Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN47302

Introduction

Warning

Warranty

AMA Information

The warranty covers defects in material or workmanship or missing components to the original purchaser for 30 days from

the date of purchase. Compass Model Ltd will replace or repair, at our discretion, the defective or missing component.

Defective components must be returned to our Distributor prior to replacement.

Any part, which has been improperly installed, abused, crash damaged or altered by unauthorized agencies is not covered.

Under no circumstances will the buyer be entitled to consequential or incidental damages. The components used in this kit

are made from special materials designed for special applications and design strengths. We recommend that all replacement

parts be original parts manufactured by Compass Model Ltd to ensure proper and safe operation of your model. Any part

used which was manufactured by any firm other than Compass Model Ltd VOIDS all warranties of this product by Compass

Model Ltd.

We strongly encourage all prospective and current R/C aircraft pilots to join the Academy of Model Aeronautics. The AMA is

a non-profit organization that provides services to model aircraft pilots. As an AMA member, you will receive a monthly

magazine entitled Model Aviation, as well as liability insurance plan to cover against possible accident or injury. All AMA

charter aircraft clubs require individuals to hold a current AMA sporting license prior to operation of their models. For

further information, you can contact the AMA at:

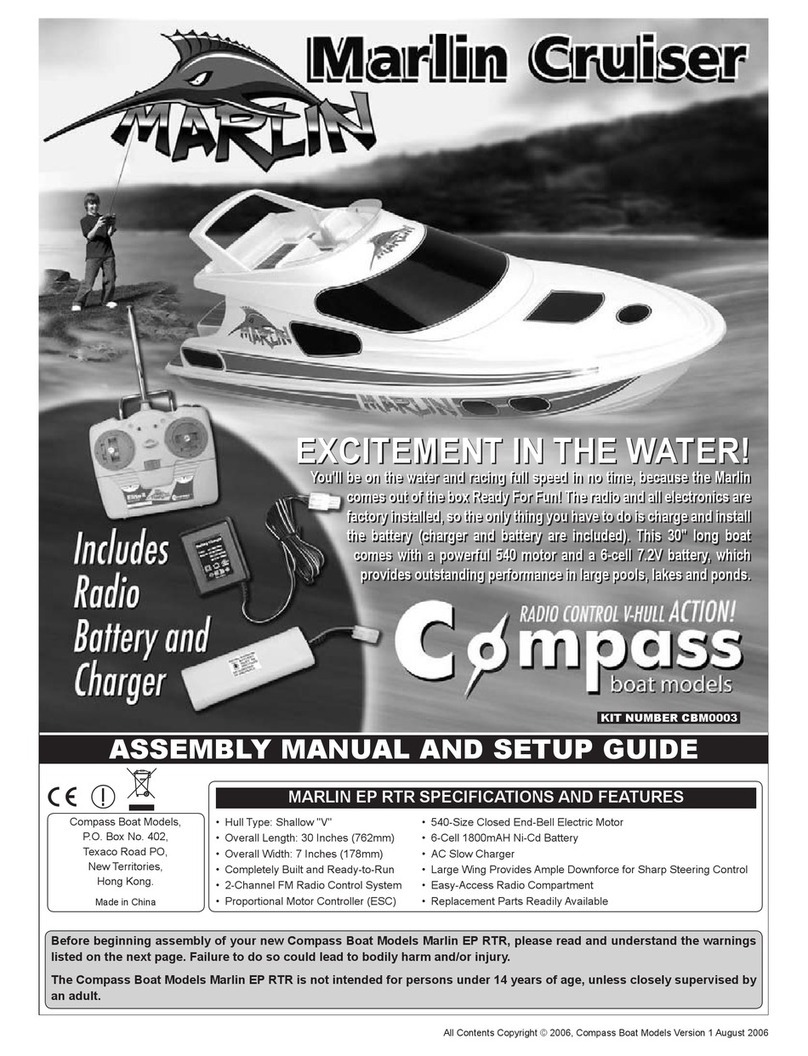

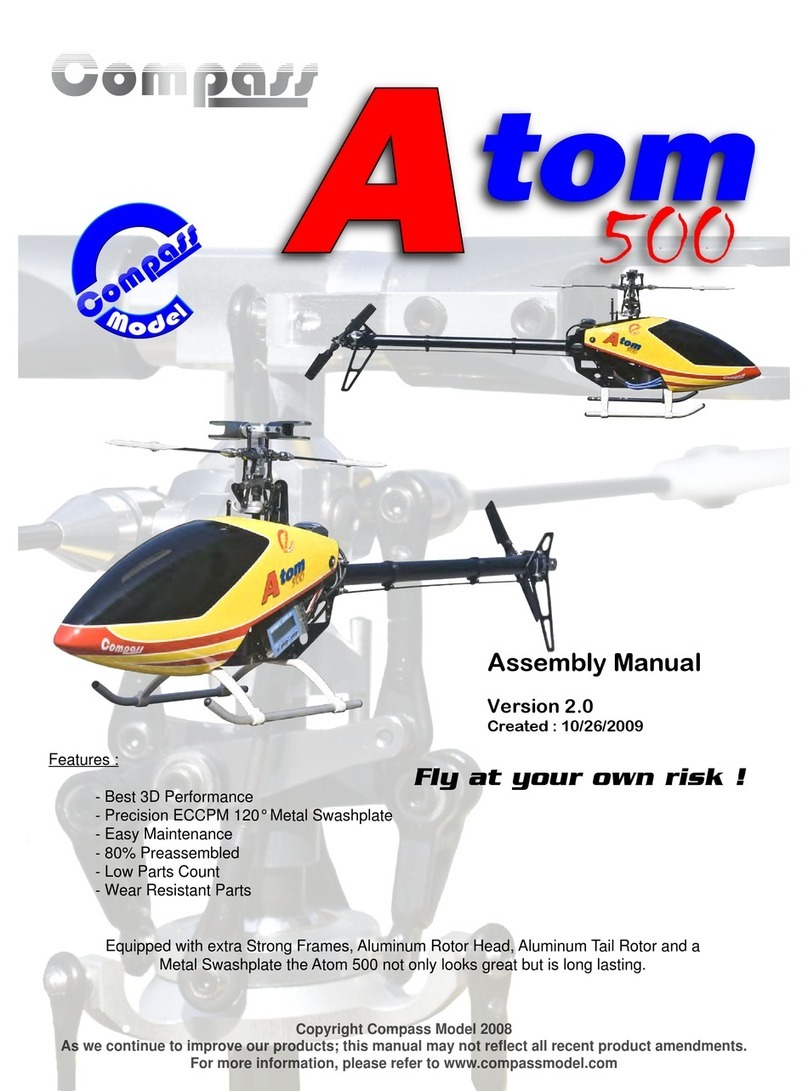

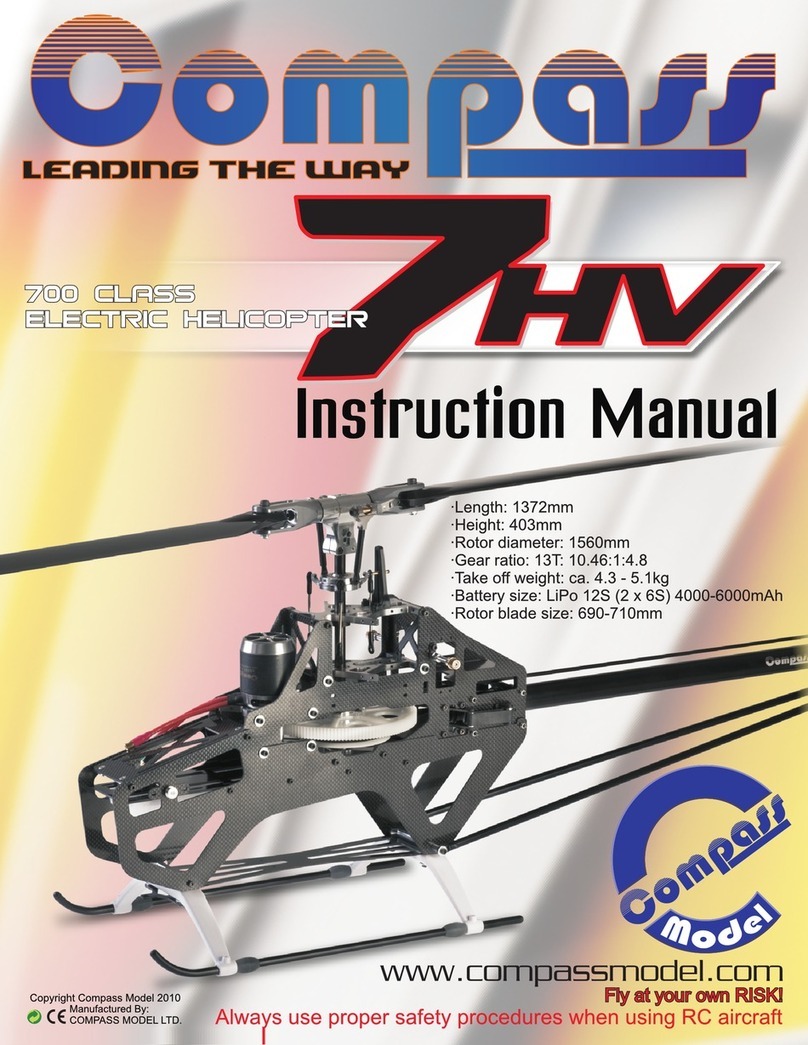

Thank you for choosing the Sport X and welcome to Compass Model. The Sport X has been designed to offer outstanding

performance. Same as other compass products, Sport X is powerful, stable, agile as well as accurate. The frame layout has

been designed to create an extraordinarily rigid platform which is both durable and further improved control accuracy. The

simple layout features light weight, low parts count and raise the center of gravity. Please read the complete manual before

assembly. Please take careful note of all precautions and assembly tips. Please also keep the manual as a reference for part

numbers and reassembly following maintenance.

Warranty Procedures

Mail all warranty information within 15 days of original purchase date. If service is required, send the component in

question (if not missing) together with a photocopy of your bill of sale and an accurate description of the problem and part.

Ship components fully insured and prepaid. Compass Model Ltd is not responsible for any shipping damages. We will, at our

discretion, notify you of any costs involved, or ship it COD. You are required to pay all postage, shipping and insurance

charges.

R/C Helicopter Safety

A model helicopter must be built exactly in accordance with the assembly instructions. Compass Model Ltd has spent much

time and efforts refining this product to make it reliable in operation and easy to build. Vibration and stress levels are high and

all fasteners and attachments must be secure for safe operation. Safe operation is the responsibility of the builder/flyer and

starts with careful construction and continues with selection and installation of reliable radio equipment and motor/engine.

The need for safety is nowhere greater than at the flying field. A number of guidelines for safe flight have been developed by

experienced flyers and are set down here. It is urged that they be read, understood and followed.

Each flying field has its own sets of safety guidelines which cannot be expressed here, so prior to any flight, refer

to the guidelines at your Flying Field.

Attention:

The radio-controlled model helicopter contained in this kit is not a toy, but a sophisticated piece of equipment. This product

is not recommended for use by children. Radio-controlled models such as this are capable of causing both property damage

and/or bodily harm to both the operator/assembler and/or spectator if not properly assembled and operated. Compass

Model Ltd. assumes no liability for damage that could occur from the assembly and/or use/misuse of this product. The 3D

Plus is a large glow powered model, it should be assembled and operated with special care. When operating your 3D Plus,

please exercise caution and safety.