8

connections (if compatible with the application) which indicates leaks by bubbling. To further check for leaks,

or if the leak detection solution can not be used, close the cylinder valve for a period of time (recommended

24 hours), and observe the high pressure gauge for a drop in pressure. If so indicated, recheck the CGA

connection and all other high-pressure port connections.

6. Never attempt to x a leak under pressure. If leaks are detected, depressurize the system and retighten

the connection. Begin again at step 3.

7. Slowly turn the line regulator knob clockwise. This will increase the pressure of the line. Adjust to the

desired working pressure and again check for leaks using the methods described above.

OPERATION

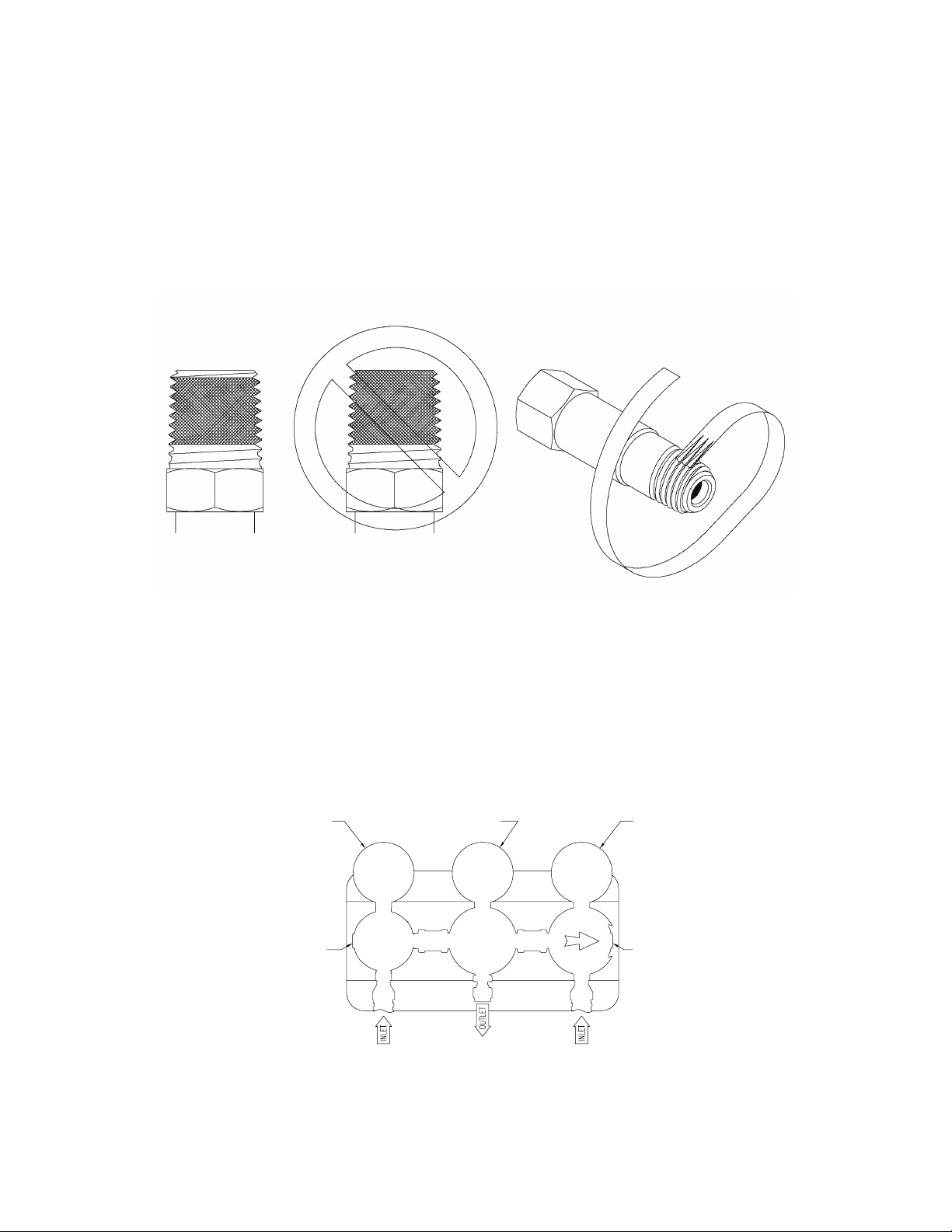

The arrow on the priority valve always points to the primary side; the bank opposite the primary side is

considered the reserve side. Starting with the arrow pointing to the right side, gas will ow from the right side

cylinder. As the gas in the primary side is depleted, the gas pressure will drop on the gauge of the primary

regulator. When the pressure drops to the pressure setting of the reserve side regulator, ow will begin from

the reserve cylinder; the inlet pressure on the primary side will stablize. This is called a changeover. At this

point, the gas pressure on the reserve side (preset regulator) will drop. This indicates that its time to change

the cylinders on the primary side. Before removing the nearly depleted primary cylinder, the priority valve

should be rotated 180°. This makes the reserve cylinder the primary source. Remove the depleted cylinder

and replace with a full cylinder. Before removing the cylinder be sure to close the cylinder valve and any

other valves that connect the cylinder to the system. Do not open any cylinder valves until all cylinders are

replaced. The full, replacement cylinder is now the reserve cylinder. Note: while changing cylinders on one

side, there will be no interruption in ow. A depleted cylinder will have the following gas pressure remaining:

Model Number

547 1XXX

547 1XXX*

547 EXXX

547 2XXX

547 3XXX

547 4XXX

Cylinder Pressure

250-350 PSIG 17-24 BAR

1050-1150 PSIG* 72-79 BAR*

1250-1500 PSIG 86-103 BAR

1800-2300 PSIG 124-159 BAR

2800-3300 PSIG 193-228 BAR

3800-4300 PSIG 262-297 BAR

*higher switch select setting for 5471XXX models

Gas will continue to ow from the primary side until the outlet pressure of the primary regulator matches the

pressure setting of the reserve regulator. (The pressure setting of the priority valve regulator changes when

the knob is turned 180°). When the gas pressure stops dropping on the primary side regulator and starts

to drop on the reserve side regulator, it is time to change the primary cylinder. The knob is rotated 180° to

the reserve side changing priority before the depleted cylinder is changed. It is helpful to maintain a log of

cylinder pressure, noting which direction the arrow is pointing on the priority valve. When the pressure gauge

is very low and the reserve side indicates that gas has begun to ow from the reserve cylinder, it is time to

rotate the knob and attach a full cylinder in reserve.

If the knob is not rotated before the empty cylinder is changed, two things can happen. First, gas may ow

from the changed cylinder to the existing cylinder. This is because the pressure setting of the regulator on

the primary side allows the regulator main valve to remain open. Second, when the cylinder is changed,

gas will begin to ow from the new cylinder, stopping ow from the existing cylinder. This means the existing

cylinder may be partially empty. After several cycles, it is possible that the reserve cylinder may empty

shortly after a switchover occurs. Always remember to rotate the knob on the priority valve regulator before

changing a depleted cylinder.

To change 5471XXX models with switch select to higher switching pressure settings to achieve maximum

outlet pressures of 800 psig. Locate the set screw that limits the travel of the right side selector knob, it is

located on the side of the knob and is screwed into a slot in the knob. When set for the lower factory default

switching pressure it is located closer to regulator body in that slot. Remove the set screw and rotate the

right side selector knob clockwise two full rotations. Reinstall the set screw. With the arrow pointing to the