5

E220 & LE220 (-plus, R-plus, Rsc) Setup & Instrucon Manual Part Number: 010521 Rev B | May 2021

Table of Contents

1. Introducon................................................................................................................................................................................................................ 6

1.1 Overview of the User Manual ......................................................................................................................................................................... 6

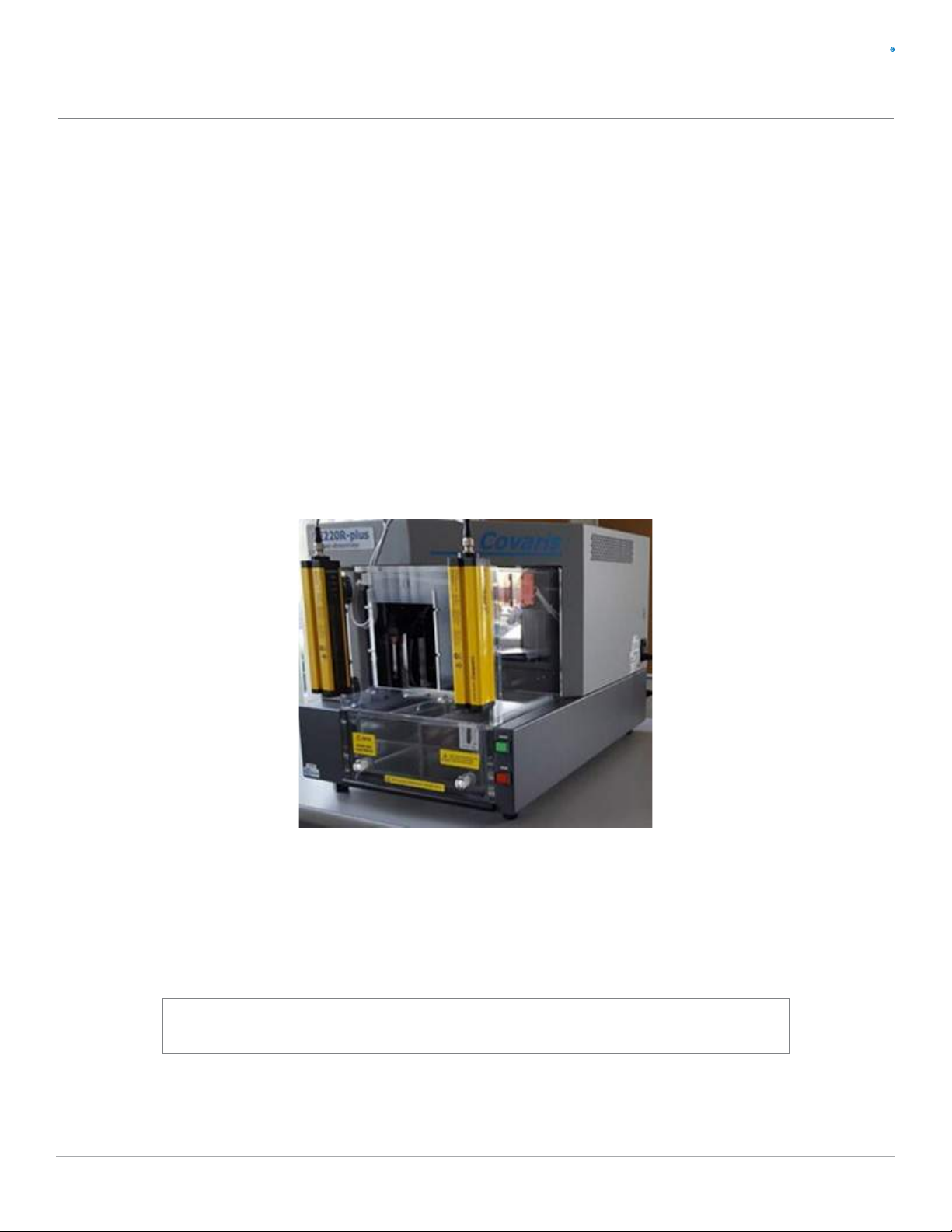

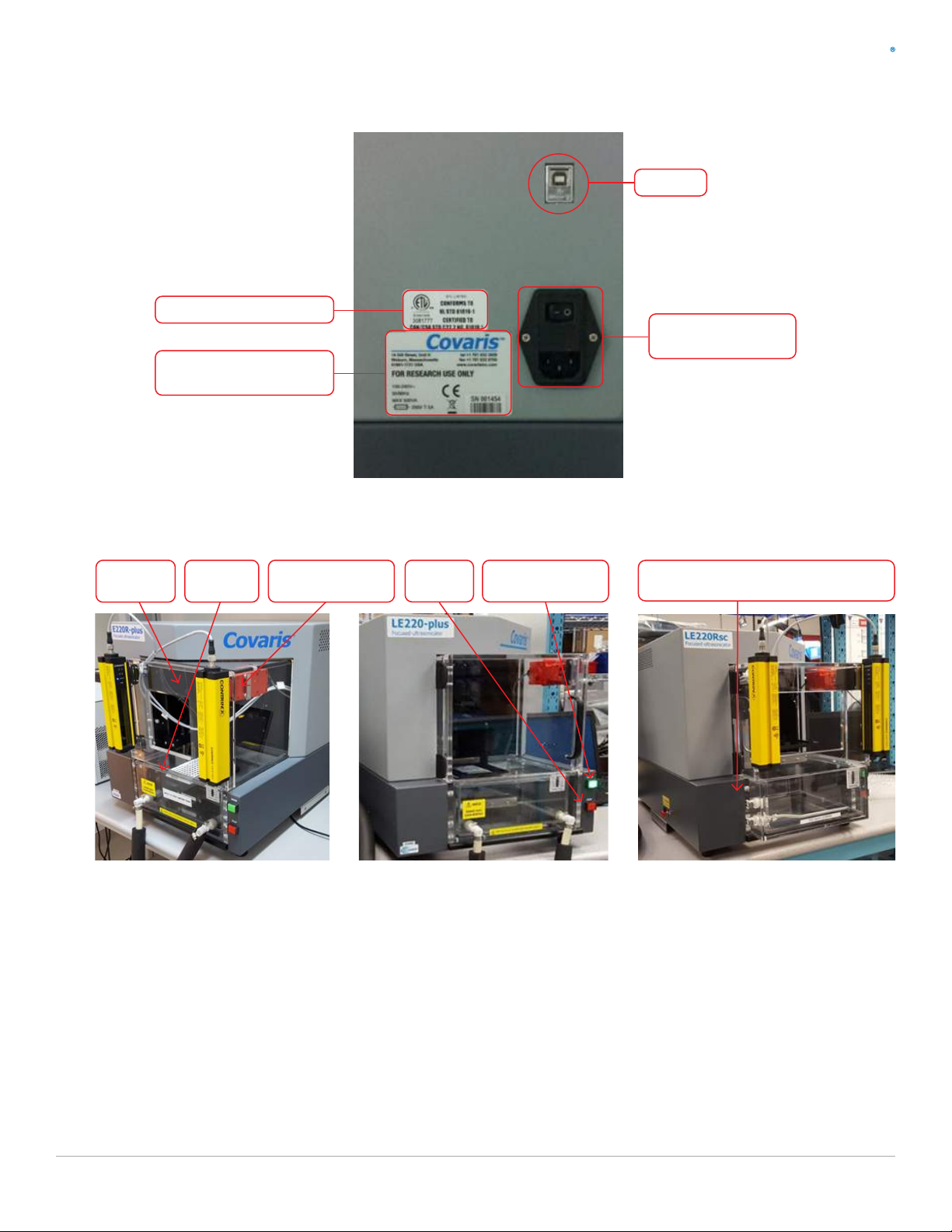

1.2 E220-plus Focused-ultrasonicator ................................................................................................................................................................. 6

1.3 E220R-plus Focused-ultrasonicator............................................................................................................................................................... 6

1.4 LE220Rsc Focused-ultrasonicator.................................................................................................................................................................. 6

2. Installaon and Setup ............................................................................................................................................................................................... 7

2.1 Assembly............................................................................................................................................................................................................. 7

3. Geng Started........................................................................................................................................................................................................... 11

3.1 Fill the Water Bath ............................................................................................................................................................................................ 11

3.2 Start the System ................................................................................................................................................................................................ 11

3.3 Preparing your System for Use........................................................................................................................................................................ 13

3.4 System Shutdown.............................................................................................................................................................................................. 16

4. AFA Operaon............................................................................................................................................................................................................ 17

5. SonoLab Soware...................................................................................................................................................................................................... 18

5.1 The Method Screen........................................................................................................................................................................................... 18

5.2 The Schedule Screen......................................................................................................................................................................................... 22

5.3 The History Screen............................................................................................................................................................................................ 24

5.4 The About Screen.............................................................................................................................................................................................. 25

5.5 The Admin Screen ............................................................................................................................................................................................. 26

6. Create and Edit Methods ......................................................................................................................................................................................... 30

6.1 Create a New Method ...................................................................................................................................................................................... 30

6.2 Using the Repeat Funcon .............................................................................................................................................................................. 36

6.3 Scanning Treatments (LE220Rsc Only) .......................................................................................................................................................... 39

6.4 Using Drag and Drop with Treatment Steps ................................................................................................................................................. 42

6.5 Modify Exisng Methods ................................................................................................................................................................................. 43

7. System Specicaons................................................................................................................................................................................................ 44

8. Maintenance............................................................................................................................................................................................................... 45

8.1 Cooling Air Intake .............................................................................................................................................................................................. 45

8.2 Water Bath.......................................................................................................................................................................................................... 45

8.3 Transducer........................................................................................................................................................................................................... 45

8.4 Safety System..................................................................................................................................................................................................... 46

8.5 Degassing System.............................................................................................................................................................................................. 46

8.6 Cleaning the System ......................................................................................................................................................................................... 46

8.7 Water Bath.......................................................................................................................................................................................................... 46

9. Troubleshoong ......................................................................................................................................................................................................... 48

10. Appendix................................................................................................................................................................................................................... 50

Appendix A: Using SonoLab Consumable-based Method Selecon................................................................................................................ 50

Appendix B: Using SonoLab Posion Restricons .............................................................................................................................................. 51

Appendix C: SonoLab 8.x Data Converter ........................................................................................................................................................... 53

Appendix D: E220 (-plus and R-plus) Series Site or Transport Preparaon ................................................................................................... 54

Appendix E: Installing SonoLab 10 Soware....................................................................................................................................................... 55

Appendix F: Humidity and Water Management for the Covaris E220-plus................................................................................................... 58

Appendix G: Connecng AutoFill to Plant Water ............................................................................................................................................... 59