RotoGen 1000 Collomix GmbH

85080 Gaimersheim

4Version 3.1-17

1. General information

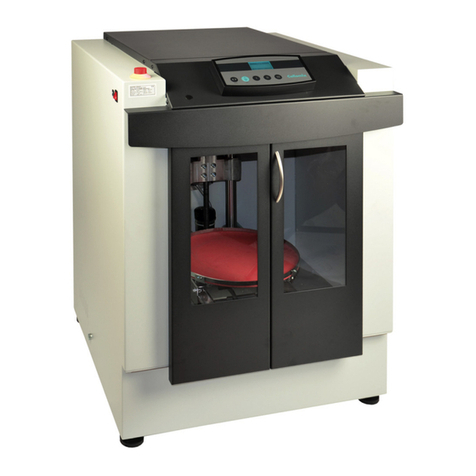

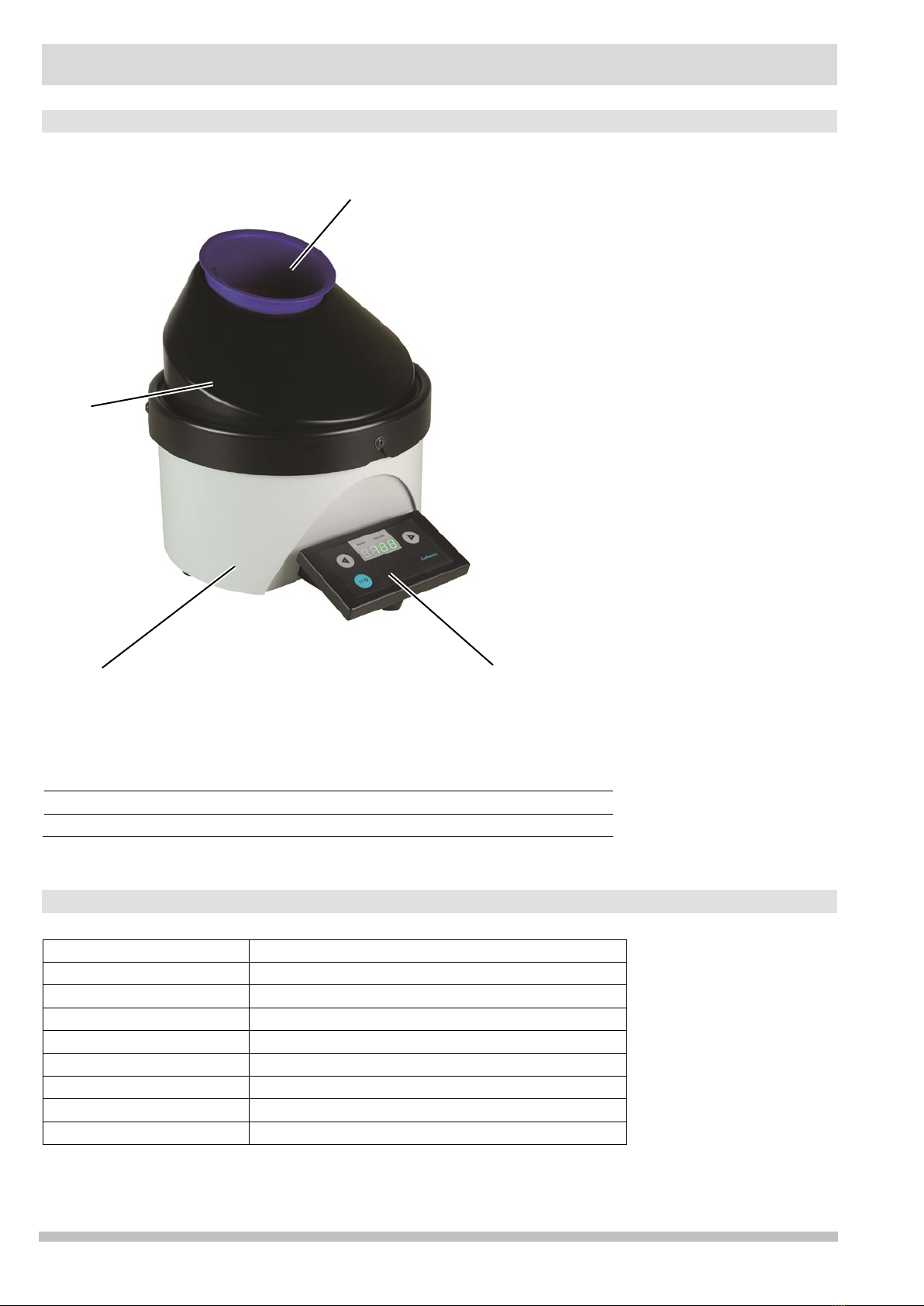

The RotoGen 1000 is a small volume stationary mixer for homogenizing liquid lacquer materials and

paints, in particular car repair paints, using mixing cup systems (for example PPS/RPS) for connecting

to spray guns.

The sealed container (e.g. mixing toner pots and mixing cups) is placed in a suitable holder/adapter

on the RotoGen 1000 and the contents are then homogenized when the container is set in a rotating

motion through two axes.

1.1 Symbols used

Important notes and instructions concerned with safety which are used in these operating

instructions are indicated by symbols.

It is essential that these notes and instructions relating to work safety are observed and complied

with. In all such cases it is important that you take particular care in order to prevent accidents,

harm to persons and damage to property.

DANGER! Risk of injury or death

This symbol indicates notes and instructions which, if not observed, could

impair health or lead to injury, lasting bodily harm or death.

CAUTION! Risk of damage to property!

This symbol indicates notes and instructions which, if not observed, could lead

to damage, malfunctions and/or the failure of the machine.

Note!

This symbol indicates tips and information which you should observe in order to

ensure that the machine provides you with efficient and trouble-free service.

1.2 Information about the operating instructions

These operating instructions describe how to use the machine safely and correctly. The notes and

instructions on safety, the regulations relating to the prevention of accidents and the general safety

regulations applicable to the area of application in the country of use must be observed.

Before starting any work on the machine you must read the operating instructions in full, in

particular the section concerned with safety and the applicable safety instructions.

All information, notes and instructions contained in these operating instructions were prepared with

due regard to applicable regulations and state-of-the-art technology and on the basis of the

knowledge and experience that we have gained over many years.

These operating instructions must be kept in close proximity to the machine where they must be

available to all persons working with or on the machine at all times.

COLLOMIX accepts no liability for any errors in this manual or for any accidental or consequential

damages arising from or in connection with the supply, performance or use of this material.

The information contained in this manual may be changed at any time without prior notice.

Should these operating instructions contain anything which you do not fully understand or contain

instructions, procedures, notes and instructions on safety which do not make perfect sense to you,

please contact our sales and service partner:

Collomix GmbH

Daimlerstr. 9, 85080 Gaimersheim

Federal Republic of Germany

Tel.: +49 (0)8458 32 98 - 0

Fax.: +49 (0)8458 32 98 30

www.collomix.com