3

CONTENTS

ON CONSIGNMENT OF THE MACHINE..........................................................................................................................................................................................................................4

SERIAL NUMBER PLATE.................................................................................................................................................................................................................................................4

INTRODUCTION..............................................................................................................................................................................................................................................................4

INTENDED USE........................................................................................................................................................................................ERRORE. IL SEGNALIBRO NON È DEFINITO.

TECHNICAL DESCRIPTION ............................................................................................................................................................................................................................................5

TECHNICAL DESCRIPTION ............................................................................................................................................................................................................................................5

GENERAL SAFETY REGULATIONS................................................................................................................................................................................................................................8

MACHINE PREPARATION...............................................................................................................................................................................................................................................9

1. INTENDED USE....................................................................................................................................................................................................................................................................9

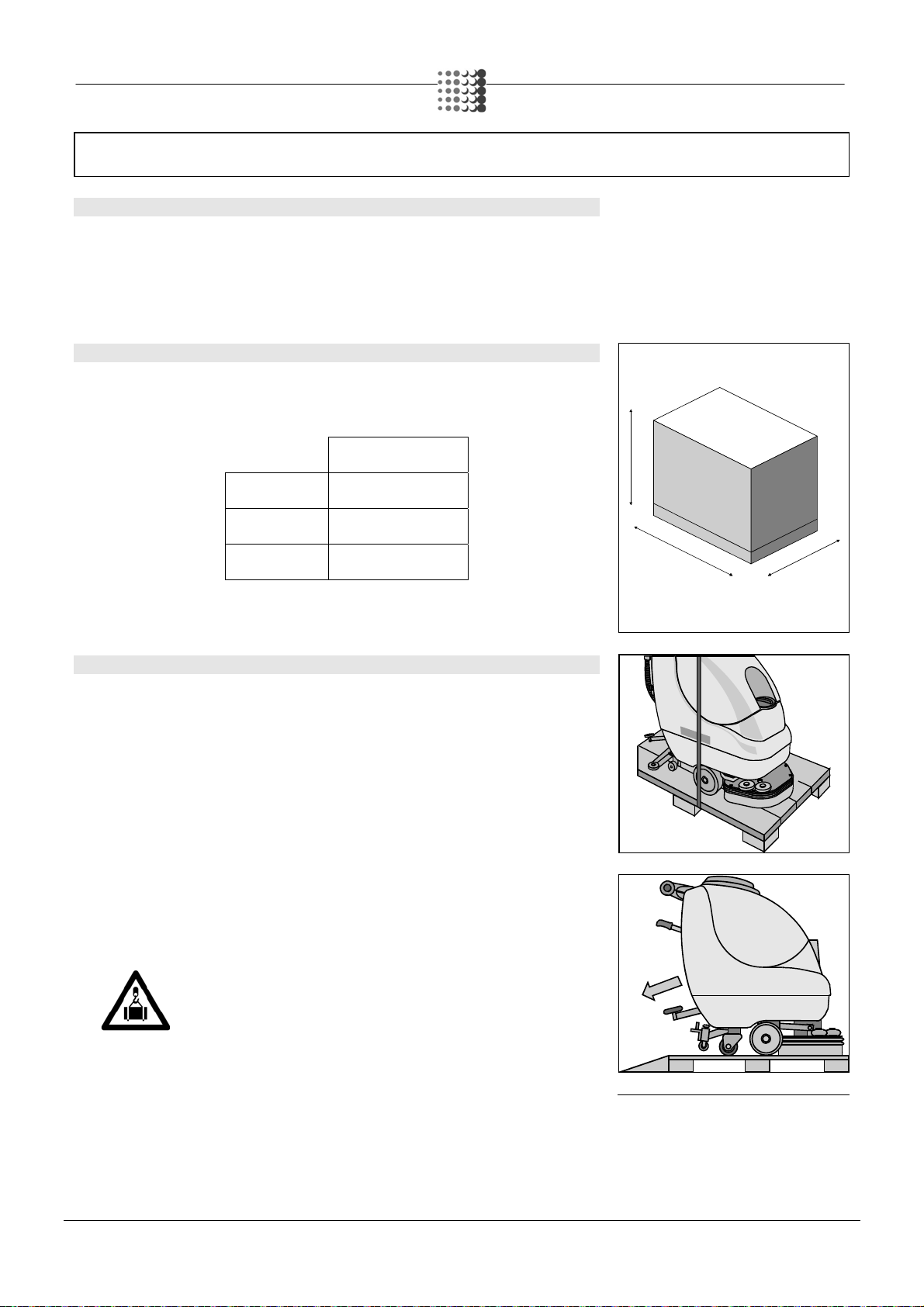

2. HANDLING THE PACKAGED MACHINE..............................................................................................................................................................................................................................9

3. HOW TO UNPACK THE MACHINE......................................................................................................................................................................................................................................9

MACHINE PREPARATION.............................................................................................................................................................................................................................................10

4. HOW TO MOVE THE MACHINE.........................................................................................................................................................................................................................................10

5. TYPE OF BATTERY (FOR B SYSTEM ONLY)................................................................................................................................................................................................................... 10

6. BATTERY MAINTENANCE AND DISPOSAL (FOR B SYSTEM ONLY)..............................................................................................................................................................................10

MACHINE PREPARATION.............................................................................................................................................................................................................................................11

7. FITTING/CONNECTION OF THE BATTERY (FOR SYSTEM B ONLY)..............................................................................................................................................................................11

MACHINE PREPARATION.............................................................................................................................................................................................................................................12

8. BATTERY CHARGER (FOR SYSTEM B ONLY).................................................................................................................................................................................................................12

MACHINE PREPARATION.............................................................................................................................................................................................................................................13

9. CONNECTION OF THE ELECTRICAL POWER SUPPLY CONNECTOR (FOR SYSTEM B ONLY).................................................................................................................................13

10. CHARGING THE BATTERY WITH BUILT-IN BATTERY CHARGER (OPTIONAL SYSTEM B ).......................................................................................................................................13

MACHINE PREPARATION.............................................................................................................................................................................................................................................14

11. BATTERY CHARGE LEVEL INDICATOR (SYSTEM B)....................................................................................................................................................................................................14

MACHINE PREPARATION.............................................................................................................................................................................................................................................15

12. HOUR COUNTER INDICATOR (OPTIONAL SYSTEM B).................................................................................................................................................................................................15

13. SOLENOID VALVE CONTROL SWITCH (OPTIONAL SYSTEM E).................................................................................................................................................................................. 15

14. INSTRUMENT PANEL COMPONENTS............................................................................................................................................................................................................................ 15

15. REAR COMPONENTS......................................................................................................................................................................................................................................................15

16. FRONT COMPONENTS....................................................................................................................................................................................................................................................16

17. ASSEMBLING THE SQUEEGEE...................................................................................................................................................................................................................................... 16

18. ADJUSTING THE SQUEEGEE INCLINATION..................................................................................................................................................................................................................16

MACHINE PREPARATION.............................................................................................................................................................................................................................................17

19. ADJUSTING THE SQUEEGEE HEIGHT...........................................................................................................................................................................................................................17

20. RECOVERY TANK............................................................................................................................................................................................................................................................ 17

MACHINE PREPARATION.............................................................................................................................................................................................................................................18

21. SOLUTION TANK / DETERGENT SOLUTION.................................................................................................................................................................................................................. 18

22. BASE SPLASH GUARD RUBBER ASSEMBLY (SINGLE BRUSH VERSION)................................................................................................................................................................. 18

MACHINE PREPARATION.............................................................................................................................................................................................................................................19

23. BASE SPLASH GUARD RUBBER ASSEMBLY (DUAL BRUSH VERSION)..................................................................................................................................................................... 19

24. BRUSH ASSEMBLY (SINGLE BRUSH VERSION).......................................................................................................................................................................................................... 19

25. BRUSH ASSEMBLY (DUAL BRUSH VERSION)..............................................................................................................................................................................................................20

26. REGULATING THE SOLUTION........................................................................................................................................................................................................................................20

MACHINE PREPARATION.............................................................................................................................................................................................................................................21

WORK............................................................................................................................................................................................................................................................................22

1.PREPARATION FOR WORK (SYSTEM B)..........................................................................................................................................................................................................................22

WORK............................................................................................................................................................................................................................................................................23

2.PREPARATION FOR WORK (SYSTEM E)..........................................................................................................................................................................................................................23

WORK............................................................................................................................................................................................................................................................................24

2. FORWARD MOVEMENTS..................................................................................................................................................................................................................................................24

3. OVERFLOW DEVICE..........................................................................................................................................................................................................................................................24

AT THE END OF THE WORK.........................................................................................................................................................................................................................................25

1. AT THE END OF THE WORK.............................................................................................................................................................................................................................................25

DAILY MAINTENANCE...................................................................................................................................................................................................................................................26

1. CLEANING THE RECOVERY TANK...................................................................................................................................................................................................................................26

2. CLEANING THE SUCTION FILTER....................................................................................................................................................................................................................................26

3. DISASSEMBLING AND CLEANING THE SQUEEGEE.......................................................................................................................................................................................................27

4. DISASSEMBLING THE BRUSH (SINGLE BRUSH BASE).................................................................................................................................................................................................. 27

4. DISASSEMBLING THE BRUSH (DUAL BRUSH BASE))....................................................................................................................................................................................................28

5. CLEANING OF THE SOLUTION DISCHARGE FILTER......................................................................................................................................................................................................28

WEEKLY MAINTENANCE..............................................................................................................................................................................................................................................29

1.CLEANING THE SQUEEGEE TUBE....................................................................................................................................................................................................................................29

2. CLEANING THE SOLUTION TANK ....................................................................................................................................................................................................................................29

3. REPLACING THE SQUEEGEE RUBBERS.........................................................................................................................................................................................................................30

TROUBLESHOOTING....................................................................................................................................................................................................................................................31

1. INSUFFICIENT WATER ON THEBRUSH..........................................................................................................................................................................................................................31

2. THE MACHINE DOES NOT CLEAN WELL......................................................................................................................................................................................................................... 31

3. THE SQUEEGEE DOES NOT DRY PERFECTLY...............................................................................................................................................................................................................31

4. EXCESSIVE FOAM PRODUCTION....................................................................................................................................................................................................................................31

6. ELECTRICAL FUSES AND THERMAL PROTECTIONS (SYSTEM E)...............................................................................................................................................................................31

DISPOSAL......................................................................................................................................................................................................................................................................32

CHOOSING AND USING THE BRUSHES......................................................................................................................................................................................................................33

EC DECLARATION OF CONFORMITY..........................................................................................................................................................................................................................34

EC DECLARATION OF CONFORMITY..........................................................................................................................................................................................................................35