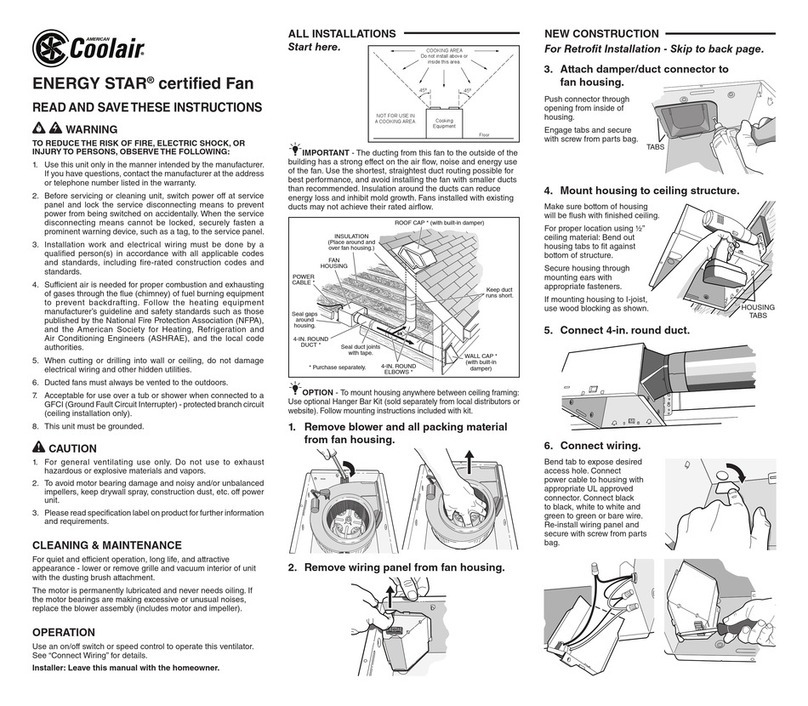

FAN ASSEMBLY AND MOUNTING

Before installation of fan, check carefully for shipping damage which may result in blade misalignment, deformed

parts or other damage. After motor has been mounted, check pulley alignment and belt tension. (For details on

pulley alignment, refer to Page 8 in this booklet.). Before connecting the power source, check motor nameplate to

be sure the correct phase and voltage will be applied. Single phase motors are shipped from the factory wired for

230 volt operation. For low voltage operation see motor manufacturer’s instructions on nameplate. Make sure

propeller turns freely without striking fan frame or any foreign object which may interfere with its operation. Note

direction arrow on orifice to make sure propeller is rotating in the correct direction when power is applied.

Motor Mounting

If the fan and housing are factory assembled, then the motor bracket is already mounted in the correct position and

this section may be skipped. If the fan is not factory mounted in the housing, the motor bracket will need to be

moved from its shipping position.

1. If needed, remove the motor bracket from its shipping position and bolt it to the uprights using the 2nd & 3rd

holes from the bottom of the uprights. Note: It may be necessary to slightly adjust the motor bracket in its slots

to achieve proper belt tension.

2. The rotary belt tensioner (if included) should be mounted on the right upright (when viewed from the back of the

fan — see Figure 5) in the 7th & 8th holes from the bottom.

3. Place the motor on the motor bracket and bolt it down using the hardware

provided. Make sure the motor base remains level.

4. The motor pulley should be placed on the motor shaft with the “set screw” side

of the pulley toward the motor. Using a long straight bar, check the alignment of

the motor pulley and the fan hub pulley. If necessary, loosen the motor pulley

set-screw and/or the motor mounting bolts and adjust as necessary. Re-tighten

pulley set screw and motor mounting bolts. IMPORTANT: Motor bracket bolts

must be secured to maintain proper belt alignment and tension.

Once the motor has been properly mounted and the pulleys have been aligned,

complete the assembly of the fan by threading the belt over the fan hub pulley

groove, motor pulley, and belt tensioner (if included) as shown in Figure 5. For

Model MNBCDD, the tensioner is assembled and should be set for proper belt

tension. If a tension adjustment becomes necessary, refer to Page 8 in this booklet.

Again, check for belt alignment using a straight bar as described above. Next, turn

the blade assembly by hand to insure free rotation. The fan is now ready to be

mounted into the wall housing, if not already factory assembled.

Fan Mounting

If the fan is not factory mounted in the housing, lift the fan (from the outside of the building) and place it inside the

assembled wall housing so that the fan panel is flush with the end of the wall housing. Using twenty 5/16” X 3/4”

bolts and twenty 5/16” whiz-lock nuts, fasten the fan

into place in the housing. Caulk around the

perimeter of the fan panel to seal the housing.

For proper fan operation, the corner deflectors must

be fastened to the fan. First, place the deflector

inside the housing such that the two shorter sides

(with the flanges and mounting holes) are against

the housing, and the longer side is against the fan

panel. The holes in the deflectors should align with

the holes in the housing. Fasten each deflector

using four of the ¼” x ¾” self-tapping screws

provided. The screws must be fastened from the

outside of the housing through the housing and then

through the deflector. See Figure 6.

Weatherproofing

IMPORTANT: To prevent rainwater intrusion, caulk the outside top seam between the top of the fan and the

housing.

Figure 5

Page 4

Figure 6

Corner

Deflector

¼” x ¾”

Self-Tap

Screws