STANDARD RECOMMENDED PROCEDURE 003-122 | ISSUE 1 | MAY 2009 | PAGE 2 OF 4 STANDARD RECOMMENDED PROCEDURE 003-122 | ISSUE 1 | MAY 2009 | PAGE 3 OF 4

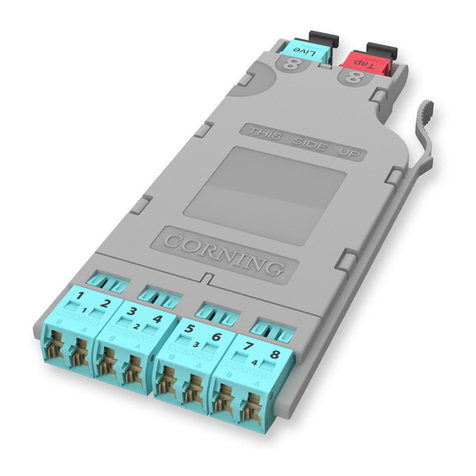

5. Connecting the Module with an MTP® Trunk

Step 1: Standard MTP connectors mated into the adapters on the back

of a CCH module have precision guide pins. To secure a

non-pinned MTP connector from a trunk into an adapter:

a) Remove the dust caps from the MTP connector on the end

of the trunk.and the MTP adapter on the back of the CCH

connector module.

b) To install the connector, grasp the connector by its boot

which is marked “push.”Align the key in the connector

with the slot in the adapter and push the connector until it

clicks in place (Figure 3).

Step 2: To unplug the connector, grasp the slider which is marked

“pull”and pull the connector out of the adapter.

DO NOT PULL ON THE BOOT TO UNPLUG THE

CONNECTOR.

Figure 3 - MTP installation

2. Precautions

Laser Precautions

WARNING: Laser light can damage your eyes.Laser light is invisible.

Viewing it directly does not cause pain. The iris of the eye will not close

involuntarily as when viewing a bright light. Consequently, serious damage

to the retina of the eye is possible. Never look into the end of a fiber or at a

connector in a microscope which may have a laser coupled to it. Should

accidental eye exposure to laser light be suspected, arrange for an eye

examination immediately.

Fiber Optic Cable Precautions

CAUTION: Fiber optic cable is sensitive to excessive pulling, bending, and

crushing forces. Consult the cable specification sheet for the cable you are

installing. Do not bend cable more sharply than the minimum recommended

bend radius. Do not apply more pulling force to the cable than specified. Do

not crush the cable or allow it to kink. Doing so may cause damage that can

alter the transmission characteristics of the cable - the cable may have to

be replaced.

3. Tools and Materials

The following tools and materials, purchased separately, are required to complete

this procedure:

• LC cleaning tool, Corning Cable Systems p/n CLEANER-PORT-LC

• MTP cleaning tool, p/n 2104466-01

4. Module Installation

Step 1: Remove a blank panel by pulling out both of the plungers of the

panel’s push/pull fasteners (Figure 2).

Step 2: Position the module’s fasteners over the proper holes in the

mounting bracket and push in all the plungers to lock the

module in place.