1. Your STATCLAVE 3

1.1 Checking the Package Contents 3

1.2 Important Information About Using

Your STATCL AVE 4

1.3 Operating Principles, Key Features and

Safety Devices 6

1.4 Unit Overview 8

1.5 Touchscreen Overview 9

1.6 Using the Operation Screens 9

1.7 Unlocking the Door 10

2. Set Up 11

2.1 Installing Your STATCLAVE 11

2.2 Connecting and Powering Your STATCLAVE 12

2.3 Connecting Your STATCLAVE’s Water

Draining System 12

2.4 Connecting your STATCLAVE to a Network 14

3. Getting Started 16

4. Filling the Water Reservoirs 17

4.1 Manual Filling Using Reservoir Top 19

4.2 Manual Filling Using Quick Connector at

Unit Front 20

4.3 Automatic Filling Using a Vista Pure Specialized

Water Filtration System with Accumulation Tank 21

4.4 Automatic Filling Using External Water

Tank and Auxiliary Pump 22

5. Loading Instruments 23

5.1 Using the Chamber Rack 24

5.2 Wrapped Instruments 25

5.3 Unwrapped Instruments 27

5.4 Rubber and Plastics 28

5.5 Textiles and Surgical Packs 28

5.6 Using Biological and Chemical Indicators 28

6. Using Your STATCLAVE 29

6.1 Running a Cycle 29

6.2 Stopping a Cycle 31

6.3 Using the Start Delay 32

6.4 Emergency Door Opening 33

6.5 Running a Vacuum Test 34

6.6 Running a Bowie-Dick Test 35

7. Sterilization Cycles 36

8. Using and Changing Settings 37

8.1 Setting Up Load Traceability with User ID,

PIN and Process Enforced Usage 39

8.2 Setting Drying Time 41

8.3 Setting the Stand-By Mode 41

8.4 Setting Up and Using Your STATCLAVE

Web Portal 41

8.5 Registering for STATCLAVE Online Access 42

9. Storing, Retrieving and Printing Sterilization

Records 43

9.1 Retrieving Cycle Information Using the

Touchscreen 43

9.2 Retrieving Cycle Information Using the

Web Portal 43

9.3 Retrieving Cycle Information Using the USB

Data Back Up 43

9.4 Connecting to a Printer 44

9.5 Adjusting your Print Settings 44

9.6 External Printer Specifications 45

10. Maintenance Procedures 46

10.1 Preventative Maintenance Message 46

10.2 Preventative Maintenance Schedule 46

10.3 Cleaning the Door Seal and Door Plate 47

10.4 Cleaning the Sterilization Chamber, Rack

and Trays 47

10.5 Cleaning and Disinfecting the External Surfaces 47

10.6 Draining the Reservoirs for Cleaning 48

10.7 Cleaning the Water Reservoirs and

Reservoir Filters 48

10.8 Cleaning the External Distilled Water Tank 49

10.9 Cleaning the Chamber Filters 49

10.10 Replacing the Bacteriological Filter 50

10.11 Replacing the Door Seal 50

10.12 Using on-Screen Instructions 51

10.13 Enabling a Technician to Access Your

STATCLAVE from a Remote Location 51

10.14 Preparing the Unit for Shipping 52

11. Troubleshooting 53

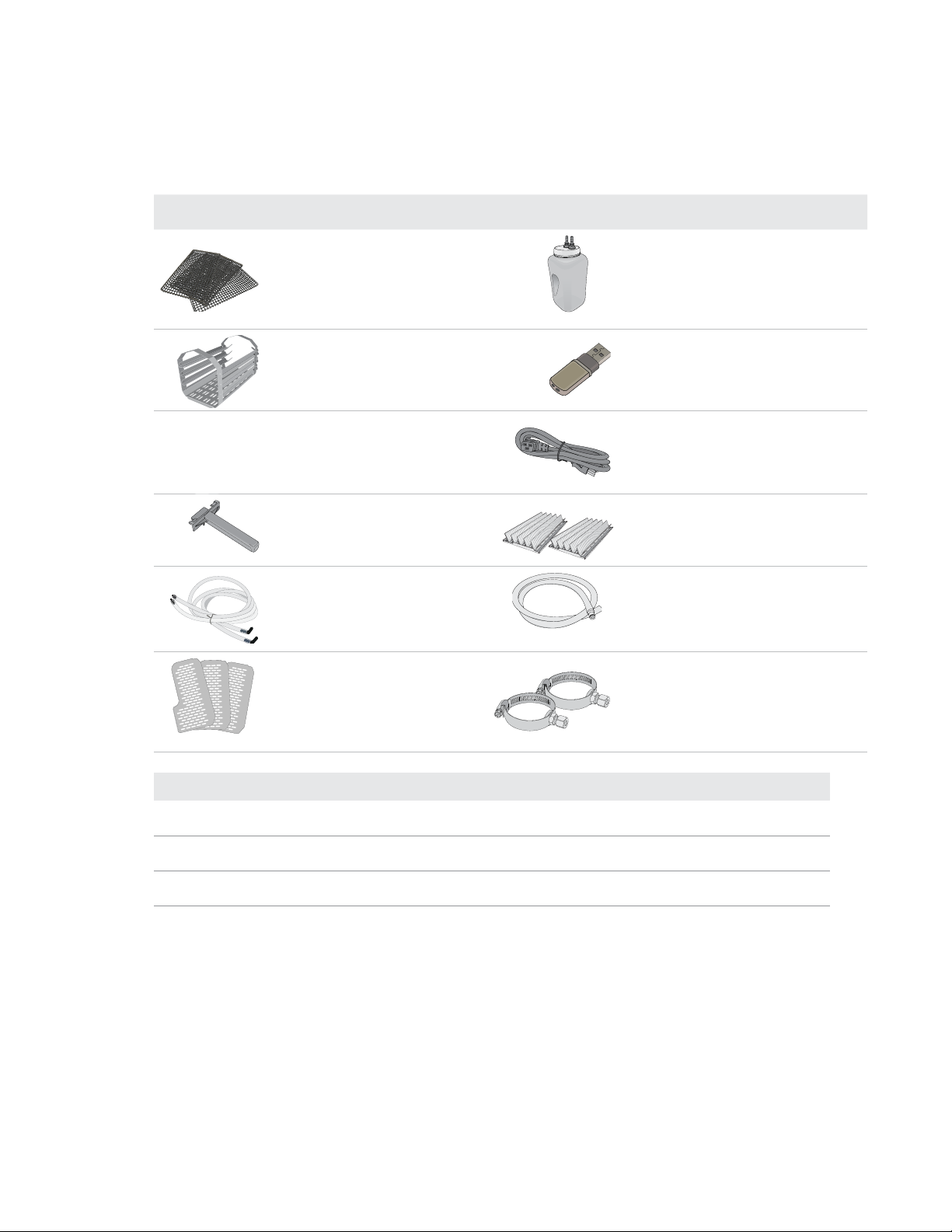

12. Ordering Spare Parts and Accessories 57

13. Warranty 58

Limited Warranty 58

14. Specifications 59

APPENDIX A 60

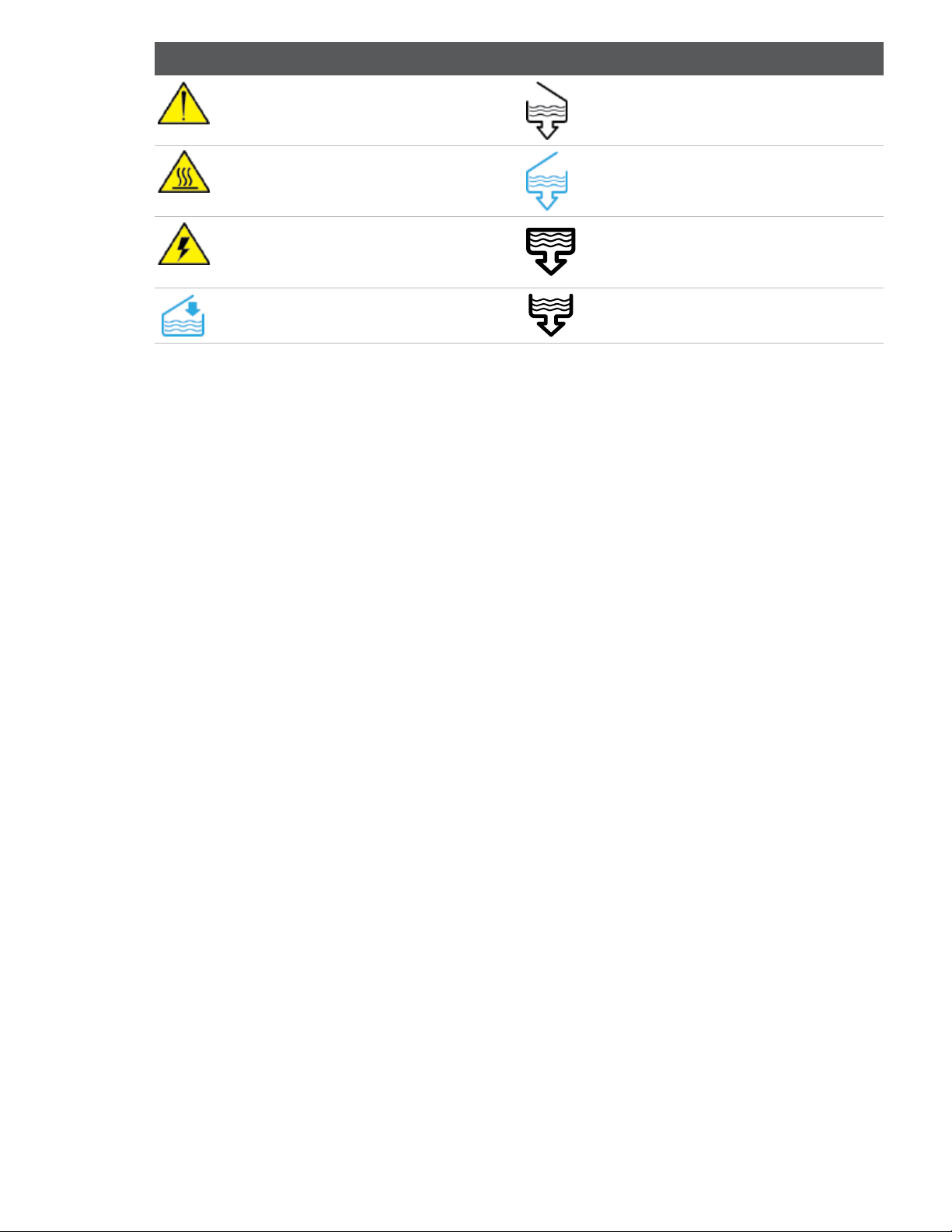

Software Icons 60

APPENDIX B 61

Software Screens 61

APPENDIX C 62

STATCLAVE Cybersecurity Statement 62