Table of contents

SMART 64 H / 200 K - i -

7$%/(#2)#&217(176

7$%/(#2)#&217(1767$%/(#2)#&217(176

7$%/(#2)#&217(176#

##

#

INTRODUCTION

How to use this Manual............................................................................................................................................. I.1

Symbols used .............................................................................................................................................................. I.2

Chapter 1 - OVERVIEW

System Components...................................................................................................................................................1.1

System’s Operating Principles..................................................................................................................................1.1

Special Features of SMART 64 H / 200 K System...................................................................................................1.1

General Features of SMART BTSR systems...........................................................................................................1.2

Chapter 2 – TECHNICAL DATA AND INSTALLATION

Technical Features.....................................................................................................................................................2.1

Installation..................................................................................................................................................................2.1

Electrical connections ............................................................................................................................................2.1

Example of Generic Application Connection on Small Circular Knitting Machines...........................................2.2

Connecting cables and Power supply devices......................................................................................................2.3

External RESET Connection................................................................................................................................2.4

Chapter 3 – OPERATING

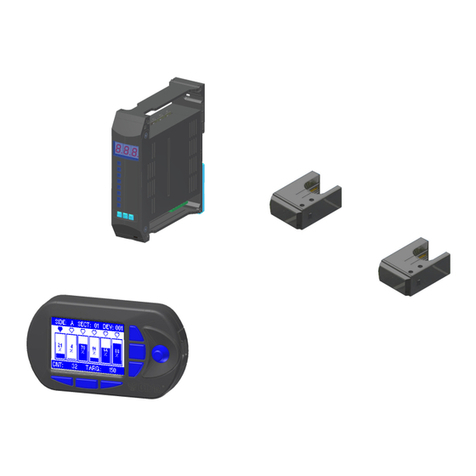

SMART 64 H / 200 K Terminal Features ................................................................................................................3.1

Meaning of Red Leds inside the SMART 64 H / 200 K Terminal’s.......................................................................3.2

IS3.. Sensors Features................................................................................................................................................3.3

Types of IS3.. sensors.................................................................................................................................................3.4

Function of the IS3.. Sensors.....................................................................................................................................3.4

Installation of the IS3.. Sensors.............................................................................................................................3.5

Interpretation of the signalling lights located on the sensors.................................................................................3.5

Settings that affect the sensor detection features.....................................................................................................3.6

Programming examples for F_START/F_STOP and relevant sensor delays .........................................................3.7

Preliminary operations for using the SMART 64 H terminal................................................................................3.8

Operating Sequences..................................................................................................................................................3.9

Activating the Learning Cycle (LEARN)...............................................................................................................3.10

Display Messages during the Control Phase..........................................................................................................3.11

Summary Diagram of SMART 64 H / 200 K Programming/Configuration Menu............................................3.12

P1 Programming Level............................................................................................................................................3.13

SYNC: Proxy / Encoder Pulse Divisor ...............................................................................................................3.13

ZERO: Machine Zero Signal Divisor.................................................................................................................3.14

PHASE: Tolerance on Phase Errors ..................................................................................................................3.14

DEVICES: IS3.. Devices Connected to the System...........................................................................................3.15

Global Automatic Numbering............................................................................................................................3.15

Single Sensor Numbering...................................................................................................................................3.15

Replacing a Sensor.............................................................................................................................................3.16

Adding a New Sensor.........................................................................................................................................3.16

KEY_COD: Password to Access the Programming Menus .............................................................................3.17

K_LEARN: Password to Access the Learning Function..................................................................................3.17