Original Language Version

© Jack Sealey Limited

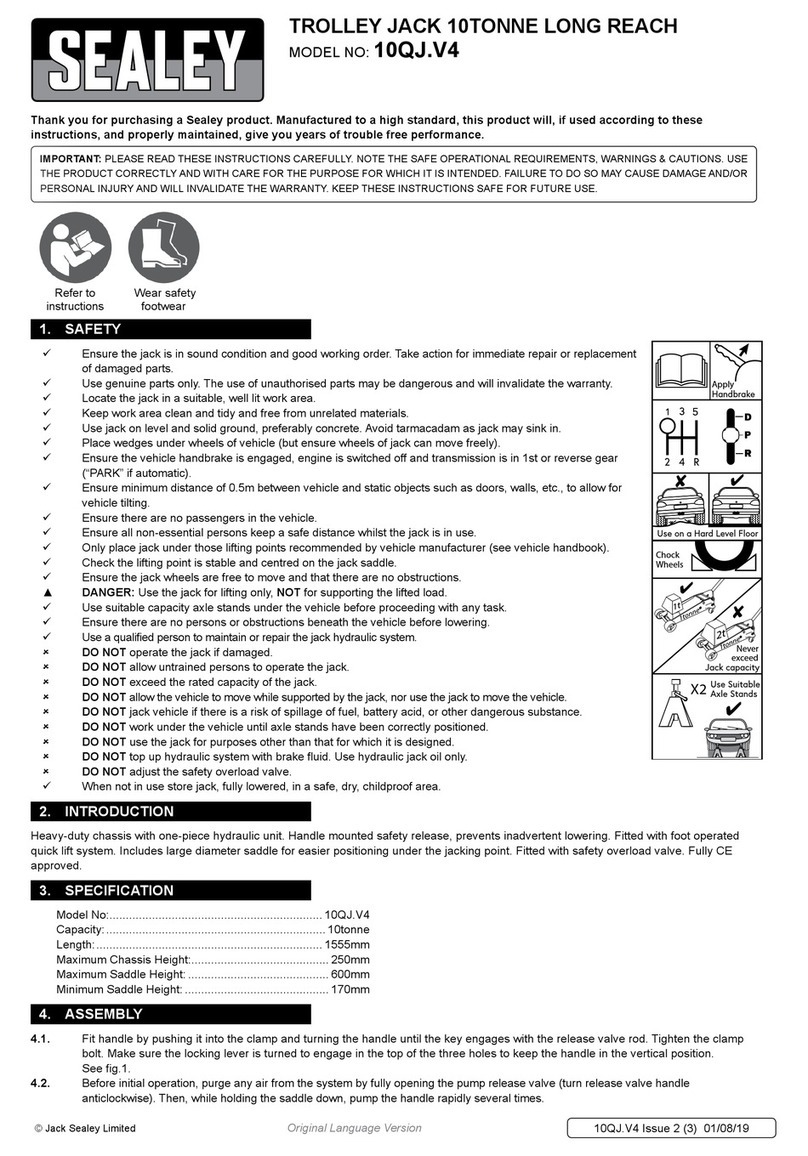

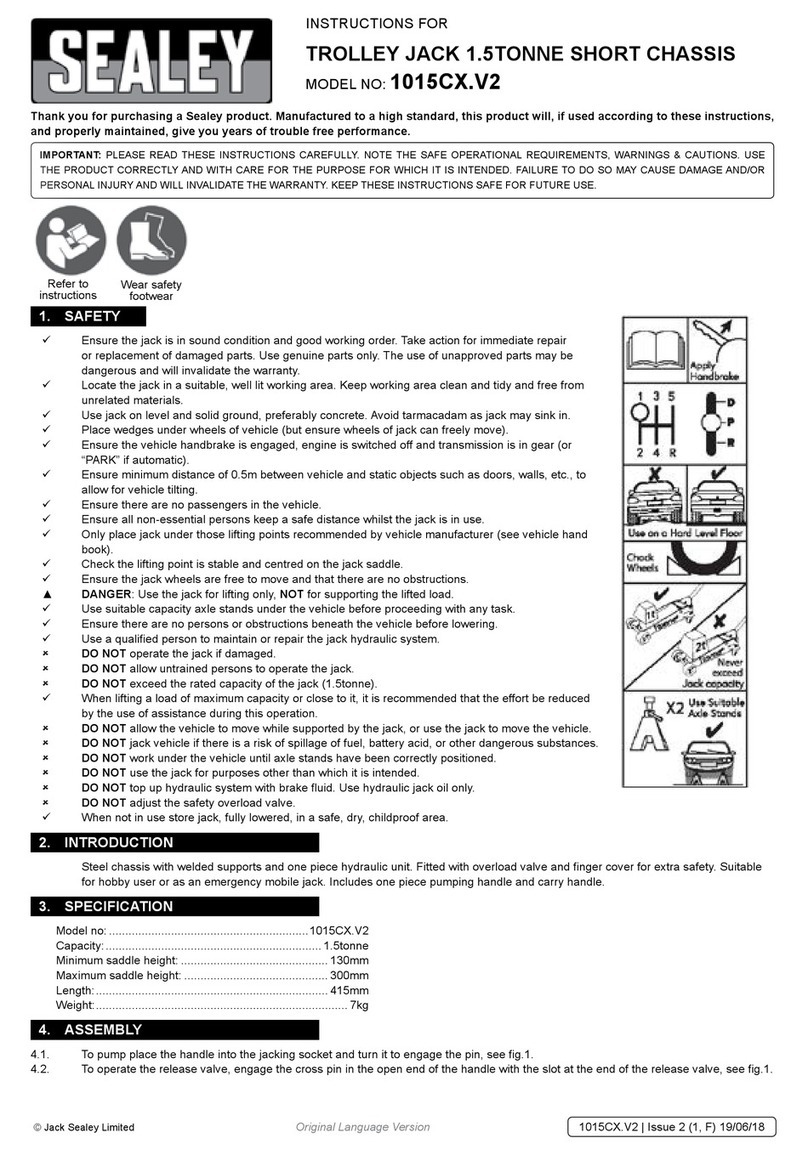

4. ASSEMBLY

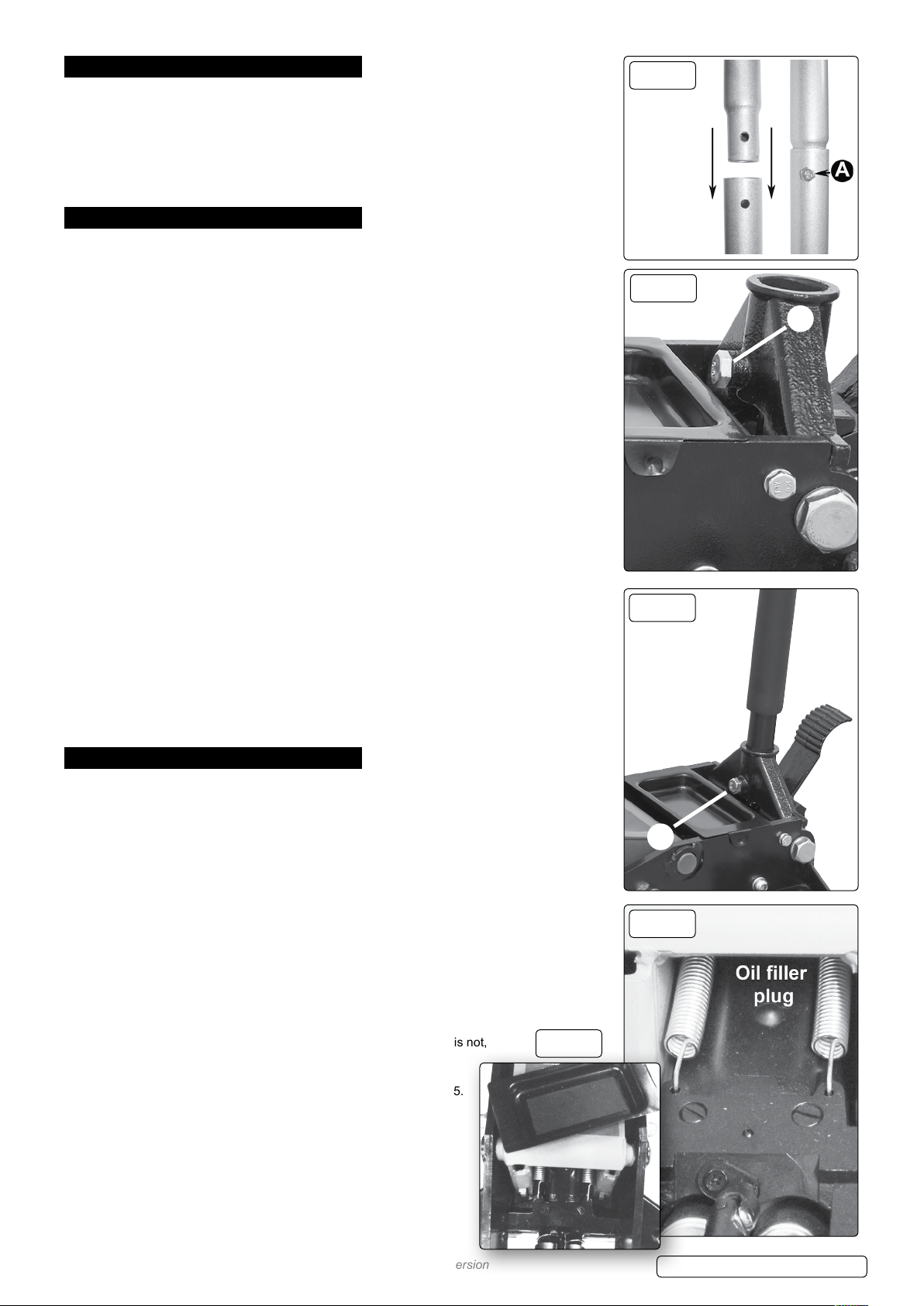

4.1. Inserttheupperhandleintothelowerhandle.Securethetwopiecestogetherwiththe

bolt (fig.1.A).

4.2. Undo the handle socket screw until it no longer protrudes into the handle socket (fig.2.B).

4.3. Insertthepumphandleintothehandlesocket,engagingthesquaredriveoftherelease

valve.

4.4. Ensure the handle is correctly inserted into the socket, then tighten the handle socket

screw (fig.3.B).

5. OPERATION

WARNING! Ensure you have read, understood and applied Section 1 safety precautions.

IMPORTANT: Before use, the operator is to visually inspect the jack for cracked welds,

damaged or missing parts or hydraulic leaks.

5.1. BEFORE FIRST USE

5.1.1. Beforeusingjackforthersttime,purgethehydraulicunitinordertoeliminateany

air in the system. Turn handle anti clockwise to open release valve.

5.1.2. Pump for 30 to 40 seconds. When complete, close the release valve by turning the

handle clockwise.

5.1.3. Place a few drops of hydraulic jack oil on pump piston and pump handle several times

to distribute oil. Thoroughly lubricate moving parts.

5.2. GENERAL JACKING

WARNING! Before lifting ensure Safety instructions are read and understood.

5.2.1. Position the jack saddle under the vehicle manufacturer’s recommended lifting point.

5.3. RAISING THE VEHICLE

5.3.1. Rotate handle clockwise to close the release valve.

5.3.2. Commence pumping handle up and down using maximum strokes until the jack saddle

reaches the vehicle manufactures jacking point. Use the foot pedal as a fast lifting

alternative method of raising saddle, especially useful in restricted spaces. Check the

jacking point is centrally located on the saddle and raise the vehicle.

5.3.3. Should the jack become overloaded, a safety excess pressure valve will open, and stop

the vehicle from lifting.

WARNING! The jack is a lifting device only and must not be used to support the load.

Use correctly rated axle stands to support the load.

5.4. LOWERING THE VEHICLE

5.4.1. Ifusingaxlestands,raisethejackhighenoughforthestandstobeeasilyremoved.

Then turn handle anticlockwise very slowly to open the valve.

5.4.2. The lowering speed is controlled by the amount you turn the handle. Lower carefully,

avoid any sudden changes in descent rate which would shock load the hydraulic

system.

WARNING! Ensure there are no persons or obstacles beneath the vehicle, or in the

path of its descent.

6. MAINTENANCE

IMPORTANT: Only fully qualified personnel should attempt maintenance or repair.

6.1. MONTHLY MAINTENANCE

Lubrication is critical to jacks. Any restriction due to dirt or rust can cause either slow

or extremely rapid jack movement, causing damage to the internal components.

To keep the jack well lubricated, carry out the following steps.

6.1.1. Lubricate the ram, the linkages and the saddle and pump mechanism with light oil.

6.1.2. Grease the wheel bearings and axles.

6.1.3. Keep all jack surfaces and warning labels clean.

6.1.4. Check and maintain the ram oil level (Section 7.3).

6.2. THREE MONTHLY MAINTENANCE

6.2.1. At three monthly intervals, check the ram for any signs of rust or corrosion. Clean the

ram as required and wipe with an oiled cloth.

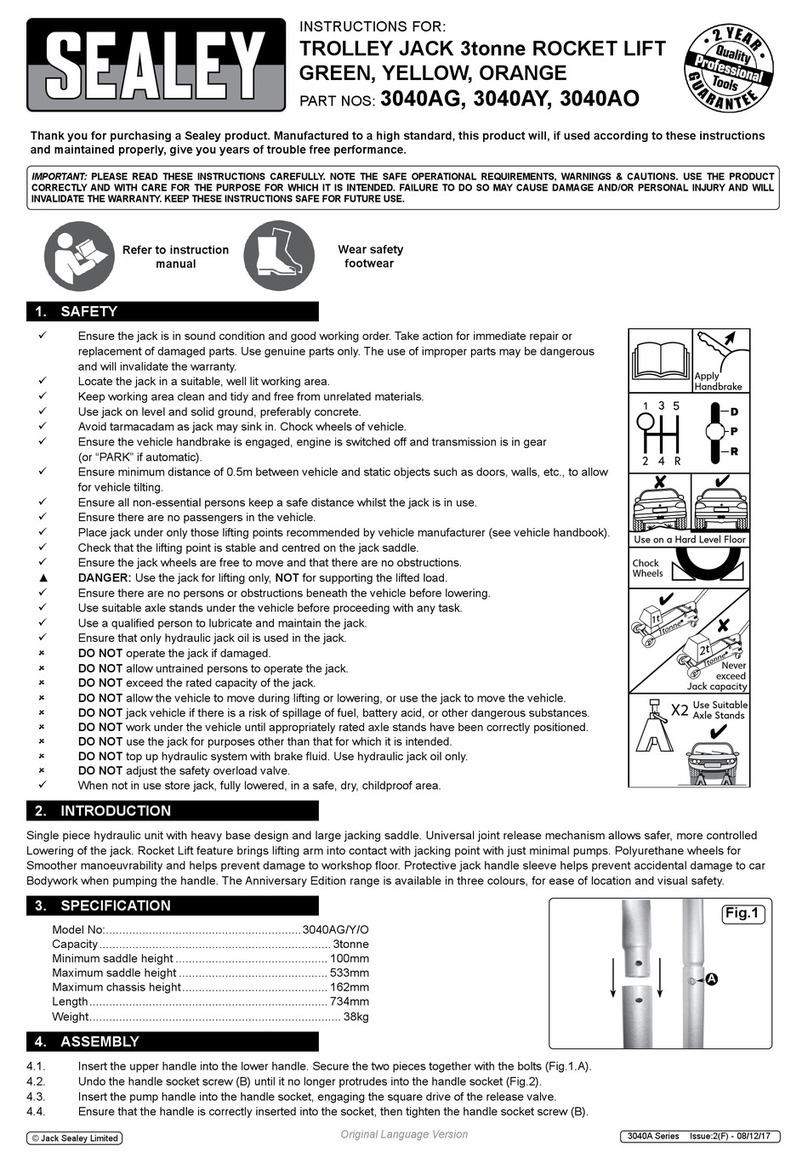

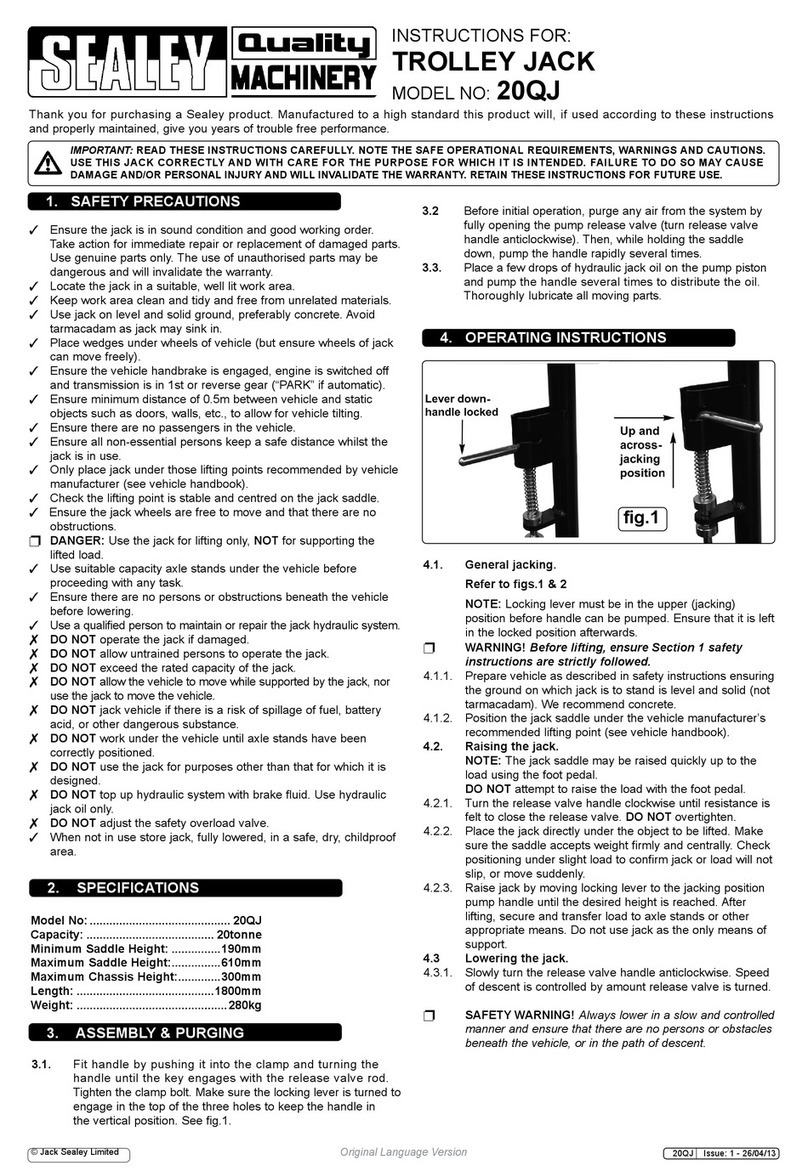

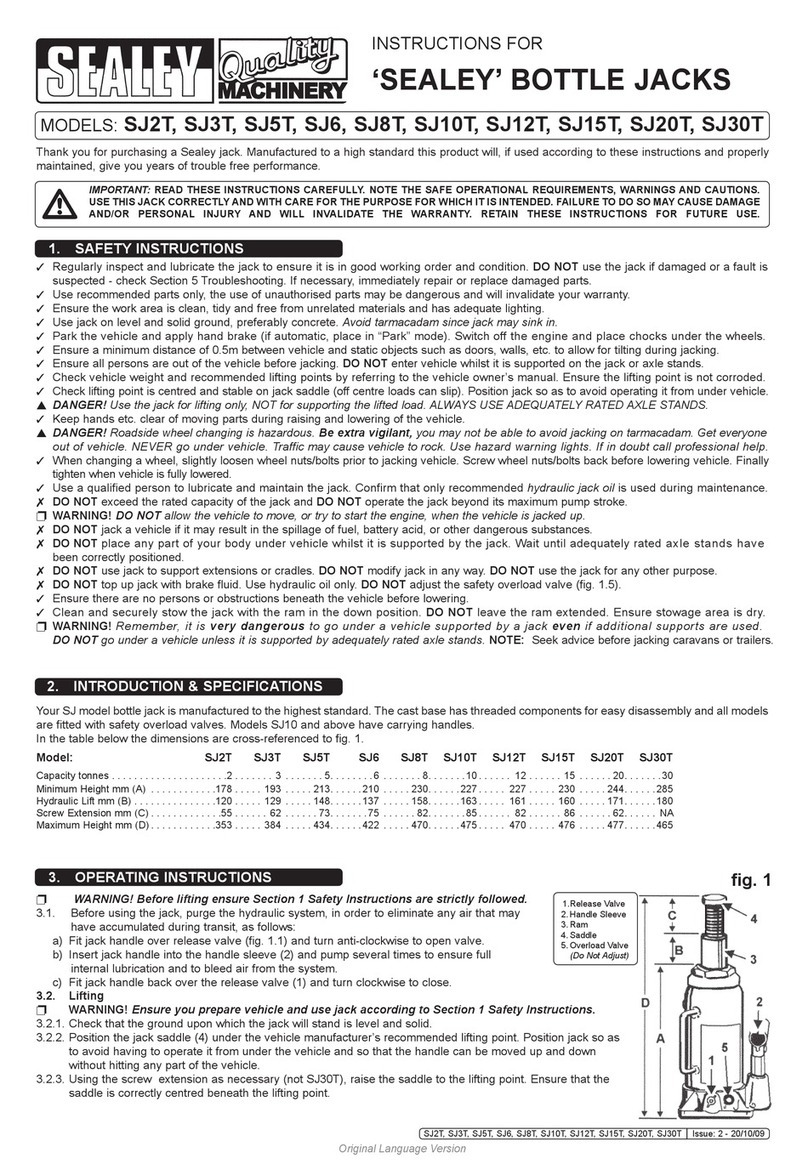

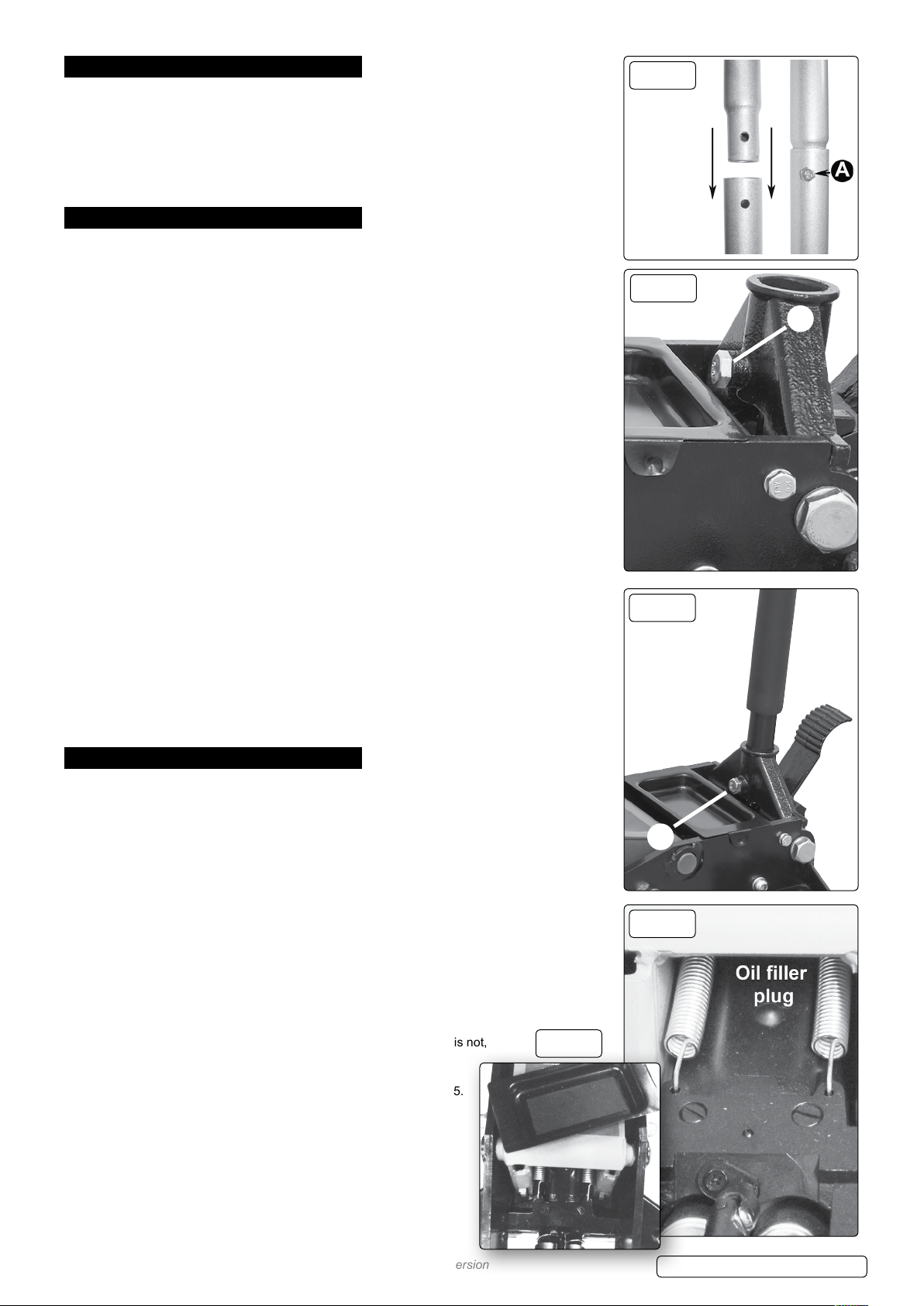

6.3. CHECKING THE OIL LEVEL

6.3.1. Fully retract the ram by turning the release valve counter-clockwise.

6.3.2. With the jack in the level position, remove the oil filler plug found under the removeable

magnetic wheel nut retention tray (fig.4 & 4.A).

6.3.3. Theoilshouldbelevelwiththebottomoftheoilfillerhole.Ifitisnot,

top up with clean hydraulic jack oil.

6.3.4. Replace the oil filler plug and check the jack operation.

6.3.5. Purge air from the hydraulic unit as required. Refer to Section 5.

NOTE: Always store the jack in the fully lowered position.

This will protect critical areas from excessive corrosion.

Owing to their size and weight, hydraulic products should

ideallyberepairedbylocalserviceagents.Wehaveservice/

repair agents in most parts of the UK. Before returning your

product please call our technical helpline on 01284 757505

for advice and troubleshooting guidance. If the jack is under

guarantee please contact your stockist.

g.1

g.2

B

B

g.4

g.3

g.4A

4040TB|Issue3(3)20/11/19