CUSTOMER RESPONSIBILITY_

Clean and stem in waterproof building.

Apply alightcoat of grease or oilto threaded parts, pivotpointsand the inside of HitchTube,

Touch up any scratches with enamel paintto avoid rusting.

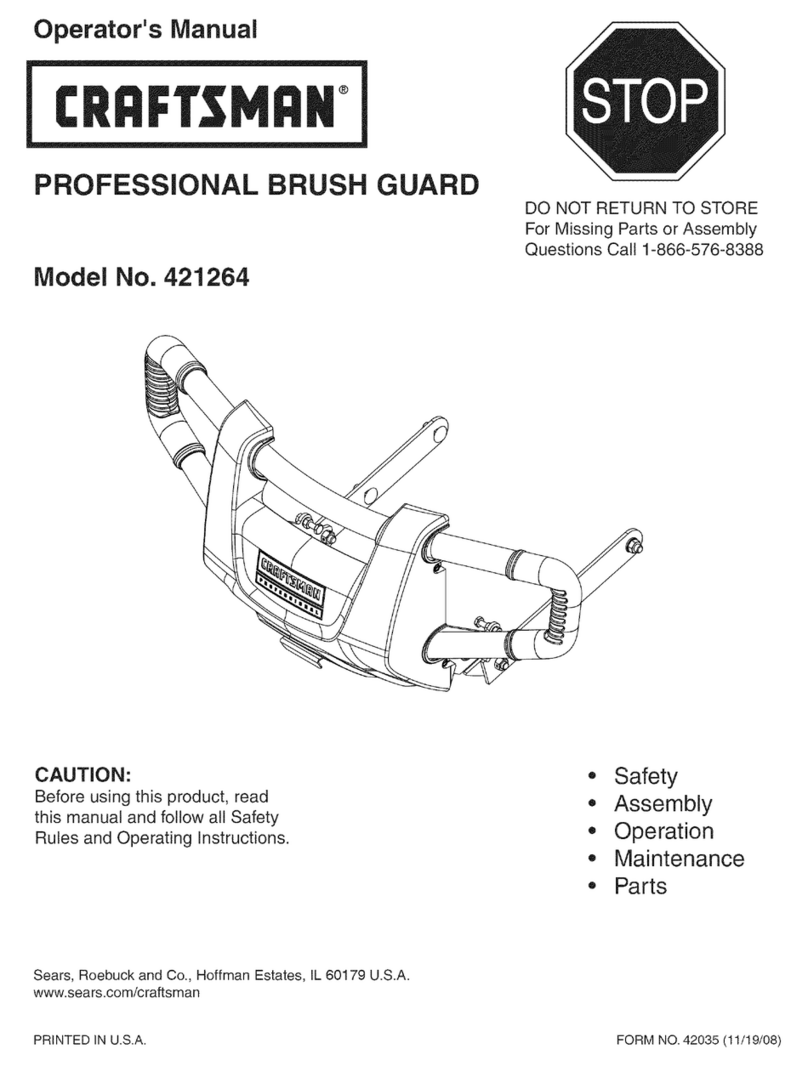

TABLE OF CONTENTS

SAFETYRULES..............................................................2

MAINTENANCE..............................................................."J

WARRANTY.................................................................i....2

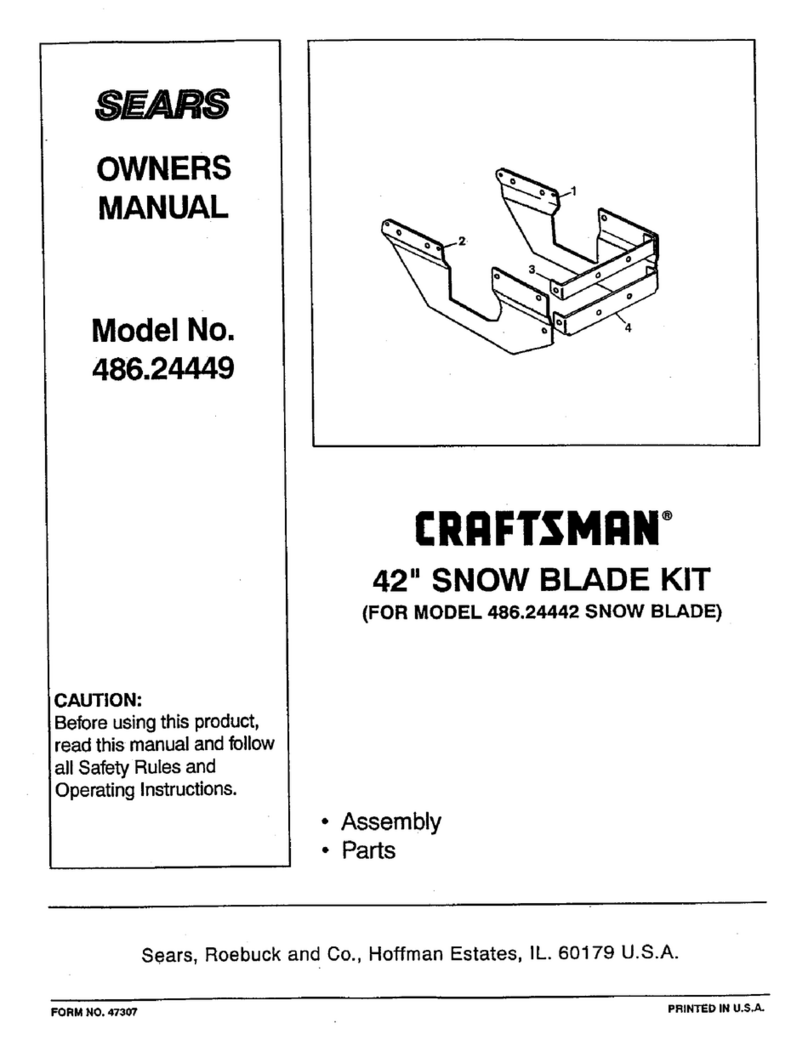

HARDWARE....................................................................3-4

PARTSREFERENCE......................................................5

PARTSLIST.....................................................................5

ASSEMBLY......................................................................6-g

OPERATION....................................................................t0

NOTES .............................................................................11

safetypnl_u_onstilto_lmut_Lsrnanual.It

rreans•ATT*ENTIONI

BECOMEALERTIyoursafelyisinvolved.

,, ,i ii i i

Limited Warranty

For two(2) years from.the date of purchase when th. = SI.eeva Hitch is meints ned and ubr cate.d

accoraing to the operating ana maintenance Instructions In the uwners ManuaJ, oeara will repair,

free of charge, any defect in material or workmanship.

This warranty does not cover:

Repairs necessar.y because of operator abuse or negll_lence including the failure to maintain the

equipment eccoromg to instructions contained in _the uwner's Manual; end Sleeve Hitch used for

commercial or rental purposes.

WARRANTY SERVICE IS AVAILABLE BY CONTA_T-ING THE NEAREST SEARS SERVICE

CENTERIDEPARTMENT N THE UNITED STAT,ES,, .Th s_w.arranty app es on y whe th a product

IS in use in me unneo _tates.

This warranty gives you specific legal rights, and you may also have other rights whiah vary from

state to stale.

SEARS, ROEBUCKAND CO,, D/8t7 WA, Hoffman Estates, IL80179 EE.UU.

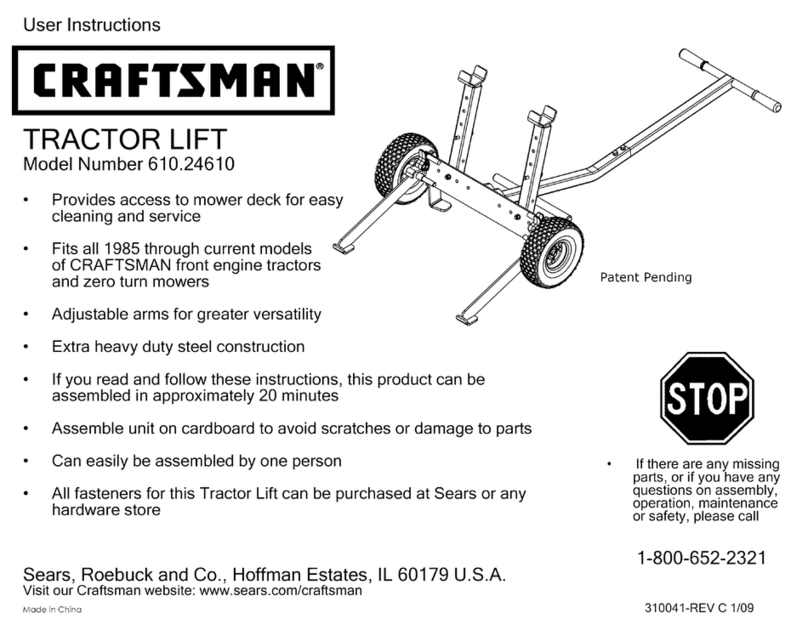

CongratulationsonyourpumhaealYourequipmenthasbeendesigned,engineered,andmanufacturedtogiveyouthebestpossible

dependabilityendperformance.

Should youexperienceany problemyoucannoteasilyremedy,pleasecontact.yournearestSeamServiceCentarlDepsrtmsnt.We

havecompetent,well-trainedtechniciansendthepropertoolsto=er_cp.orrap=atyourequipment.Pleasereadandretainthis

Owner'sManual.The instructionswillenableyoutoassembleend mmntamyoureqmpmentpmpedy.Alwaysobservethe 'Safely

Rules'priorto use.

RULES FOR SAFE OPERATION

• Knowcontrolsa_l howtostop towingequipmentq_. RF.ADTHE OWNEN8 MANUAL

• Donotallow Childrento upstate the vehicle,Donotallowedulintoodarabbwithoutproper inslzu,'_n orwithouthavingmadthe

Owners Manual,

a Doeotcarryp_sensers, Keepddldmnendpet6soldedistaltcemvay,

• Alwayswearsubatanclalfootwee¢,De notw_r _dcthlngIhstcangetcaughtInmovingpe_ts.

• Keepyoureyesand mindonyourtawingequlpment/ellechmentandaresbeinge=avered.DonotletctherJnteres_distractyou.

•Stayaldrtfarbolas inlos te/TalnalKI o0tnrhiddenhazards.

•DonotdriveclosetocreaM, ditches, andpubli€hlghwmys.

•Watchoutfortraffi:whsecr_sll_ or nearroadways.

aWhenusinganyattachment,don'tallow any=qenearthevehiclewhileIn operation.

a Keep_le vehicleendeltachment Ingood oberdug mndlbn andImepsaintydnvlm_inplace.

• KeepeUnuts, bob, endscrewstighttobe sum theequipmentIsIn_woddngcondition.

• ThevehP.._endattac_lnlentshouldbeMoppedandIrlBpOcledfordamageafter_king anyforeignobjecLThe damageshould=e repaired

beforerosta_ngandoparalingtheeqt_nt.

•See towing equipmentOwnsr'oManualtar safeoperationoftheequlpmact.

AMAINTENANCE ....

The keytoyearsoftmubis..fmeserviceIstokeesyourEquipmentdean anddW.

Occasionally_o=k allmovingp_t= for flee movementsnd, ifnecauwy, lubricatewithoiL.

Should rustdmmlop,ImndI_hllyIld UIsnp_l( m_onanlel,

Psriodk_lly_heCkallfnstenemfortlsntnems.

.