CNC 3018-PRO User manual

1

Contents

Parts list·························································1

Machine Installation·········································· 4

Grblcontrol····················································11

Getting Started··············································· 14

Lasergrbl······················································ 15

Offline controller·············································18

Common Problem············································21

1

Parts list

Serial

number

Name

Type

Qty

Picture

1

working desk

15*180*300mm

1

2

Aluminum

20*40*290mm

2

3

Aluminum

20*20*290mm

2

4

X Linear guide

Φ10*360mm

2

5

Y Linear guide

Φ10*290mm

2

6

X screw

T8(365mm)

2

7

Y screw

T8(295mm)

2

8

Bakelite

1

9

Stepper motor

42*34mm

2

10

Spindle

775ER\100w\8000rmp

1

11

X Z-Parts

1

12

Y-Axis slider

10mm

4

2

13

Y-Axis nut seat

T8-4

1

14

Milling Cutter

Φ3.175mm\20°\0.1mm

10

15

Spindle wires

60mm

1

16

Stepper wires

60mm

3

17

Offline

controller(Optional)

1

18

Power Supply

24V\5A

1

19

Control Board

1

20

USB Cable

1.5m

1

21

Plate Clamp

4

22

Winding Tube

2m

1

23

U Disk

4g

1

24

Allen Wrench

2mm

1

2.5mm

1

3mm

1

3

4mm

1

25

Bolt

M5*10mm

4

M5*16mm

43

M4*14mm

8

26

Copper Nut

2

27

T Nut

M5*20

16

28

Slider Nut

M5*30

10

29

Spring

0.8*12*30mm

2

30

Coupling& Set Screw

5*8mm

2

31

ER Wrench

13*87*2mm

1

17*88*2mm

1

32

Brush

1

33

Rolled Strip

1

4

Machine Installation

Bakelite:

STEP1 Base Installation

5

Step2 Table Installation

Note: First fix one end of the coupling to the 42 stepper motor, and then fix the 42 stepper motor to the

aluminum profile

Completed

6

Step3 Base & Bakelite-C Installation

Note: the distance between Bakelite-C and 2040 aluminum profile is 37.5mm, and Bakelite-C should be kept at

90°from the bottom

Tips: First put the T-nut in the gap of 4040 aluminum profile, corresponding to the hole, and then tighten the

screw

Completed

7

Step4 X-Z Axis Assembly Installation

Note: 1. First fix the coupling to the 42 stepper motor, and then fix the 42 stepper motor to the bakelite-C.

2. First fully insert the spring and brass nut into the Z-X axis assembly, and then tighten the X screw.

Step5 Bakelite-D Installation

8

Completed

Step6 Spindle Installation

9

Note: The screw M4*30mm here requires a 3mm hexagon wrench. When connecting the spindle motor cable,

observe the direction of spindle rotation and turn clockwise to indicate that the connection is correct.

Otherwise, change the connection position.

Step7 Control Board Installation

Note: only need to fix the screws in the upper row

10

Step8 Wiring Diagram

11

Grblcontrol

1、Install the driver(software->Drive->CH340SER.exe)

Note: You need to exit the anti-virus software before installing the driver

2、Determine your Machine's COM port:

Windows XP: Right click on "My Computer", select "Properties", select "Device Manager".

Windows 7: Click "Start" -> Right click "Computer" -> Select "Device Manager" -> "Ports (COM &

LPT)"

Your machine will be the USB Serial Port (COMX), where the “X” represents the COM number, for

example COM5.

If there are multiple USB serial ports, right click each one and check the manufacturer, the machine will

be "CH340".

Note: You need a USB cable to connect the control board and the computer to see the port number.

12

3、Open GrblControl software(software -> Grblcontrol -> grblControl.exe)

Tips: Right-click "Send to", select "Desktop Shortcut", and then you can open it directly on the desktop.

●Console window print ” [CTRL+X] < Grbl 1.1f ['$' for help]” If the connection is successful.

●Console window print ” Serial port error 1: No such file or directory “ indicate that the connection is

failed.

13

Grblcontrol Use

Toll setting

Note: When performing knife setting, when the moving knife just touches the object, click "Zero xy" and

14

"Zero z", and finally click "Send".

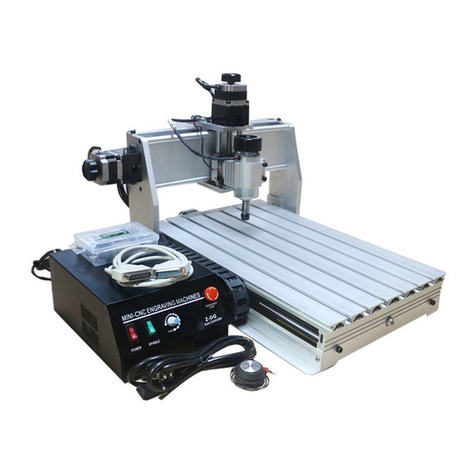

Getting Started

After the machine is assembled, you can perform basic machine tests. The following is the recommended

start up sequence for the system:

1.Confirm that the USB cable of the control board is plugged into your computer, and then start the computer.

2.Start the Candle software and verify in the status window that no errors are displayed. Under normal

circumstances, when the control board is connected to the software, it will display "Idle". If a red error

"alarm" appears, you need to click the "reset" of Candle with the mouse, and then click "unlock" to reach the

"idle" state.

3.Make sure that the 24V power supply is connected to the control board first, and then the other end is

connected to 110V-220V. Press the white "on/off" button on the control panel.

4.Next, click the "Spindle" button to turn on the spindle motor. Move the slider left and right to verify

whether the motor speed changes.

5.Adjust the value of "Feed" to the range of 200 to 500. Use the mouse to click the direction button on the

left to confirm whether the X axis and Y axis are moving. In a similar manner, click the up and down buttons

on the far right to verify that the Z axis moves normally. If there is no problem with all these tests, it means

that your engraving machine can work normally. Shut down the machine using the reverse start process.

6.Close the control panel.

7.Unplug the 24V DC power supply from the power supply.

8.Close the Candle program and turn off the computer. Remember, if you run the machine offline, the USB

cable must be disconnected from the control board.

15

Lasergrbl

1.Install lasergrbl software: Before installing the software, we have to install the CH340SER

driver on the computer ,Then use the USB cable to connect to the computer (don't

plug it offline), open the Lasergrbl software (laser->Lasergrbl) and install .

●Console window print ”Grbl 1.1f ['$' for help]”If the connection is successful.

●If the port selection is wrong, no information will be returned.

2.Turn on the laser, adjust the laser focus

The laser will be turned on with low power model. Then Rotate the lens to minimize the spot.

16

3.RASTER IMAGE IMPORT

Raster import allows you to load an image of any kind in LaserGRBL and turn it GCode instructions

without the need of other software. LaserGRBL supports photos, clip art, pencil drawings, logos,

icons and try to do the best with any kind of image.

It can be recalled from “File, Open File”menu by selecting an image of type jpg, png or bmp.

17

Click this button to start if use the computer control.

Notice: speed and S value are different with material,it is recommended that the

speed of engraving mode is 500~1000, the power is 500~800, the speed of cutting

mode is 50~300, and the power is 900~1000.

Tips: Enter "$32=1 in the control window ,It can be set to M4

laser mode for better engraving effect.

4.If you use offline controller, you can save the program as an "NC" file

18

Offline controller

1.Connect offline controller to computer via USB cable(can not connect offline

controller line)

Note: Use USB cable to transfer files, don't insert SD card into card reader to transfer, it is

easy to crash.

2.Copy the NC file to offline controller

Table of contents

Other CNC Industrial Equipment manuals