CNC4PC C25S User manual

USER’S

MANUAL

C25S- SMOOTH STEPPER LPT

BOARD Rev. 1

APR, 2016

User’s Manual

Page i

USER'S MANUAL

TABLE OF CONTENTS

Page #

Contents

1.0 FEATURES.....................................................................................................................1

2.0 SPECIFICATIONS ..........................................................................................................1

3.0 FUNCTIONAL BLOCK DIAGRAMS ...............................................................................2

3.1 Inputs 10, 11, 12 13 and 15 (Port 1 and Port 2) Schematic ........................................2

3.2 Inputs 2-9 (Port 2) Schematic......................................................................................2

4.0 SET JUMPER IN THE S.S..............................................................................................3

5.0 WIRING DIAGRAMS.......................................................................................................3

5.1 Connecting Switches or push button .........................................................................3

5.2 Connecting NPN sensors (For any input)...................................................................4

5.3 Connecting PNP sensors (For any input)...................................................................6

5.4 Other connection (For any input)................................................................................7

6.0 DIMENSIONS..................................................................................................................8

User’s Manual

Page 1

1.0 FEATURES

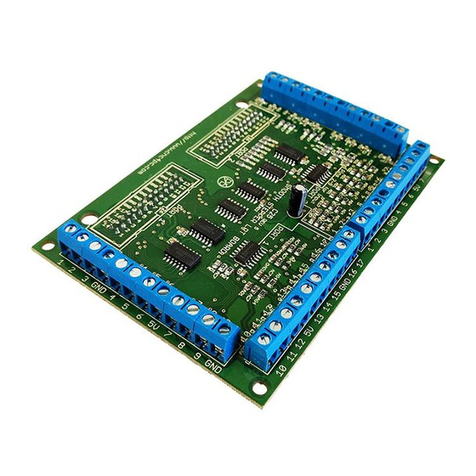

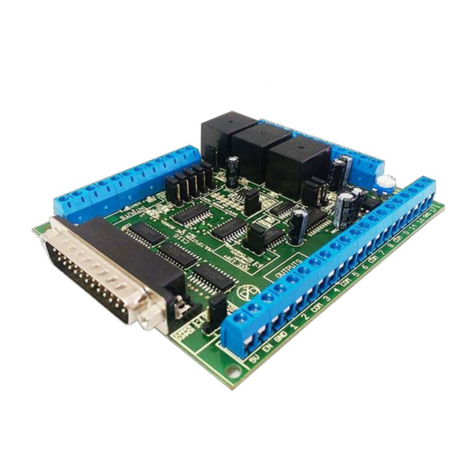

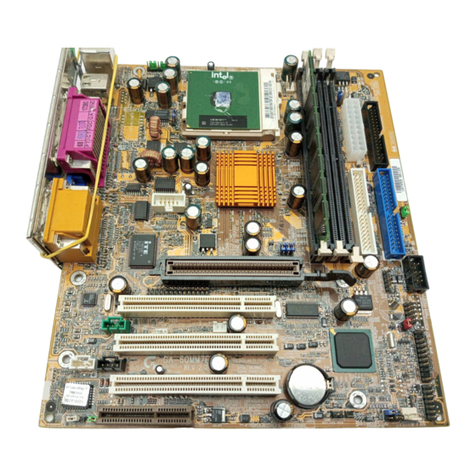

•34 Inputs and Outputs on 2 ports.

•Full access to all the pins of the Smooth Stepper Board.

•Connects directly to the Smooth Stepper (from Warp9).

The board is provided with sockets that allow the Smooth Stepper Board to be

plugged directly into this board. No ribbon cables required. When using the

Smooth Stepper board there is no need to use an additional power supply to power

the board. It will draw power from the Smooth Stepper board.

•Built-in Passive Low Pass Filters for the all inputs.

This board includes lowpass filters to reduce the effect of the noisefrom the drivers

or other devices over the inputs signals.

•All TTL 5VDC signals.

Interface directly with parallel port interface products and other CNC4PC cards.

5VDC (TTL) cards are very common among automation devices.

•Input and output pins with close by ground connections.

Forget about grounding problems. Easily connect your pin by using your close by

ground connection. No need to be an electronics expert to ground all your stuff.

•Push-lock connections for all terminals.

You only have to push-lock the wires to make all your connections.

2.0 SPECIFICATIONS

DIGITAL INPUT SPECIFICATIONS

Numbers of inputs

5 on Port1, 13 on Port2

On-state voltage range

3.5 to 5V DC

Maximum off-state voltage

Aprox. 1.5V

Type

Active High

DIGITAL OUTPUT SPECIFICATIONS

Number of outputs

12 on Port1, 4 on port2

Maximum output voltage

(5V power supply voltage) +0.5V

Maximum off-state voltage

0.33 V

User’s Manual

Page 2

3.0 FUNCTIONAL BLOCK DIAGRAMS

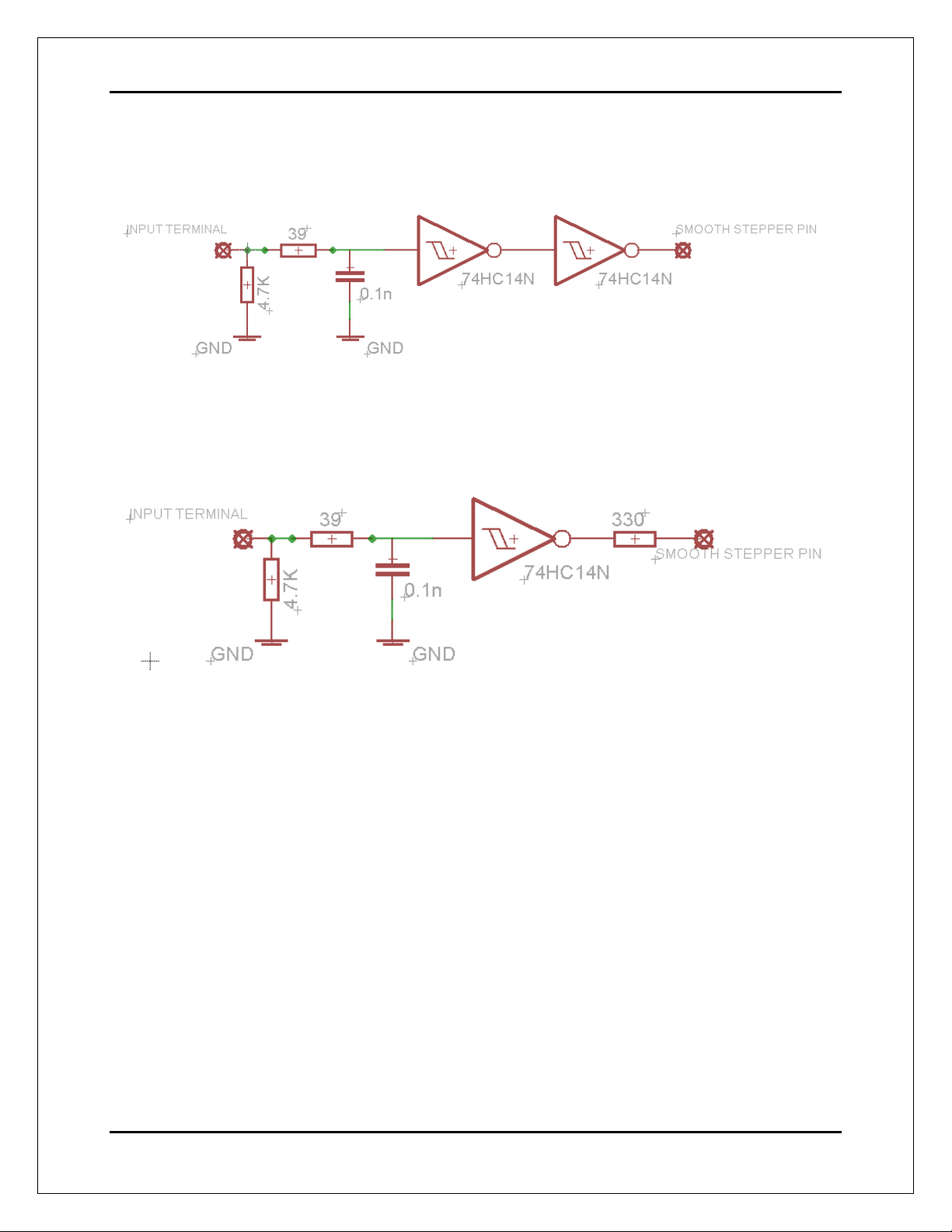

3.1 Inputs 10, 11, 12 13 and 15 (Port 1 and Port 2) Schematic

Simplified functional block diagram

Note: The Smooth Stepper includes an Schmitt Trigger in those input pins.

3.2 Inputs 2-9 (Port 2) Schematic

Using an RC Low Pass filter followed by a Schmitt Trigger gate will reduce the effect of

the noise from driver or other devices. This eliminates the high frequency components of

the noise and generating a fast changing signal.

Outputs 1, 14, 16 and 17 (Port 1 and 2) and outputs 2-9 (port 1).

All those pins are directly wired to the C25 output terminals.

User’s Manual

Page 3

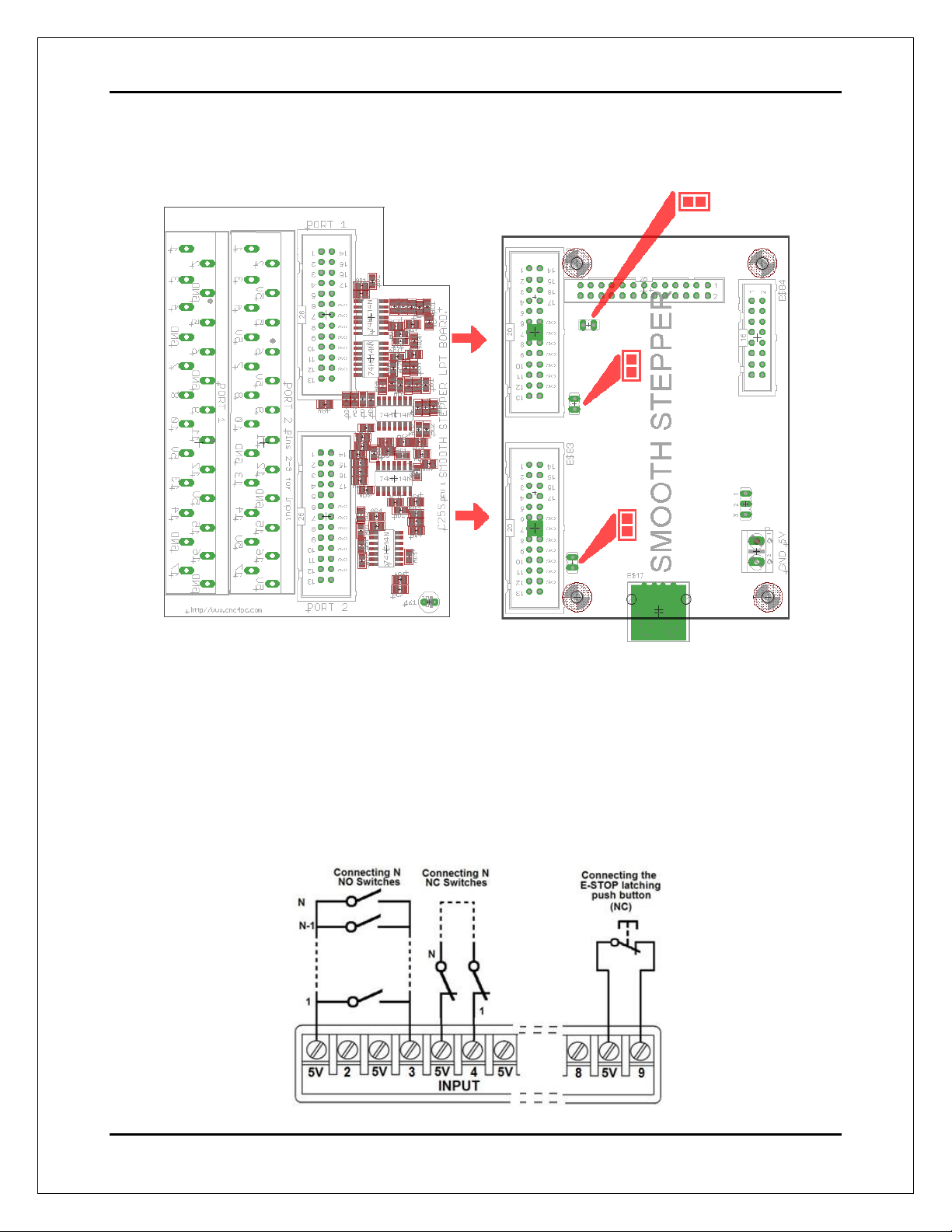

4.0 SET JUMPER IN THE S.S

5.0 WIRING DIAGRAMS

Different kind of sensors and switches can be connected to inputs board, but this board

support onlyTTL signal. If you need to connect devices that generates 12Vor 24V signals

in some cases is necessary add external resistors.

5.1 Connecting Switches or push button.

User’s Manual

Page 4

WIRING DIAGRAM TO CONNECT SWITCHES

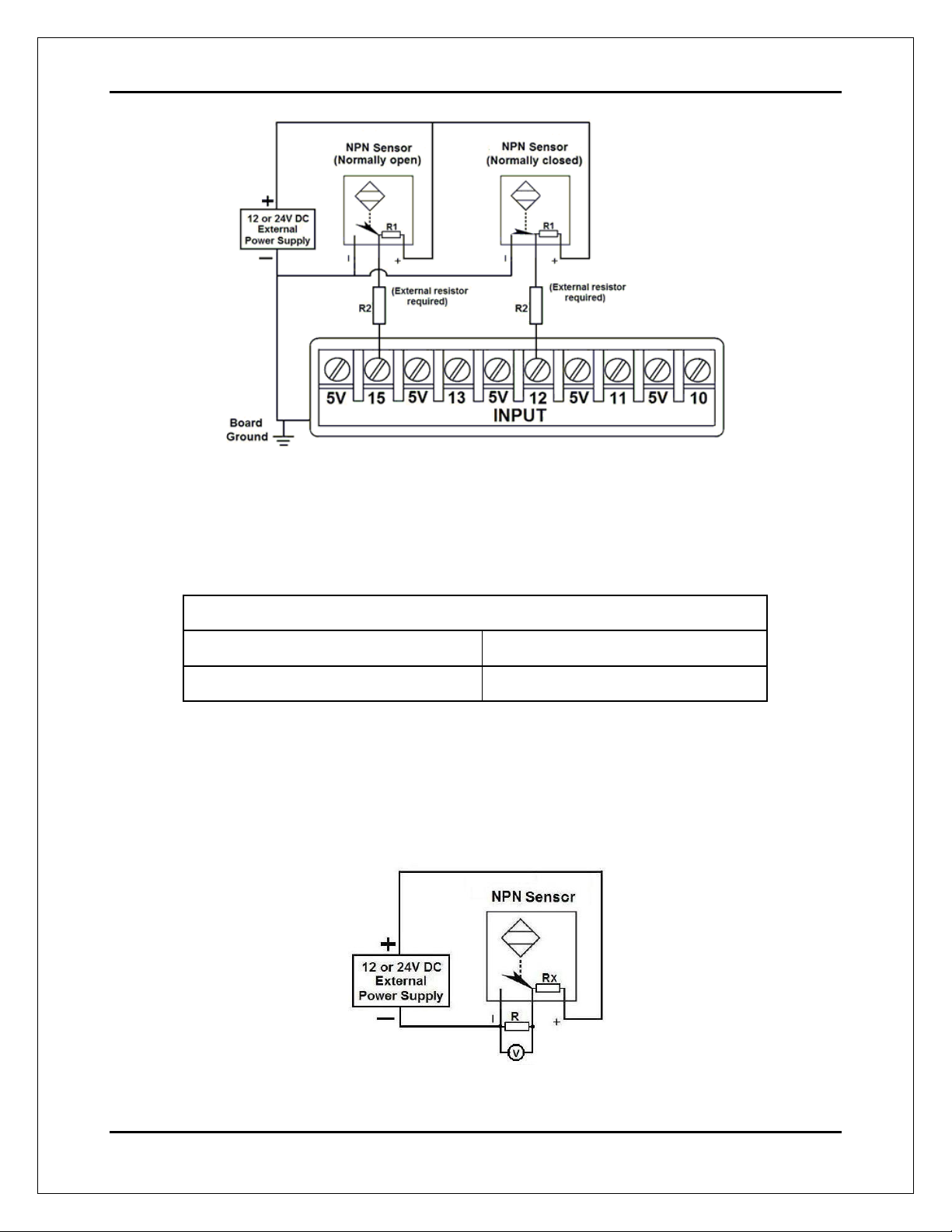

5.2 Connecting NPN sensors (For any input)

Wiring diagram to connect NPN open collector proximity sensors

WIRING DIAGRAM TO CONNECT IN PARALLEL NPN OPEN COLLECTOR

PROXIMITY SENSORS

Connecting NPN open collector proximity sensor with the C25

R1 Value (12V)

R1 Value (24V)

Aprox. 10KΩ

Aprox. 25KΩ

User’s Manual

Page 5

Wiring diagram to connect NPN proximity sensors with internal pull up resistor

Some NPN proximity sensors have an internal pull-up resistor (R1). It is necessary to

know its value in order to safely connect the sensor with the BOB. Follow this

recommendation:

Connecting NPN open collector proximity sensor with the C25

(R1+R2) Value (12V)

(R1+R2) Value (24V)

Aprox. 10KΩ

Aprox. 25KΩ

CALCULATING THE R1 VALUE

Note: Rx is the unknown resistor value.

RX = VEX.(R/V) - R (1)

User’s Manual

Page 6

Where:

VEX is the external power supply voltage

V is the voltage across the R resistor

A voltmeter is required to calculate the internal resistor value (Rx). Do the connection as

are shown in the figure above and do the calculations using the equation (1).

Note. R value has to be known to do this operation. A 4.7KOhm@1/2W is

recommended.

For example, if you are using a 12V power supply (VEX), and use a 4.7KOhm as

external resistor (R), and the voltage across R is 6V, using the equation 1, the Rx

value is 4.7KOhm.

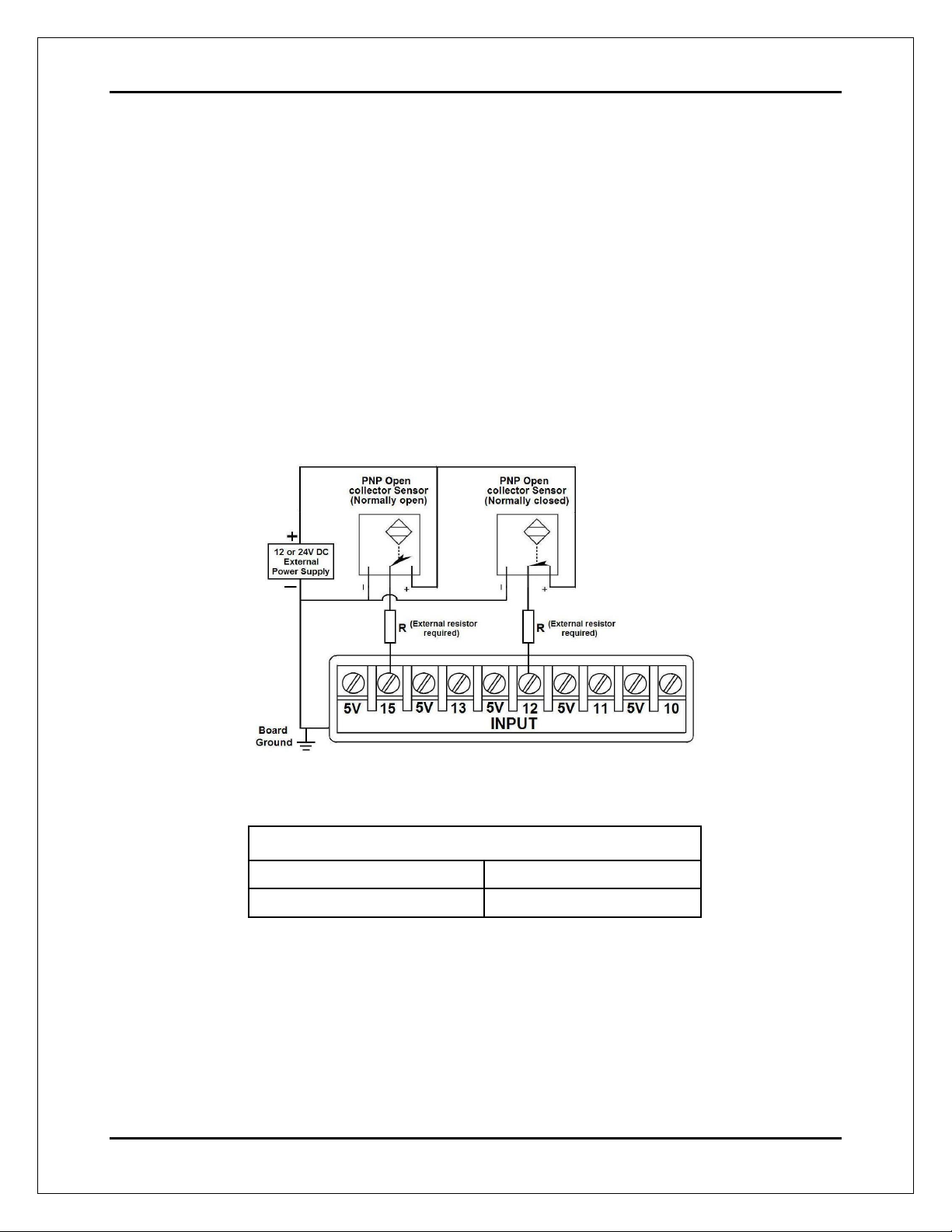

5.3 Connecting PNP sensors (For any input)

Wiring diagram to connect PNP proximity sensors

Connecting PNP proximity sensor with the C25

R Value (12V)

R Value (24V)

Aprox. 10KΩ

Aprox. 25KΩ

User’s Manual

Page 7

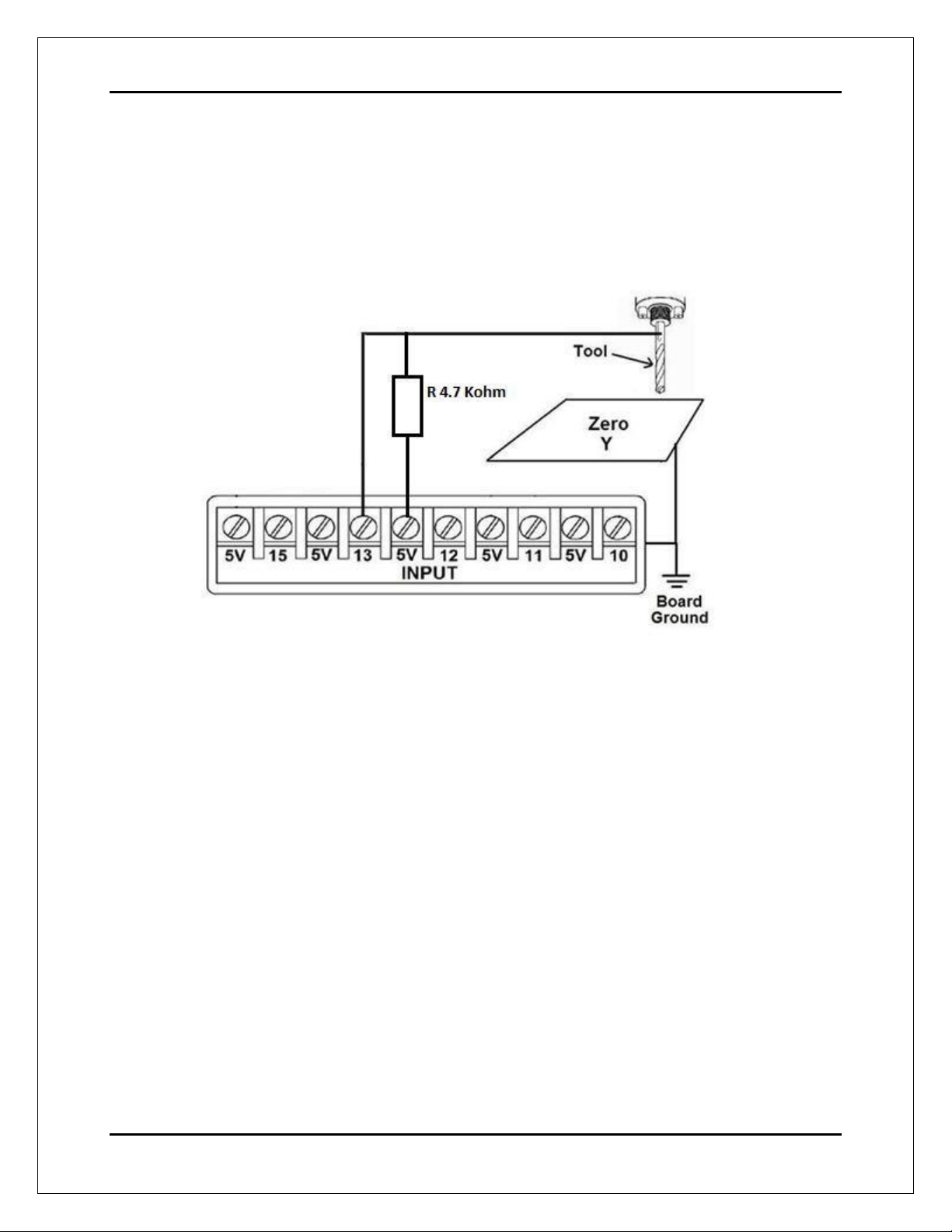

5.4 Other connection (For any input)

Other connections can be implemented by setting the inputs with pull-up resistor.

In this case connect an external 4.7KOhm resistor between the input terminal and

the 5V terminal.

Wiring diagram to do an “Auto Tool Zero”

User’s Manual

Page 8

6.0 DIMENSIONS

All dimensions are in Millimeters.

DISCLAIMER

Use caution. CNC machines can be dangerous machines. Neither DUNCAN USA, LLC

nor Arturo Duncan are liable for any accidents resulting from the improper use of these

devices. This product is not a fail-safe device and it should not be used in life support

systems or in other devices where its failure or possible erratic operation could cause

property damage, bodily injury or loss of life.

Table of contents

Other CNC4PC Motherboard manuals