Collomix GmbH ROTA 400

D-85080 Gaimersheim

Version G 1.5-18 9

3.5 Safety-relevant components

The machine is equipped with various safety devices. These help to avoid dangers to body and life

through electrical and mechanical impacts on the persons working with the biaxial mixer and they

help to limit any material damages to the system.

Do not bypass, remove, or render ineffective the safety equipment.

Do not operate the system if the safety equipment is not complete or fully functional.

Closed housing

The housing, which can only be opened with tools, forms a fixed, separating safety device.

Machine door with interlocking device

The door forms a locking, separating unit with interlocking device. The machine cannot be started

when the door is open. The door is only released after the mixing process has ended and the mixing

vessel is released.

Loading shelf

The loading shelf prevents reaching into the mixing room when the doors are closed.

EMERGENCY STOP Switch

In emergencies the function of the EMERGENCY STOP switch is

To safely disconnect of the control voltage supply and therefore, bring the machine to a halt.

To halt the machine, if needed.

3.6 Residual Risks

If all precautions are taken, there may be obvious residual risks. Adhering to the safety instructions,

the designated use, and the operating instructions as a whole can reduce residual risks!

DANGER

Danger of death by dangerous voltage

There is a residual electrical energy in lines and equipment after the system is switched off.

Only allow qualified electricians to perform work on the electrical supply system. Turn off on

the main switch. Disconnect the system from the power supply

Replace any damaged cable. Rectify any lose connections. Correct loose connections.

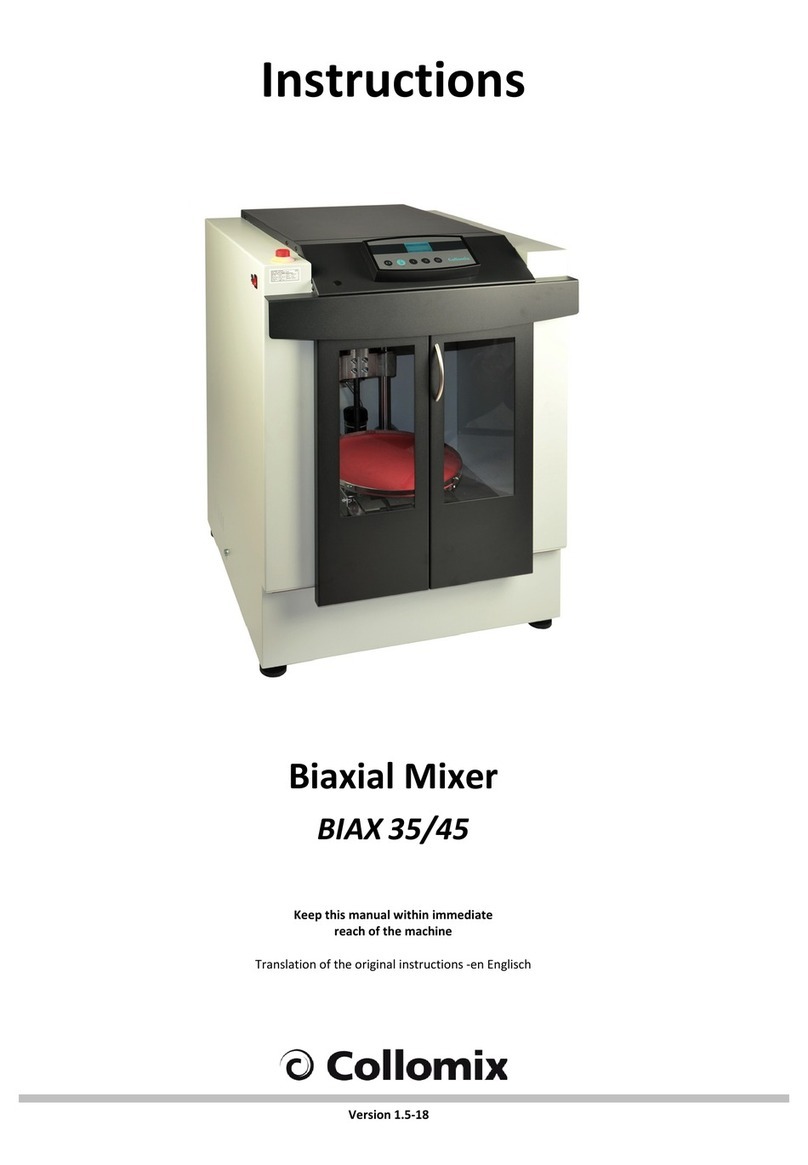

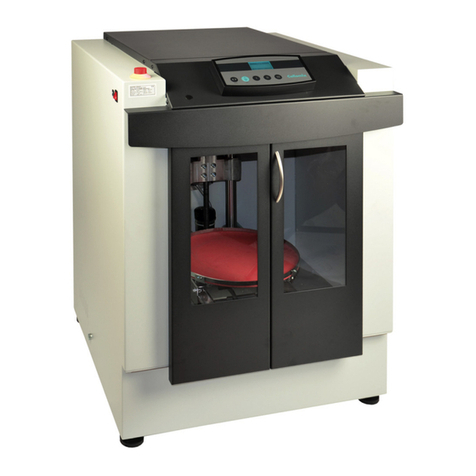

4. Equipment Description

The biaxial mixer is a stationary mixing device for closed, tightly closing, round and oval vessels

made of metal or plastic. It is suitable for mixing colours, colour concentrates, building and industrial

lacquers, and other materials with low viscosity.

The area of application ranges from the colour wholesale to retail trade, the lacquer and chemical

industry to any similar areas. This mixing device is especially suited as system component for colour

dosing systems.

The container is automatically clamped into the machine and mixed by simultaneously rotation

about its longitudinal and transverse axis.

The necessary mixing time and the suitability of the containers must be determined by mixing trials

prior to use.