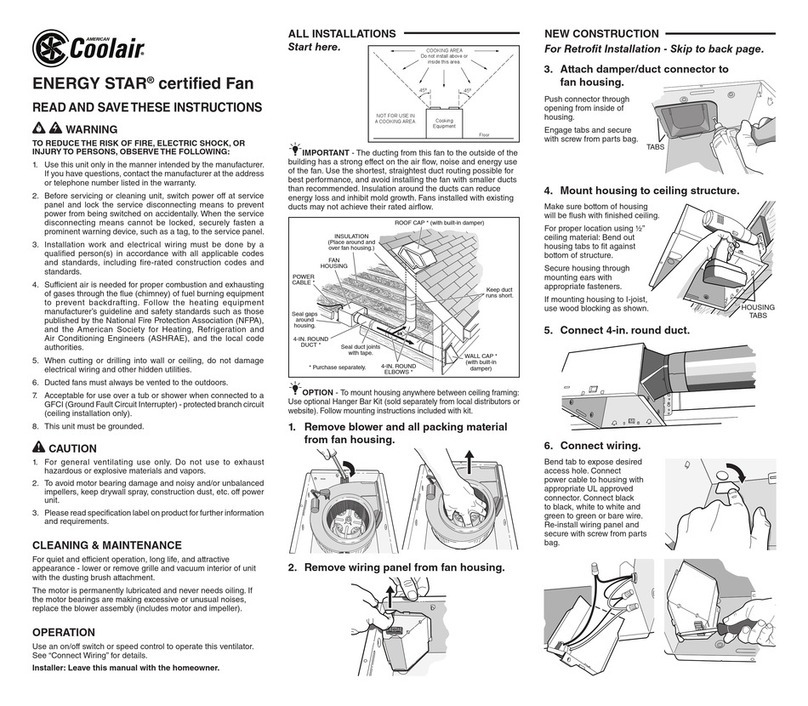

CONE ASSEMBLY

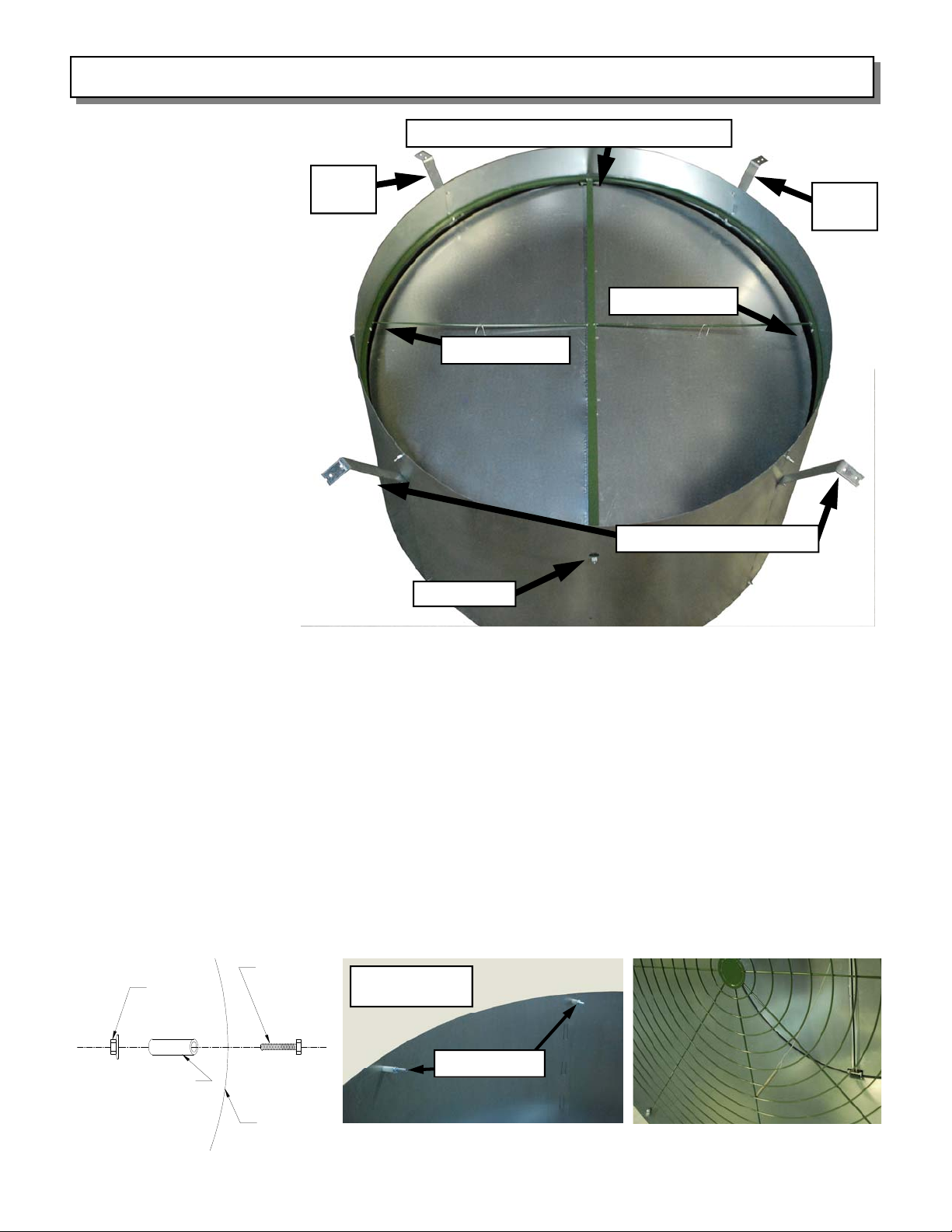

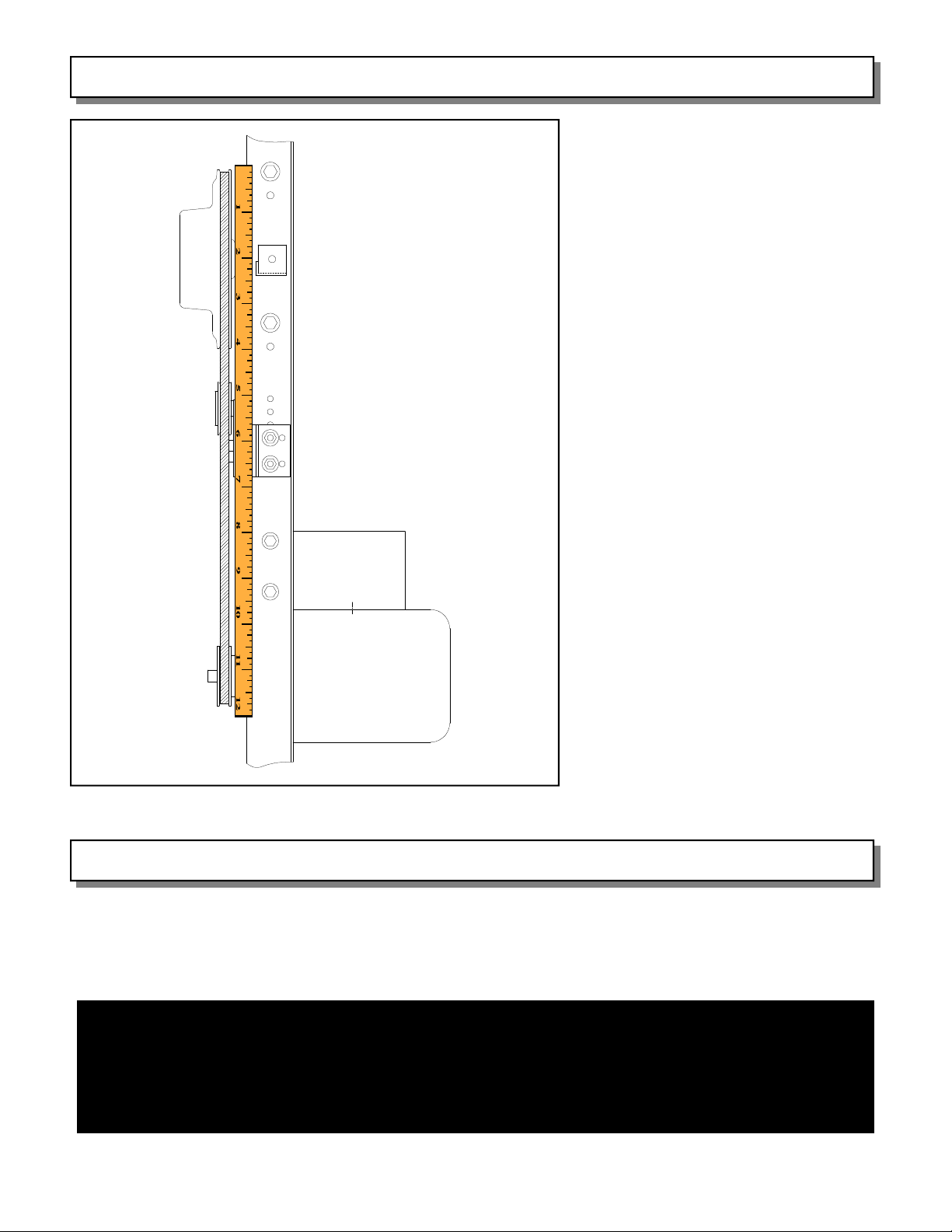

Next, the damper door ring assembly should be fastened to the

cone. Note that the damper door ring assembly has a top — where

the door-restraining cable is permanently attached — and a bottom

(where the cable spring is held in place for shipment by a rubber

band). Take the damper door ring assembly, making sure the doors

open downward, and insert it at an angle into the cone as shown in

Figure 15. The top end with the door-restraining cable permanently

attached should be opposite the drain hole in the cone. Once the

entire ring assembly has been placed inside the cone, level the ring

and align the pre-drilled ring holes with the corresponding

overlapping holes in the cone. From the inside of the assembly,

place a 1/4” X 1-1/4” bolt through the holes in the 3-o'clock and 9-

o’clock positions of the ring (locating the drain hole at the 6-o’clock

position), through the Handles, and fasten with two 1/4” whiz-lock

nuts. Continue fastening the door assembly to the cone using two

5/16” X 1/2” self-drilling screws: one adjacent to the drain hole

(bottom), and one on the opposite side (top) of the cone. See

Figure 16.

Page 5

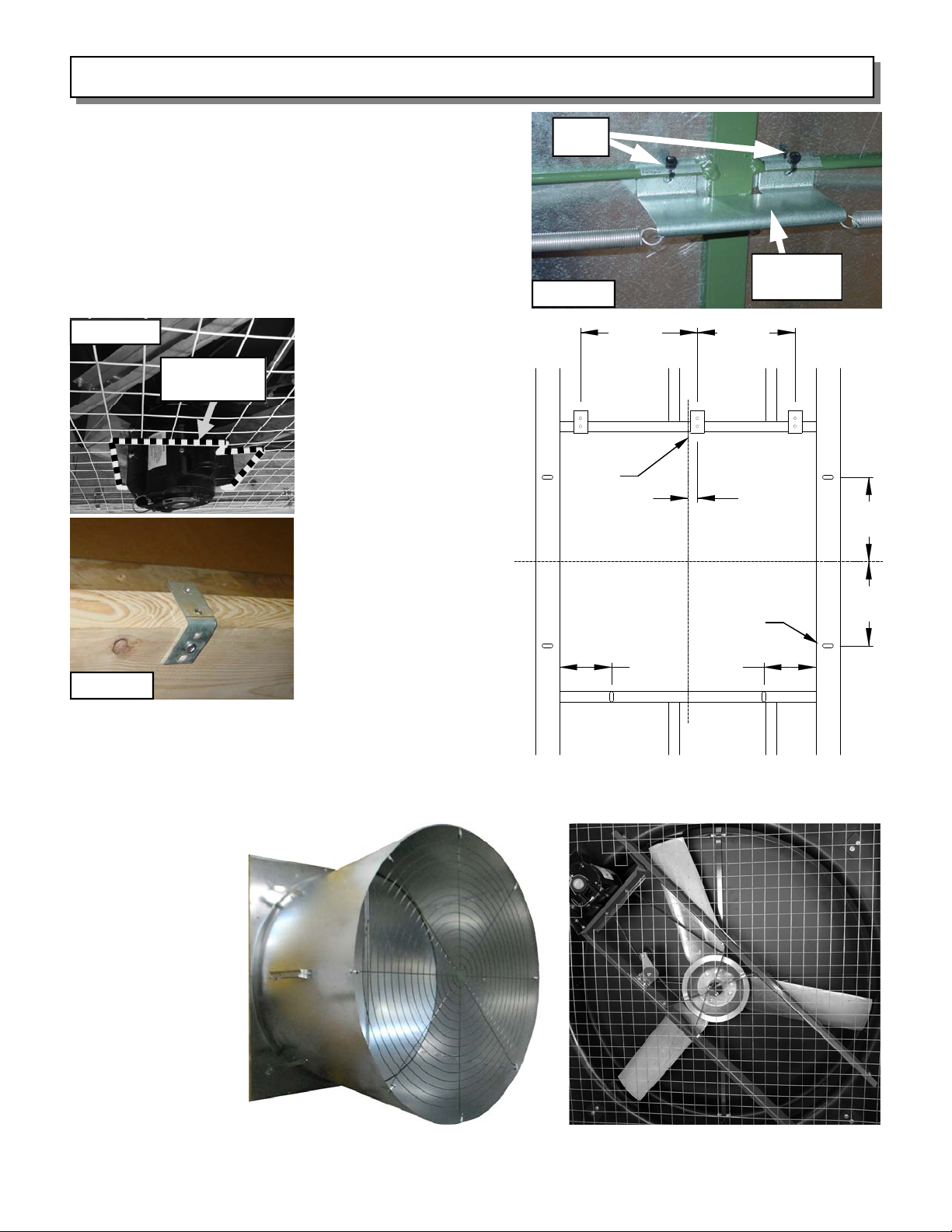

The discharge cone consists of four cone quarter

panels that are joined by an interlocking tab-and-

slot design. The panels used for the top and

sides of the cone are identical. The bottom cone

panel has a 3/4” drain hole located in the middle

of the panel towards the small diameter end.

Begin construction by placing one panel on the

ground. Slide a 2x4 under the slotted edge of

the cone as shown in Figure 10. Next, aligning

the tabs in a second panel with the slots of the

first, join the two panels by inserting the tabs into

the slots — see Figure 11. Fasten the two panels

together using two 1/4” X 3/4” bolts up through

the bottom of the panels and two 1/4” whiz-lock

nuts in the end overlapping holes of the two

panels, as shown in Figure 12. Repeat this

process for the two remaining panels. The 4

panels in the flat is shown in Figure 13.

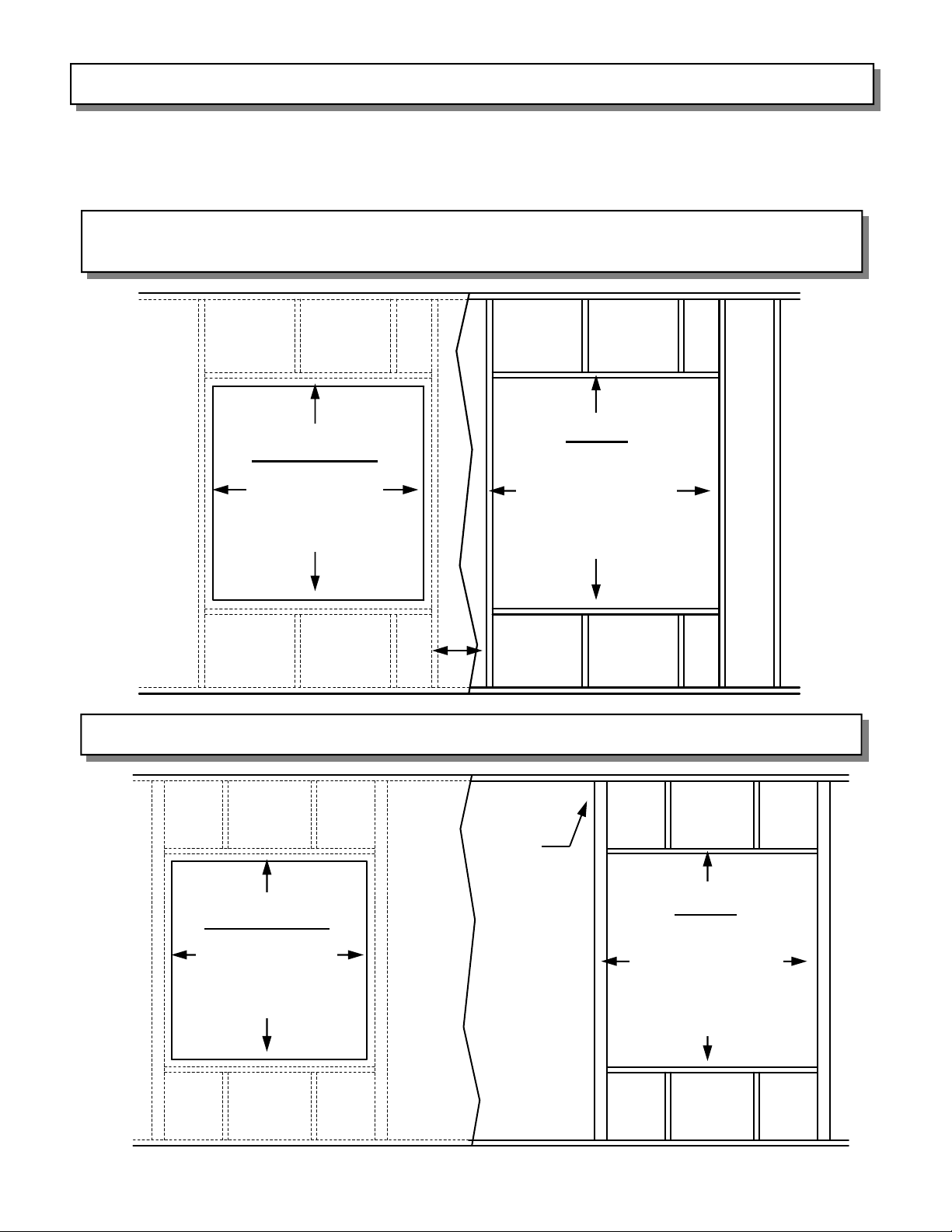

Now, the cone may be completed by fastening

the fourth panel to the first panel. To do this,

bring the edge of the fourth panel to the edge of the first and insert the tabs into the slots. Fasten the first and

fourth panels using two 1/4” X 3/4” bolts and four 1/4” whiz-lock nuts in the end overlapping holes of the two panels.

The cone should now be placed such that the larger diameter opening is on the ground as shown in Figure 14.

A Handle Mounting Hole is located near the center of the Side Panels. (The Side

Panels are the two panels adjacent to the Bottom Panel, which contains the drain

hole, as shown in Figure 14.) Once all four panels are fastened together, attach

one end of a Handle to the Side Panel using a 1/4” X 3/4” bolt, through the Handle

Mounting Hole of the Side Panel and then through one end of the Handle.

Fasten with a 1/4” whiz-lock nut. Do not fasten the other side of the Handle at this

time. Repeat this process with the other Handle on the other Side Panel.

Figure 15 — Damper Ring Insertion

Figure 14

1/4” Bolt

& Nut

Drain

Hole

Door-Restraining

Cable End

Figure 13 — Cone Panels in the Flat

Bottom

Panel

Figure 10

Figure 12 Figure 11

Handles