7

ENGLISH

CONTRACOR® CK-50 Art. 50100

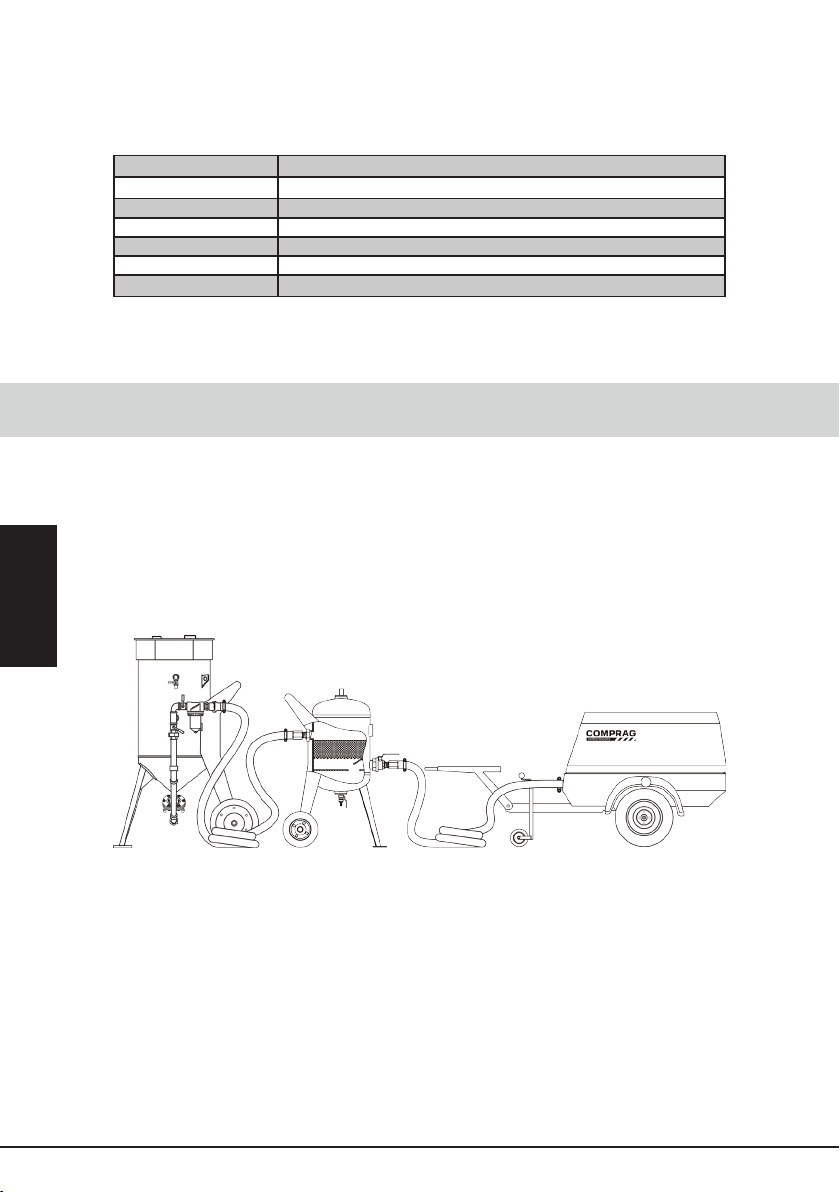

3.3. Air Requirements.

The CK-50 Portable Moisture Separators requires min. 5 m3/min by 4 bar and max. 22

m3/min by 10 bar for the efcient operation.

At lower/higher volume and pressure CK-50 Portable Moisture Separator does not remove

as much moisture and oil.

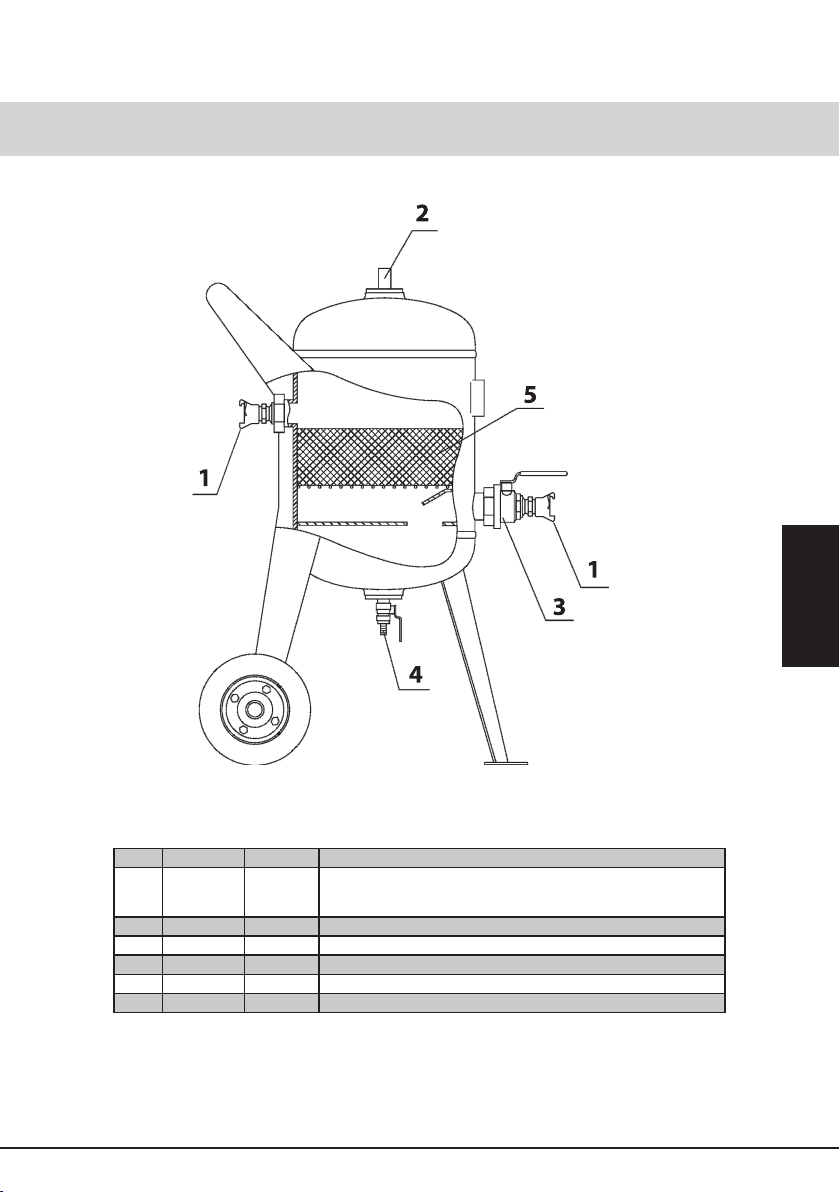

3.4. Cleaning.

Once a day completely open the drain ball valve (7) to blow out any debris that may have

accumulated.

If the stainless-steel mesh becomes caked with oil and dirt, disconnect the CK-50 Portable

Moisture Separator from the air line and clean it with warm water.

4. Warranty and warranty service regulations

Please, ensure that this warranty card is lled in clearly, correctly with completely by

the seller organization, that sells you our product.

1. CONTRACOR warrants production (hereinafter referred to as “equipment”)

manufactured by CONTRACOR to be free from defects in workmanship preventing normal

equipment operation during twelve months. This period of time is calculated from the

date of purchase lled in by the Seller organization (hereinafter referred to as “Seller”) in

this warranty policy.

2. Obligations arising from this warranty are fullled by the Seller or authorized

organizations. Please contact the Seller to obtain the list of authorized organizations.

3. This warranty is limited to the repair or replacement of the defective part only,

the defect of the part appeared during the period of warranty, without any payments by

the purchaser if conditions of the warranty are observed. Repair or replacement of defect

parts will not extend the warranty coverage on the equipment beyond the original expira-

tion date.

4. Above-mentioned warranty term does not apply to assemblies and parts if in the

user’s guide supplied with the equipment a special warranty term is specied for these

assemblies and details.

5. This warranty is not applied to the defects, caused by improper use or use with

violation of intended use, wrong storage, drops or impacts, incorrect maintenance, damage

caused by freezing or use with violation of user’s manual requirements.

6. The warranty does not cover electric motor damage caused by one phase failure.