Page 1

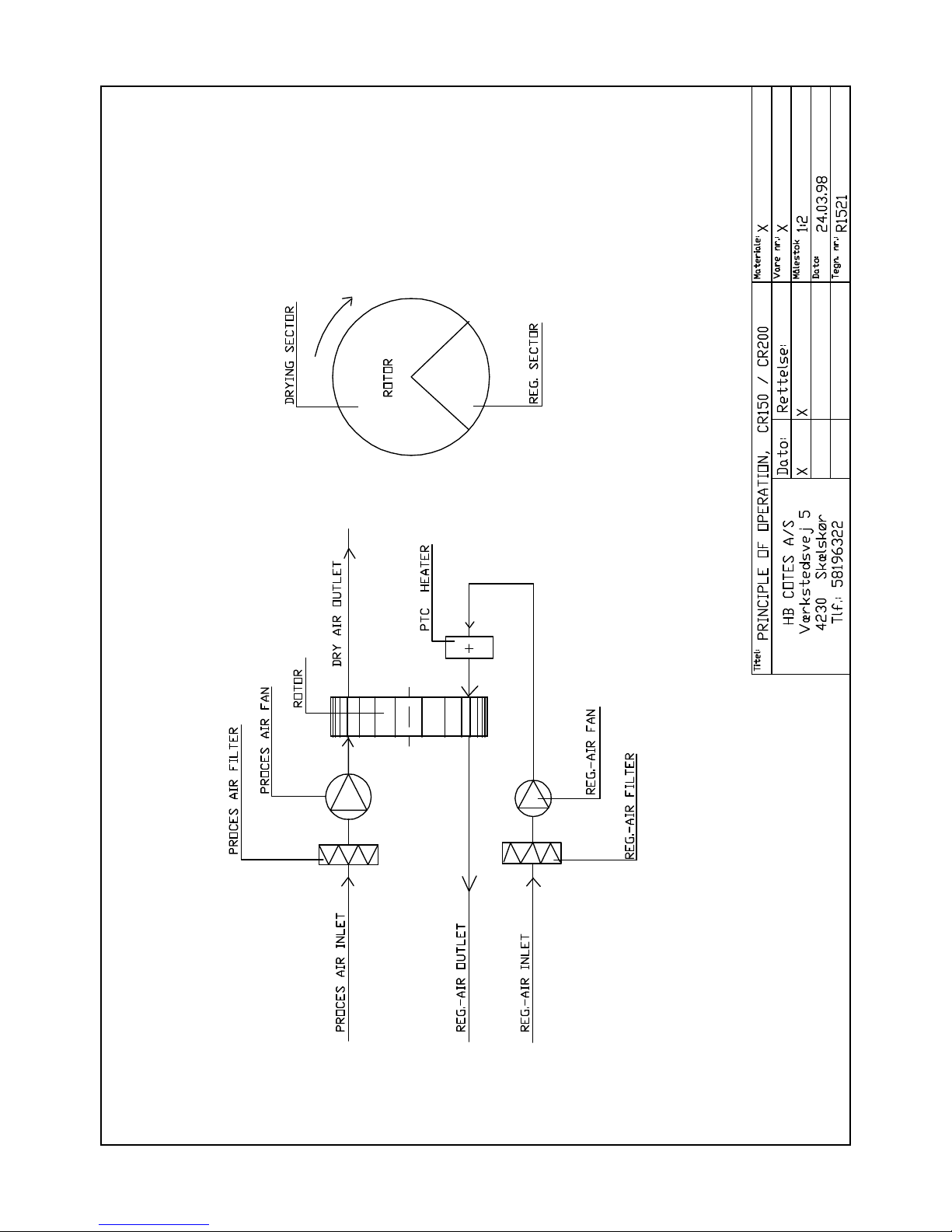

The dehumidifier removes water from an airflow through, and

the removed water is carried away from the dehumidifier with

the regeneration air (henceforward called reg.-air).

Water adsorption and -extraction takes place in an rotor made

of water resistant silica gel.

The air flows in the dehumidifier divides the rotor in two

parts : drying part and reg.-part.

Two separate air flows goes through the rotor as this:

- the main air (moist air inlet) goes through the drying

part, and leaves the dehumidifier as dry air

- the reg.-air coming from the outside to the reg.air fan,

through the internal hose to the electric PTC- heater and

will be heated to 130C (at 20C inlet).

Going through the reg.-part this energy will be used for

evaporation of the adsorbed water. The water vapours and

the reg.- air now leaves the dehumidifier through the reg.

- air outlet (see page 2, fig. 2).

The two air flows are fixed and the rotor turns - this gives

an automatic process of simultaneous water adsorption and wa-

ter extraction.

The inlet conditions of the air to be dried, determines how

much water the dehumidifier will remove.

On page 8 the capacity diagram shows how much water will be

removed per kg air going through.

(shown in the diagram R617)

- inlet air conditions 20C, 60 %RH, gives water content 8,7

g/kg

- the diagram shows then dry air condition of X= 3,7 g/kg

- removed per kg air is then: 8,7 - 3,7 = 5,0 g/kg

Dry air flow is nominal 200 m3/h = (x 1,2) = 240 kg/h

Capacity, removed water per hour = 240 x 5,0 = 1200 g/h

= 28,8kg/day

- at 230V.

The temperature of the dry air is higher than for the inlet

air. This is caused by the evaporation heat release and heat

gain from the rotor. The temperature is shown to be 41C.

1. PRINCIPLE OF OPERATION.

CAPACITY DIAGRAM R617 (page 8 ):

Example:

Capacity CR200 at this condition: