COWIN.FA PLUSTEP-P User manual

1. Safety management

============================ 1

2. Products features ============================ 2

2-1) the highest Torque ============================ 2

2-2) the fastest response features ============================ 2

2-3) complete stop ============================ 2

2-4) High Speed ============================ 2

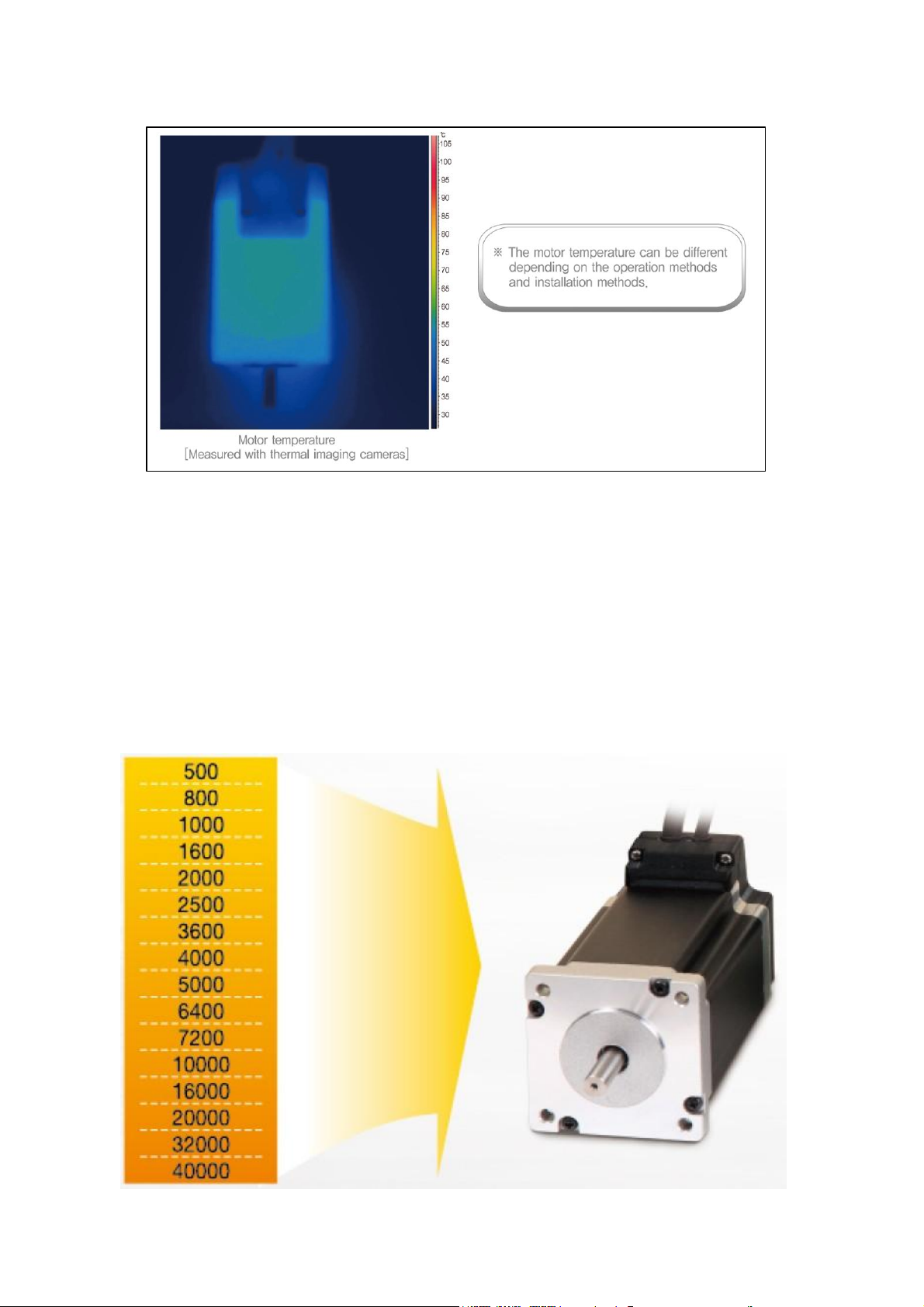

2-5) reduced motor heat ============================ 3

2-6) slim encoder ============================ 3

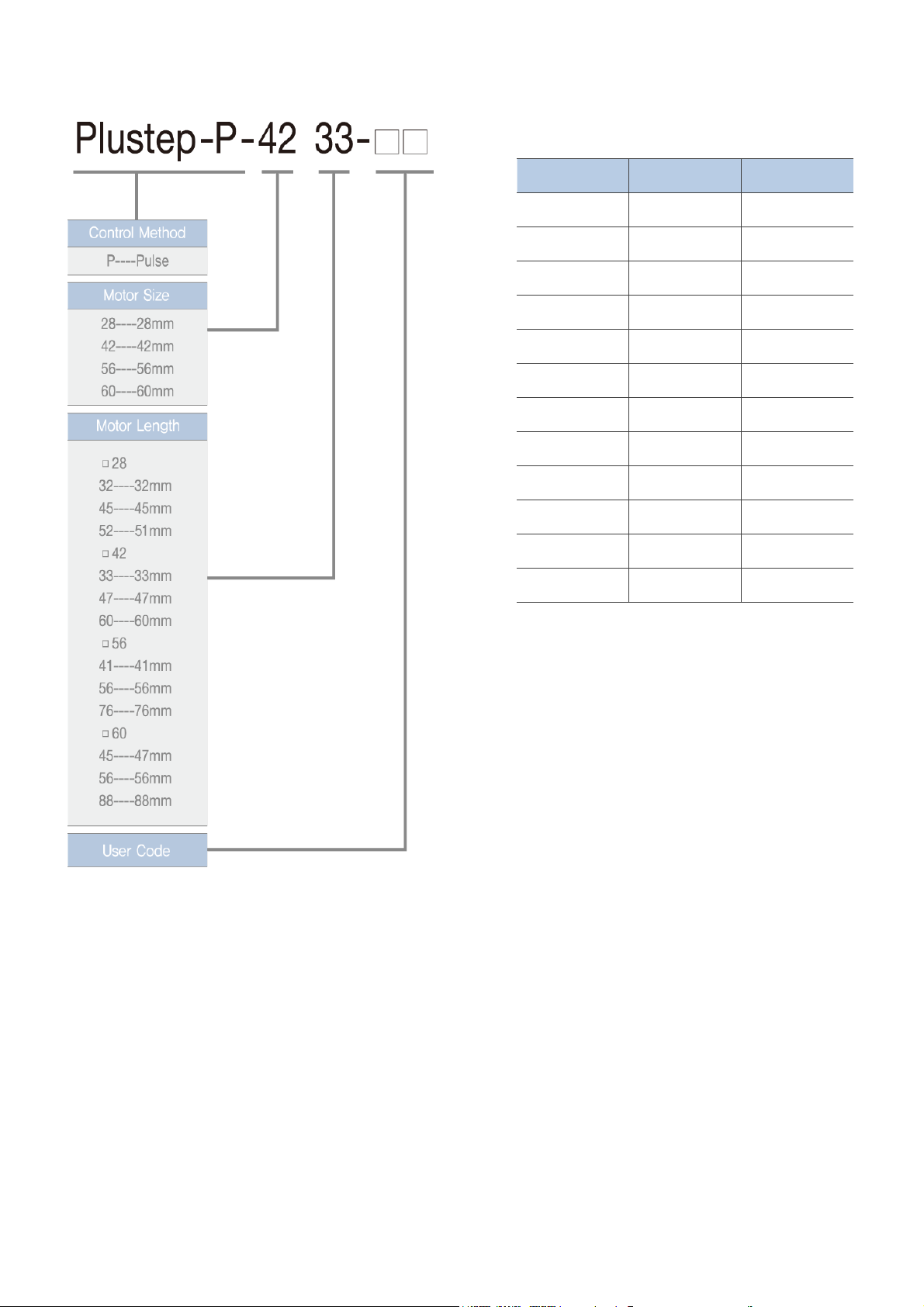

2-7) High Resolution ============================ 3

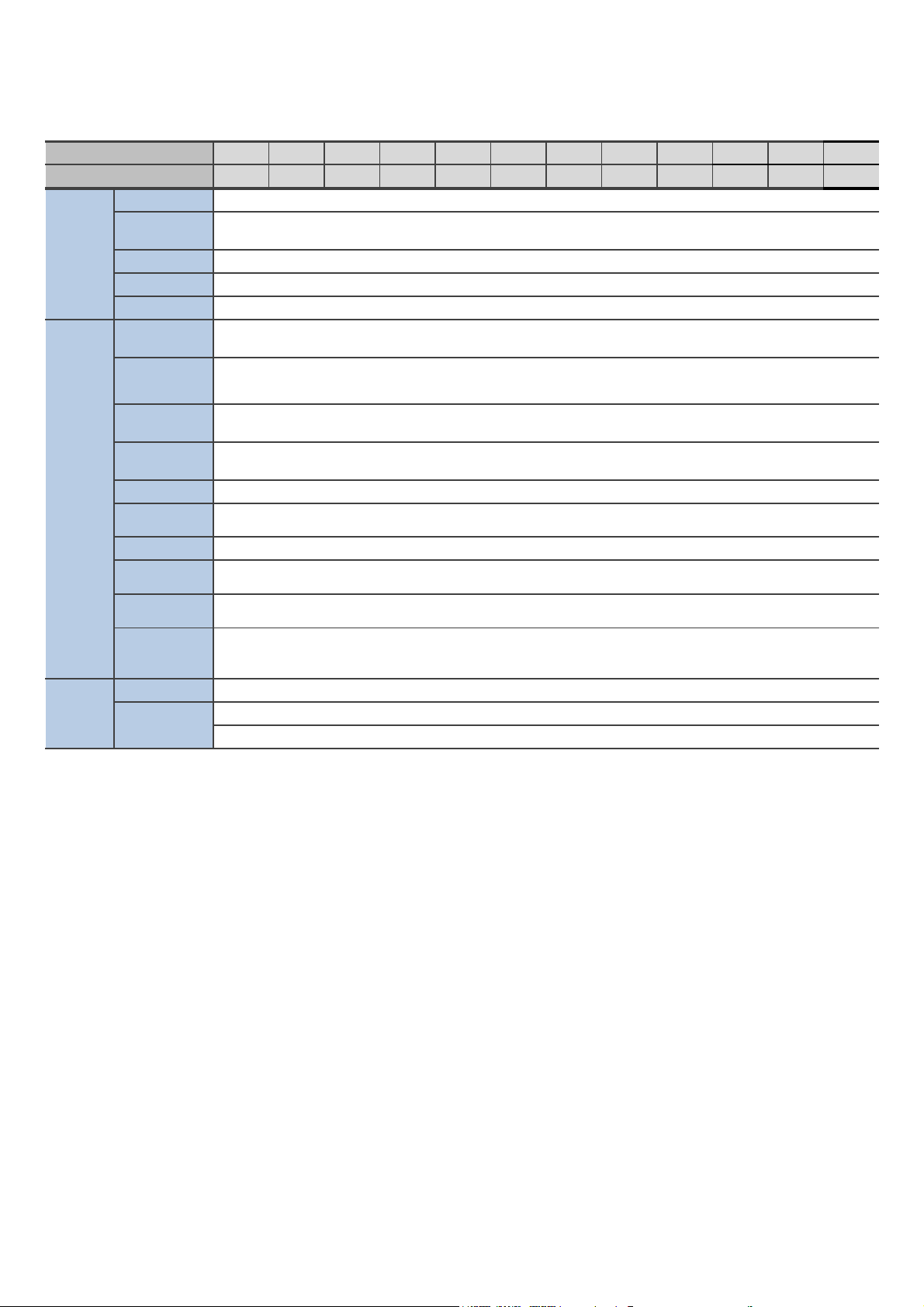

3. Plustep-P model and order code ============================ 4

3-1) Plustep-P model ============================ 4

3-2) ORDER CODE ============================ 4

4. Plustep-P driver specification and size ============================ 5

4-1) Driver specification ============================ 5

4-2) Driver size ============================ 6

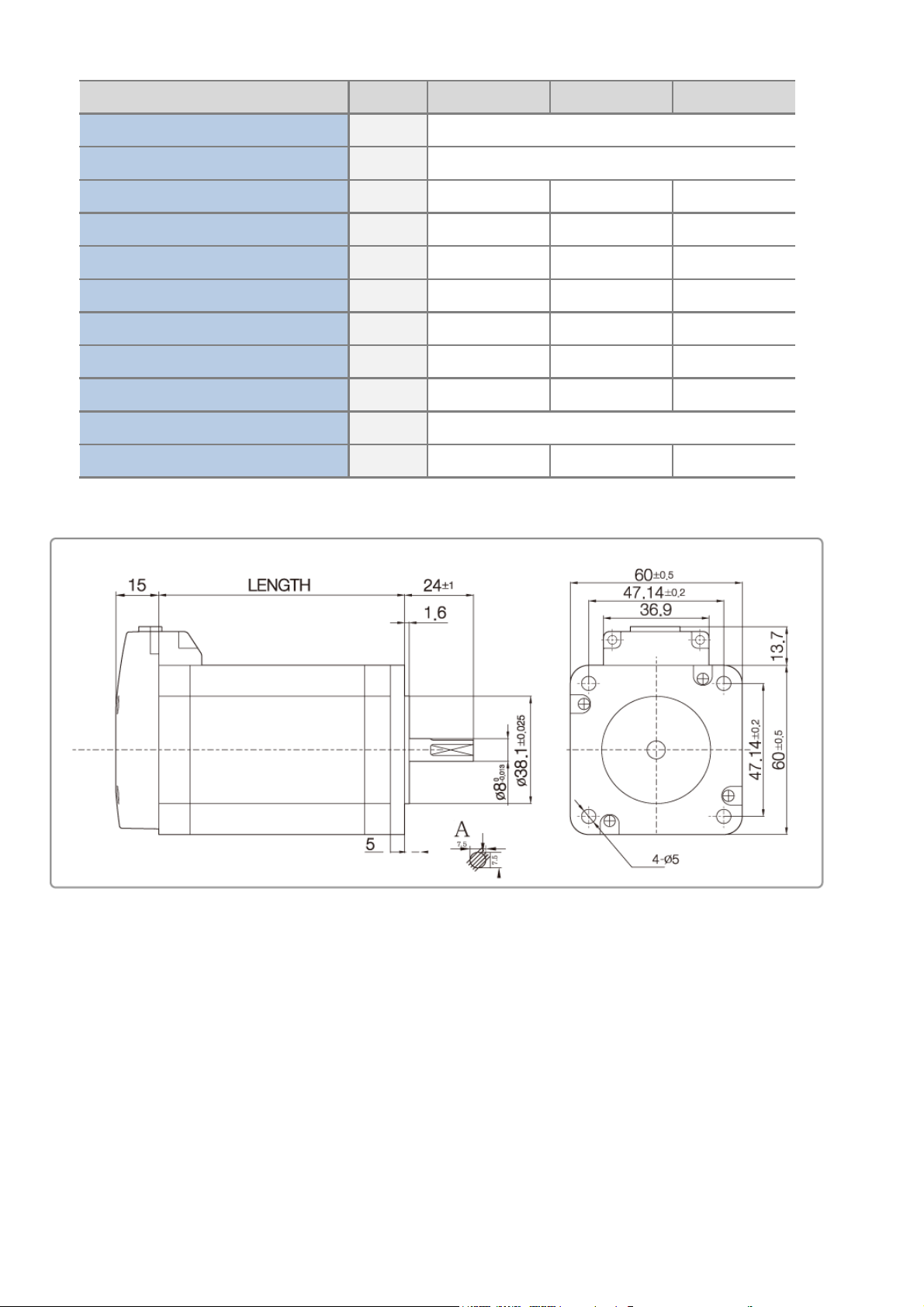

5. Motor specification and size ============================ 7

5-2) PSM-42 SERIES ============================ 7

5-3) PSM-56 SERIES ============================ 8

5-4) PSM-60 SERIES ============================ 9

6. Motor torque characteristics ============================ 10

6-2) PSM-42 SERIES ============================ 10

6-3) PSM-56 SERIES ============================ 10

6-4) PSM-60 SERIES ============================ 10

7. Installation and wiring ============================ 11

7-1) Precaution for installation ============================ 11

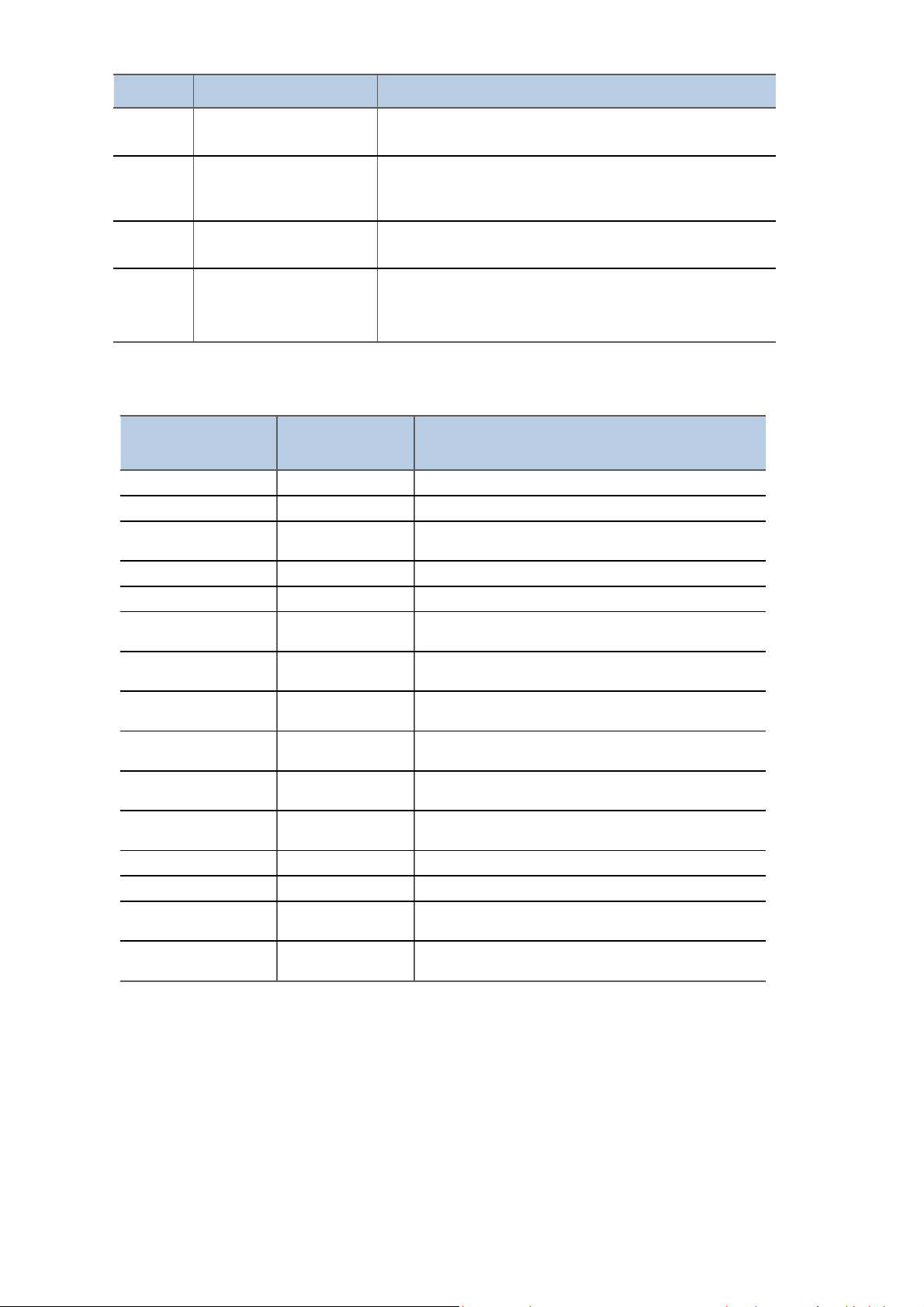

8. External wiring ============================ 12

9. Setting and operation ============================ 13

9-1) Status display LED ============================ 14

9-2) Pulse input mode setting switch (SW3-1) ============================ 15

9-3) Motor rotation direction switch (SW3-2) ============================ 15

9-4) Resolution setting switch (SW1) ============================ 16

9-5) Imposition value setting switch (SW2) ============================ 16

9-6) Position-gain setting switch (SW4) ============================ 17

9-7) Input-output signal connector (CN5) ============================ 18

9-8) Encoder connector (CN6) ============================ 18

9-9) Motor connector (CN1) ============================ 19

9-10) Power connector (CN10) ============================ 19

10. System configuration ============================ 20

10-1) Optional cable ============================ 20

11. Control input and output ============================ 21

11-1) Input signal ============================ 21

11-2) Output signal ============================ 22

12. Appendix ============================ 23

12-1) Connection diagram of intermediate cable for motor ============================ 23

12-2) Connection diagram of intermediate cable for encoder ============================ 23

12-3) Internal parameter setting program ============================ 24

Table of contents

5-1) PSM-28 SERIES

6-1) PSM-28 SERIES

============================ 7

============================ 10

0

WWW.COWINFA.COM

Please be sure to fully understand the manual before using this product.

1-1) This product is used to drive a step motor. There is no guarantee for the safety

if it is used for other purposes.

1-2) Please keep the following operating environment.

① The power of this product is DC +24 V and it should be used within the input range of

± 10%. Please be careful about excessive input or reverse input.

② This product is intended to be suitable for the industry standard electromagnetic environment.

③ This product should be used within 0 ℃ ~ 50 ℃ temperature and the storage temperature

④ This product should be used within the humidity of 35% ~ 85% RH and

1-3) Please be careful on the following points when installing.

① Please remove the power plug during installation or maintenance of this product.

② Please install all connecting parts such as power plugs only when this product is firmly fixed.

③ Please turn on the power only after the product is completely installed.

④ Please turn on the power only after the product is completely installed.

⑤ The arbitrary modification by an user is outside the warranty and the company will not be liable for it.

1. Safety management

is between -20 ℃ and 70 ℃.

stored within the humidity of 10% ~ 90% RH without condensation.

1

WWW.COWINFA.COM

2. Product Features

2-1) The highest torque

It can be operated with torque

at maximum 30% higher

in the area of its class.

2-2) The quickest response feature

It has the quickest response feature

with more than 20% faster

2-3) Complete stop

PluStep completely stops after stop

and therefore, does not

generate subtle vibration.

2-4) High Speed

PluStep can work without any out-of-phase

in the area of high speed because

the high torque occurs for 100% load

by having monitored the current position

with encoder feedback.

than its class.

2

WWW.COWINFA.COM

2-5) Reduced motor heat

PluStep has achieved low heat compared to high torque by applying our proprietary technology.

2-6) Slim Encoder

The slim design of encoder minimizes the total length of motor.

2-7) High Resolution

Plustep uses a high degree encoder executable 40,000 resolution/rotation of the basic specification

and therefore, it can be used at no additional cost according to the existing encoder pulse options.

(Maximum 40,000 pulses/rotation)

3

WWW.COWINFA.COM

3-1) Plustep-P model

3. Plustep-P model and order code

3-2) ORDER CODE

Motor model

Driver name

PLUSTEP-P-2832

PSM-2832

PSD-2832

PLUSTEP-P-5656

PLUSTEP-P-5676

PSM-2845

PSM-2852

Unit name

PSM-4233

PSM-4247

PSM-4260

PSM-5641

PSM-5656

PLUSTEP-P-2845

PLUSTEP-P-2852

PLUSTEP-P-4233

PLUSTEP-P-4247

PLUSTEP-P-4260

PLUSTEP-P-5641

PSM-5676

PSD-2845

PSD-2852

PSD-4233

PSD-4247

PSD-4260

PSD-5641

PSD-5656

PSD-5676

PSD-6045

PSD-6056

PSD-6088

PLUSTEP-P-6045

PLUSTEP-P-6056

PLUSTEP-P-6088

PSM-6045

PSM-6056

PSM-6088

4

WWW.COWINFA.COM

4. PluStep-P driver specification and size

4-1) Driver Specification

PSM-2832 PSM-2845 PSM-2852 PSM-4233 PSM-4247 PSM-4260 PSM-5641 PSM-5656 PSM-5676 PSM-6045 PSM-6056 PSM-6088

PSD-2832 PSD-2845 PSD-2852 PSD-4233 PSD-4247 PSD-4260 PSD-5641 PSD-5656 PSD-5676 PSD-6045 PSD-6056 PSD-6088

Input voltage

Current

consumption

Temperature

Humidity

Vibration

Rotational

speed

Maximum

input frequency

Protective

function

LED display

Imposition

setting

POSITION GAIN

Pulse input

method setting

Motor rotational

direction setting

Speed/position

control

command

Input signal

Input,

output

Output signal

Functions

1 – 16 (set by rotary switch)

1 clock, 2 clock DIP switch setting

Abnormalities such as overheating, low voltage, over-speed, speed difference, over-current

Power supply (Green), alarm (Red), Inposition (Orange), Servo On (Blue)

0 – 15 (set by rotary switch)

Encoder signal (A+, A-, B+, B-, Z+, Z-) (Output through relevant AM26LS31)

Motor rotational direction setting by DIP switch

Pulse input (Photo coupler)

Servo on / off, alarm reset, position command pulse (Photo coupler)

Alarm out, imposition out (Photo coupler)

24VDC ±10%

Applicable motor

Driver type

Environ

ment

500KHz (duty50%)

500, 800, 1000, 1600, 2000, 2500, 3600, 4000, 5000, 6400, 7200

10000, 16000, 20000, 32000, 40000 (set by rotary switch)

Maximum 1A (excluding motor current)

In use: 0 ~ 50 °C, In storage: -20 ~ 70 °C

In use: 35 ~ 85 % RH, in storage: 10 ~ 90 % RH

0.5G

0 ~ 3,000RPM

Resolution

5

WWW.COWINFA.COM

4-2) Driver size

6

WWW.COWINFA.COM

5-1) PSM-28 SERIES

5. Motor specification and Size

UNIT PSM-2832 PSM-2845 PSM-2852

---

---

VDC 3.8 4.56 6.2

A 0.67 0.67 0.67

Ohm 5.6 6.8 4.9

mH 3.4 4.9 7.2

N.m 0.059 0.093 0.117

g-㎠912 18

kg 0.11 0.14 0.2

℃

mm

32±1 45±1 51±1

M O D E L

DRIVE METHOD

BI-POLAR

NUMBER OF PHASES

2

VOLTAGE

CURRENT per PHASE

RESISTANCE per PHASE

INDUCTANCE per PHASE

HOLDING TORQUE

ROTOR INERTIA

WEIGHTS

AMBIENT TEMPERATURE

-20℃ ~ +50℃

LENGTH (L)

7

WWW.COWINFA.COM

5-2) PSM-42 SERIES

UNIT PSM-4233 PSM-4247 PSM-4260

---

---

VDC 2.76 3.84 8.76

A 1.2 1.2 1.2

Ohm 2.3 3.2 7.3

mH 3.4 6 16.6

N.m 0.32 0.54 0.68

g-㎠35 68 102

kg 0.22 0.35 0.5

℃

mm

33.5±1 47.5±1 60±1

M O D E L

HOLDING TORQUE

ROTOR INERTIA

INDUCTANCE per PHASE

RESISTANCE per PHASE

CURRENT per PHASE

WEIGHTS

LENGTH (L)

AMBIENT TEMPERATURE

BI-POLAR

2

-20℃ ~ +50℃

VOLTAGE

NUMBER OF PHASES

DRIVE METHOD

8

WWW.COWINFA.COM

5-3) PSM-56 SERIES

UNIT PSM-5641 PSM-5656 PSM-5676

---

---

VDC 2 2.5 3.2

A 2.8 2.8 2.8

Ohm 0.7 0.9 1.13

mH 1.4 2.5 3.6

N.m 0.55 1.26 1.7

g-㎠131 400 480

kg 0.37 0.7 1

℃

mm 41 56 76

HOLDING TORQUE

ROTOR INERTIA

CURRENT per PHASE

RESISTANCE per PHASE

INDUCTANCE per PHASE

M O D E L

DRIVE METHOD

BI-POLAR

NUMBER OF PHASES

2

VOLTAGE

WEIGHTS

AMBIENT TEMPERATURE

-20℃ ~ +50℃

LENGTH (L)

9

WWW.COWINFA.COM

5-3) PSM-60 SERIES

UNIT PSM-6045 PSM-6056 PSM-6088

---

---

VDC 1.36 1.6 2.8

A 4 4 4

Ohm 0.34 0.4 0.7

mH 0.8 1.38 3.5

N.m 1 1.4 2.4

g-㎠275 400 840

kg 0.6 0.77 1.4

℃

mm

47±1 56±1 88±1

NUMBER OF PHASES

2

M O D E L

DRIVE METHOD

BI-POLAR

WEIGHTS

AMBIENT TEMPERATURE

-20℃ ~ +50℃

LENGTH (L)

VOLTAGE

CURRENT per PHASE

RESISTANCE per PHASE

INDUCTANCE per PHASE

HOLDING TORQUE

ROTOR INERTIA

10

WWW.COWINFA.COM

6. Motor torque characteristics

6-1) PSM-28 SERIES

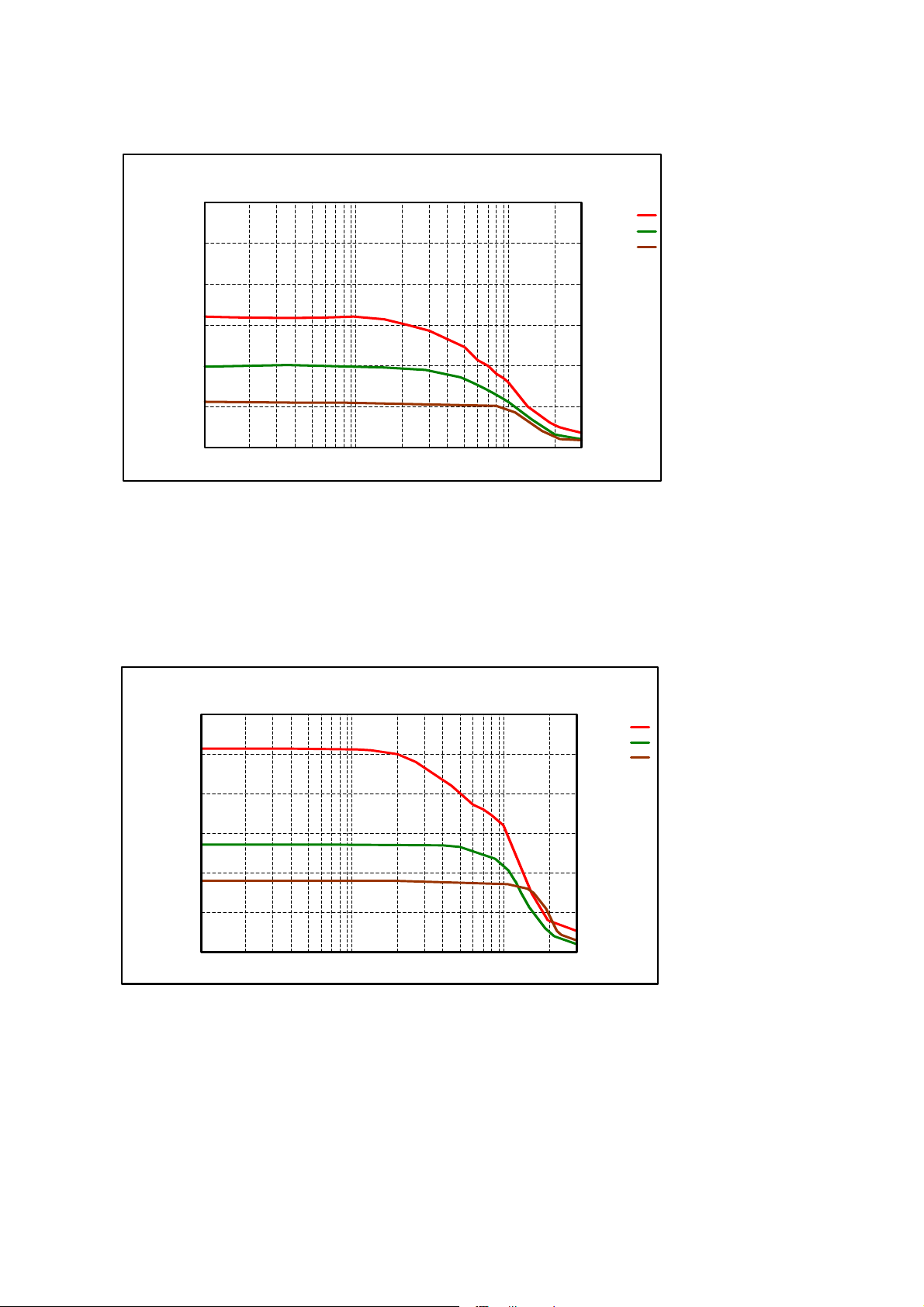

6-2) PSM-42 SERIES

Speed(RPM)

1011021033x103

0

200

300

400

500

600

700

Torque(mN . m)

PSM-4260

PSM-4247

PSM-4233

11

WWW.COWINFA.COM

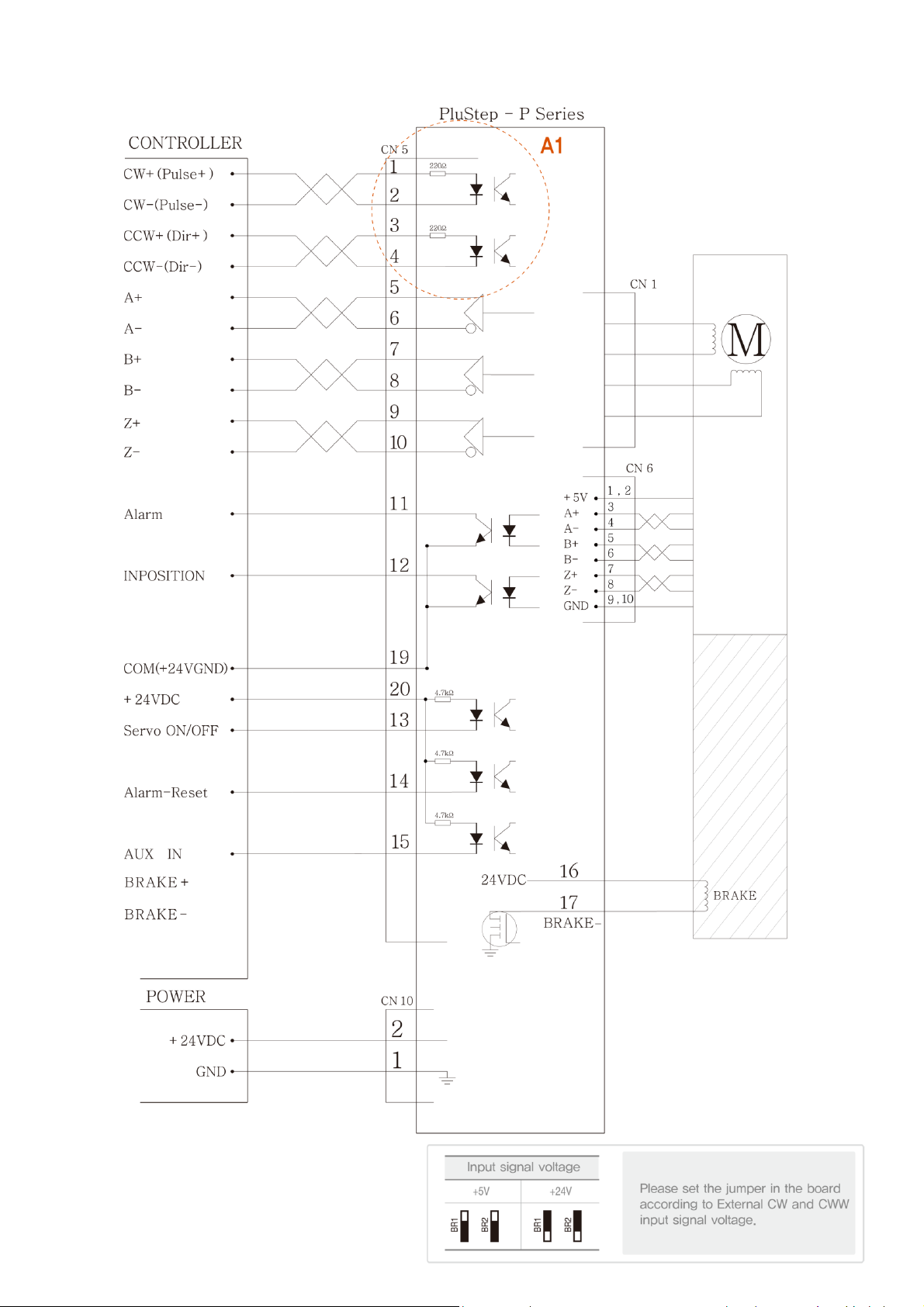

6-3) PSM-56 SERIES

6-4) PSM-60 SERIES

Speed(RPM)

1011021033x103

0

0.5

1

1.5

2

2.5

3

Torque(N . m)

PSM-5676

PSM-5656

PSM-5641

Speed(RPM)

1011021033x103

0

0.5

1

1.5

2

2.5

3

Torque(N . m)

PSM-6088

PSM-6056

PSM-6045

12

WWW.COWINFA.COM

7. Installation and wiring

7-1) Installation and wiring

① It should be used only at the room ambient temperature of 0 ℃ ~ 50 ℃.

② When the case is over 50 ℃, the heat should be dissipated to the outside.

③ It should be installed away from direct sunlight, magnetic or radioactive objects.

④ When installing more than 2 drivers in parallel, they should be installed with the distance

of more than 20mm vertically and 50mm horizontally as shown in the figure below.

More than 50mm

More than 20mm

13

WWW.COWINFA.COM

8. External wiring diagram

14

WWW.COWINFA.COM

9. Setting and Operation

Status Display

LED

Resolution setting

switch (SW1)

Inposition value

setting switch (SW2)

PO-Gain setting

switch (SW4)

Pulse input setting and

rotational direction

convert switch (SW3)

Input/output signal

connector (CN5)

Encoder connector (CN6)

Motor connector (CN1)

Power connector (CN10)

Green

Red

Blue

Orange

4

TX

RX

GND

Number

Functions

1

+5V

2

3

15

WWW.COWINFA.COM

9-1) Status display LED

① Status display LED function and lighting condition.

② Protection function contents and number of LED flashing

Color Function Lighting condition

Green Power input display Lighting when the power is turned on

Red Alarm display

Flickering when the protection function is activated (The

contents of activated protection function can be known

by number of flickering)

Blue Servo On /Off Servo ON: lighting, Servo OFF: lights-out

Orange

Positioning completion

signal display

Lighting when position deviation from the target position

is within the value set by the rotary switch (SW2) after

having completed the position command pulse input.

Number of LED

flashing

Name of Error Description

1Over-current When the current exceeds the set limit

2Over-speed When the speed exceeds the set limit

3Overload

When the motor torque exceeds the set limit for

more than 5 seconds

4Overheating Drive internal temperature exceeds 55 ℃

5Low current Motor supply voltage is less than the lower limit

6

Motor

connection error

Motor connection error

7

Encoder

connection error

Encoder connection error

8Location tracking

Command during operation and actual position

exceed 90 degrees

9

Position error

exceeds

The error exceeding 90 degrees occurs when

Motor stops

10 Inposition error

Error exceeding 1 after completion of operation

occurs for more than 3 seconds

11 Input pulse error

When the input pulse exceeds the limit

frequency

12 System fault Drive system error (MCU)

13 EEPROM error When parameter storage device error occurs

14

Default in motor

setting

Motor select error

15 Servo on error

In case input pulse is supplied

before completion of Servo ON

16

WWW.COWINFA.COM

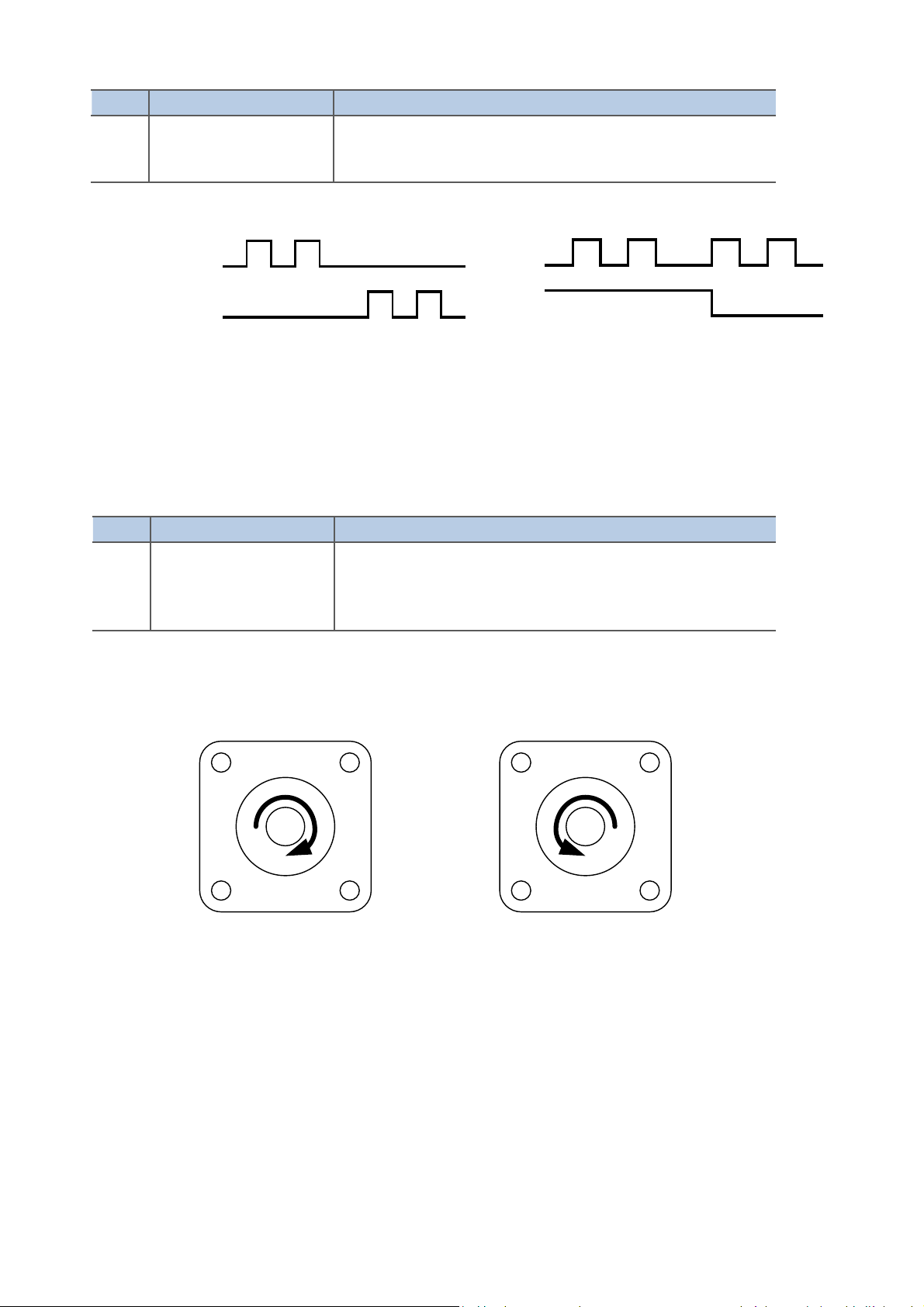

9-2) Pulse input mode setting switch (SW3-1)

9-3) Motor rotation direction switch (SW3-2)

CW(Pluse) Pin

CCW(Dir) Pin

Rotational Direction

CW

CCW

CW

CCW

CW Direction

CCW Direction

Display

Switch name Function

1CLK/

2CLK

Motor rotation

direction selection

Driver CW (+ Dir signal) input basis.

SW3-2 ON: CCW (- Direction)

SW3-2 OFF: CW (+ Direction)

※ CW is set at the time of shipping

Display

Switch name Function

1CLK/

2CLK

Pulse input

mode selection

Pulse input mode can be selected One Pulse or Two Pulse.

SW3-1 ON: Pulse One Pulse input mode

SW3-1 OFF: Pulse Two Pulse input mode

M M

17

WWW.COWINFA.COM

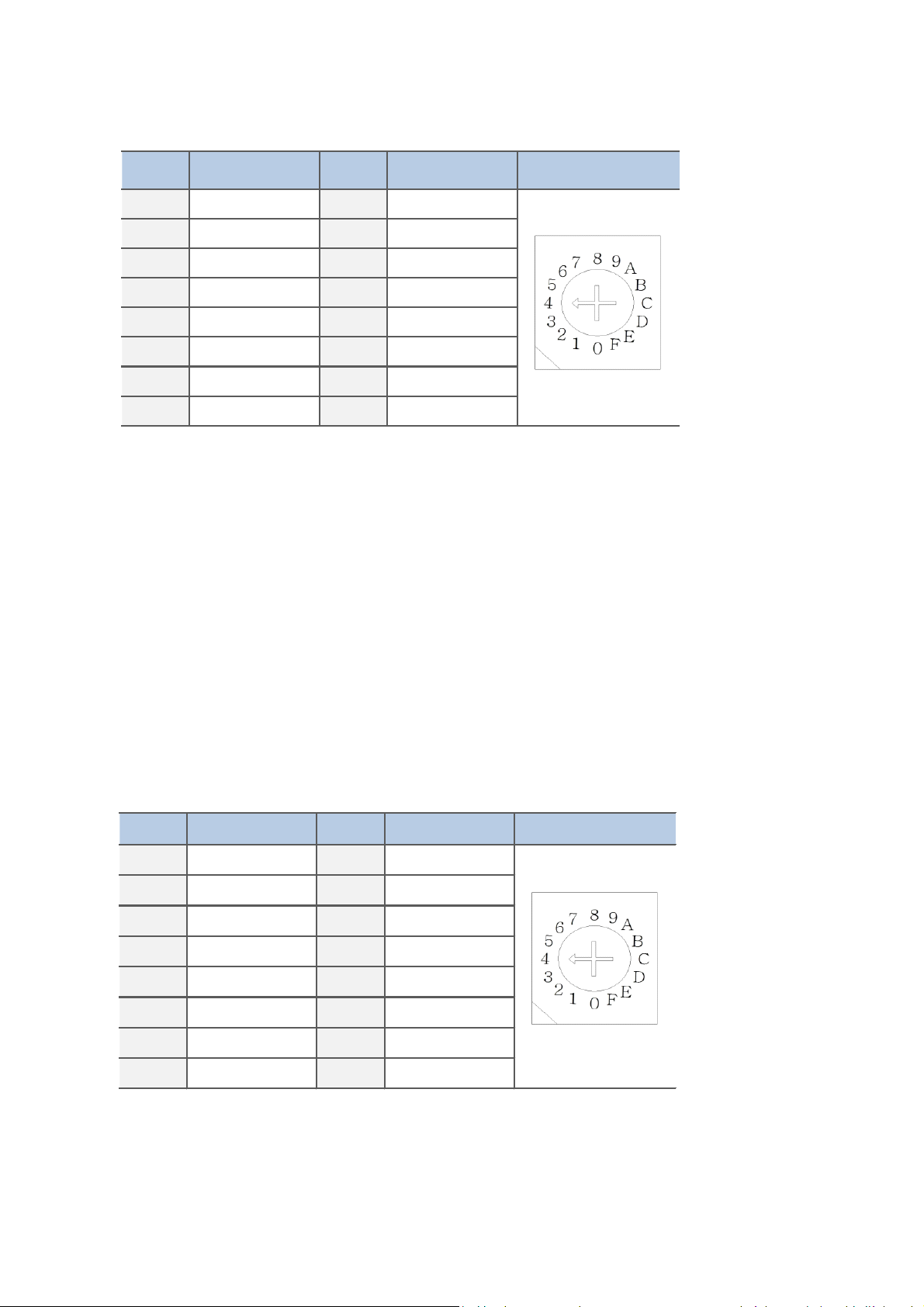

9-4) Resolution setting switch (SW1)

It refers to the number of pulses sent from the host controller per one rotation of the motor.

9-5) Inposition value setting switch (SW2)

It indicates the output conditions of positioning completion signal. If the position deviation from

the target position is less than the set inposition value after the completion of position command

pulse, the positioning completion signal is output.

NO

Pulse / Rotation NO Pulse / Rotation SW1

0500 85000

1800 96400

21000 A7200

31600 B10000

42000 C16000

52500 D20000

63600 E32000

74000 F40000

NO Inposition NO Inposition SW2

0088

1199

22A10

33B11

44C12

55D13

66E14

77F15

18

WWW.COWINFA.COM

This manual suits for next models

12

Table of contents

Popular Control System manuals by other brands

Skov

Skov FarmOnline+ DataLink 131545 Technical user guide

roco

roco 10810 quick guide

Wigersma & Sikkema

Wigersma & Sikkema UNICOM 300 Installation and user manual

CNC Router Parts

CNC Router Parts CRP4896 Assembly instructions

Lindsay

Lindsay Barrier Systems X-LITE installation manual

Express

Express ASX-31003-C Installation, operating and maintenance instructions