CNC4PC UC300ETH User manual

___________________________________________________________________________

USER’S

MANUAL

VER.1

C76- MULTIFUNCTION CNC BOARD

Rev. 3

OCTOBER 2021

___________________________________________________________________________

Contents Page #

FEATURES.....................................................................................................................3

I/O SPECIFICATIONS.....................................................................................................4

BOARD DESCRIPTION..................................................................................................5

POWER TERMINALS AND CONFIGURATION JUMPERS............................................5

4.1 Power terminal...........................................................................................................5

4.2 Source Output 5VDC.................................................................................................6

4.3 Source Output 10-24VDC..........................................................................................6

4.4 Input terminals for port_1 and port_2 ......................................................................6

4.5 Select inputs of port_1 and port_2...........................................................................7

JUMPER POSITION .......................................................................................................9

5.1 Selecting the SCHP operation mode........................................................................9

5.2 Jumper configuration driver enable.......................................................................10

5.3 Jumper configuration driver fault...........................................................................10

5.4 Configuration jumper pin 16 or 17.........................................................................10

LPT_3 AND LPT 5 INPUT EXPANSION PORT............................................................11

LPT_4 OUTPUT EXPANSION PORT ...........................................................................12

ANALOG I/O PORT PINOUT........................................................................................13

CONNECTION EXAMPLE FOR SHIELD C78 ..............................................................14

9.1 RJ45 shield C78 connection for axes, Limits and Encoder..................................14

9.2 RJ45 shield board description................................................................................14

9.3 Pinout.......................................................................................................................15

CONNECTION EXAMPLE FOR SHIELD C77 ..............................................................16

10.1 Terminal Shield Screw-on.......................................................................................16

10.2 Shield board description.........................................................................................16

DRIVER DISCONNECTION JUMPERS........................................................................17

E-STOP TERMINAL......................................................................................................17

TYPICAL CONNECTIONS............................................................................................18

LED INDICATOR ..........................................................................................................19

WIRING SAMPLE ENCODER ......................................................................................21

DIMENSIONS................................................................................................................22

___________________________________________________________________________

USER'S MANUAL TABLE OF CONTENTS

FEATURES

•Designed for UC300ETH motion controller.

•3 Expansion Ports. It has 3 x IDC26 connector for adding Breakout or

Relay Boards.

•Built-in PWM-Based Speed Control and Two Built-in Electromechanical

Relays with NO and NC positions for spindle control.

•The system monitors:

-E-Stop

-Safety Charge Pump.

-VFD Fault.

-Driver Fault.

•Outputs can be 500mA open collector or +5vdc at 50mA TTL.

•Electromechanical Relay with NO and NC positions for general purpose

(Port_2 16 or 17, jumper-selectable).

•Microcontroller based SCHP.

•Optoisolated inputs working at 5-24VDC.

•Can be powered with a voltage between +10 and +24VDC.

•Status LEDs on all input and Output connections.

•DIN Rail mountable.

•Pluggable Screw-On Terminals.

•It is compatible with family of C34 connector boards that allow quickly

connecting to popular drives connecting not just the step and direction

signals, but also the fault and enable signals.

•High speed input *New

___________________________________________________________________________

I/O SPECIFICATIONS

Inputs and Outputs are jumper selected to be TTL or Open collector.

PINS

PORT1

PORT2

PORT3

PORT4

PORT5

TOTAL

INPUT

5

13

13

5

13

49

OUTPUT

12

4

4

12

4

36

TOTAL

17

17

17

17

17

93

OPTOISOLATED DIGITAL INPUT TTL SPECIFICATIONS

On-state voltage range

5 to 24VDC

Maximum off-state voltage

0.8V

Typical signal delay

2.8uS

DIGITAL OUTPUT TTL SPECIFICATIONS

Maximum output voltage

5VDC

Maximum output current

24mA

Maximum off-state voltage

0.44 V

Maximum supported frequency

400KHz

Typical signal delay

10nS

Time of transition to high impedance state

12nS

___________________________________________________________________________

BOARD DESCRIPTION

POWER TERMINALS AND CONFIGURATION JUMPERS

4.1 Power terminal

The board requires an external power supply which can deliver 10-24VDC@700mA to power

the logic of the board and the UC300, but keep in mind that each output can deliver up to

500mA and if powering other breakout or relays boards. So, you will need to add all the

expected power consumption.

___________________________________________________________________________

4.2 Source Output 5VDC

4.3 Source Output 10-24VDC

10-24VDC can be sourced to sensors or other cards requiring it.

4.4 Input terminals for port_1 and port_2

These terminals support signals 10-24VDC, you can connect sensors NPN, PNP, switches,

capacitive sensors, etc. set jumpers depending on signal voltage.

PORT_1

___________________________________________________________________________

PORT_2

HIGH SPEED INPUT PORT_2 PIN 2, 3, 4 AND 5

These terminals support signals 5VDC

4.5 Select inputs of port_1 and port_2

Set the Jumper to COM = +5VDC, GND or 10-24VDC to determine the common for the input

signals to be used.

___________________________________________________________________________

___________________________________________________________________________

JUMPER POSITION

5.1 Selecting the SCHP operation mode

The Safety Charge Pump uses pin 17 on port 2. When the SCHP is enabled on the board, then

the output of the terminals will be active while the Safety Charge Pump signal is present and

inactive while the SCHP is not present.

1-2: SCHP ON 2-3: SCHP OFF

Note: also, that Relay3 on can also be tied to pin 17 or 16 on port 2. If the jumper is set

to be tied to pin 17, then the relay will activate while the system is active. This can be

ideal to control power to DC servos or to handle servo brakes. Or enable/disable any

other feature that is associated to the system been active.

___________________________________________________________________________

5.2 Jumper configuration driver enable

When you need to use the Driver enable to ON put the jumper, if you need it OFF remove the

jumper

1-2: Driver enable ON 2-3: Driver enable OFF

5.3 Jumper configuration driver fault

When you need to use Driver Fault to ON set the jumper, if you need to OFF remove the

jumper.

1-2: Driver fault ON 2-3: Driver fault OFF

5.4 Configuration jumper pin 16 or 17

1-2: PIN16 2-3: PIN17

___________________________________________________________________________

LPT_3 AND LPT 5 INPUT EXPANSION PORT

LPT 3/LPT 5

Equivalent P.P. Pin

UC300 Function

P_1

OUTPUT

P_2

INPUT

P_3

INPUT

P_4

INPUT

P_5

INPUT

P_6

INPUT

P_7

INPUT

P_8

INPUT

P_9

INPUT

P_10

INPUT

P_11

INPUT

P_12

INPUT

P_13

INPUT

P_14

OUTPUT

P_15

INPUT

P_16

OUTPUT

P_17

OUTPUT

P_18

GND

___________________________________________________________________________

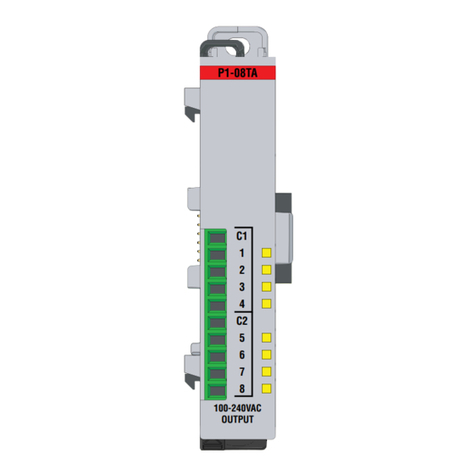

LPT_4 OUTPUT EXPANSION PORT

LPT 4

Equivalent P.P. Pin

UC300 Function

P4_1

OUTPUT

P4_2

OUTPUT

P4_3

OUTPUT

P4_4

OUTPUT

P4_5

OUTPUT

P4_6

OUTPUT

P4_7

OUTPUT

P4_8

OUTPUT

P4_9

OUTPUT

P4_10

INPUT

P4_11

INPUT

P4_12

INPUT

P4_13

INPUT

P4_14

OUTPUT

P4_15

INPUT

P4_16

OUTPUT

P4_17

OUTPUT

P4_18

GND

___________________________________________________________________________

ANALOG I/O PORT PINOUT.

The analog port contains 2 analog inputs and 2 analog outputs. This port also contains a 5Volts

power output.

Pin

Signal direction

1

5 Volt output

2

Ground

3

Analog input 1.

4

Analog input 2.

5

Ground

6

Analog output 1.

7

Analog output 2.

8

5 Volt output

9

5 Volt output

10

Ground

11

Analog input 1.

12

Analog input 2.

13

Ground

14

Analog output 1.

15

Analog output 2.

16

5 Volt output

___________________________________________________________________________

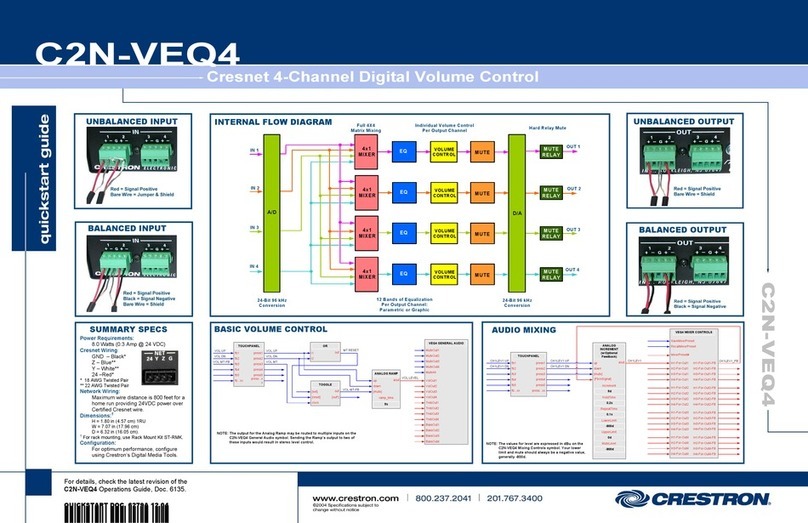

CONNECTION EXAMPLE FOR SHIELD C78

9.1 RJ45 shield C78 connection for axes, Limits and Encoder

9.2 RJ45 shield board description

___________________________________________________________________________

9.3 Pinout

RJ45 Distribution

RJ45_7

RJ45_8

RJ45_9

RJ45_10

RJ45 PIN

P.P. PIN

RJ45 PIN

P.P. PIN

RJ45 PIN

P.P. PIN

RJ45 PIN

P.P. PIN

1

GND

1

GND

1

GND

1

GND

2

5VDC

2

1_13

2

NC

2

2_17

3

NC

3

1_12

3

NC

3

2_16

4

2_4(INDEX)

4

1_11

4

2_11

4

2_1

5

NC

5

1_15

5

1_15

5

2_14

6

2_2(enc. A)

6

2_11

6

NC

6

NC

7

NC

7

12/24VDC

7

12/24VDC

7

5VDC

8

2_3(enc. B)

8

NC

8

NC

8

12/24VDC

___________________________________________________________________________

CONNECTION EXAMPLE FOR SHIELD C77

10.1 Terminal Shield Screw-on

10.2 Shield board description

___________________________________________________________________________

DRIVER DISCONNECTION JUMPERS

Note: 1-2: Cable disconnection detection.

2-3: No cable disconnection detection.

This configures how cable disconnect is to work. Set according to C34 board manual.

E-STOP TERMINAL

Connect an E-STOP push button as is shown in the below images.

Pin 10 port 1 is used for E-Stop. Since this board controls the enable line, and the

enable line is the one responsible for notifying the controller of the e-stop condition, the

user does not have a direct access to the pin itself, just to the e-stop terminal on the

board. The E-Stop terminal is tied to the enable line and will trigger the e-stop. A fault

or E-Stop triggers a low for 5 seconds to notify the controller of the fault condition, then

resets to high again.

___________________________________________________________________________

TYPICAL CONNECTIONS

-Connection with the terminal of output external of 24VDC

-Connection with the terminal of output external of 5VDC

___________________________________________________________________________

LED INDICATOR

The standby LED lights indicate that the system is ready but disabled. When Status

LED, (Green LED) lights, it indicates that the system is enabled.

There are 4 possible error sources: a driver fault, E-STOP error, SCHP error or VFD

alarm. A LED will light close to the source of the fault.

VFD Connection and configuration jumper

___________________________________________________________________________

The VFD Alarm monitoring feature can be enabled or disabled:

For the Variable speed control go to

http://cnc4pc.com/Tech_Docs/VARIABLE_SPEED_CONTROL.pdf

For Configure the control software go to

http://cnc4pc.com/Tech_Docs/CONFIGURATION_OF_CONTROL_SOFWARE.pdf

For Replacing Potentiometer go to

http://cnc4pc.com/Tech_Docs/Replacing%20a%20Potentiometer.pdf

UC300ETH MOTHER BOARD

https://cnc4pc.com/uc300eth-ethernet-motion-controller-b.html

This manual suits for next models

2

Table of contents

Other CNC4PC Control Unit manuals

Popular Control Unit manuals by other brands

herdstar

herdstar Bintrac Installation and operation manual

Gifas-electric

Gifas-electric TrafficLED installation instructions

Mutable Instruments

Mutable Instruments Kinks Installation

HEROSE

HEROSE 05411 operating instructions

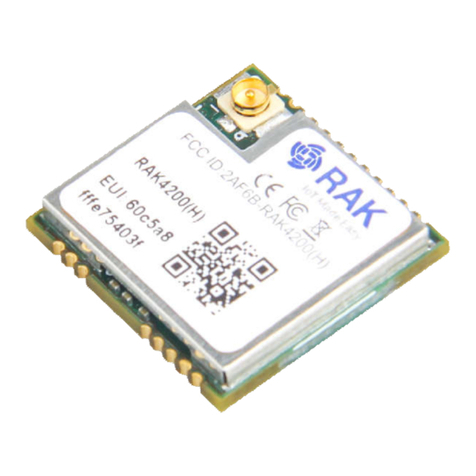

RAKwireless

RAKwireless RAK4200 quick start guide

Triax

Triax 692855 Configuration guide