Crane Source Space Vector SV100 Assembly instructions

Table of contents

Other Crane Source Controllers manuals

Popular Controllers manuals by other brands

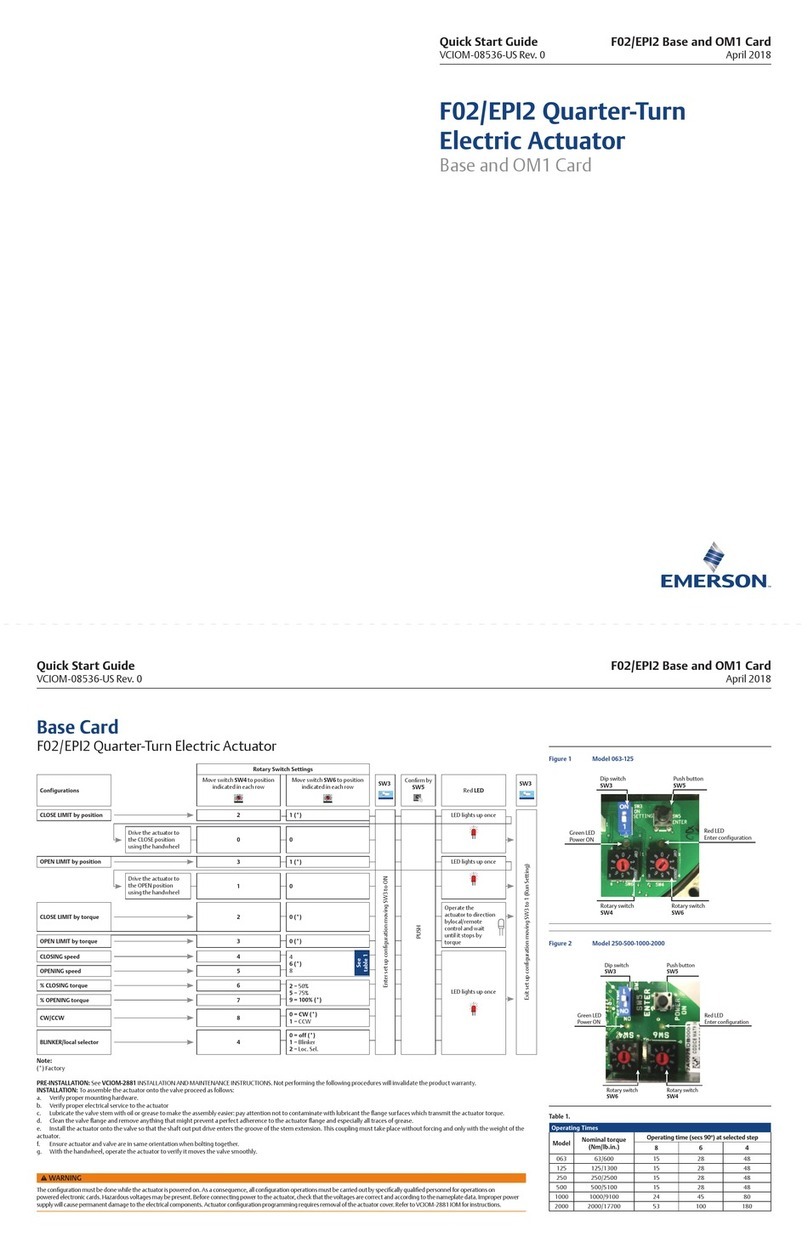

Emerson

Emerson F02/EPI2 quick start guide

Watts

Watts HF scientific Air Sentinel II 110010 Installation and operation manual

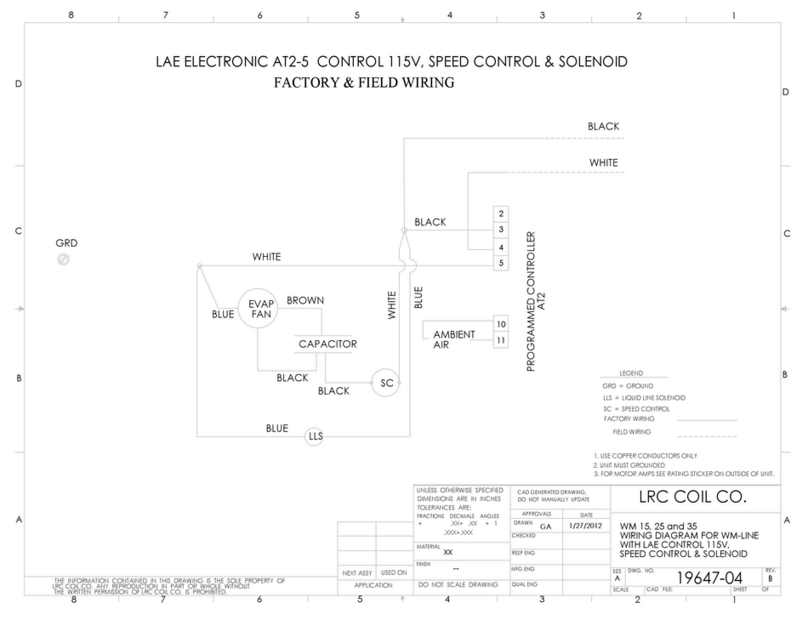

LAE electronic

LAE electronic AT2-5 Instructions for use

Moxa Technologies

Moxa Technologies ioPAC 8020 user manual

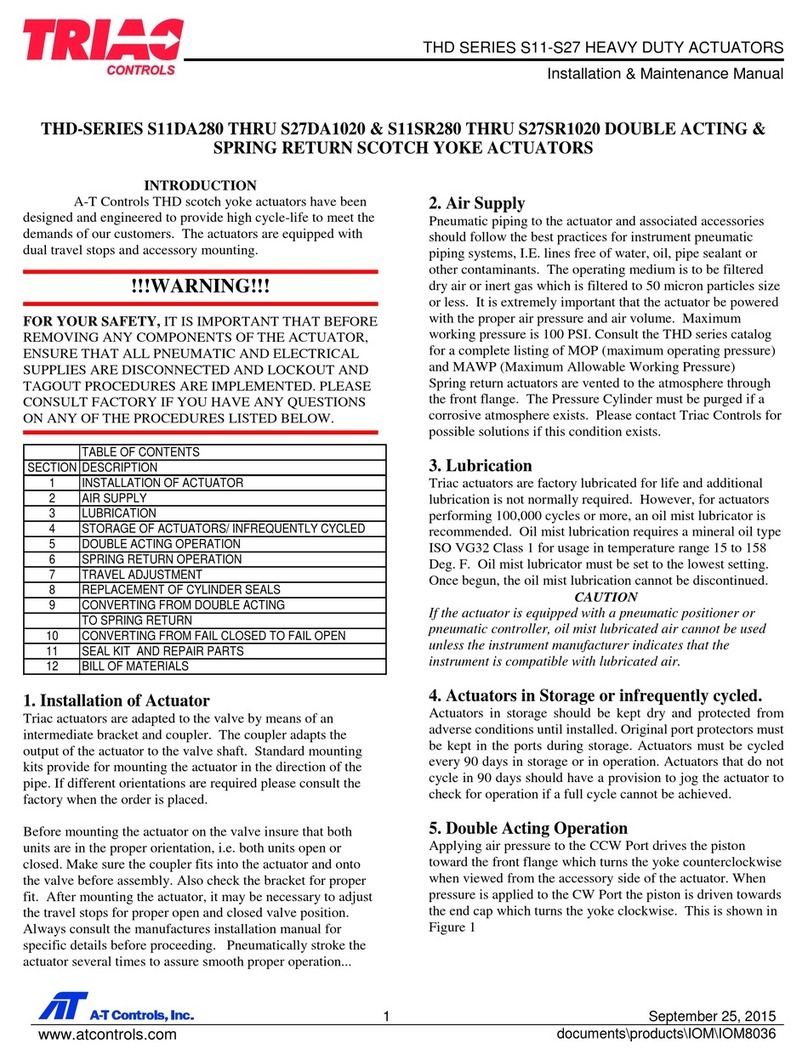

TRIAC

TRIAC THD S11 SERIES Installation & maintenance manual

HID

HID Signo 25B install guide

RST

RST FRC-Q Series manual

Beijer Electronics

Beijer Electronics EXTER T60 installation manual

Parker

Parker XLR Series Maintenance Instructions & Parts List

Detection Systems

Detection Systems DS7400Xi reference guide

Siemens

Siemens SIMATIC manual

ADLINK Technology

ADLINK Technology Qseven quick start guide

YASKAWA

YASKAWA Motoman DX200 instructions

Danfoss

Danfoss VLT Micro Drive FC 51 Series Programming guide

HighPoint

HighPoint SSD7540 Quick installation guide

Honeywell

Honeywell LeakFilm MC Technical manual

Metso

Metso Quadra-Powr X Installation maintenance and operating instructions

Hubbell

Hubbell Electric Fire Pump Controllers LXi-2700 Specifications