SAFETY & WARNINGS

4

This appliance has been designed for non-

professional, domestic use only.

Do not use this appliance to heat a room.

Do not place any pot or pan on the open oven door.

The door is made of glass and it can break if loaded

with a weight.

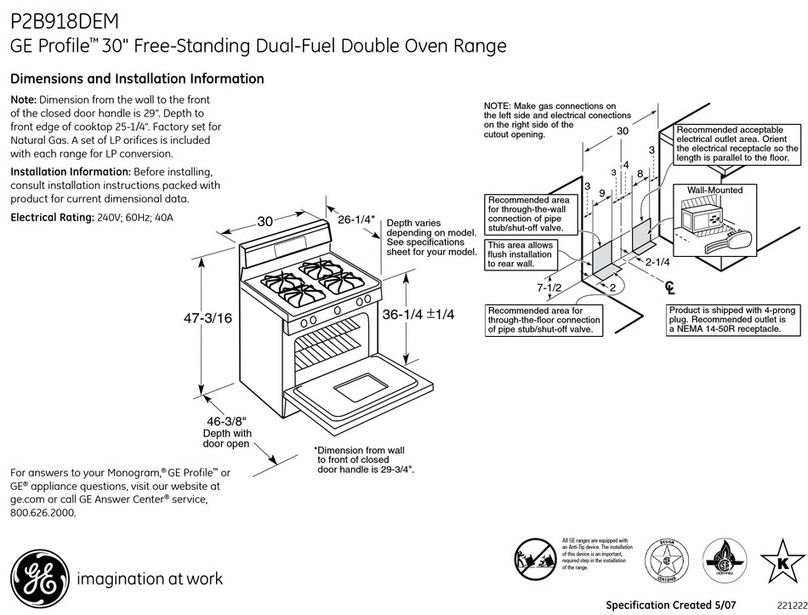

Before beginning installation, please read these

instructions completely and carefully.

Do not remove permanently affixed labels, warnings,

or plates from the product. This may void the

warranty. Please observe all local and national codes

and ordinances.

Please ensure the range is properly grounded.

The installer should leave these instructions with the

consumer who should retain for local inspector's use

and for future reference.

The plug should always be accessible.

Installation must conform with local codes or in the

absence of codes, the National Fuel Gas Code

NSIZ223.1/NFPA54. Electrical installation must be in

accordance with the National Electrical Code, ANSI/

NPA70 - latest edition and/or local codes. IN

CANADA: Installation must be in accordance with the

current CAN/CGA-fe 149.1 National Gas Installation

Code or CAN/CGA-B 149.2, Propane Installation

Code and/or local codes. Electrical installation must

be in accordance with the current CSA C22.1

Canadian Electrical Codes Part 1 and/or local codes.

Installation of any gas-fired equipment should be

made by a licensed plumber. A manual gas shut-off

valve must be installed in the gas supply line ahead of

the oven in the gas flow for safety and ease of

service.

WARNING: This appliance shall not be

installed with a ventilation system that blows

air downward toward the range; this type of

ventilation system may cause ignition and

combustion problem with the gas appliance

resulting in a personal injury or unintended

operation.

WARNING: An air curtain or other overhead

range/cooktop hood, which operates by

blowing a downward airflow onto a range/

rangetop/cooktop, shall not be used/installed

in conjunction with this gas range.

the gas flow for safety and ease of service.

WARNING: This appliance shall not be

installed with a ventilation system that blows

air downward toward the range; this type of

ventilation system may cause ignition and

combustion problem with the gas appliance

resulting in a personal injury or unintended

operation.

WARNING: An air curtain or other overhead

range/cooktop hood, which operates by

blowing a downward airflow onto a range/

rangetop/cooktop, shall not be used/installed

in conjunction with this gas range.

PLEASE READ AND FOLLOW THESE

IMPORTANT INSTRUCTIONS FOR THE SAFETY

OF YOUR HOME AND OF THE PEOPLE LIVING

IN IT.

Save this Manual for local electrical inspector's use.

Read and save these instructions for future

reference. Observe all governing codes, ordinances

and regulations. Installation and service must be

performed by a qualified installer, service agency or

the gas supplier.

WARNING: If the information in this manual

is not followed exactly, a fire or explosion

may result causing property damage,

personal injury, or death.

WARNING: Do not store or use gasoline or

other flammable substances in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

•Do not light any appliance.

•Do not touch any electrical switch.

•Do not use any phone in your building.

•Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions closely.

•If you cannot reach your gas suppliers, call the

fire department.

In Massachusetts: All gas products must be installed

by a "Massachusetts" licensed plumber or gasfitter.

A "T" handle type manual gas valve must be

installed in the gas line connected to this appliance.

WARNING: NEVER use this appliance as a space

heater to heat or warm the room. Doing so may

result in carbon monoxide poisoning and

overheating of the oven.

WARNING: This range can tip over, causing

possible injury or death. Install the anti-tip

device shipped with the range. See Page 7

of this manual.

WARNING: Read this instruction booklet

before installing and using the appliance.

The manufacturer will not be responsible for

any damage to property or to persons

caused by incorrect installation or improper

use of the appliance. The manufacturer

reserves the right to make changes to its

products when considered necessary and

useful, without affecting the essential safety

and operating characteristics.