Operating Panel

RS-232 Configuration Data Port

The RS-232 connector (shown in Figure 4) on the front

operating panel allows direct connection to a personal

computer without any special cables or connectors. This

port is used only for configuring the control with ProView

application software. All settings, metering, events, and

oscillography data are available from this port. The port is

Data Communication Equipment (DCE) wired for direct

connection to a personal computer.

A 9-pin RS-232 cable (Catalog Number KME5-66) to

connect from the PC to the RS-232 data port is available

as an accessory.

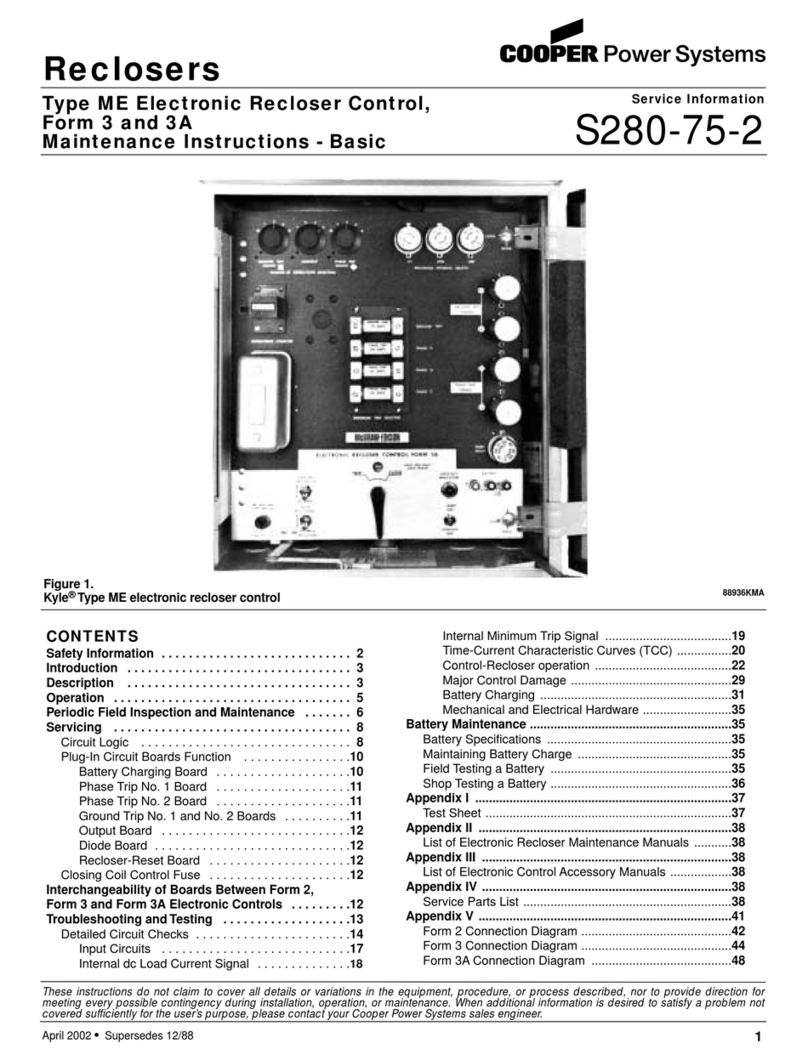

HOT LINE TAG ON/OFF Toggle Switch and LED

Indicator

Hot Line Tag is provided for live-line work applications. All

closing operations are disabled when the Hot Line Tag

feature is activated.

Hot Line Tag prevents all closing attempts from the control

and shifts protection to one trip-to-lockout on the composite

curve of the Hot Line Tag definite time and the TCC1 curve

(whichever is faster). Hot Line Tag takes precedence over

Cold Load Pickup, Non-Reclosing, and Fast Trips

Disabled.

Hot Line Tag is activated from either the operator panel

toggle switch, serial communications, or a discrete SCADA

function. All sources must be off to de-activate Hot Line

Tag.

To activate the function from the operator panel, flip toggle

switch up to the ON position. See Figure 7. The LED

indicator illuminates when the function is active.

The Hot Line Tag function may only be reset by the source

which initiates it. For example, if Hot Line Tag is activated at

the operator panel, the reset function is only possible at the

operator panel, and not via SCADA command.

CLOSE CIRCUIT DISABLE

Close Circuit Disable (Figure 7) is a removable fuse that,

when removed from the front operating panel, disables the

close circuit from the control to the recloser. Removing the

fuse from the control disables all electrical closing of the

recloser and provides a physical disconnect to the recloser

closing circuit. As a result, the control cannot perform a

close operation. This disconnect overrides all close

functions and makes a remote or manual close operation

impossible.

Note: When the Close Circuit Disable fuse is removed, the trip

circuit remains active and will trip per the programmed

time current curve for a faulted condition.

TRIP (Lockout) Pushbutton

The TRIP pushbutton (Figure 7) provides front-panel access

to trip (lockout) the recloser. When pressed, the TRIP

pushbutton opens the recloser and locks out the control.

Note: In the event of main microprocessor failure, the trip circuit

can operate independent of the main microprocessor.

CLOSE Pushbutton

When pressed, the CLOSE pushbutton (Figure 7) returns

the control to the initial or home sequence position, closing

the recloser. The control is ready for the start of a new trip/

close sequence.

Note: The Close Malfunction alarm must be reset before

Closing will be allowed.

Note: Pressing the CLOSE pushbutton from the Lockout

position initiates Cold Load Pickup (CLPU) protection, if

the feature is enabled.

The user does have the ability to block COLD LOAD

PICKUP through the LCD menu or by configuring one of

the Option one-touch function keys via the Idea

Workbench feature in ProView.

If the recloser is closed, pushing and holding the CLOSE

pushbutton does not activate the Cold Load Pickup

feature. See Cold Load Pickup in the Control Features

section of this manual.

S280-70-3

9

TRIP CLOSE

HOT LINE TAG

ON

CLOSE

CIRCUIT

DISABLE

F6 RECLOSER CONTROL

(LOCKOUT)

Figure 7.

TRIP (Lockout) pushbutton; CLOSE pushbutton; Hot

Line Tag switch and Hot Line Tag red indicator LEDs.

WARNING: Hazardous voltage. Do not use Hot

Line Tag as a substitute for a visible disconnect.

Always establish a visible disconnect prior to performing

any work requiring a de-energized line. Failure to comply

may cause death, severe personal injury, or equipment

damage. T276.0

IMPORTANT: Hot Line Tag is intended solely for live-line

work applications, such as maintenance, repairs or

improvements to the distribution system, that occur

while the line remains energized.

IMPORTANT: Hot Line Tag activation does not cause

the recloser to trip open. It only prevents the recloser

from closing.

IMPORTANT: If the power save feature is enabled

(default), and more than ten minutes elapses since the

last panel operation, all the LEDs, except HOT LINE TAG

(if active), will turn off.

IMPORTANT: If the CLOSE button is pressed after the

Close Circuit Disable fuse is removed, do not reinstall the

fuse until after the ALARM LED illuminates (within approx-

imately five seconds) to indicate CLOSE MALFUNCTION.

Re-installing the Close Circuit Disable fuse prior to the

CLOSE MALFUNCTION ALARM indication will cause the

control to close the recloser.