CPG Freno User manual

A

INSTALLATION MANUAL

INSTALLATION MANUAL

Modular Rain Garden

INSTALLATION MANUAL

1

System Overview

Freno is a pre-cast modular system that allows rapid construction of rain gardens that can serve

as bio-retention areas.

• The system can be installed using light equipment. System components require equipment

with a lifting capacity of ______lbs. Many Compact Excavators and Skid-Steer Loaders are

well suited to this task. Typically a two man crew is all that is required to install the system

(one machine operator and one laborer).

• Each Freno module has built-in connection inserts that allow easy attachment to lifting

equipment using 3/4” common thread bolts.

• The Freno system can be built in a variety configurations using a limited number of modules

that are mechanically connected using stainless steel rods.

• No concrete footing is required. The system components are installed on a compacted base

material footing.

• Because Freno Components are produced in a controlled factory environment, structural and

aesthetic quality control is assured.

Modular Rain Garden

2

INSTALLATION MANUAL

Modular Rain Garden

System Components

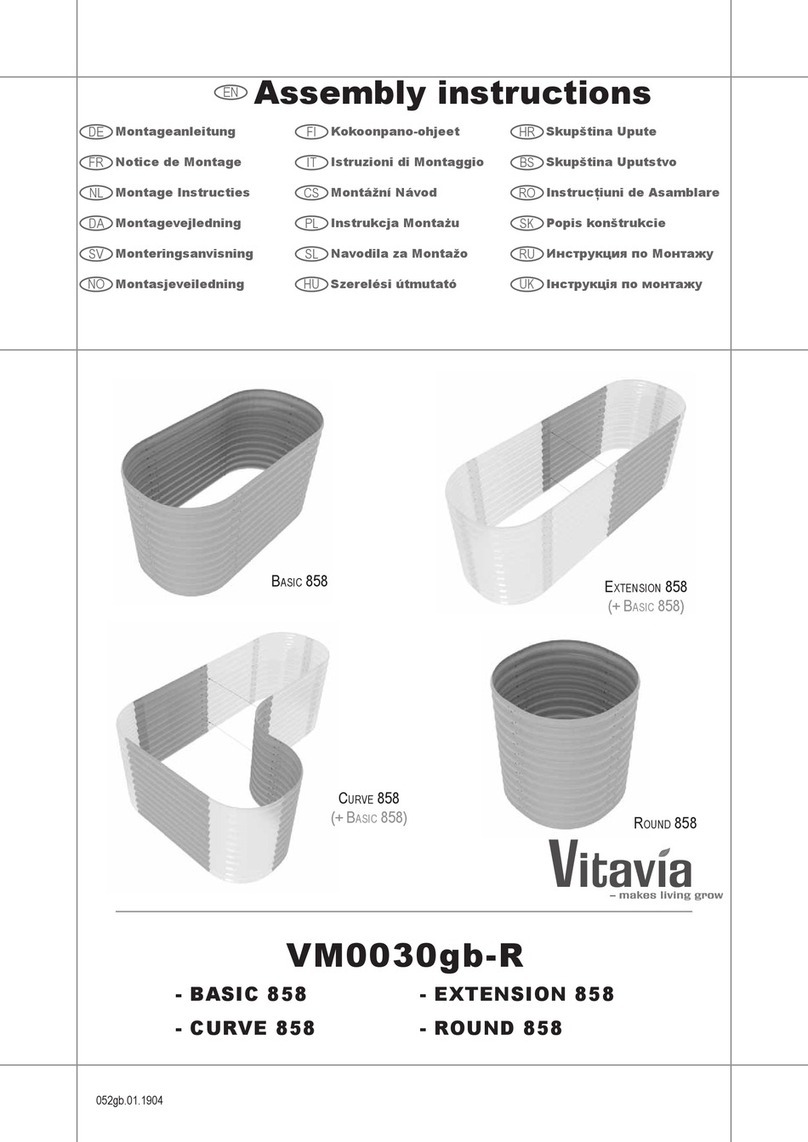

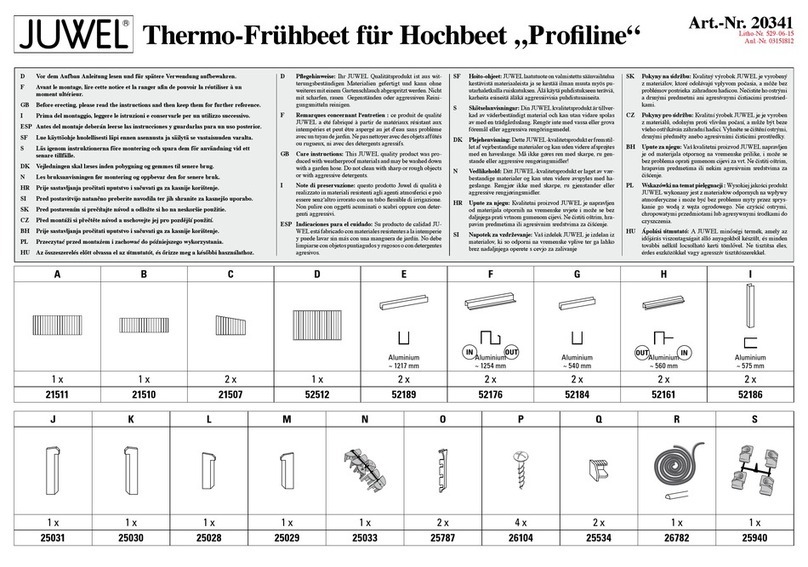

The Freno System consists of five basic module shapes that can be used to construct a variety of

configurations of structures.

The modules each have lifting connections placed to assist in connecting the system to

lifting equipment to facilitate placement of the modules during construction and for potential

attachment of accessories to the finished structure.

The modules are designed to overlap and connect with 1/2” stainless steel pins.

N • MODULE T • MODULE

T2 • MODULES • MODULE

3

INSTALLATION MANUAL

System Configuration : Endless Options

The Freno System allows great flexibility in the construction of a variety of structure

configurations because it is a kit of parts. Here are several examples of possible configurations.

rendering rendering

rendering rendering

4

INSTALLATION MANUAL

Modular Rain Garden

Pre-Construction Planning

Before beginning construction, planning will help assure a successful

installation. Here are several important steps to include in your planning

process:

Implement A Safety Plan

Request marking of underground utilities from your local service prior to excavation.

Call 811 or use the state specific information at http://www.call811.com/state-

specific.aspx.

Place construction barriers and hazard markings to limit access to the site while

under construction and divert traffic dangers away from site workers.

Pre-Construction Site Review

Obtain engineering plans for the project and any required permits.

Note any access restrictions requiring special planning, and any overhead wires

or obstructions that may interfere with lifting equipment. Review your equipment

requirements in light of site conditions.

Review plans and note any site issues that conflict with project plans for discussion

with project designers.

Plan how to stage pallets of Freno Modules and other materials for efficient material

handling based on installation configuration and mark the site accordingly prior to

material delivery.

PLANNING

5

INSTALLATION MANUAL

Construction Scheduling Considerations

Schedule installation and fill of the Freno™ System at a time when surrounding

surfaces have been stabilized and sedimentation is controlled. It is critical that the

bio-retention fill not become contaminated by sedimentation during construction.

A typical Freno™ installation will be completed rapidly (one to two days of

construction time per structure is typical, depending on complexity and size), but

some care should be taken if construction will be interrupted for any reason, or if the

surrounding site soils are not stabilized.

The planting soils should not be delivered to the site before the Freno™ System has

been installed and the under-drain system, if any, has been installed.

It may be most efficient to place the plant materials after paving has been

completed to avoid repetition of effort since performing the paving work may

require access from within the bio-retention area, which could damage the plant

materials.

The construction sequence is very straightforward:

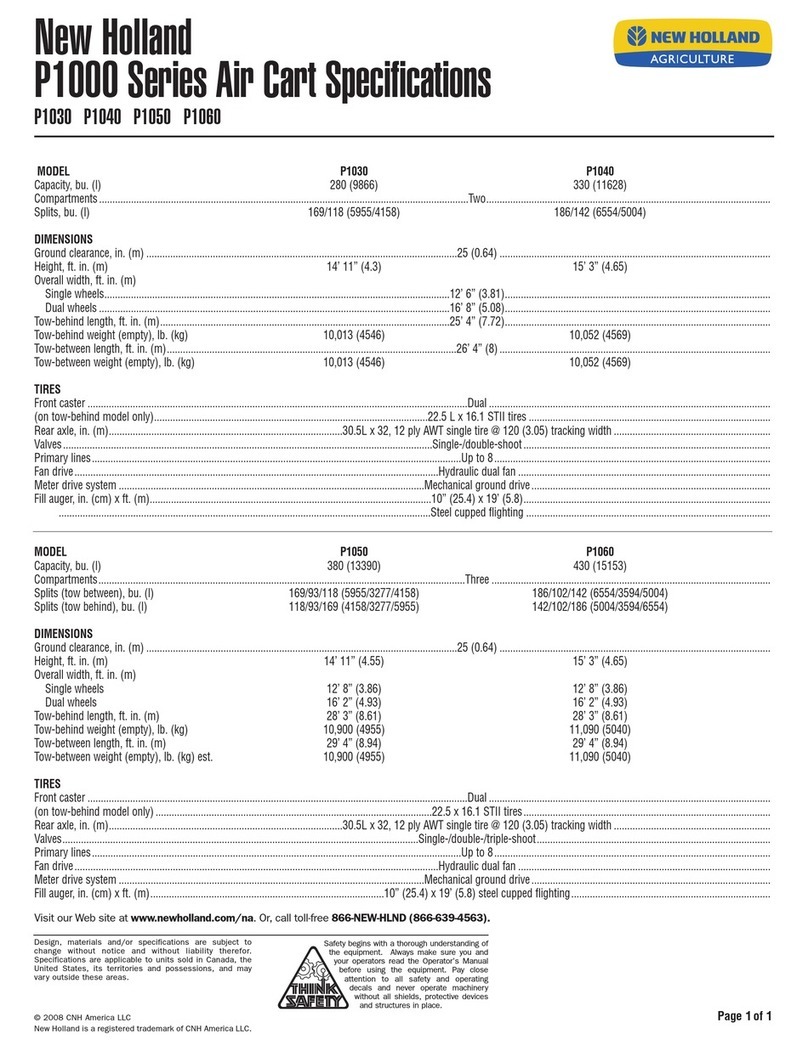

Stage Material Typical Equipment

Required

1Pre-Construction Site

Review

Safety barriers and markers None

2Site Preparation,

Demolition and

Excavation (installation of

under-drain, if required)

Under-drain system materials (if

required). Order base material

and Freno Module delivery.

Compact excavator and

skid-steer loader

3Place and Compact Base

Leveling Pad

Base Material and Freno Mod-

ules

Plate compactor,

skid-steer loader

4Place Freno Modules Pins, Lifting Clutches Compact excavator or

skid-steer loader

5Backfilling and

Planting

Crushed stone backfill, Bio-

retention fills - planting soils,

sands and aggregates, plants

Skid-steer loader

SCHEDULING

6

INSTALLATION MANUAL

Modular Rain Garden

Place safety barriers, markings and signs

as required by site safety plan.

Locate all underground utilities before

beginning demolition and excavation,

and resolve any conflicts with site plans.

Remove existing pavements, plant

material or structures from the area

to be excavated. Grade site to plan

elevations. Stabilize graded area to

minimize sedimentation during con-

struction. Place erosion control devices,

as required to prevent sedimentation of

the system.

Excavate trench to the depths and

shape called for in the plans, minimizing

compaction of site soils in the trench as

much as possible.

[recommendation regarding amount

of over excavation and illustration

- Rendering of plan view of

recommended trench configuration].

If your system will include an under-

drain, excavate for under-drain system

and install pipe to connect into local

stormwater drainage system per

specifications. Backfill as specified.

Take care not to damage the under-

drain during placement of aggregate

fills. Sizing and installation for the

under-drain pipe system should be

specified in the project plans.

Prior to covering the under-drain

system, the inspector will need to

inspect the under-drain installation, its

connections, and any filter fabrics that

are used.

STAGE 1

Site Preparation, Demolition and Excavation

Place safety barriers

Site preparation and demolition

Excavation

rendering of excavation

7

INSTALLATION MANUAL

The leveling pad is the foundation of the

system and placing it correctly is a key to

a successful installation.

[Filter fabric?]

Use a readily compacted base material

consisting of granular inorganic soils

(some common names for this type of

material are “Class #5”, “Road Base”,

etc). The material’s maximum particle size

should be 3/4” (20mm) and minimum

particle size should be such that no more

than 10% of the material passes a No.

200 sieve.

Place and level a string line (or use a laser

leveling device) to assist in installing the

base material in a level condition to the

elevation specified in the plans.

The leveling pad should be 18” wide

and at least 6” thick after compaction

(see drawing for typical leveling pad

dimensions and placement), which will

require placement of greater than 6”

base material before compaction.

Compaction should be performed

using a mechanical plate compactor.

Compaction should be performed to

95% Standard Proctor or 90% Modified

Proctor. (soil testing standards to

determine % of maximum soil density).

Take care to assure that the compacted

base material is level and at plan

elevation, as this will speed the process

of leveling the Freno Modules when they

are installed.

STAGE 2

Place, Compact and Level Base Leveling Pad

Compacting base material

rendering of leveling pad dimensions

8

INSTALLATION MANUAL

Modular Rain Garden

STAGE 3

Freno Modules are designed to be

easily connected to lifting equipment.

Stage the pallets of Freno components

near where they will be installed. Freno

modules can be handled using a Skid-

Steer loader or Compact Excavator

capable of lifting _____ lbs.

Attach the lifting attachments to

the Freno Module using the lifting

connections (Figure ___) that allow

connection to bolts with 3/4” common

thread. Connect the lifting connections

to a chain (with rated strength of at least

_____) See Figures _-_ Securely attach

the chain to the lifting equipment. See

Figures _-_.

Install Freno™ Modules

A. Connecting Freno

Modules to Lifting

Equipment.

close up showing how to attach

9

INSTALLATION MANUAL

STAGE 3

Using the lifting equipment, place

Modules in the sequence shown below in

Stage 3.C.

Adjust as necessary to make sure each

Module is level, in proper alignment and

at plan elevation.

Check plans and assure that modules

are oriented correctly with respect to

whether intake slots should be placed on

top or bottom.

As the modules are installed, shore the

system using temporary braces as shown.

These braces will no longer be necessary

after the structure has been backfilled,

but will help assure the modules stay in

their proper position during construction.

To assist in leveling the module, a heavy

plastic covered mallet may be useful

to seat the module and make minor

adjustments. Additional base material

may be added/removed underneath the

panel to address any low/high areas.

(Keep the panel attached to the lifting

equipment while adjustments are made,

and follow safety precautions).

Install and connect adjacent modules in

the sequence shown in the next section.

Align, level, and check elevations as you

go.

Install Freno™ Modules

B. Placing and

Leveling Modules.

Adjusting a Freno Module

Installing temporary bracing

Confirming that base is level

10

INSTALLATION MANUAL

Modular Rain Garden

STAGE 3

Install Freno™ Modules

C. Sequence of Module Installation.

To start construction, place and level an end module. Then install and connect the adjacent

module to build a corner.

Step 1: Place and level first end Module

Step 2: Establish a corner by placing next module. Using a

second T2 panel, install the foundation for the intake structure.

Confirm this module is level,

at the right elevation and

oriented correctly before

moving on.

Construction Notes:

Take care to assure that a

right angle is established at

the corner.

The two T/2 Modules are

the foundation for the intake

structure, in this case installed

adjacent to the corner. Place

and level each module and

level relative to each other.

11

INSTALLATION MANUAL

STAGE 3

Install Freno™ Modules

C. Sequence of Module Installation.

Step 3: Continue to install modules on first side.

The connecting rods should

be placed in the Modules

prior to installation of next

Module so that the next

unit can be lifted onto the

connection. Level, confirm

correct alignment and

elevation as you go.

Step 4: Once the first side is completed, start installing the

modules on the other side.

Step 5: Continue installing Modules on this side.

Place a connecting rod in

the end Module before

placing the first side Module.

Confirm the Modules are

placed at a right angle to

ensure correct orientation of

the structure.

Install all but one Module on

this side. The end Module

needs to be installed

before the last side Module

because the side Module will

rest on the end Module.

12

INSTALLATION MANUAL

Modular Rain Garden

Install Freno™ Modules

C. Sequence of Module Installation.

Step 6: Install the other end Module.

Adjust the end Module to

provide proper spacing for

placement of the last Side

Module.

Step 7: Install the final side Module.

Step 8: Install the water intake structures using the N• Mod-

ules as shown in Stage 3-D.

Here is where careful

measurement and

orientation of the prior

modules pays off.

Detailed instructions for this

step are found in the next

section.

STAGE 3

13

INSTALLATION MANUAL

STAGE 3

Install Freno™ Modules

D. Building Water Intake Structures.

The foundation for the water intake

structure is built as described above us-

ing T/2 Modules.

After all of the base modules have been

installed and temporarily braced, and

during the backfill process described

in Stage 4 below, backfill the exterior

of the structure near and around the

intake structure with angular crushed

stone, being careful to assure that the

T/2 modules remain correctly aligned

and level.

Place first N Module as shown in Step

8A

Place second N module in an inverted

position over the first N module as

shown. Adjust position to align with the

top of adjacent modules as shown Step

8B.

Step 8A: Placement of first N•Module.

Step 7: Placement of second N•Module.

Correct orientation of N•Modules

14

INSTALLATION MANUAL

Modular Rain Garden

Backfilling and Planting

STAGE 4

Once the modules have been installed,

install the observation well, if specified,

prior to commencing back fill.

Before adding bio-retention fill

materials, make sure that the site

is stabilized so that they will not

be contaminated by excessive

sedimentation in a storm event.

Backfill the excavated area outside of

the structure in 8” lifts using crushed

angular stone and backfill the interior

of the structure with the prescribed

fills (sands, aggregates, filter fabrics,

and planting soils per plan) so that the

inside and the outside of the system are

backfilled in alternating lifts. Remove

temporary shoring

Follow the plan specifications for

material types and layer thicknesses

of the bio-retention fill materials.

Do not compact the interior fills,

and consult the project designer for

recommendations regarding overfill of

the planting soils since approximately

20% more may be required to account

for natural settlement.

As you backfill the interior, install

erosion protection at the water intake

locations.

Water bio-retention materials and

allow to settle and adjust heights to

plan specifications, as required, before

adding plant materials and final mulch

layer as specified.

Place plants once soils have settled.

Add mulch layer to achieve final grade.

Step 9: Backfilling structure.

Step 10: Placing, Planting Soils.

Erosion control at water intake

15

INSTALLATION MANUAL

STAGE 3

Paving and Finishing

The structure is now ready, but should not be placed in service until all of the drainage area

has been stabilized and approved by the inspector. If there will be any delays before paving

is completed, make sure sediment controls remain in place. Complete the pavement repair or

placement around the structure per plan

Modular Rain Garden

Nationwide Availability

The Concrete Products Group LLC (CPG) consists of regional market leaders in the concrete products

industry. We offer high performance, cost effective products for the construction of buildings, stormwater

management and low impact development of sites

800.789.0872

www.concreteproductsgroup.com

2203 E. McCarty Street

Jefferson City MO 65101

To order Freno™

call 800-299-2594

Table of contents