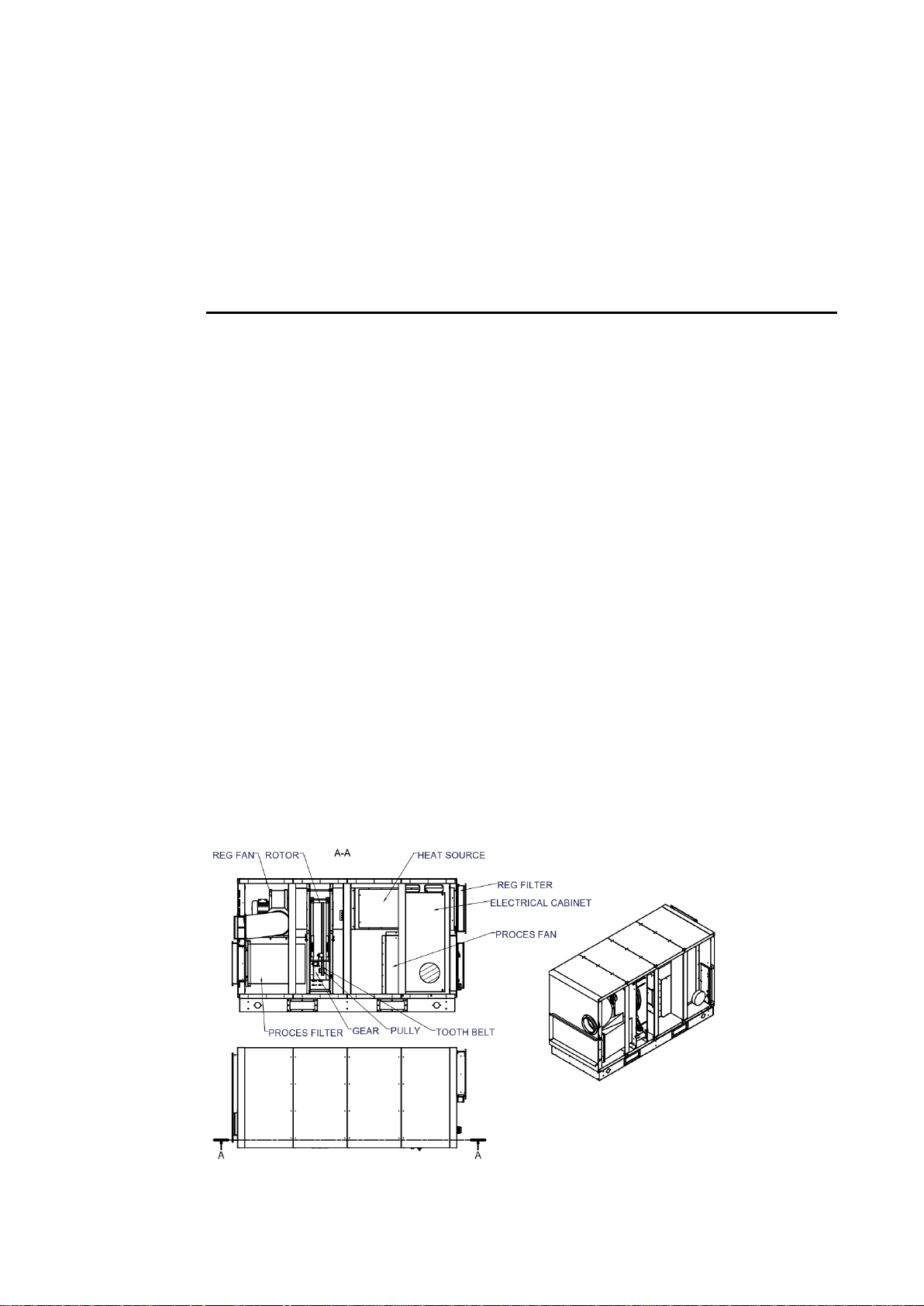

COTES CRP/CRT INSTALLATION, OPERATING AND SERVICE HANDBOOK page 8/92

Design priorities

The Cotes CRP/CRT Flexible range features an eye-catching modern industrial design appearance,

along with exceptional reliability.

It is designed to ensure the unhindered passage of air through the unit, which reduces

•Energy consumption

•Pressure losses

•Noise levels.

All the components, ancillary equipment and features are optimized for better performance,

exceptional service life and easy maintenance.

All components (except HR module) are mounted inside the Cotes CRP/CRT cabinet, which can be

extended to house extra components if needed.

Capacities

The Cotes CRP/CRT range currently features models with process air flows of between 2,000

m3/hour and 40,000 m3/hour. Higher air flows of up to 100,000–150,000 m3/hour are available on

request.

At process air inlet conditions of 20°C and 60% relative humidity (%RH), the capacities (the amount

of water vapour that can be removed from the air) of these CRP/CRT units are between 13 kg/hour

and >300 kg/hour. For details about a specific capacity or particular requirements, please consult

Cotes or your Cotes dealer.

Configurations

STANDARD configuration

The STANDARD configuration provides:

•High dehumidification capacity

•High energy efficiency

•Stainless steel cabinet on the outside

•Easy installation

•Low-noise running

•Low maintenance costs, reducing overall operating costs

•Easy cleaning

•Attachment of external humidity sensor (external humidity control and sensors are not

included as standard, but are available for purchase from Cotes)

•Mechanical hour counter, to keep track of how long the unit has been in operation

•Overheating alarm

•Remote start/stop option

•External fault signal and operation signal