COATS 9500Tire Changer • iii

Operator Protective Equipment

Personal protective equipment helps make tire servic-

ing safer. However, equipment alone does not take the

place of safe operating practices. Always wear durable

work clothing during tire service activity. Loose fitting

clothing should be avoided. Tight fitting leather gloves

are recommended to protect operator’s hands when

handling worn tires and wheels. Sturdy leather work

shoes with steel toes and oil resistant soles should be

used by tire service personnel to help prevent injury in

typical shop activities. Eye protection is essential during

tire service activity. Safety glasses with side shields,

goggles, or face shields are acceptable. Back belts pro-

vide support during lifting activities and are also helpful

in providing operator protection. Consideration should

also be given to the use of hearing protection if tire

service activity is performed in an enclosed area, or if

noise levels are high.

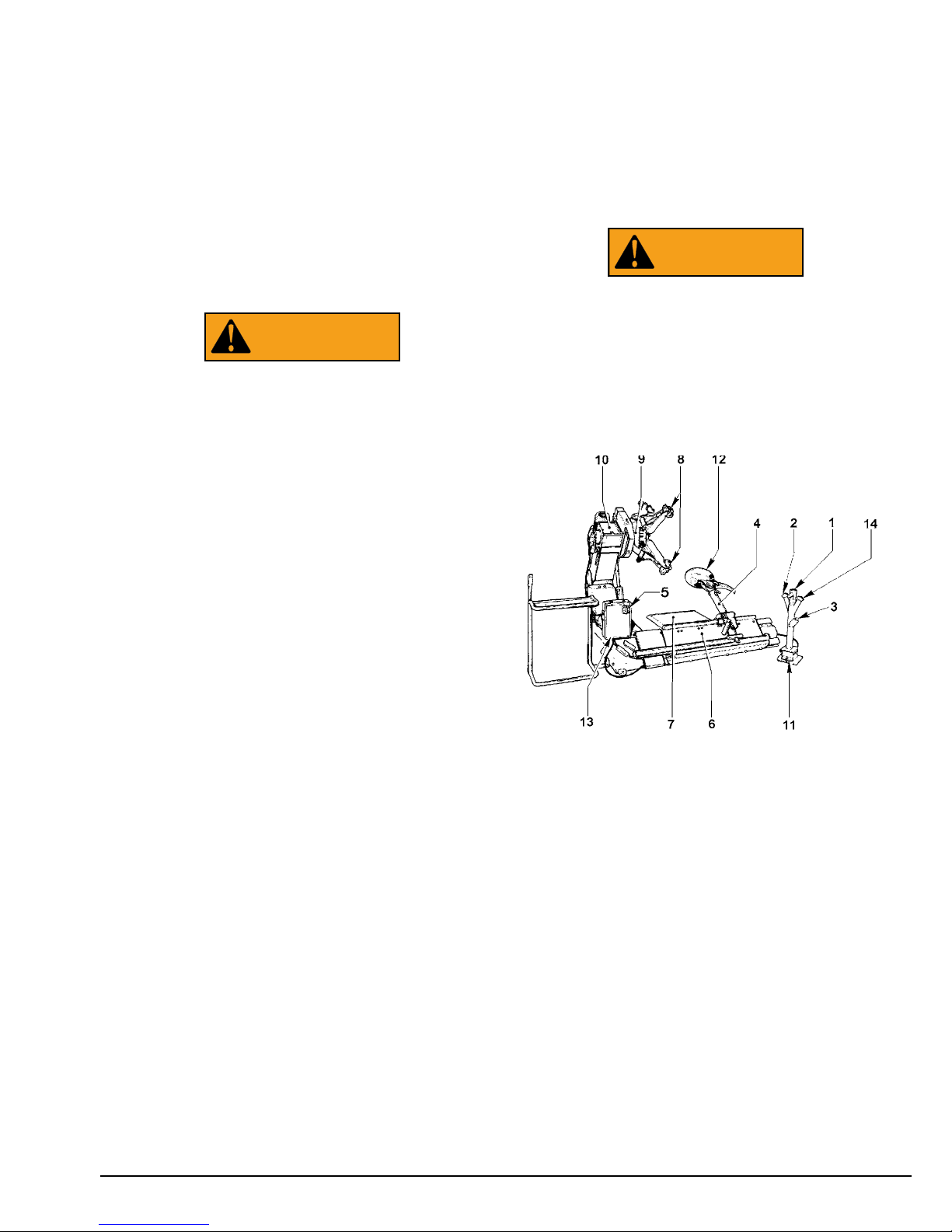

Safety Devices

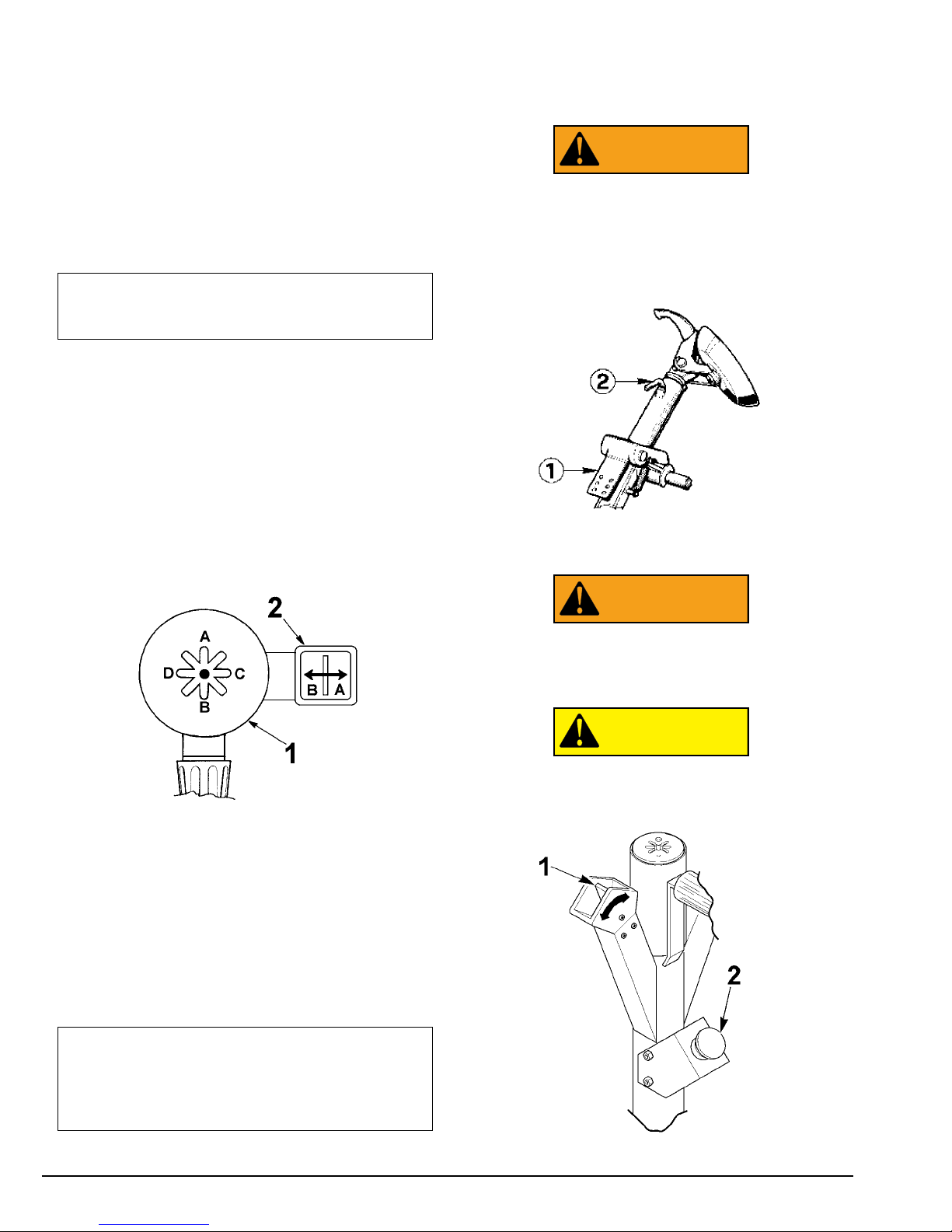

This machine has several protectors to prevent com-

pression or crushing hazards to body areas. Keep these

devices properly maintained and do not disable or in

any way shortcut the safety controls and opertations.

There is a micro-switch protection under the chuck

arm to prevent compression.

The rotation speed of the chuck has been limited to a

maximum of 8 rpm to prevent dragging or en-trapping

hazards.

There is an emergency button on the portable control

unit.

Important Safety Instructions

Only properly trained personnel should serv-

ice tires on the 9500. Read all safety and

operating instructions thoroughly before

using the tire changer.

ALWAYS

remove all wheel weights and the valve core

to deflate the tire before servicing.

ALWAYS

cover the electric motor and switch box

before hosing down the tire changer. Be sure water

does not enter the motor or switch box.

ALWAYS

disconnect the electric power and air supply

before attempting any maintenance.

ALWAYS

keep all working surfaces clean and free of

tire lube buildup.

ALWAYS

be aware of what each person is and will do

before attempting any two-person operation.

Safety Precautions

A. Before servicing any tires, wheels or rims all per-

sonnel should receive thorough training for the proper

servicing of truck tires, wheels and rims. Consult with

your local city, country state, and national safety and

health administrators to receive clarification of any pub-

lications available governing this serious matter.

B. During the use and maintenance of the machine it

is mandatory to comply with all laws and regulations for

accident prevention.

C. The electric power source must have a ground

cable and the ground cable of the machine (yellow and

green) must be connected to the ground cable of the

power source.

D. Before any maintenance or repairs are accom-

plished the machine must be disconnected from the

electric supply. The unit should only be serviced by a

qualified service technician.

E. Never wear ties, chains or other loose articles

when using, maintaining or repairing the machine. Long

hair is also dangerous and should be kept under a hat.

The user must wear proper safety attire, i.e. gloves,

safety shoes and glasses.

F. Maintain all electric cords in good repair.

G. Keep safety features in place and in working order.

H. Keep working area clean. Cluttered areas invite

accidents.

I. Avoid dangerous environments. Don’t use power

tools or electrical equipment in damp or wet locations,

or expose them to rain.

L. Nobody should be allowed to stand next to or near

the wheel, when mounting/demounting a tire or clamp-

ing a wheel.

M. Keep the work area well lighted.

N. Properly anchor the machine to the floor.