6 7

• Flammable liquids should not be measured, in particular substances with ash-point

below 0°C (ether, acetone).

• The pipet controller should not be used for drawing acids with a concentration above 1 mol/L.

• The pipet controller should not be used for drawing solutions with a temperature

above 50°C.

• The pipet controller should be operated in the temperature range from +10°C to +35°C.

• The pipet controller is suitable for general laboratory use only. It must be used only by

personnel who know the health risks associated with the substances that are normally

used with this instrument.

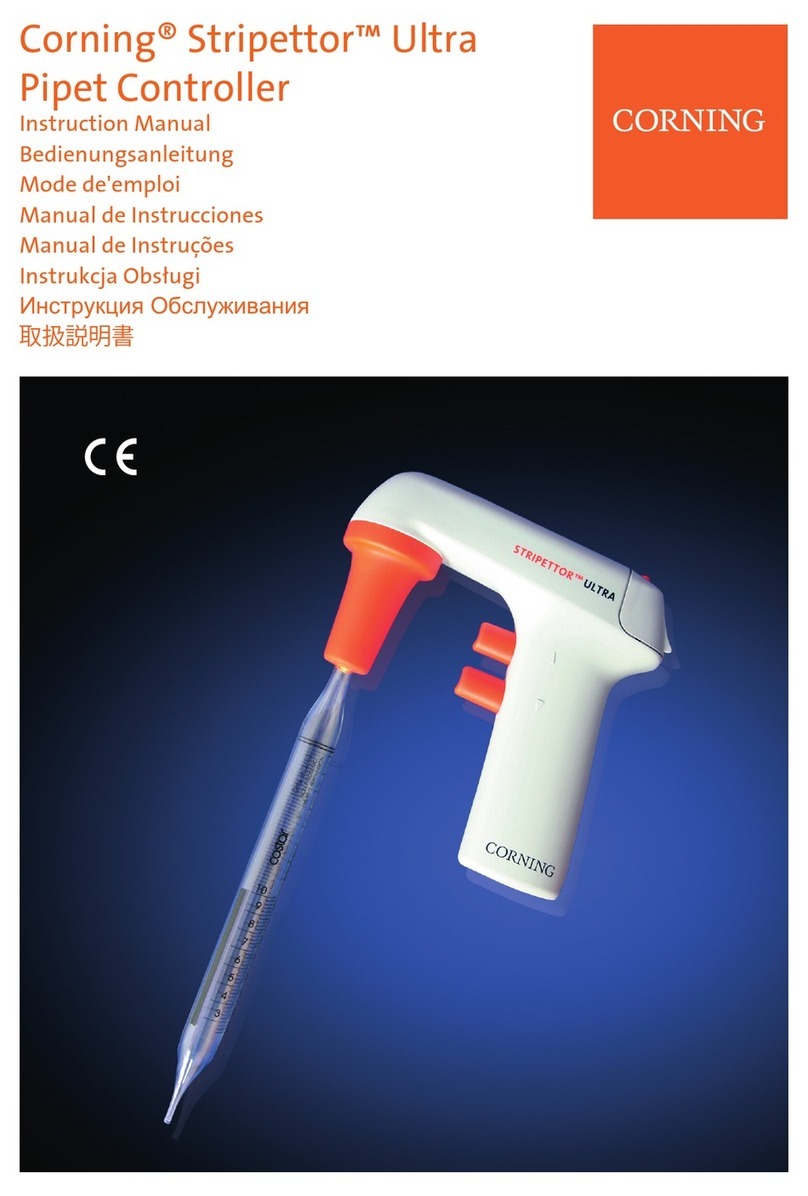

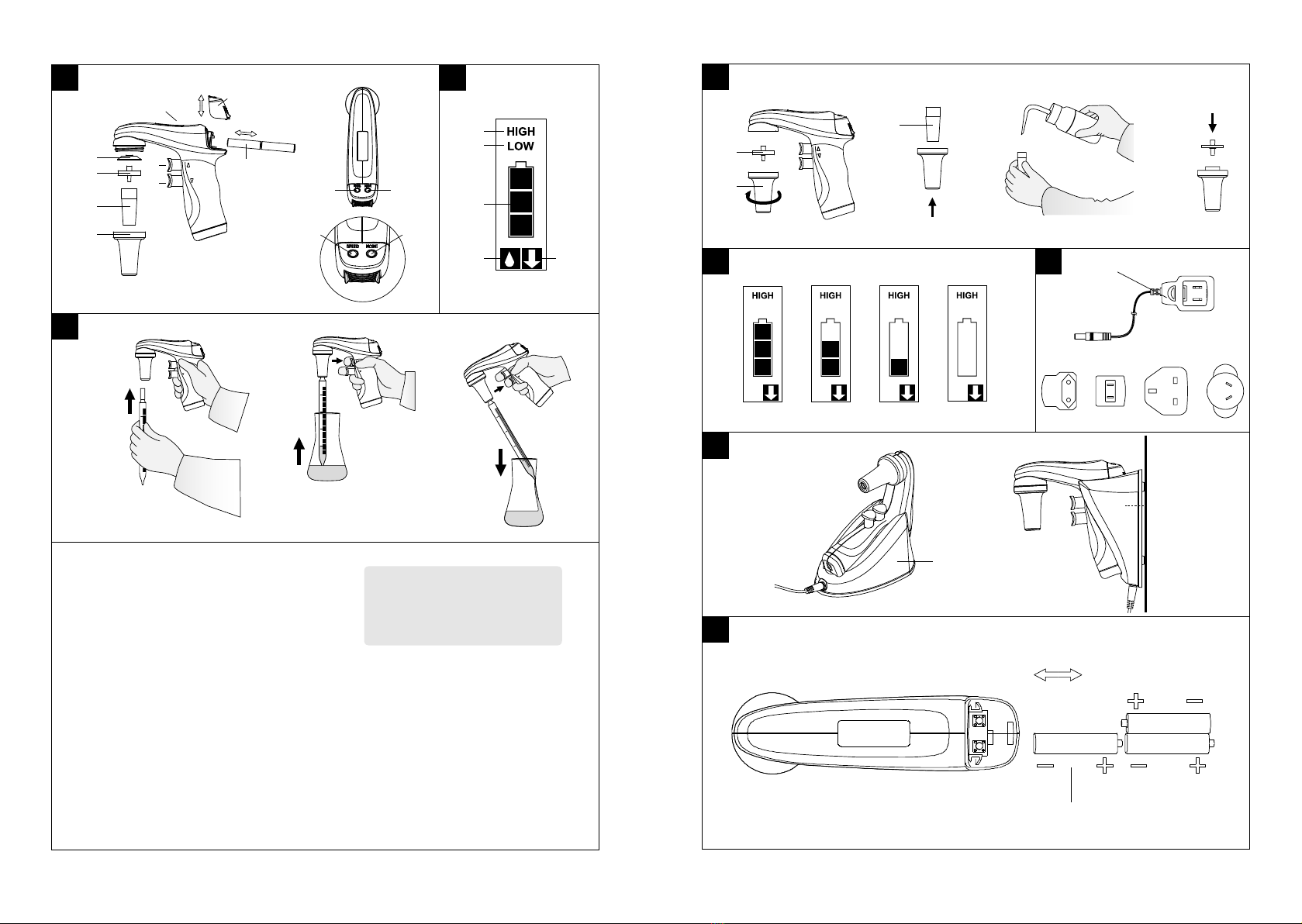

4. Turning on the Falcon® Pipet Controller

The pipet controller is switched on by pressing any of the buttons (Figures 1A, B, C, D).

The display will show the selected aspiration mode, dispense mode, and the battery level

indicator (Figure 2.3). Examples of the display indications are shown in Figure 5. The battery

is discharged and requires charging if the indicator displays one “bar” (Figure 5.3).

The batteries need to be recharged if the indicator does not display “bars” (Figure 5.4).

When the batteries are fully charged, the indicator displays three “bars” (Figure 5.1).

• The pipet controller will switch off automatically if not used for 5 minutes.

• The pipet controller should be charged only with the original charger.

• The main voltage should conform to the specication on the charger.

• Charging should be done in accordance with section 8 of this instruction for use.

5. Aspirating and Dispensing Liquids

Attaching a pipet

CAUTION: Before attaching a pipet, check to ensure the pipet is not damaged, has no

dents or sharp edges in the gripping section. Check to ensure the gripping section is dry.

The pipet controller should be gripped as close to the upper end as possible and

carefully inserted into the pipet controller holder until resistance is felt (Figure 3A).

Do not apply excessive force, to prevent damage to thin pipets controller and to avoid

injury risk. A pipet that has been correctly attached and sealed in the holder should

not tilt to the side.

After attaching a pipet, hold the device in such a way as to keep the pipet controller

in a vertical position with an attached pipet. When not in use, it is not recommended

to leave the pipet attached for long periods, for example overnight or over a weekend.

NOTE: Do not rest the pipet controller on the bench if there is liquid in the pipet.

Filling the pipet

Before aspirating is started, set the suction speed switch using the HIGH/LOW switch

(Figure 1C):

• HIGH position: fast aspirating (Figure 2.1)

• LOW position: slow aspirating (Figure 2.2)

It is recommended to choose the LOW position for pipets with a volume up to 5 mL,

and the HIGH position for pipets with a volume greater than 5 mL.

Holding the pipet controller vertically, immerse the pipet end in the liquid to be drawn

up (Figure 3B), and press the aspiration button gently. The pipet lling speed depends

on the pressure applied to the aspirating button. The greater the pressure applied,

the faster the liquid is aspirated into the pipet.

It is recommended to draw a slightly larger liquid volume than required (due to meniscus

above the required volume mark), reducing the aspiration speed, particularly in the nal

lling stage, so as not to overll the pipet.

Setting the Volume

After lling the pipet, the end should be dried with an absorbent paper that will not

leave impurities, in order to remove any excess solution on the outside surface of the

pipet. To set the required liquid volume precisely, press the dispense button gently

(Figure 3C), dispense the excessive liquid from the pipet until the meniscus of the liquid

aligns exactly with the required volume mark on the pipet.

Emptying the Pipet

Holding the vessel in an angled position, place the pipet end in contact with the vessel

wall and press the dispense button gently (Figure 3C). The dispensing intensity may

be adjusted depending on pressure applied to the dispense button. The greater the

pressure applied, the faster the outow of liquid from the pipet.

The pipet controller has two dispense modes. The dispense mode is selected with the

BLOW/GRAV switch (Figure 1D).

• Gravity mode marked with the icon on the display (Figure 2.4): Dispensing is effected

in gravity mode, which means that the liquid ows out of the pipet by its own weight.

• Blow out mode marked with the icon on the display (Figure 2.5): Dispensing is

effected in gravity mode; however, when the dispense button is pressed to the middle

position, the pump is started and fast emptying of the pipet with a blow out is affected.

CAUTION: During gravimetric dispensing the pipet may not be completely emptied due

to the characteristics of pipets used with the pipet controller.

6. Troubleshooting

If during your work the pipet controller is not functioning correctly, check the cause

and correct the fault.

Problem Possible Cause Action

The pipet falls out

(the holding force of

the pipet is too small),

or tilts to the side too

much.

The pipet holder (Figure 1G)

is dirty or wet.

Take out the pipet holder,

and clean, wash, and dry it.

The pipet holder is damaged. Replace the pipet holder

with a new one.

The pump is working,

but the pipet control-

ler aid does not draw

liquid or draws liquid

very slowly.

The lter (Figure 1H) is dirty.

Take out the pipet holder,

take out the lter; if it is

dirty, replace it with a new

one.

The pipet holder and/or the

connector gasket (Figure 1J) is

damaged.

Replace the mechanically

damaged elements with

new ones.