M220 Service Manual Page 4 410085 Rev. B

1). Scope of This Manual................................................................................................... 6

2). Safety and EMC Compliance Information ................................................................... 6

2.1 General Instrument Safety.................................................................................... 6

2.1.1 Acoustic Safety............................................................................................. 6

2.1.2 Safety and Electromagnetic Compatibility (EMC) Standards...................... 6

3). Introduction................................................................................................................... 7

Transducer....................................................................................................................... 7

Interlock Subsystem........................................................................................................ 7

Control Electronics System............................................................................................. 7

4). Maintenance and Repair ............................................................................................... 8

Recommended Daily Maintenance................................................................................. 8

Troubleshooting.............................................................................................................. 8

Diagnosis......................................................................................................................... 9

Contamination............................................................................................................. 9

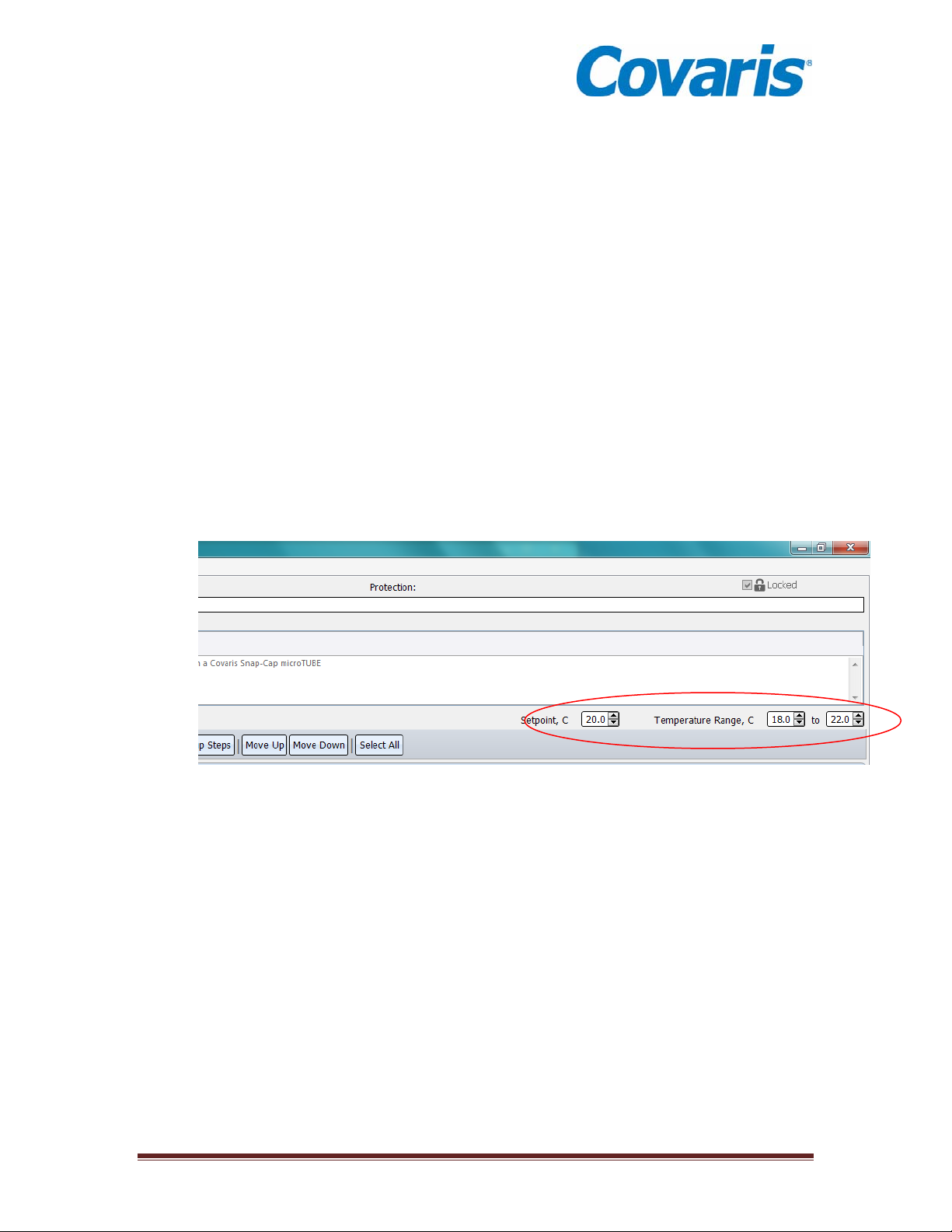

Bath Temperature........................................................................................................ 9

Position of Treatment Vessel...................................................................................... 9

Water Level Errors...................................................................................................... 9

Acoustic Power Issues .............................................................................................. 10

Interlock Errors......................................................................................................... 10

Communication Errors.............................................................................................. 10

Other Indicators ........................................................................................................ 10

Repair Procedures......................................................................................................... 11

General Procedures................................................................................................... 11

Removing the outer Covers ...................................................................................... 11

Replacing the Water Level & Temperature Sensor Assembly................................. 16

Diagnosing and Replacing Printed Circuit Boards:...................................................... 25

RF Power Board........................................................................................................ 26

Controller Board:...................................................................................................... 29

Thermo-Electric (TE) Controller Board ................................................................... 33

Capacitor Reserve Board .......................................................................................... 35

Power Supplies.......................................................................................................... 38

24 Volt Supply.......................................................................................................... 38

48 Volt Supply.......................................................................................................... 38

Acoustic Power Testing Procedure................................................................................... 43