Compu Pool C-CPP Commercial Series Manual 10

7.3.2 The ideal salt level is 3500 ppm. A low salt level will reduce efficiency of the

chlorinator and result in low chlorine production. A high salt level can cause a salty

taste to the pool. In addition, operating the unit outside the recommended salt

range will rapidly reduce the longevity of the cell. The salt in the pool/spa is

constantly recycled and the loss of salt throughout the swimming season should be

small. This loss is due primarily to the addition of extra water to replace water lost

from splashing, backwashing, and draining (because of rain). Salt is not lost due to

evaporation.

7.3.3 If salt content is too high you will need to reduce the level of water in the pool/spa

and refill the pool/spa with fresh water that has not been diluted with salt.

7.3.4 To initially start a pool with the correct amount of salt, add salt to the pool at a rate

of 0.03 pounds of salt for every 1 gallon of water.

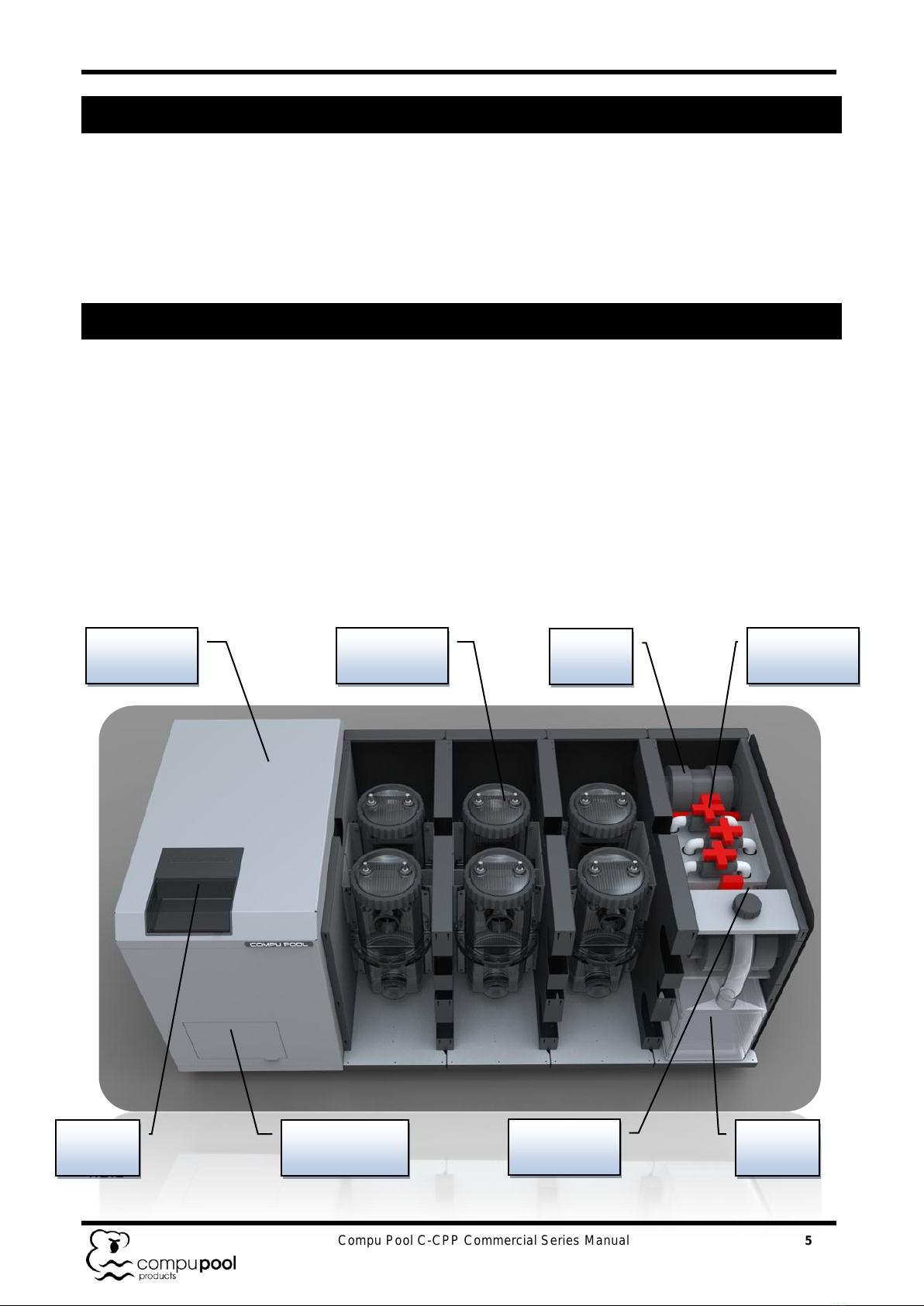

8.0 INSTALLATION

8.1 Positioning

8.1.1 The C-CPP series chlorinator must be installed in a room or area that is protected

from the environment and weather. The chlorinator must not be installed into a

location that is used for chemical storage as this will void the warranty.

8.1.2 Water leaks, no matter how small should be attended to immediately. If there is

water in the vicinity of the chlorinator, condensation may form on the internal

electrical components which can result in malfunction. The warranty will not cover

malfunction due to condensation or weather.

8.1.3 The chlorinator must be positioned downstream from the filtration plant and

upstream from any heating equipment.

8.1.4 Positioning should allow for easy access to the electronics module door, control

panel, cell bays and valves.

8.1.5 The chlorinator can be moved into position with either a forklift or pallet jack(s).

8.2 Plumbing

8.2.1 The C-CPP series chlorinator must be plumbed to the main return pipe of the pool

after the filtration system.

8.2.2 A branch line needs to be taken from the main filtration return line and diverted

through the Chlorinator to create a bypass installation. This must be done in the

manner shown in the plumbing diagram in the following section (Figure 1). Installing

the Chlorinator in this manner avoids excessive pressure on the Chlorinator and

filtration system. Additionally the Chlorinator can be isolated from the main flow

return line to enable uninterrupted filtration.