Lifting

1.Placevehicleinpark,withemergencybrakeon

andwheelssecurelychockedtoprevent

accidentalvehiclemovement.

2.Locateandclosereleasevalvebyturninghandle

clockwise,firmly.Positionjacksaddleunderlift

point.

3.Verifyliftpoint,thenpumphandletocontactlift

point.Tolift,pumphandleuntilloadreaches

desiredheight.

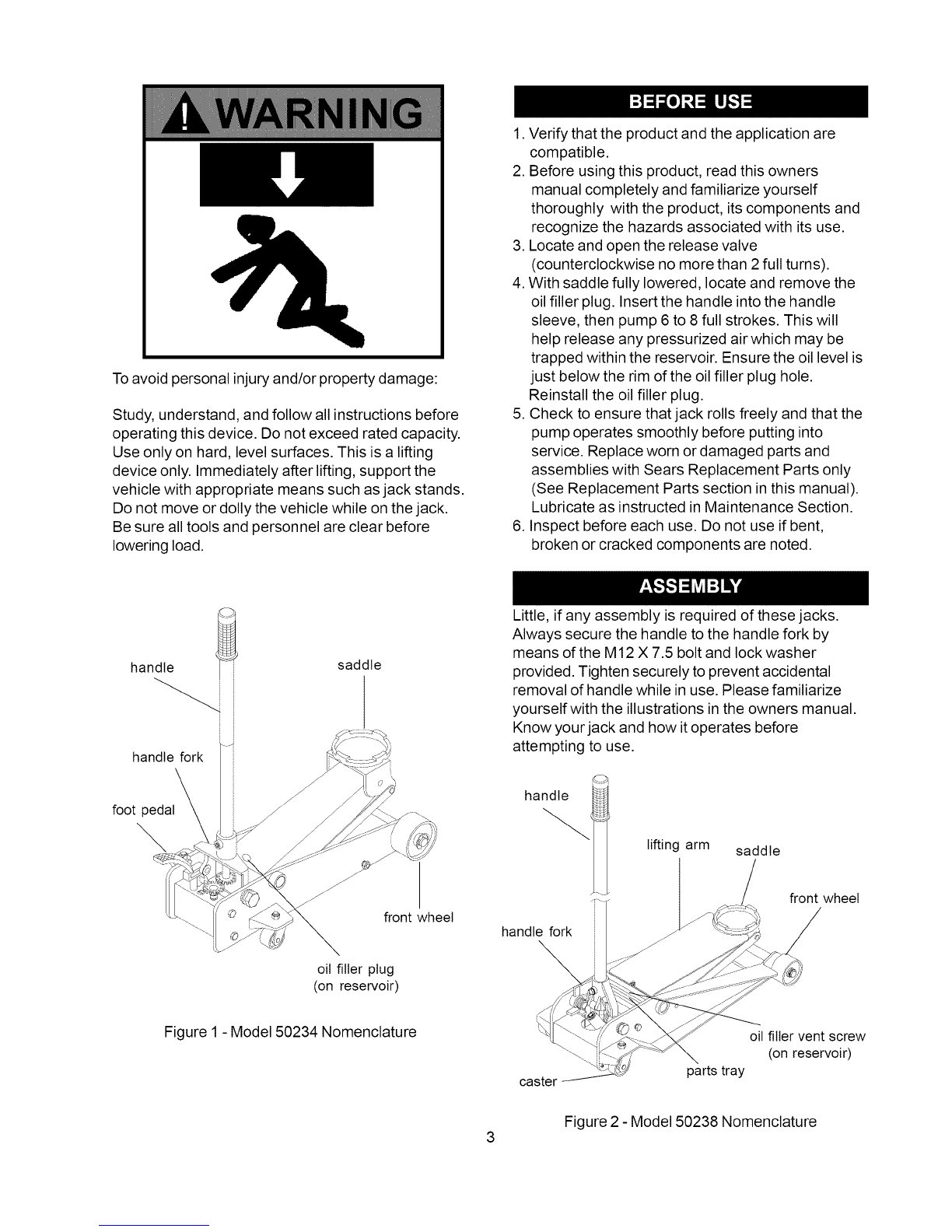

Note:Model50238featuresa2speedhydraulic

systemthatallowstheliftarmtoberaisedtothelift

pointin1or2strokesofthehandle.Aftertheloadis

contacted,2or3additionalpumpsmayberequired

tofillthelowpressurecavityofthehydraulicsystem

andbeginthehighpressure,loadliftingprocessat

approximately.5"-.75"inchesperfullhandle

stroke.Model50234featuresafoot(orhand)

operatedpedalthatisintegraltothepumppiston

assembly.Thisallowstheusertoraisethejack

saddletocontacttheloadwithoutpumpingthrough

thefullarcoftheoperatinghandle.

4.Transfertheloadimmediatelytoappropriately

ratedjackstands.

CAUTION:Usethehandleprovidedwiththisproduct

oranauthorizedreplacementhandletoensure

properreleasevalveoperation.Whenusingtolift

vehicle,liftonlyonthemanufacturer's

recommendedliftpoints.Refertoyourvehicle

owner'smanual.

Lowering

1.Raiseloadhighenoughtoclearthejackstands,

thencarefullyremovethosejackstands(always

usedinpairs).

2.Slowlyturnthehandlecounterclockwise,butno

morethan1/2turn.Iftheloadfailstolower:

a.Useanotherjacktoraisethevehiclehigh

enoughtore-installjackstands.

b.Removetheaffectedjackandthenthestands.

c.Usingtheotherjack,lowertheloadbyturning

theoperatinghandlecounter-clockwise,butno

morethan1/2fullturn.

Important:Useonlyagoodgradehydraulicjackoil.

AvoidmixingdifferenttypesoffluidandNEVERuse

brakefluid,turbineoil,transmissionfluid,motoroilor

glycerin.Improperfluidcancausefailureofthejack

andthepotentialforsuddenandimmediatelossof

load.

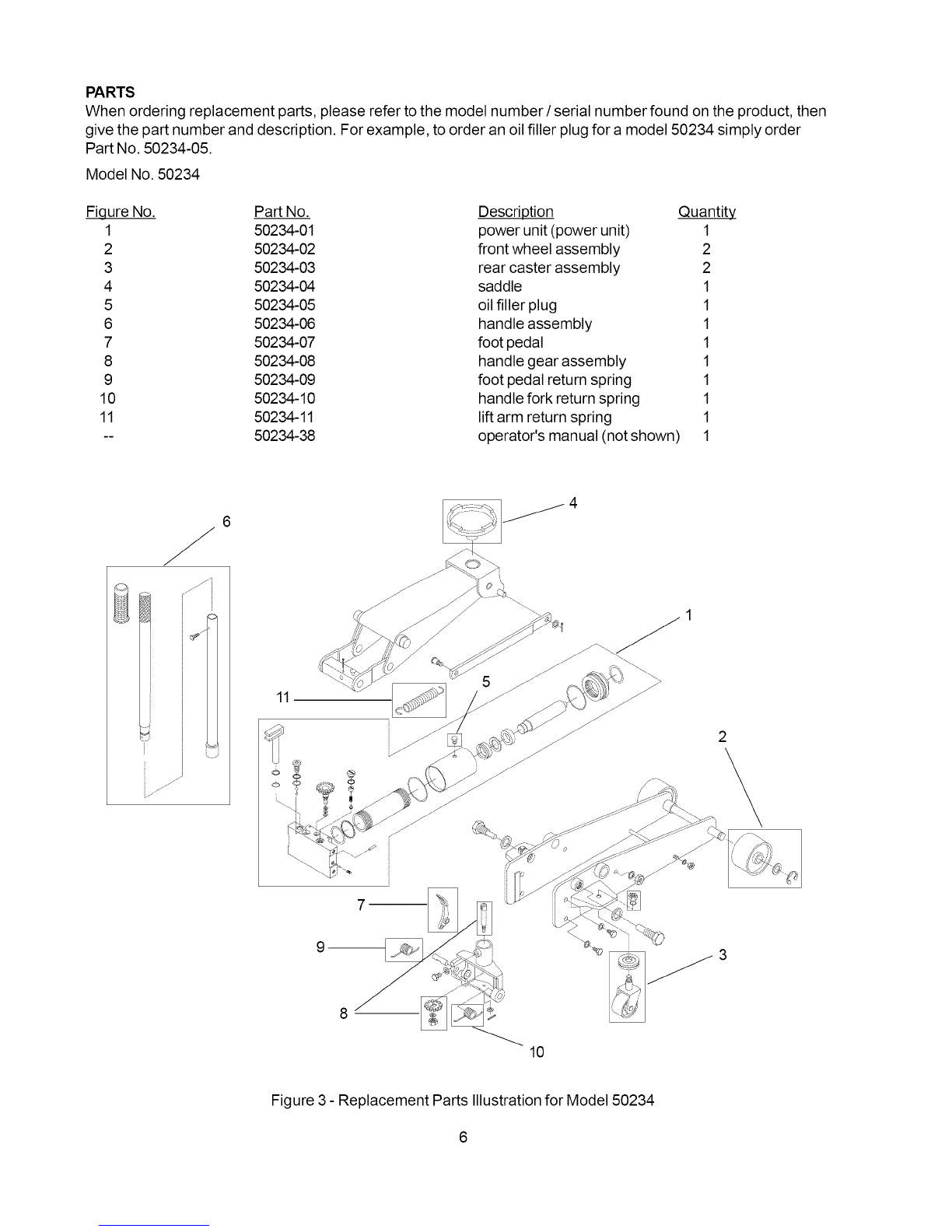

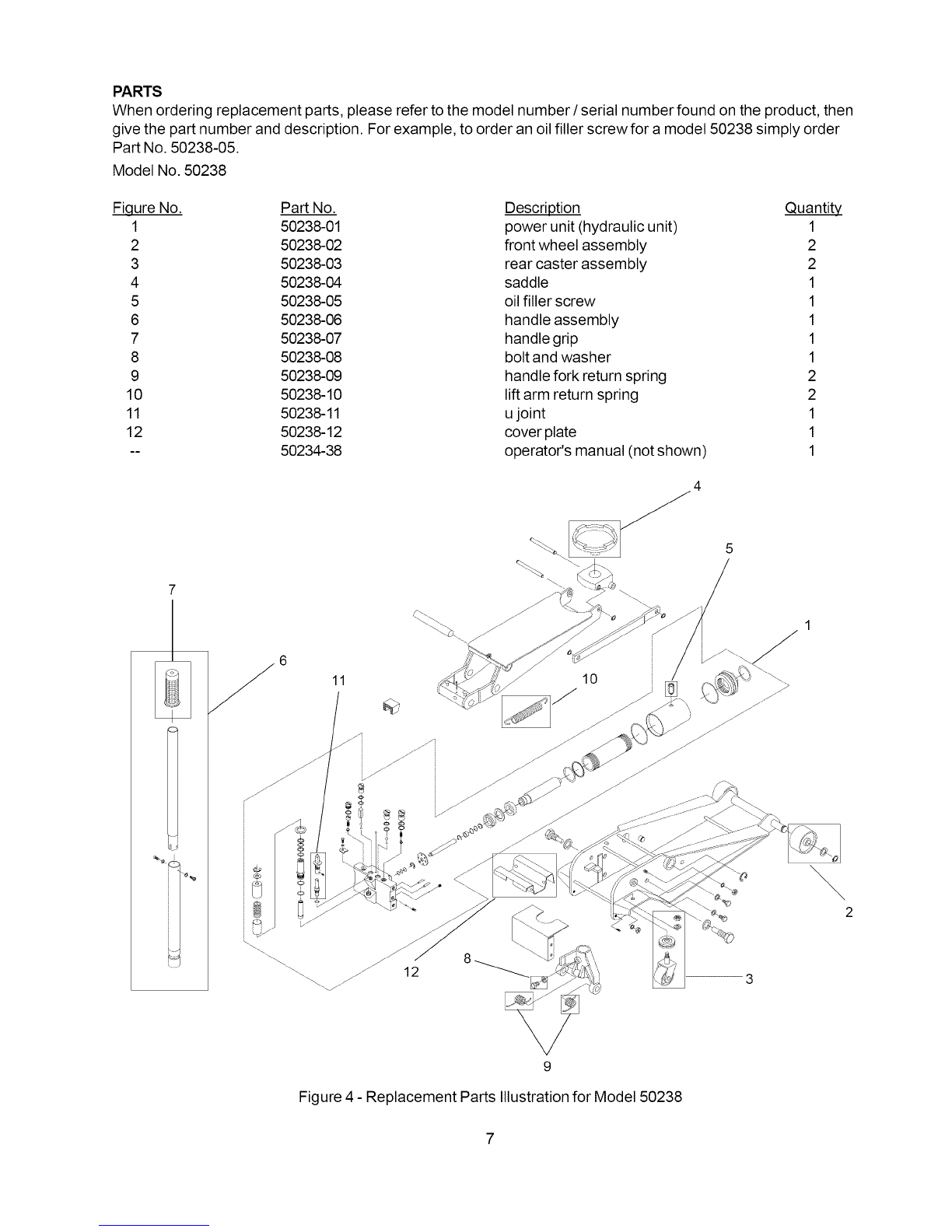

Addingoil

1.Withsaddlefullyloweredandpumppistonfully

depressed,setjackinitsupright,levelposition.

Locateandremoveoilfillerplug/screw.

2.Fillwithoiluntiljustbelowtherimoftheoilfiller

plughole.Reinstalltheoilfillerplug/screw.

Changingoil

Forbestperformanceandlongestlife,replacethe

completefluidsupplyatleastonceperyear.

1.Withsaddlefullyloweredandpumppistonfully

depressed,removetheoilfillerplug/screw.

2.Laythejackonitssideanddrainthefluidintoa

suitablecontainer.

Note:Disposeofhydraulicfluidinaccordance

withlocalregulations.

3.Fillwithoiluntiljustbelowtherimoftheoilfiller

plughole.Reinstalltheoilfillerplug/screw.

Lubrication

1.Aperiodiccoatingoflightlubricatingoiltopivot

points,axlesandhingeswillhelptopreventrust

andassurethatwheels,castersandpump

assembliesmovefreely.

Cleaning

Periodicallycheckthepumppistonandramfor

signsofrustorcorrosion.Cleanasneededand

wipewithanoilycloth.

Note:Neverusesandpaperorabrasivematerialon

thesesurfaces!

Storage

Whennotinuse,storethejackwithpumppiston

andramfullyretracted.