...... .......

I I i I II ........ /BUSHING _, BUSHING

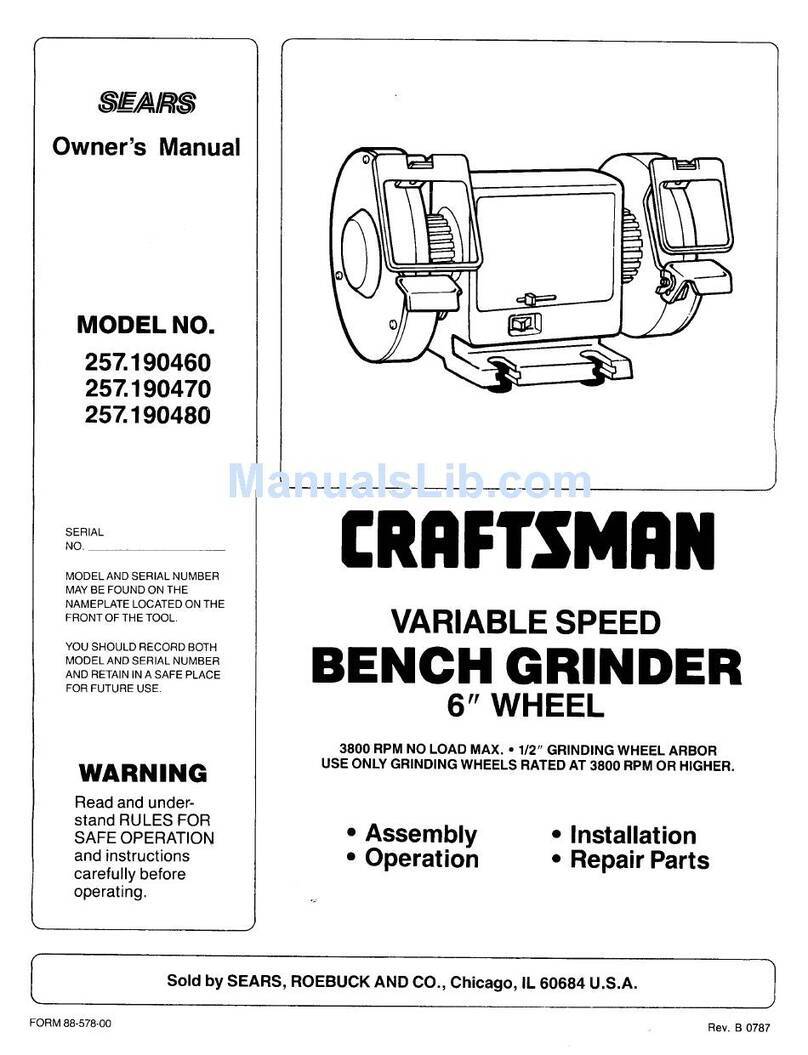

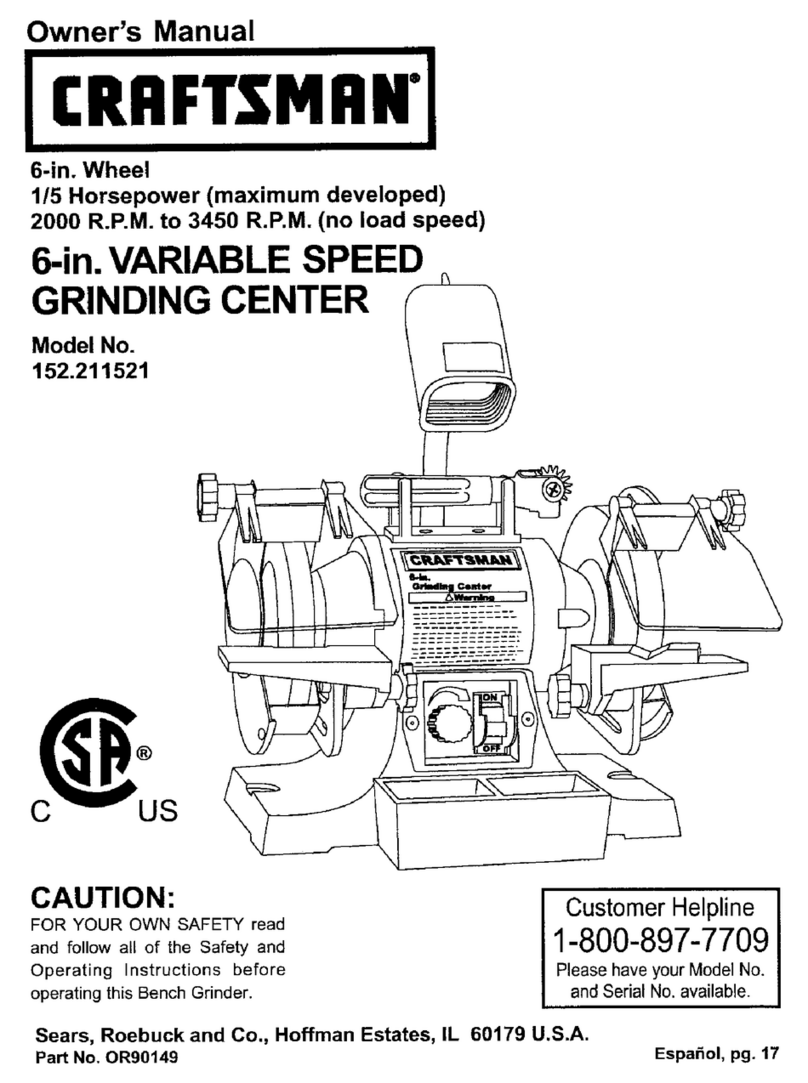

ILLUSTRATION FOR MOUNTING GRINDER

Using a second nut on each bolt, jam-tighten

against the first to prevent loosening by vibration.

A Craftsman workbench provides a good mount-

ing for your grinder, when drawer space is de-

sired as well as surface space.

Mount unit to bench top using two wood screws

through base grommets at front of grinder only.

Use two _" x 1_" round-head screws. Tighten

screws until clearance between base and surface

of bench is 3/16"(see illustration above).

15 ampere lighting circuit fuses should be satisfac-

tory. Otherwise, a "delayed-action" type fuse de-

signed to meet the demands of motor protection

and minimize possible nuisance of "blown" fuses

From momentary overloading.

The following wire sizes are recommended for ex-

tensions or special circuits.

Length of Two-Conductor

Extension

15 feet or less

50 feet or less

100 feet or less

Wire Size Required

(American Wire

Gauge No.)

No. 14

No. 12

No. 10

.To start, move the toggle switch to "ON" posi-

tion. (Note: The lamp is also controlled by this

circuit.) If grinder does not start immediately,

disconnect power and check for lack of current

at power source. If, after verification of suffi-

cient power at source, the grinder will not start,

return it to point of purchase for inspection.

TO OPERATE:

BE SAFE! USE EYESHIELDS FURNISHED WITH

GRINDER AND WEAR RECOGNIZED EYE

PROTECTION. STAND AWAY FROM FRONT

OF GRINDER DURING FIRST MINUTE OF

OPERATION.

Before starting grinder, follow instructions in the

next two paragraphs concerning grounding, pro-

viding proper fuses and wire chart for electrical

extension wire sizes.

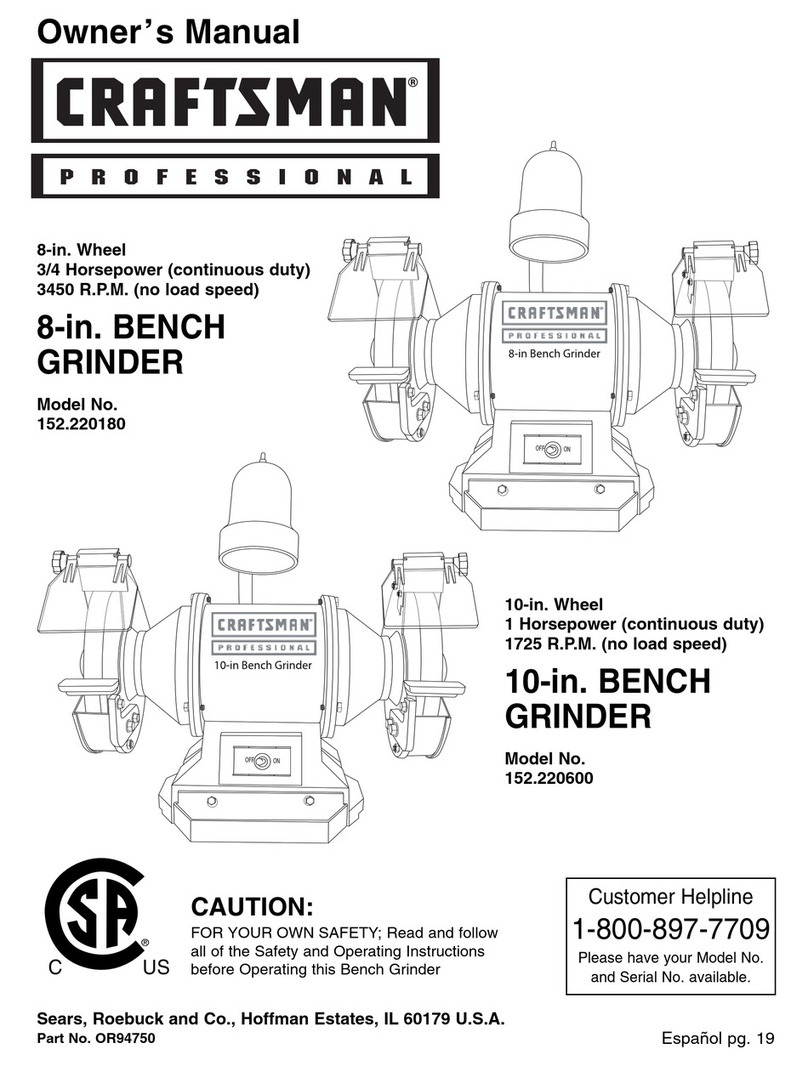

This grinder is equipped with a 3-conductor cord

having a fixed grounding conductor. Receptacle

not having provision for the grounding pin will re-

quire a plug adapter as shown in illustration below.

Protection of the operator may be insured by AL-

WAYS CONNECTING THE GROUND WIRE 1"O A

PERMANENT GROUND BEFORE PLUGGING IN

THE POWER LEADS. This connection can be rnade

to the receptacle cover screw, if the outlet box is

properly grounded, or to another suitable ground

such as a water pipe.

PLUG ADAPTER

GROUND WIRE

BE SURE BOX IS GROUNDED

If this grinder is not required to start under load

and is not overloaded after starting, the standard

.

.

The tool rests should be positioned securely to

support the material to be ground so that it

makes contact with the wheel slightly above

center-line of shaft at the desired angle.

Begin grinding by moving workpiece into con-

tact with the wheel gradually. Move from side

to side across the wheel evenly to remove ma-

terial more smoothly and help retain the

squareness of the wheel surface.

DO NOT FORCE WORK AGAINST GRIND-

ING WHEELS! EXCESSIVE PRESSURE MAY

CAUSE DAMAGE OR BREAKAGE.

Grinder should run near full speed for effec-

tive grinding and buffing.

TO MAINTAIN:

1. When vitrified wheels become irregular or

glazed from use they may be trued and

cleaned, returning them to near-new condition

with the cutting face fresh and square. Use a

Sears wheel dresser to keep your wheels in

good condition.

2. Clean out any accumulation of cuttings and

abrasive each time outer cover is removed.

.

Note: Wheel guards (Key No. 9) may be re-

moved for some adaptations of accessory

wheels without voiding the guarantee, how-

ever, disassembly of electrical connections or

end frames (10 & 18) by anyone other than

an authorized electric motor repair station will

void the guarantee.

Lubrication was provided at the factory for the

life of the ball bearings.