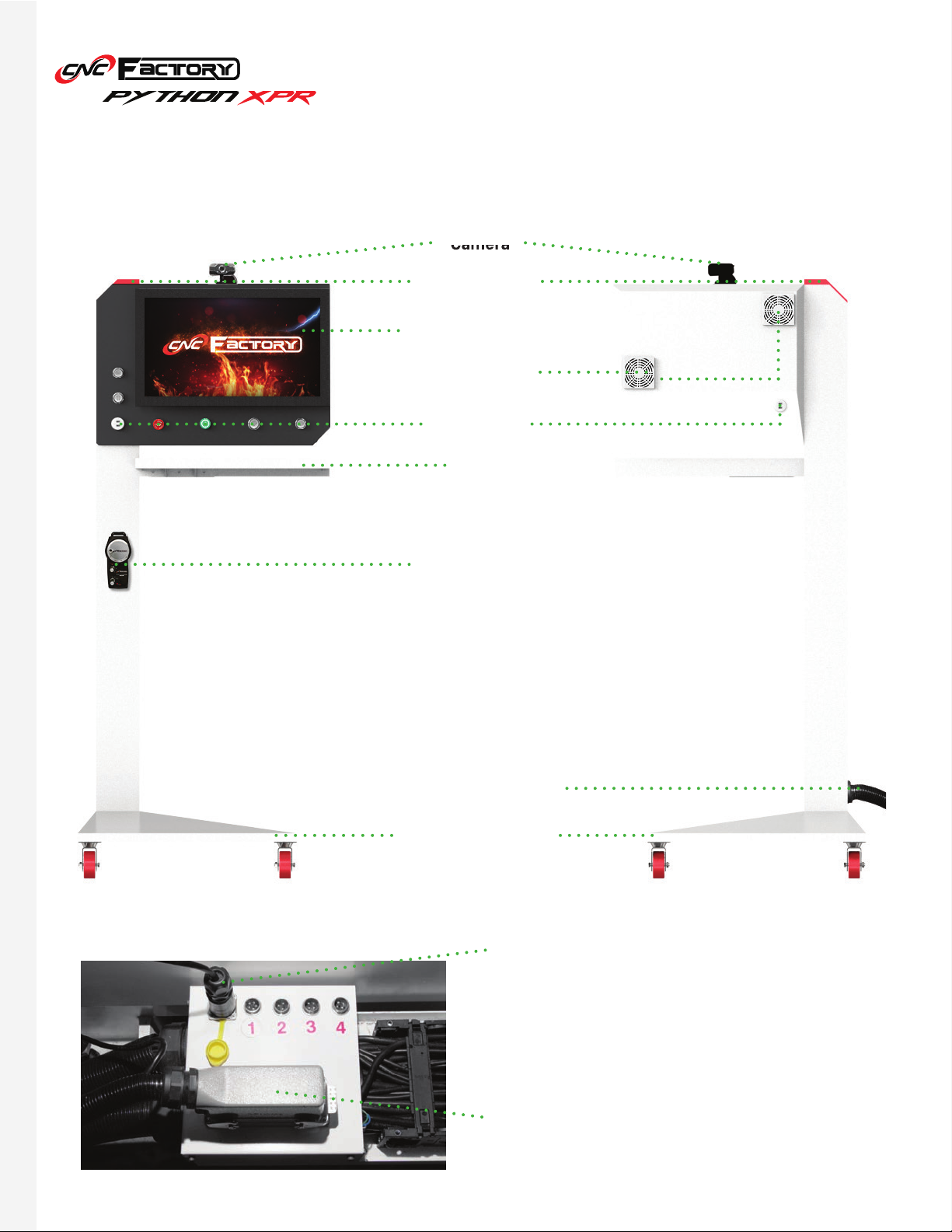

Camera

Parts of your Control Cart

Camera

Safety Light

21” Touchscreen

Cooling Fans

MPG Remote

Base with lockable

wheels

USB Ports

Desk

Power & Signal Cord

Powers up the CPU & Screen.

Sends a network signal to the main controller.

1: Loading table power 3: Unloading table data

2: Unloading table power 4: Light curtain

*Soon, a 5th port for loading table data will be available.

Power Cord

Signal Cord

15

Tells the router’s current operating status. For the XPR series, the rear side of the routers have similar safety lights.

• White Light- Static mode: no operation is in progress and the router is ready for a command. In this mode, the

bottom right of the screen will display “Ready”

• Red Light- Alarm mode: there is an operational issue or error. In this mode, the ‘Alarm’ display at the bottom

right of the screen will blink red with “Not Ready” beside it.

• Green Light- Operation mode: operation is in progress. No other command may be executed unless the

current operation is stopped. In this mode, the bottom right of the screen will display “Busy”.

Safety Light

Start Button

Pause Button

Press to start operation. You will have to physically press the button to run a program. This is intentional to prevent

unintended starting from accidental pressing of touchscreen buttons or to prevent people with internet access to

your controller from operating your router remotely.

Pauses the operation. While on pause, your router is still fully powered, motors are still running, the spindle or drill

block are still spinning (although the feed will be zero), and it will not affect all other commands that are queued

up. To resume operation, press the Start button again.

Start Button

Safety Light

Pause Button

USB Ports

Power

Button

Vacuum ButtonsE-Stop

Button

Camera

16

USB Ports

E-Stop Button

Vacuum Buttons

Move clockwise to move on an axis’ positive direction. Move

counterclockwise to move on an axis’ negative direction.

Controls the range of movement (either by 1mm, 10mm, or

100mm increments).

Status lights (1st bar: power indicator, 2nd bar: signal

quality, 3rd bar: low battery).

The MPG remote requires two AA batteries. Remove the protective rubber case

to access the battery terminal (at the back).

Dual ports for importing files or connecting wireless devices (keyboard, mouse).

Instantly shuts everything down including power to the loading and unloading tables (if available). You will need to

restart all files interrupted by this shutdown.

Sends signals to the vacuum box to turn on/off your vacuum pumps. Each button corresponds to a designated

pump (maximum of 2 vacuum pumps).

Controls the axes

• Turning all the way counterclockwise turns the remote

off. Selecting an axis automatically turns it on.

Wireless Handheld MPG Remote

Power Button

Turns the controller and the router on/off. When turning it on, allow a few seconds for the controller to power up.

Once the safety light turns white, it means the main controller is operational and you may click on the Viper icon

on your desktop.

If there are pending alarms, the safety light may light up red after powering on.

Before turning off your router, we recommend shutting down the PC before pressing the power

button. Skipping this step may degrade your PC over time.

17

BASIC OPERATIONS

Turning On the Router

1. Make sure there is no object or person around the router’s motion area to prevent collision.

2. Make sure power and air are connected to the router.

3. Make sure all the E-Stop buttons are released.

4. Rotate the main contact switch clockwise until it clicks in place.

5. Press the green power button on the control cart. The power is on once it turns red.

It may seem counterintuitive, but RED light = controller is ON

GREEN light = controller is OFF

6. After booting into Windows, wait for the Safety Light to turn on, then double click the Python icon on the

desktop and wait for the program to initialize. If you click the Python icon before the safety light comes on,

a Connection Setting window may appear. Just press [F2 IP Connection] to resolve this error.

7. Press and hold the button on the spindle to put the previous tool back into the spindle. Release the button

to lock the tool.

8. Make sure no alarm is pending or flashing. Go to the Utilities screen, click [Spindle warm up].

9. Once the spindle warm up is completed, the machine is ready to use.

Main contact switch at the side of

the router.

Power button on the control cart. Wait for the safety light to turn

white before starting the program.

Python program icon

on the controller

desktop.

Utilities

Screen Tab

Spindle Warm

Up button

Warm up the spindle only

during intitial spindle

setup or when not in use

for a prolonged time.

Otherwise, you can warm

it up once a month.

18

Turning Off the Router

1. On the Utilities screen, switch to Jog Mode by clicking on the [Jog] button.

2. Jog the machine to the tool changer side, press and hold the button on the spindle to release tool and put

that tool in the tool changing station.

3. Jog the Z-axis all the way up.

4. Close the Python software by click the top right X.

5. Shut down Windows.

6. Press the power button on the control cart.

7. Rotate the main contact switch to the OFF position.

8. Disconnect air from the router. Your drill block will drop down after air is disconnected.

As long as you jog the Z-axis all the way up BEFORE turning the machine off, it

should not hit your vacuum table.

Utilities Screen

Tab

Close

Window

Jog button

Z-axis controls

19

Getting Started with your Shortcuts

By default, you will have the following shortcuts pre-installed on your controller’s desktop:

To begin operating, click on the Python icon on your desktop. After loading, you will see the Main Screen.

This is where you upload all your files from your CAD/CAM software. When saving files here, we

recommend saving all files of a single job in 1 folder. We do not recommend saving a folder inside another

folder (or multiple file levels) as this may cause a program error.

The program contains all the controls for

all

functionalities of CNC Factory 5th generation

routers. Further upgrades may be required on your router to perform all these functionalities.

Please contact support@cncfactory.com if you wish to upgrade your router.

• Python icon

• CNC File folder [This PC > Local Disk (C:) > Network > CNC > NcFiles]

20

Main Screen

This is the first screen you see after opening the Python shortcut. It shows real-time information of your machine

location and speed. These will make better sense once you have gone through the rest of the operations in this

manual. There is no action needed on your part for this screen.

This standard CNC display shows the following information:

Feed Speed

Spindle Speed

Axes Info

Function Keys Menu

Date Time Main TabsCurrent File

Main Navigation Belt

Back Button

Press to go back to

the previous page,

or multiple times to

return to the Main

Screen.

Table of contents

Other CNC Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Rodix

Rodix FEEDER CUBE FC-40 Plus Series Adjustments and Set Up

ABB

ABB HT611078 Operation manual

Tyco Electronics

Tyco Electronics DT-3000 Customer's manual

SAMCHULLY

SAMCHULLY TS Series instruction manual

Salda

Salda AVS Series Mounting and installation instructions

ABB

ABB PVI-6000-TL-OUTD-W Quick installation guide