Continental Hydraulics Installation Manual

Page 10 of 15 CEM-SD-A CHI 1013477 May 2012

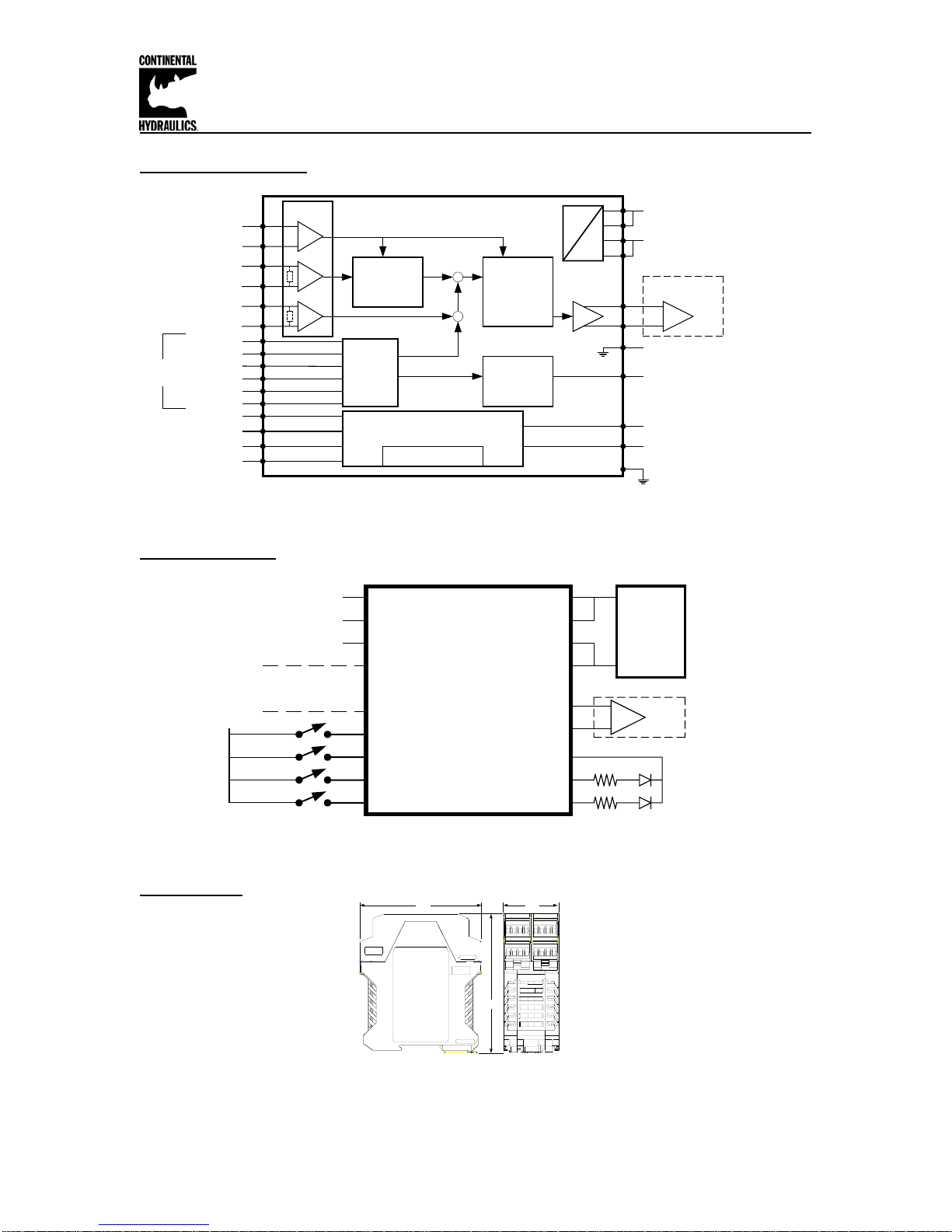

Scaling of analog input:

This module has a native analog voltage input range of 0 to +10v for command and feedback.

These inputs can be scaled and offset with software to allow a wide variety of input voltages. A

few examples are:

0 to +10v, 0 to +5v, +1 to +5v, +0.5 to +4.5v

The AIN:W parameter adjusts command port, and AIN:X parameter adjusts the feedback port.

Each can be independently set for either voltage or current command, and each can be

independently scaled.

Example: AIN:W V will set the command input to voltage. Default range = 0 to +10v

Example: AIN:W C will set the command input to current. Default range = 4 to 20mA

Example: AIN:X V will set the feedback input to voltage. Default range = 0 to +10v

Example: AIN:X C will set the feedback input to current. Default range = 4 to 20mA

Analog voltages or currents are scaled with the following linear equation:

Output = A/B * (Input – C)

“Output” of this scaling equation must always be equal to the module native input range, 0 to

+10v. “Input” can be any voltage within this 10v range.

The ratio of A/B allows for a decimal scaling factor. These two numbers are chosen to provide a

“gain” to the input signal. A and B must be whole numbers. Range is -10000 to 10000.

(Default; A = 1000, B = 1000)

C is an offset, measured as a percentage of range. C has units of 0.01%, and has the range of

–10000 to 10000. (Default; C = 0)

Scaling of voltage inputs:

Example: Typical AIN parameter settings for popular command and feedback voltages:

Command A B C description

0 to +10v 1000 1000 0 100% scale, 0% offset

0 to +10v 1 1 0 100% scale, 0% offset

0 to +10v 10 10 0 100% scale, 0% offset

0 to +5v 10 5 0 200% scale, 0% offset

+1 to +9v 10 8 1000 125% scale, 10% offset

+0.5 to +4.5v 10 4 500 250% scale, 5% offset

0 to 8v 10 8 0 125% scale, 0% offset

Scaling of current inputs:

Example: Typical AIN parameter settings for popular command and feedback currents:

Command A B C description

4 to 20mA 20 16 2000 125% scale, 20% offset

4 to 20mA 1250 1000 2000 125% scale, 20% offset

4 to 20mA 5 4 2000 125% scale, 20% offset

0 to 20mA 20 20 0 100% scale, 0% offset