TABLE OF CONTENTS

INTRODUCTION...............................................................................................4

GENERAL.......................................................................................................4

WARRANTY...................................................................................................4

GENERAL INFORMATION................................................................................5

IN PECTION..................................................................................................5

OPERATOR MANUAL....................................................................................5

IN TALLATION...............................................................................................5

GA CONNECTION.......................................................................................5

GA PRE URE...........................................................................................5

COMMI IONING..........................................................................................6

PECIFICATION .............................................................................................6

IN TALLATION...............................................................................................6

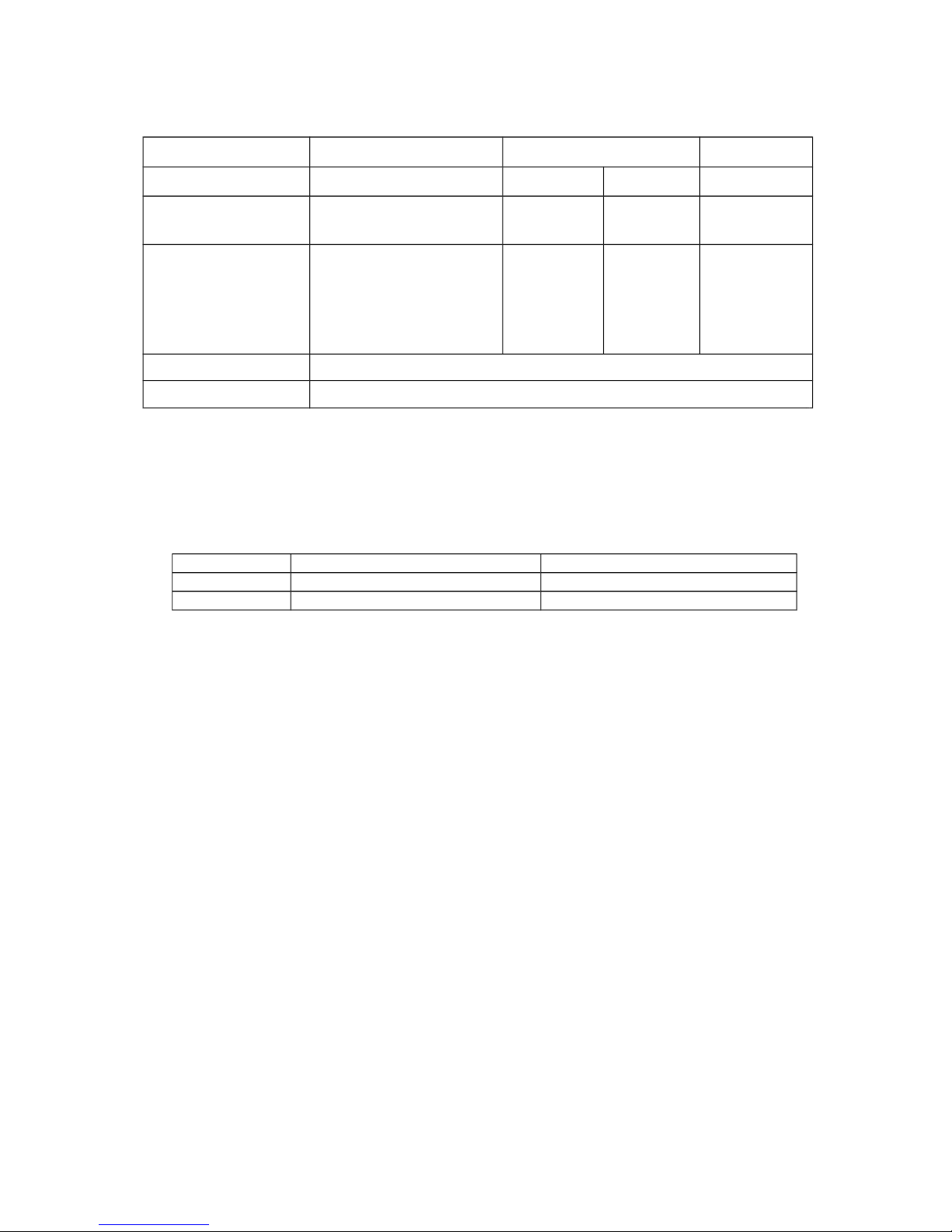

Appliance specification...................................................................................8

TE T POINT PRE URE..............................................................................8

VENTILATION AND AIR UPPLY..................................................................8

DIMEN ION .................................................................................................9

ACCE ORIE ..............................................................................................9

OPERATING IN TRUCTION ........................................................................10

LIGHTING IN TRUCTION .........................................................................10

IGNITION PROCEDURE..............................................................................11

OPERATOR MAINTENANCE..........................................................................14

CLEANING TAINLE TEEL..................................................................14

ERVICE.........................................................................................................15

RECOMMENDED ERVICE........................................................................15

BURNER ADJU TMENT ...........................................................................16

PARE PART .............................................................................................17

TROUBLE HOOTING.....................................................................................18

Exploded view of GF4...................................................................................19

Exploded view of GF3...................................................................................21

Gas fryer Manual Page 3