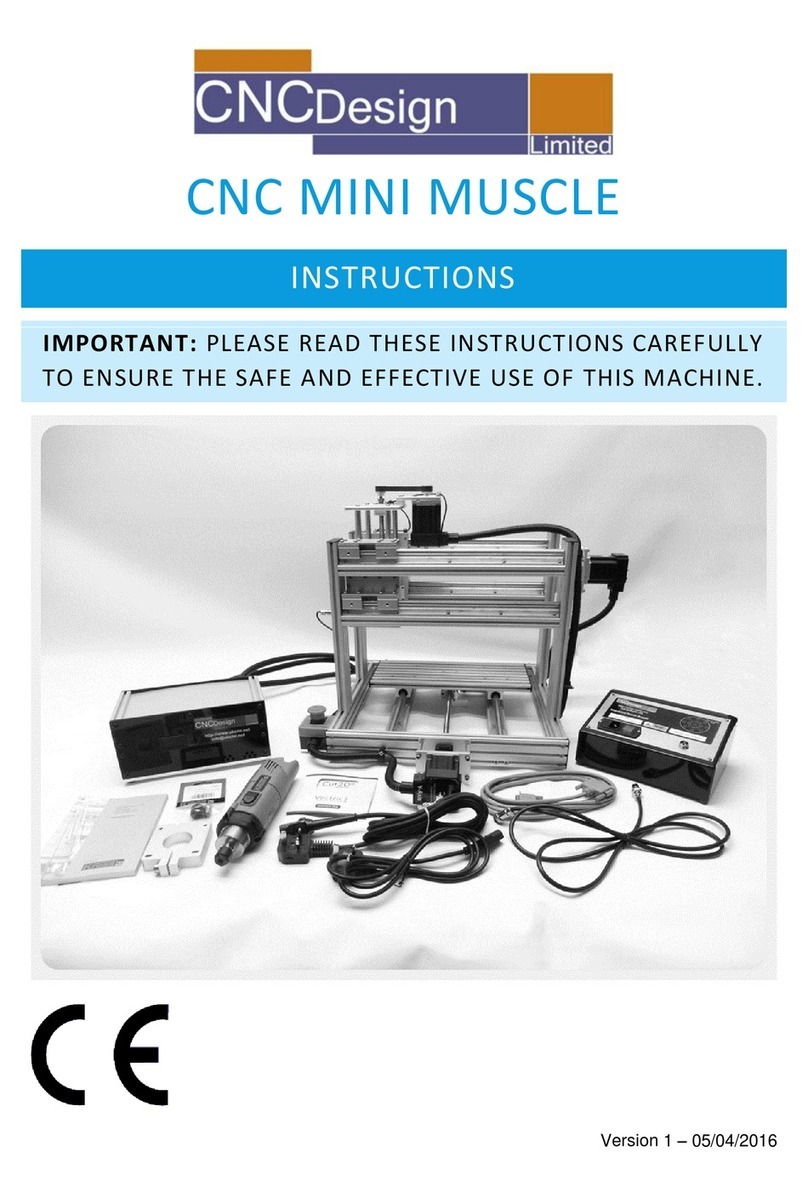

CNC MM32L User manual

Other CNC Power Tools manuals

Popular Power Tools manuals by other brands

Atlas Copco

Atlas Copco ETP TBP131-150-13 Product instructions

RIDGID

RIDGID R883 Operator's manual

molex

molex RAST 5.0 Arbor Press Terminator Operation manual

Chicago Electric

Chicago Electric 41053 Set up and operating instructions

BGS technic

BGS technic 9919 instruction manual

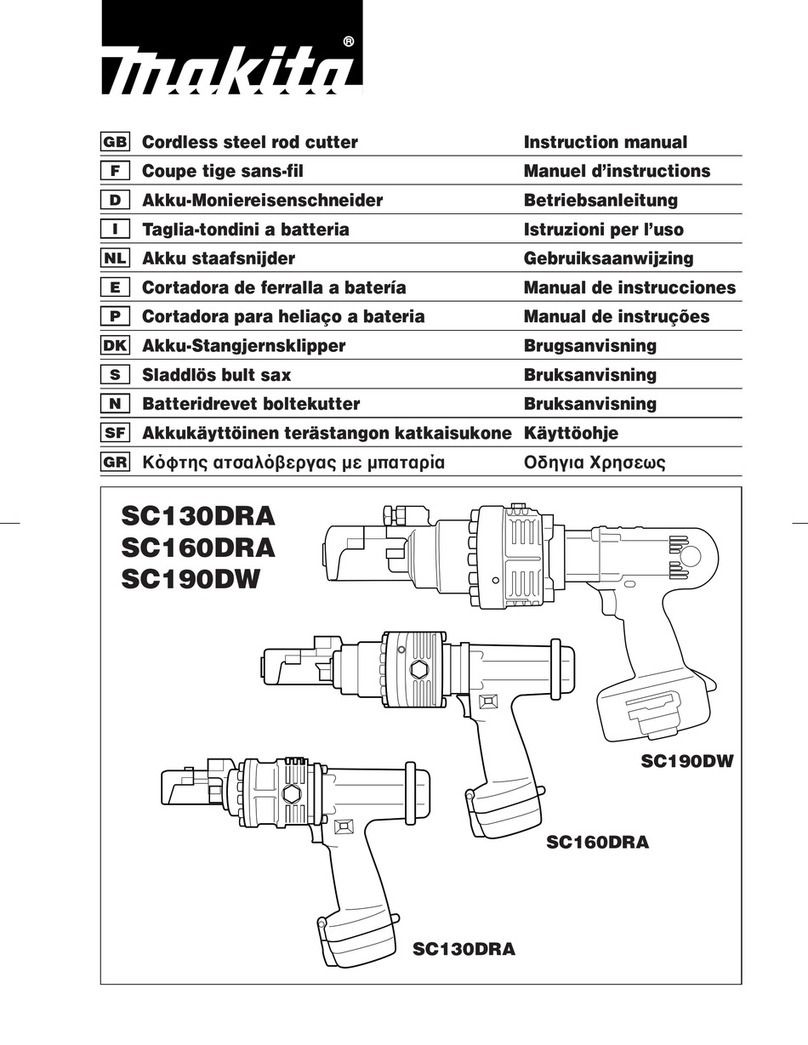

Makita

Makita DTW450 instruction manual