-4-

2. N.F.P.A. Standard 51, Oxygen-Fuel Gas systems for Welding and Cutting, N.F.P.A., 470 Atlantic Avenue,

Boston, Massachusetts 02210

3. N.F.P.A. Standard 51B, Cutting and Welding Processes (same address as #2).

4. CONCOA publication ADE 872, Safety Precautions in Welding and Cutting.

5. Local Ordinances

6. O.S.H.A. Standard 29 CFR

7. C.G.A. Pamphlet C-4, American National Standard Method of Marking Portable Compressed Gas Containers

to Identify the Material Contained.

8. C.G.A. Pamphlet G-4, Oxygen – Information on the properties, manufacture, transportation, storage,

handling, and use of oxygen.

9. C.G.A. Pamphlet G-4.1, Equipment Cleaned for oxygen service.

10. C.G.A. Pamphlet G-4.4, Industrial Practices for Gas Oxygen Transmission and Distribution Piping

Systems.

11. C.G.A. Pamphlet G-5, Hydrogen – Information on the properties, manufacture, transportation, storage,

handling, and use of hydrogen.

12. C.G.A. Pamphlet G-6, Carbon Dioxide – Information on the properties, manufacture, transportation,

storage, handling, and use of carbon dioxide.

13. C.G.A. Pamphlet G-6.1, Standard for Low Pressure Carbon Dioxide Systems at Consumer Sites.

14. C.G.A. Pamphlet P-1, Safe Handling of Compressed Gases in Containers.

15. C.G.A. Safety Bulletin SB-2, Oxygen Deficient Atmospheres.

*C.G.A. pamphlets can be obtained from the Compressed Gas Association, 1235 Jefferson Davis Highway, Arlington,

VA 22202-3239, (703) 979-0900. Publications: (703) 979-4341. Fax: (703) 979-0134.

Keep all cylinders and manifolds away from any source of high temperature over 120°F (50°C) or possible fire hazards.

High-pressure gas contained in a closed cylinder becomes increasingly dangerous when exposed to high temperature

because pressure increases and the strength of the cylinder decreases. Manifolds installed in open locations should be

protected from weather conditions. During winter, protect the manifold from ice and snow. In summer, shade the

manifold and cylinders from continuous exposure to direct sunlight. Always leave access to the manifold for cylinder

replacement. Always secure cylinders, whether in use or in reserve.

LOCATION

The site chosen for the manifold installation shall be level, well ventilated, and at a safe distance from sources of

flames, sparks, and excessive heat. The manifold should not be placed in an area that may subject the manifold to

damage from passing trucks, cranes, or other heavy machines. Oxygen manifolds must not be installed under shafting,

belting, or other places where oil can drip on them. Under no circumstances should liquid product be allowed into

the hoses or manifold. For other location guidelines, see NFPA Standard 50 and 51.

INSTALLATION

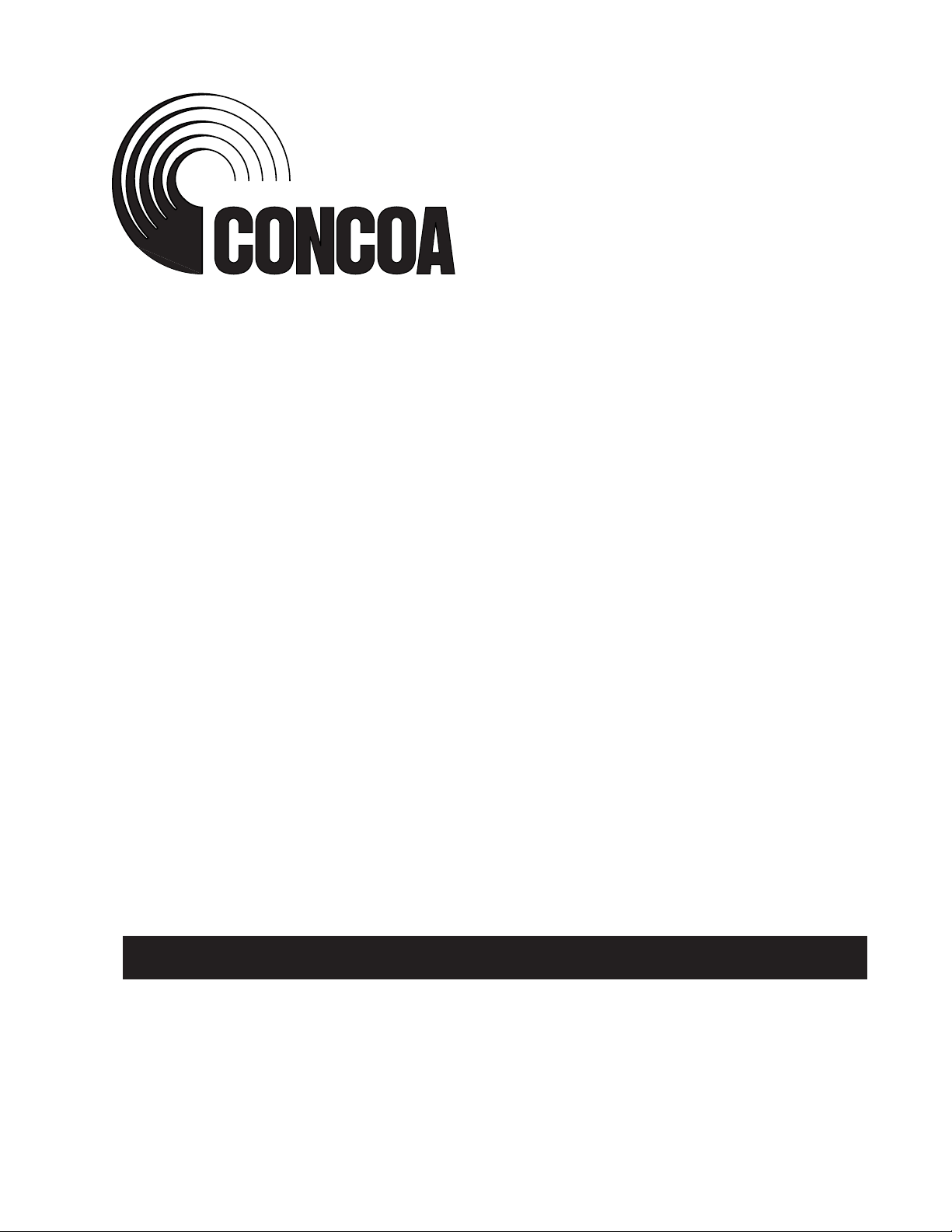

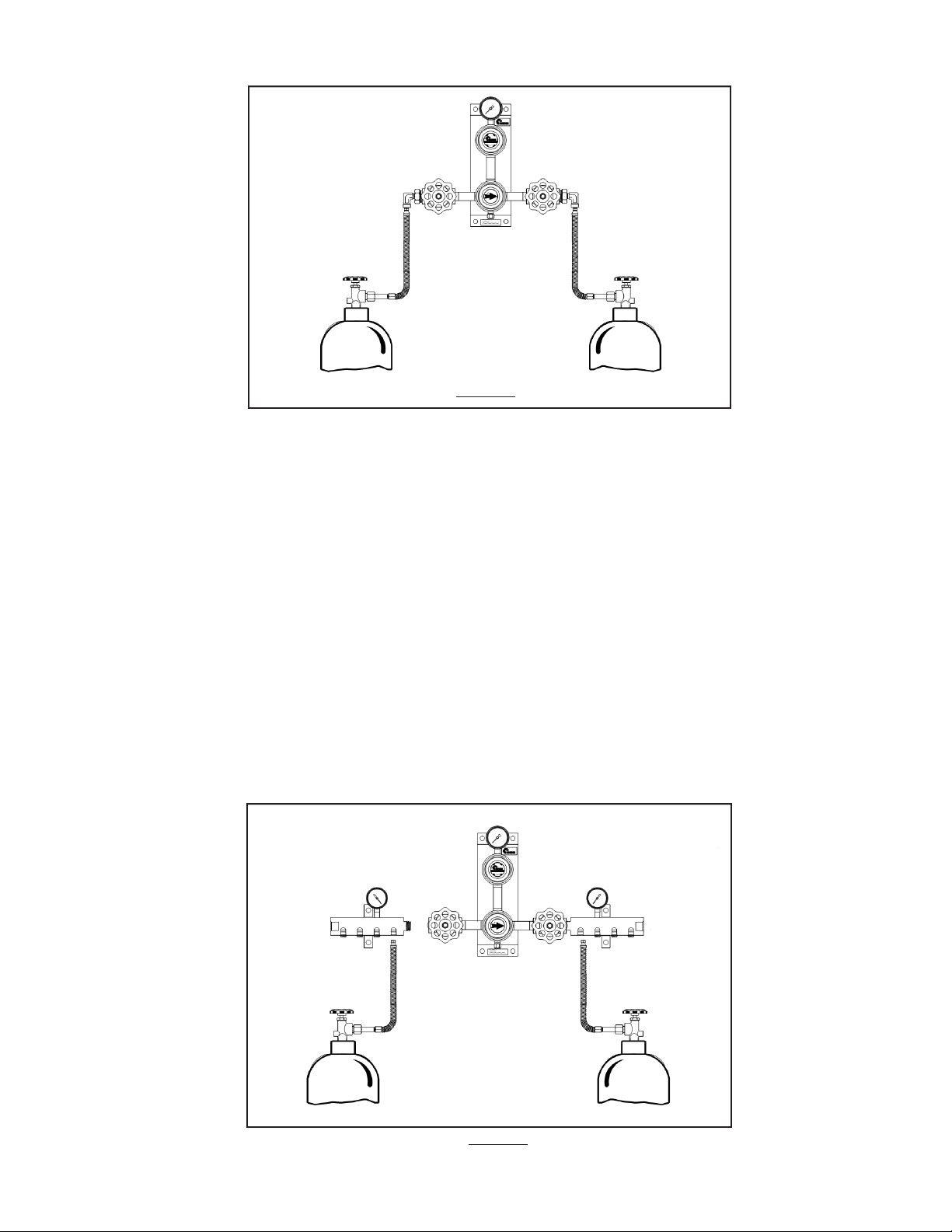

Installing the system:

1. Be sure to consider all factors when selecting materials.

2. Do not use oil or grease on fittings.

3. Be sure that all fittings are secure and leak tight. PTFE tape should be used on pipe threads as illustrated in

Figure1.

4. Purge devices:These devices can be purchased as accessories. Purge devices are used to remove toxic, corrosive,

or flammable gases from the customer’s system to a safe discharge area. This is particularly helpful when an

internal problem occurs (such as regulator malfunction).