2

Congratulations!

The Co-Motion Co-Pilot equipped with a Pinion gearbox is

an excellent choice for world travel. These instructions will

help you feel comfortable with packing and assembly of your

new bike. Soon enough you’ll be looking for more destina-

tions to take your bike with you.

Your Co-Pilot bike is designed to fit into a 26 x 26 x 10”

travel case. These dimensions are important because they

fall within the non-oversize bag regulations stipulated by

most airlines, saving you from additional bag fees.

Using our Co-Pilot travel case you will have room for the

complete bike plus some essentials like pedals, tools, cloth-

ing, maps and small bike bags. Keep in mind the Co-Pilot

travel case is designed to meet the airline regulations, there-

fore it won’t have room for racks, panniers or fenders.

Getting Started

The first rule here is to avoid rushing and situate yourself in

an area with enough room for you, the bike and the travel

case. You’ll need the following items, at a minimum, and

your particular setup may require additional tools:

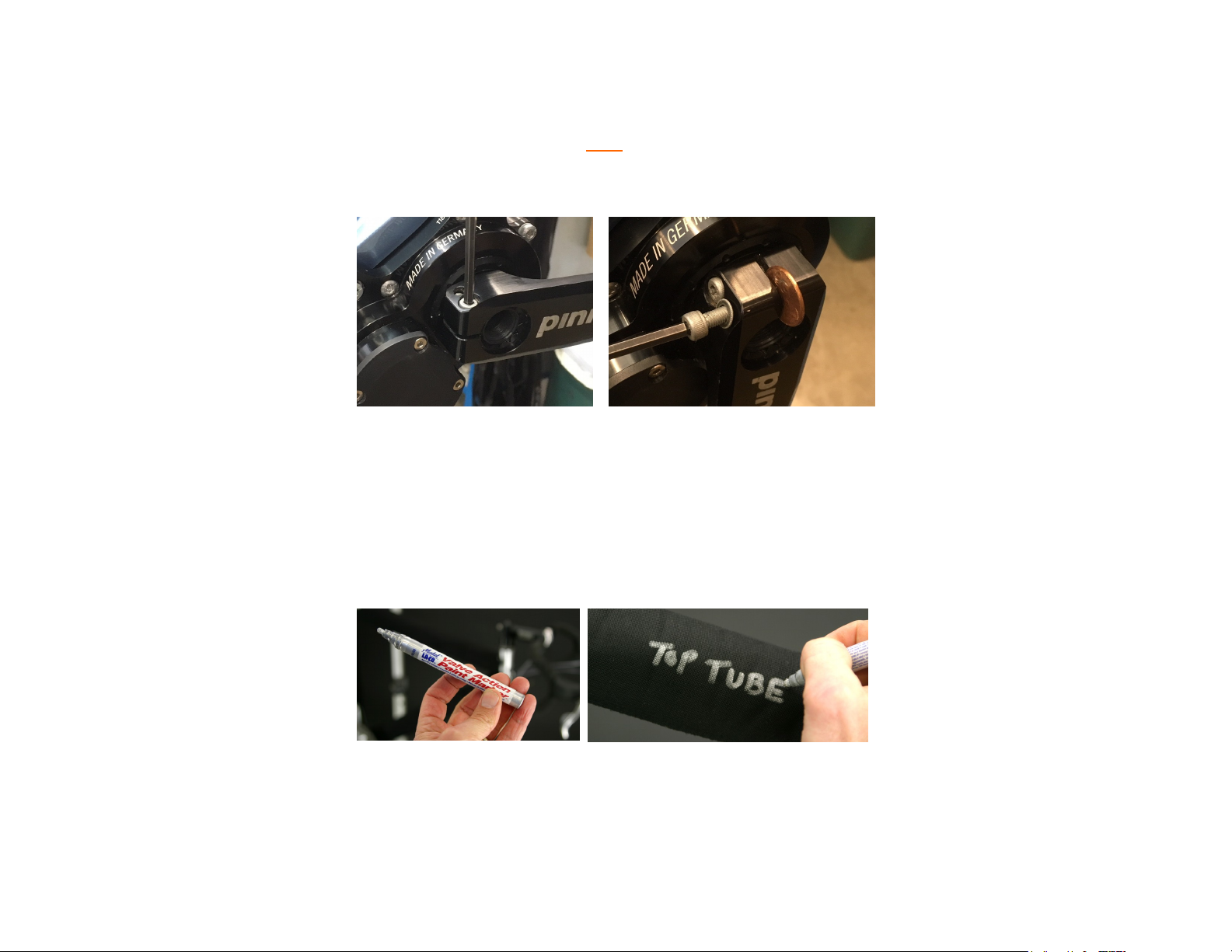

Universal spanner that fits the S&S couplers

A multi-tool or Allen tools in sizes 4mm, 5mm, 6mm

A pedal wrench for your particular pedal type

Torx T25 wrench and Centerlock rotor tool if needed

Some rags or towels to clean up grease

A sharp pair of scissors and paint pen

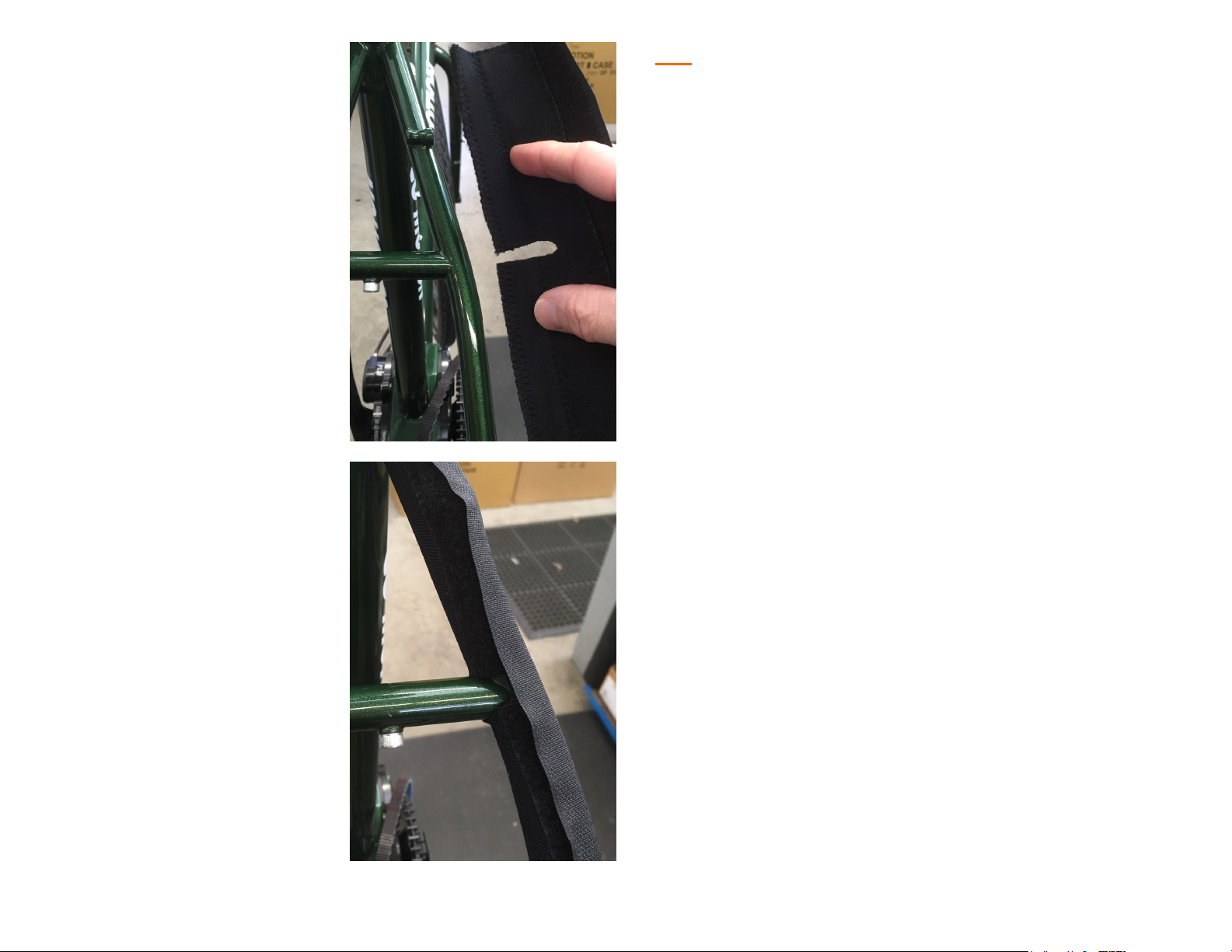

A bag of zip-ties and Padding kit ready to cut or install

Torque wrench with Allen adapter

If you’re not familiar with bicycle terms, a knowledgeable

friend or bicycle maintenance manual will be helpful.