1

ParkerHannifinCorporation

AutomationActuatorDivision

135QuadralDrive

Wadsworth,Ohio44281

Telephone330/336-3511

Facsimile330/334-3335

PM-XLR-B

Service Information & Parts List

Issued: February 15, 1994

Supersedes: April 1, 1993

GENERAL

XLR Series Reach Slides are pneumatic linear actuators that

incorporate linear ball bearings and support shafts which pro-

vide positive load support and torque resistance.

This manual contains maintenance instructions, replacement

parts information and information on various slide options.

Consult the factory or product catalog for additional information.

SPECIFICATIONS

•Maximum Operating Pressure: 100 psi

• Operating Characteristics: Double Acting Standard

(Single Acting Available)

• Four Support Rod Sizes: 1/4", 3/8", 1/2", 3/4"

• Output Force @ 60 psi: 15 - 105 lb

• Maximum Breakaway Pressure: 5 psi

• Operating Temperature Range:

Standard 0° to +180°F

Viton Seals 0° to +250°F

• 304 Stainless Steel Cylinder Body

• Stainless Steel Piston Rod

• Mounting: Unrestricted

A. Inspection and Replacement Procedure for Bearings,

Seals, Support Shafts and Cylinder.

1. Remove locknut #12.

2. Remove stop collar, #7 and bumper, #6 or rear load

plate, 13c. (bumper, shock option)

3. Unscrew cylinder piston rod from tool plate, #13 and

remove tool plate and shafts, #16 from housing, #5a.

4. Remove cylinder mounting nut, #11.

5. Pull cylinder, #1 from slide housing, #5.

6. Remove the four press fit seals, #14.

7. Remove the four bearings, #15.

8. Inspect cylinder, bearings, seals and support shafts

and replace if necessary.

9. Clean all parts thoroughly.

XLR Series Reach Slide

Maintenance Instructions & Parts List

Provide Model Number and Serial Number When Ordering Spare Parts.

B. Reassembly Procedure.

1. Apply a few drops of Loctite RC/609 to the outside

diameter of the bearings, #15.

2. Press the four bearings, #15 into housing, #5a.

3. Press the four seals, #14 into the housing, #5a, securing

the bearings with no play.

4. Apply a liberal amount of bearing lubricant to all four

bearings.

NOTE: Recommended lubricant is Synco Super Lube with

Teflon or compatible NLG1 Grade 2 grease.

5. Replace cylinder, #1. Install using nut, #11.

6. Replace support shafts, #16 and tool plate, #13.

7. Screw piston rod of cylinder into tool plate and replace

locknut, #12.

8. Replace bumpers & stop collars.

(Applies to bumper option only.)

MOUNTING

The XLR Reach Slide incorporates square nut "T" slots on all

mounting surfaces and four through holes. The "T" slot feature

allows the slide housing to be positioned after mounting. An

assortmentofsquarenutsareincludedwiththeslidetofacilitate

mounting. Additional square nuts can be ordered - each kit

contains 8 square nuts (4 primary, 4 secondary).

LUBRICATION

The pneumatic cylinder and internal bearings are pre-lubricated

at the factory and are suitable for non-lubricated applications.

However,additionalairlinelubrication will increase the lifeofthe

unit.

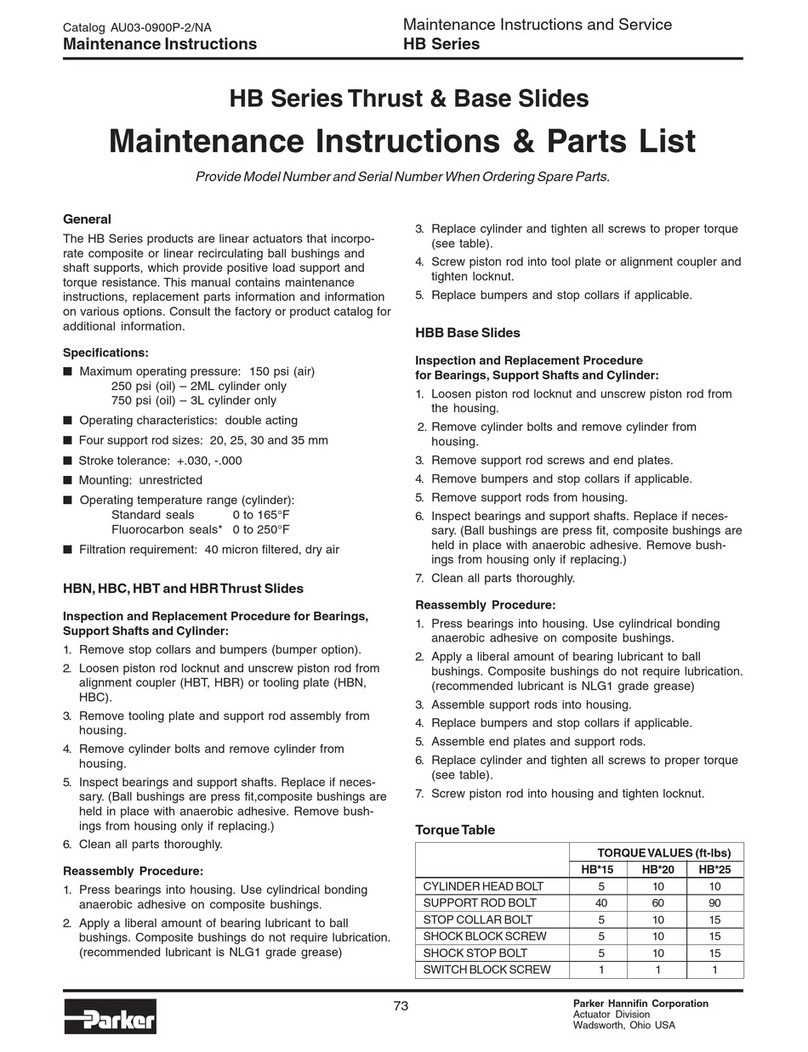

Model Kit Number

04 NK04

06 NK06

08 NK08

12 NK12