408- 8718

Rev H2of 6

The workstationjacks can be used in faceplates or

walloutlets for use on wallboxes that are at least

50.8 mm [2 in.] deep. The workstationjacks can be

installed using the SL jack housing (includedwith the

kit) or Parallel Dress Clip1374206--1 (simplex) or

1374205--1 (duplex) shown in Figure 1.

For available adapter plates, patch panels,

enclosures, faceplates and wall outlets, and

installation instructions, refer to 408--8844.

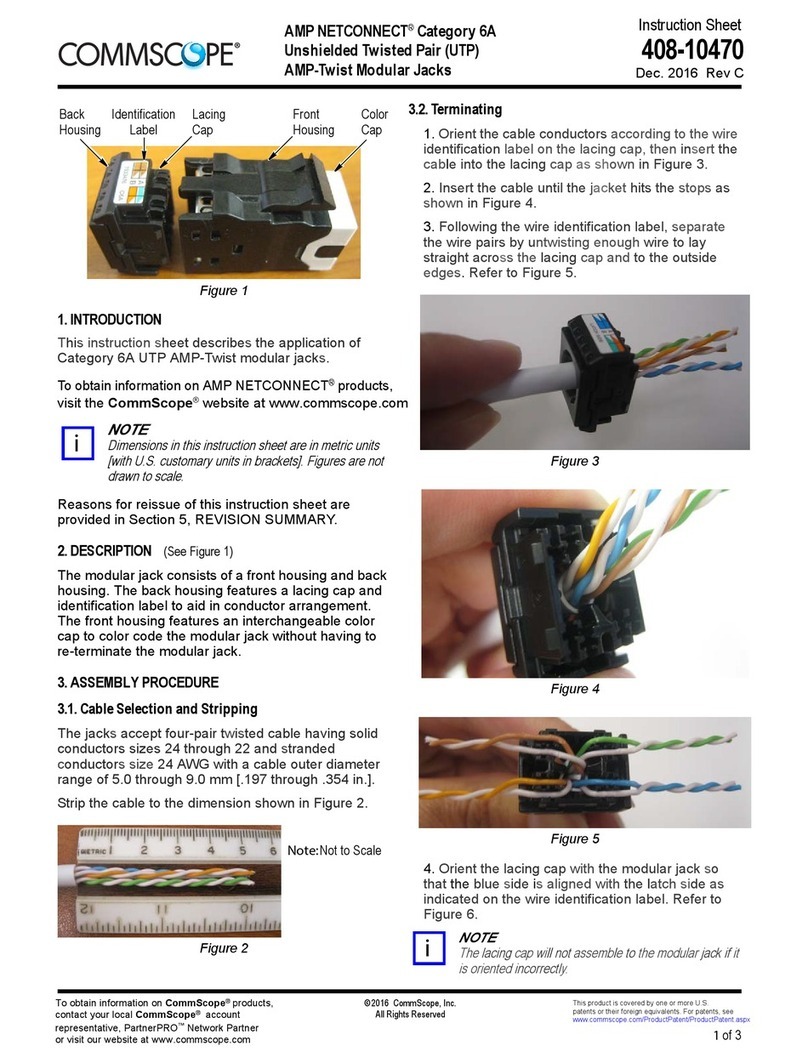

2. DESCRIPTION (Figure 1)

Each patch paneljack kit contains six MT--RJ jack

module assemblies (each with protective cover), an

icon wheel,900-- m berguide (black), and two

actuation keys.

Each workstationjack kit containsone MT--RJ jack

module assembly (with protective cover), SL jack

housing,900-- m (black) berguide,jack boot, and

an actuation key.

The jack kits are shipped with the protective

covers installed onto the jacks. Keep protective

covers in placeuntil ready for connection.

Each jack has two channelsdesignated (on the top of

the jack) with “A” and “B.”

3. ASSEMBLY PROCEDURE

ALWAYS weareye protection when working with

optical fibers. NEVER look into the end of

terminated or unterminated fibers. Laser radiation

is invisible butcandamageeye tissue.

NEVEReat, drink, or smoke whenworking with

fibers. This could lead to ingestion of glass

particles.

During assembly, keep kit components and tools

as clean as possible to avoid contamination in

the optical interface.

3.1. Tools and Materials

The following toolsand materials are necessary for

preparation, assembly, inspection,and maintenance

of the assembly. Follow the operating instructions

(408--series) packagedwith the toolsand safety

guidelinespackagedwith the materials.

A. Required

— Fiber Optic Combination Strip Tool1278947--1

(408--4577)or1754708--1

— Micro--Strip Strip Tool492109--2 (for 900-- m

buered ber)

— Alcohol Fiber Wipe Packet 501857--2 or

lint--free tissuesand isopropyl alcohol greater

than91% (99% preferred)

— Fiber Optic Cleaver 1871696--1 (408--10086)

The above items are included in MT--RJ Jack

Termination Kit 1278346--1 and LightCrimp Plus

and MT--RJ Jack Combination Termination Kit

1278118--4.

—Cannedair (commercially available)

— Test Kit (408--4579):

TEST KIT OPTICAL FIBER

TEST EQUIPMENT

CONNECTOR

INTERFACE

1278861--1 50/125-- m MultimodeSC

1278861--2 50/125-- m MultimodeStraight Tip (ST) Style

1278862--1 62.5/125-- m MultimodeSC

1278862--2 62.5/125-- m MultimodeST Style

1278863--1 Singlemode SC

1278863--2 Singlemode ST Style

B. Optional

— Visual FaultLocator 1828352--1

— Bare Fiber Adapter 934--125

(available from RIFOCS )

—200¢Microscope Kit 1754767--1

— 2.5mm Universal Adapter 1754766--1

(includedwith microscope)

— MT--RJ Microscope Adapter 1754768--1

(use with microscope)

3.2. Preparation

A. Stripping the Cable

1. For workstation jacks,slide the jackboot(small

diameter end rst) onto the ber.

IMPORTANT —For correct system polarity, Channel“A”

must be connected to Channel “B” andChannel “B”

must be connected to Channel “A” on any cable run

or cable assembly (including fiberoptic equipment).

Refer to Figure 2.

2. Using the beroptic combination strip tool, strip

the cable jacket to expose approximately381 to

508 mm [15 to 20 in.] o ber. Trim the strength

members even with the jacket.

3. Using the micro--strip strip tool, strip the ber to

35 to 37 mm [1.38 to 1.46 in.].

NOTE

i

NOTE

i

DANGER

DANGER

CAUTION

!

NOTE

i

®

µ

µ

µµ

µ

µ

µ

™