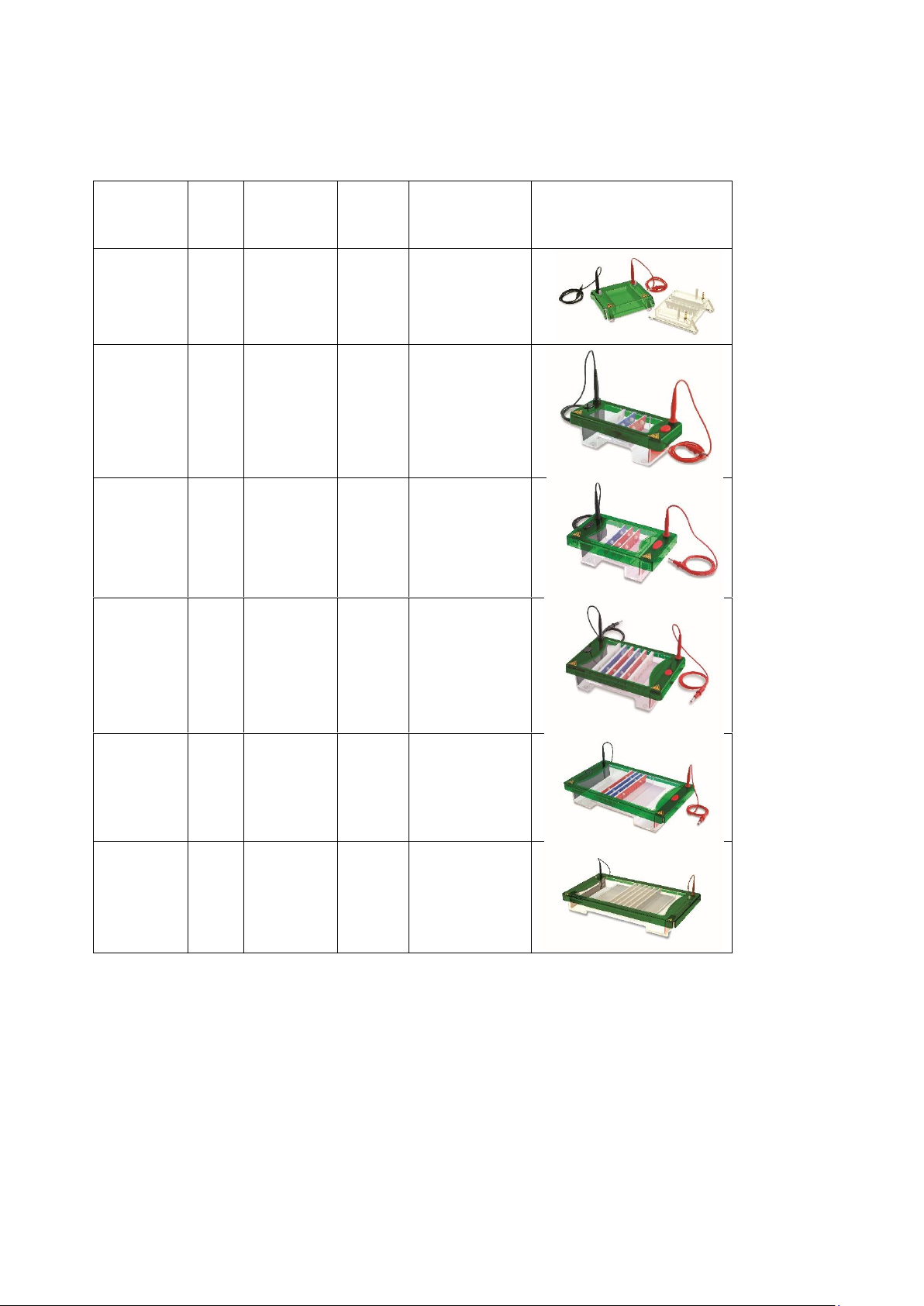

Horizontal Gel Electrophoresis units

1

Safety Information

Precaution

•When used correctly, these units pose no health risk.

•However, these units can deliver dangerous levels of electricity and are to be operated only by

qualified personnel following the guidelines laid out in this instruction manual.

•Anyone intending to use this equipment should read the complete manual thoroughly.

•The unit must never be used without the safety lid correctly in position.

•The unit should not be used if there is any sign of damage to the external tank or lid.

•Always isolate electrophoresis units from their power supply before removing the safety cover.

Isolate the power supply from the mains first then disconnect the leads.

•Do not exceed the maximum operating voltage or current.

•Do not operate the electrophoresis units in metal trays.

•Acrylamide is a volatile, cumulative neurotoxin and suspected carcinogen. Wear effective protective

clothing and follow recommended handling and disposal procedures.

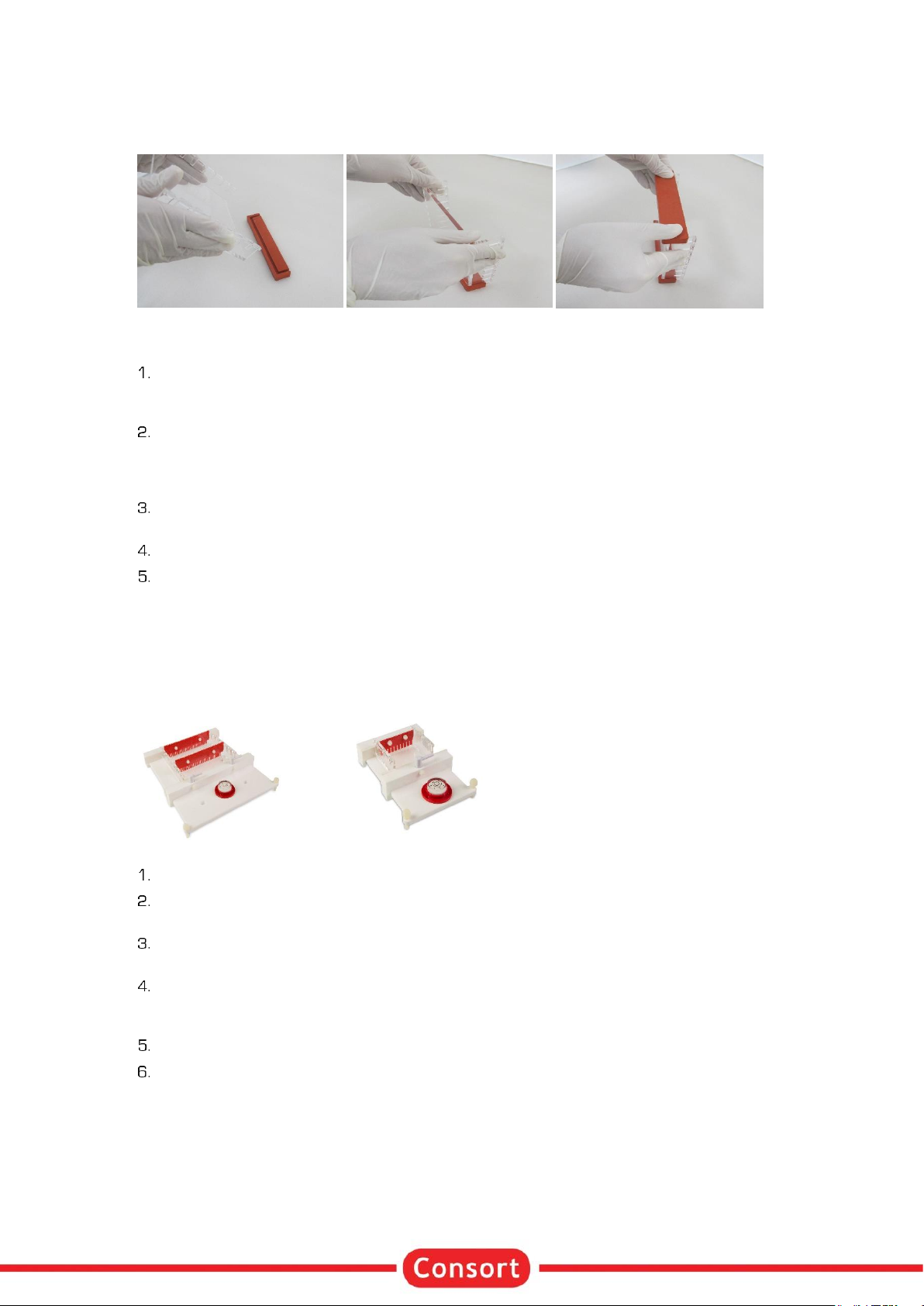

•Polymerised gels contain some unpolymerised monomer. Handle with gloves only. Following the

replacement of a platinum electrode have the unit inspected and approved by your safety officer

prior to use.

•Do not fill the unit with running buffer above the maximum fill lines.

•Do not move the unit when it is running.

•Caution: during electrophoresis very low quantities of various gases are produced at the electrodes.

The type of gas produced depends on the composition of the buffer employed. To disperse these

gases make sure that the apparatus is run in a well ventilated area.

General care and maintenance

•Units are best cleaned using warm water and a mild detergent. Water at temperatures above

60°C can cause damage to the unit and components. The tank should be thoroughly rinsed with

warm water or distilled water to prevent build up of salts but care should be taken not to damage the

enclosed electrode and vigorous cleaning is not necessary or advised. Air drying is preferably before

use.

•The units should only be cleaned with the following: warm water with a mild concentration of soap or

other mild detergent (compatible detergents include dish washing liquid, hexane and aliphatic

hydrocarbons). The units should not be left to in detergents for more than 30 minutes.

•The units should never come into contact with the following cleaning agents, these will cause

irreversible and accumulative damage: acetone, phenol, chloroform, carbon tetrachloride,

methanol, ethanol, isopropyl alcohol alkalis.

•In case of Rnase Decontamination clean the units with a mild detergent as described above. Wash

with 3 % hydrogen peroxide (H2O2) for 10 minutes. Rinsed with 0.1 % DEPC- (diethyl pyrocarbonate)

treated distilled water (Caution: DEPC is a suspected carcinogen. Always take the necessary

precautions when using.) RNaseZAP™ (Ambion) can also be used. Please consult the instructions for

use with acrylic gel tanks.